Step 1. Unscrew and take off the trucks.

Step 2. Unscrew this screw.

Step 3. Take these two screws off, one on each side.

Step 4. Take this off and toss it!

Step 5. Screw the two screws you just took out back in. Advanced Option: Don't screw these back in for truck equalization, but be careful, the trucks may come apart.

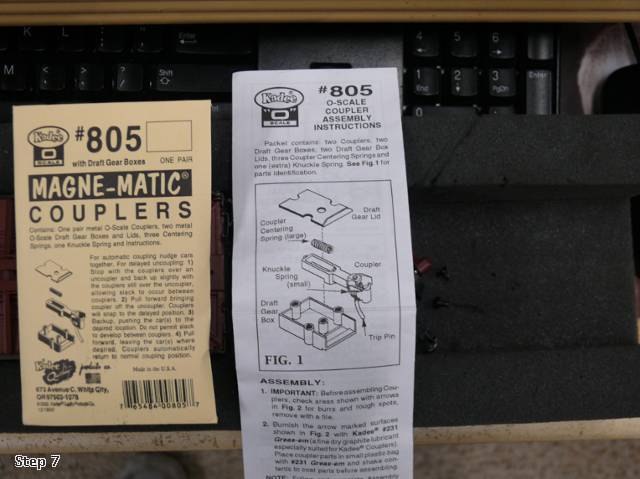

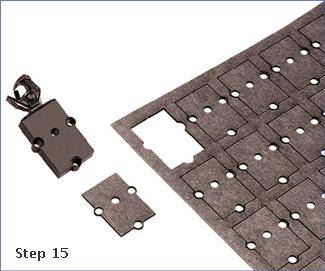

Step 6. Buy these couplers (Kadee 805s)

Step 7. Open up the package, follow these super easy assembly instructions.

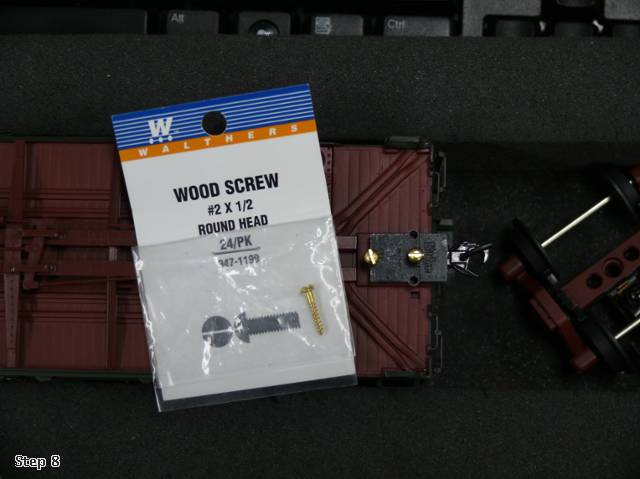

Step 8. Buy these screws from Walthers.

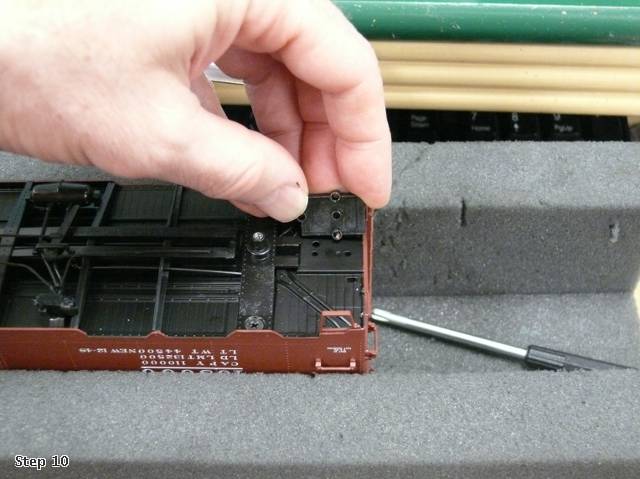

Advanced Option: You will notice that Atlas places the holes a little too far forward, causing the coupler box to stick out a bit.

You can see here how the pre-drilled Atlas holes are too far forward.

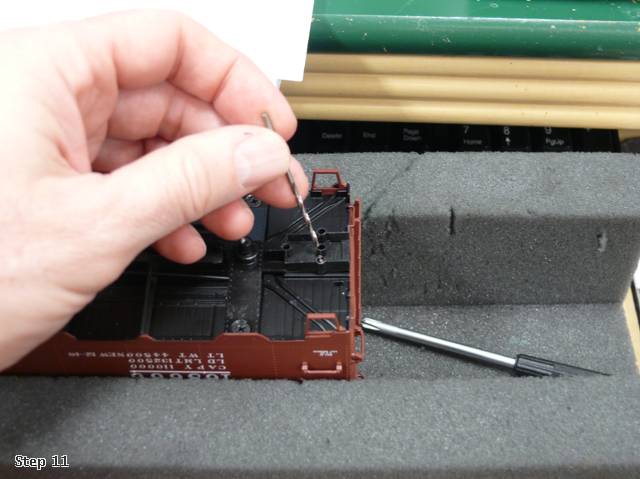

You may drill new holes if you like with a #51 drill bit, to do a proper job. Using the Kadee box as a guide/locator. The you can use #2 X 1/2" round head stainless steel sheet metal (i.e. self taping) screws from Micro Fasteners (1-800-892-6917)

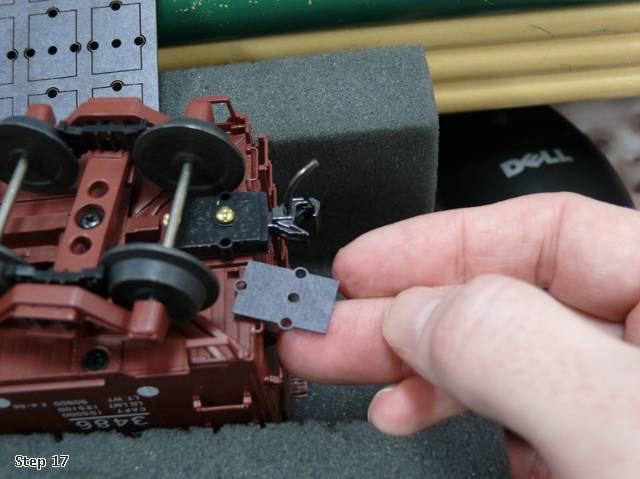

Step 9. Screw the coupler assembly in with the Walthers screws as shown, and put the trucks back on.

Buy one of these. A Kadee Height Gauge. Buy it here:http://www.kadee.com/

Put your car on the track to see if the height gauge is even with your new Kadee coupler.

If it does not match buy these.

You can buy them here:

Then take off your coupler, and screw one or two of these underneath the coupler box to get to match the height of the gauge. Most likely all Atlas cars will need these, so you can do this in step 9.

Done. You now have a 3RS Atlas freight car.

Of course you should have all these supplies before you start.