Dear All

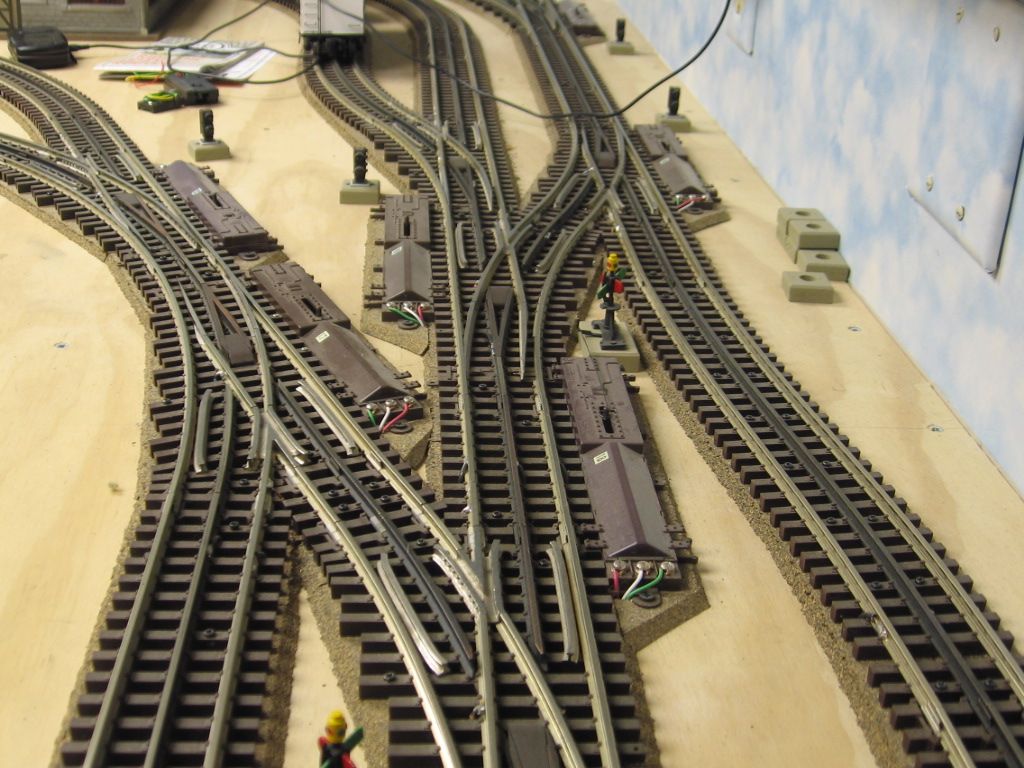

Thanks for the replies. Sorry about the delay on my part just have been very busy. Between selling the Fastrack, purchasing the Atlas track, life, work and family, so little time to enjoy the trains if any. I almost forgot that tax man wants some of my time as well to fill out some form again.

Dear Jim

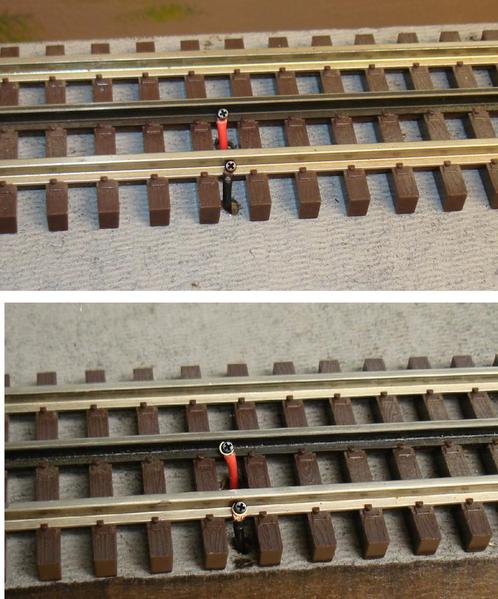

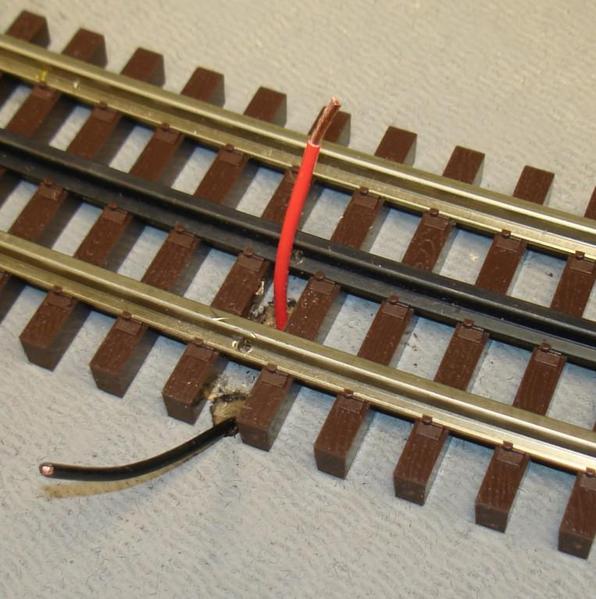

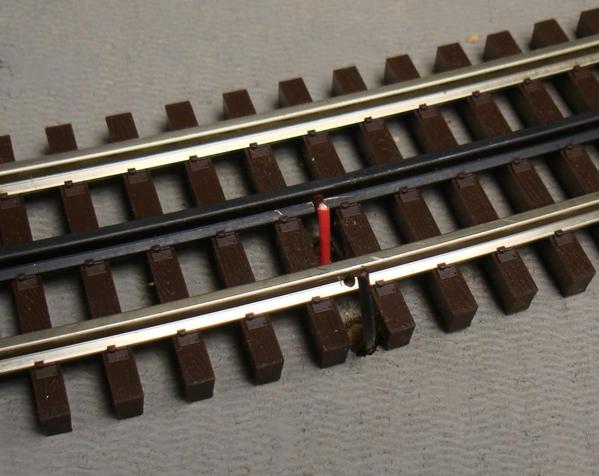

Thanks for the info. With the information you supplied me, instead of purchasing the Atlas terminal connectors I went out and purchase a Hakko FX888D Digital Soldering Station. I am going to use this to make the roll your own terminal for Atlas. Beside is is a good soldering station and I can use it for other parts of the layout.

Dear Mike CT

Very nice work, I am impressed. If you area located in Fairfield county CT I would love to buy you a cup of coffee and talk about your layout.

Dear Ernie

Do you have any photo that you can share I would love to see your layout as well.

Dear Willygee

Thanks for the tip, you are the other reason why I purchased the Hakko. Let me tell you a quick story it is like using Harbor Freight Tools, they are good to a point but after that you have to go with the professional tools.

Dear gentlemen

Between this thread and the one on solder irons https://ogrforum.ogaugerr.com/t...ering-irons-1?page=1 I decided to purchase the correct tools. I purchased a lot of items from Radio Shack when they went through the reorganization some of them good and mostly bad. The wrong soldering irons, the wrong solder and various other items. I have no one to blame but myself and my inexperience and this is part of the learning curve. On one hand a good mechanic with bad tools no mechanic at all. On the other hand a bad mechanic with good tools does not make him/her a good mechanic either. As I stated before I graduated from novice to intermediate on the skill level and needed to upgrade my tools. This was happening over a period of time and I knew that I had to improve my skills and what was holding me back, I am using the wrong tools!

I believe that I have purchased the last of the Atlas track that I need for this layout tonight. As you folks are the voice of experience are laughing because you have been this road before and you are right and you know I missed something. Thank you for your time, experience, skill, trick and tips.

I will keep all of you posted as to my progress on this project.

Again thank you!