Thank you so much to everyone for their responses and suggestions!

Richie C: Thank you so much for that Scenery Source List, I had no idea that it existed. Great resource!

Ed (Golden Prarie Railroad): Thank you so much for the detailed decal instructions.

Dave C: Thanks for the comparison of the two methods (dry transfer versus wet)

Magicland: I'm leaning your direction. I think printing my own will give me the opportunity to fiddle with the font size and type face to get it right/close.

Joe (CNJ #1601): Thanks for the excellent tip on aligning dry transfer letters. What do you think about wet decals versus dry transfer for working around the details of the surface to which the decal is applied?

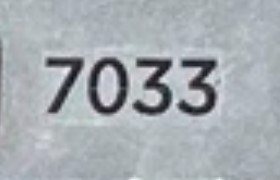

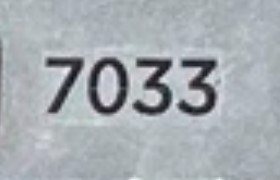

There are places that will create custom dry transfers, so that you don't have to place individual letters. I first explored this option when creating a few custom AAR California Zephyr cars. AAR took possesion of at least 6 former California Zephyr cars, but Atlas only made 3 of them. So I decided to buy 3 extra Atlas models for ARR and change the nubmers. So, for example, I turned an Atlas ARR 7034 into 7033.

Didn't get the font perfect, but doesn't look bad from a distance. However, up close...

I didn't really want to paint (clear coat) the Atlas car, because I feared that would make the difference between the two cars even more noticable. I later got original "artwork" for the lettering/font used by Atlas for these numbers, so I could get custom decals (wet or dry transfer) created that would match perfectly (but custom dry transfer sheets can get a little pricey).

Anyways, the "obvious" decal (in the 7033 images) is what I'm trying to avoid in this 25-tonner project.

But after reading responses, and thinking about it more, since I am planning on weathering this loco, I don't think any decal silvering will be visible after even light weathering is completed.

One final thought (possibly overkill). When these models are mass-produced by our favorite importers, they are usually lettered with some type of pad printing, correct? Could one use 3d printing to create such a pad? Then use that pad to do the "printing"? Talk about having one shot to get it right!

Thanks again for all the ideas!