With respect to the question of why the eccentric cranks on some locomotives lead the main crank, while on others they lag, here's a partial explanation for Walschaerts gear, at least.

Engines fitted with Walschaerts gear can be arranged to derive the proper motion of the valve stem for forward travel of the locomotive by either (1) dropping the link block in the rocking link or (2) raising the link block in the rocking link. The eccentric crank will therefore lean ahead of the crank pin, or will lag behind it, when rods are at BDC, depending upon whether the proper valve motion for forward movement (or reverse) is being derived from the top or the bottom of the rocking link.

In the most common application of Walschaerts gear, the bottom of the rocking link is closer to the cylinder/valve chest than the top of the link when the rods are at BDC. In other words, the rocking link slants backward, like this -- \ . When the gear is set up this way, the eccentric rod leads the crank pin.

In the less-common arrangement, however (which is geometrically opposite), with the rods at BDC, the rocking link leans forward, like this -- /. In this configuration, because the valve motion for forward travel of the locomotive is derived from the opposite end of the rocking link, the eccentric pin lags the crank pin in order to impart opposite motion to the rocking block.

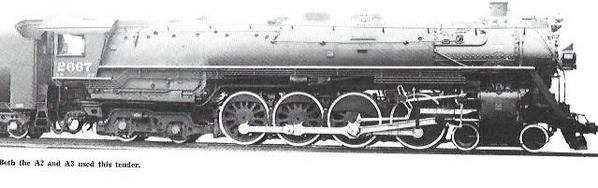

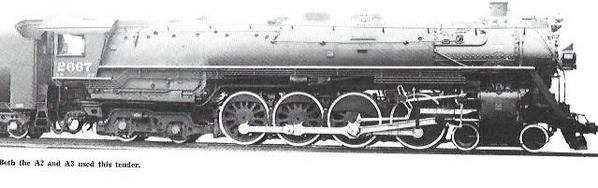

This difference can be seen in the photos below of two locomotives fitted with different configurations of the same basic Walschaerts gear. Presumably the common arrangement had some design and/or production benefits, but I don't know exactly why it became the standard. As far as I know, Baker gear was always driven by a leading eccentric crank, because the basic mechanism was not reversible in the same way as the Walschaerts rocking link.

(1) The most-common arrangement for Walschaerts gear: eccentric crank leading the main crank, with the rocking link leaning backward, when rods are at BDC:

(2) The other possible arrangement for Walschaerts gear: eccentric crank lagging the main crank, with the rocking link leaning forward, when rods are at BDC: