quote:

Originally posted by Billsrr:

Rich, I would like to convert my atlas diesels to kadee's. What are the steps to mount the pilot and mounting the kadees?

Bill,

It varies a little from engine to engine. I found that Bill Serratelli at Atlas, who was a tremendous help to me, didn't even realize all of the parts involved, so there was some trial and error. What follows is a general overview. If you have questions about a particular engine, I'll try to answer them. I'm calling up the steps and parts from memory. I can probably run down specific part numbers from my order lists, if needed:

For the Dash 8s (both standard and wide cab) you re-use the three rail pilot and fix it using a plastic spacer part that fits between the pilot and the frame. An additional part having a name like "coupler mount" or something like that provides the mounting area for the scale coupler and also fills the oversized hole in the pilot. These parts are unpainted plastic, so you will have to paint. Basically the steps required are:

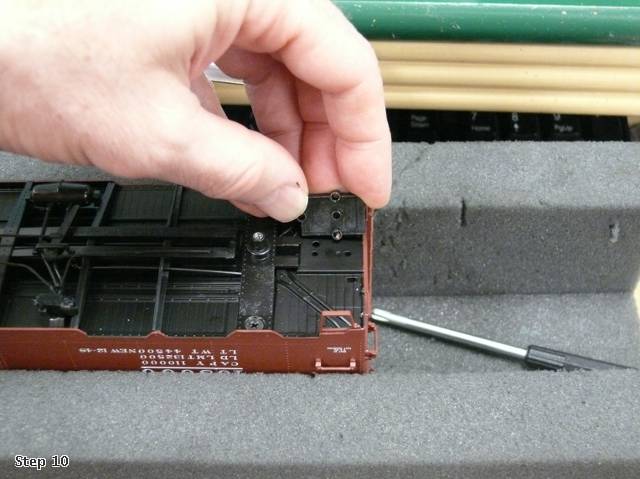

1. Remove the three rail pilot. You either have to drop the trucks or cut it off right where it mounts to the truck block. (Since it is extremely tight inside the Dash 8 shell, I opted to cut it off).

2. Regardless of how you remove the three rail pilot, you then have to cut off the tab that mounts to the truck block or that will foul the truck.

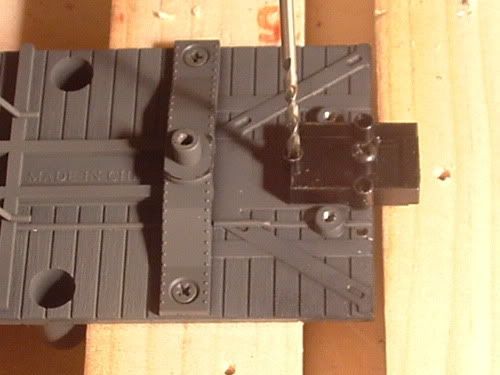

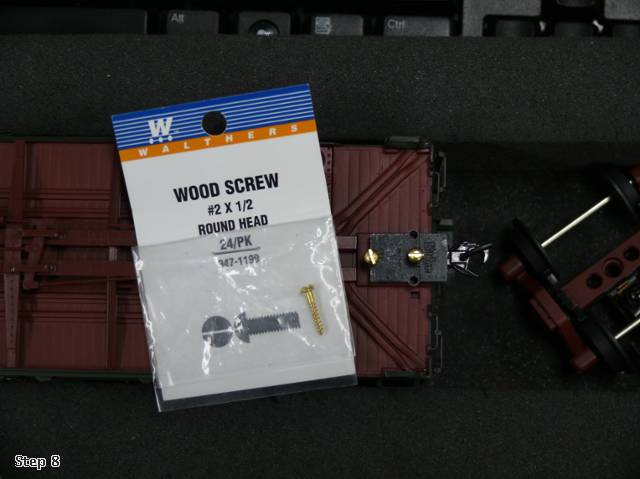

3. You probably will need to tap the mounting screw holes the frame (although a unit I bought in the last run came with these already tapped). Use a 2.5 mm tap. The screws to mount the pilot, spacer and coupler mount are available from Atlas. I don't recall the length, but I think its getting up around 18 mm (pretty long).

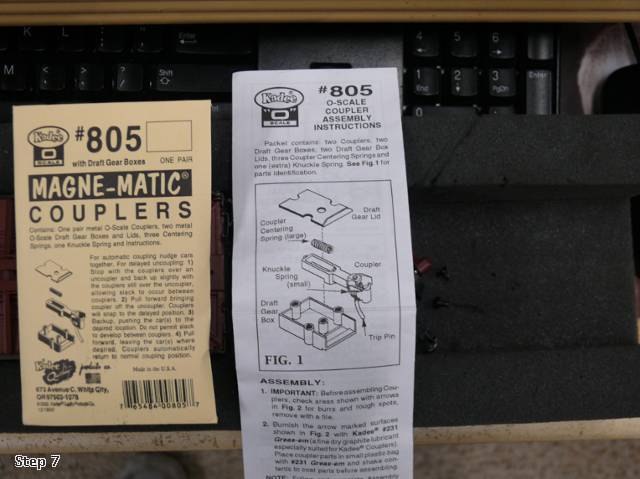

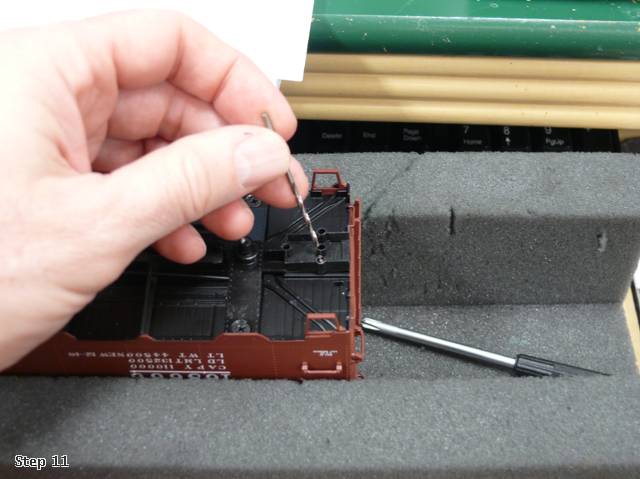

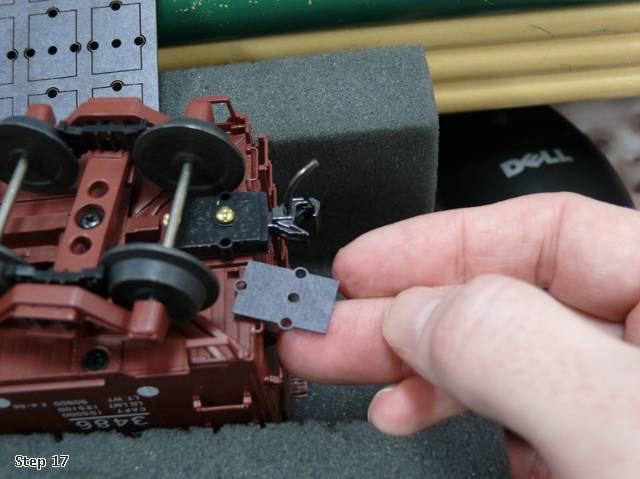

4. The Atlas scale coupler uses a single screw to mount. To mount Kadees, I drilled my own hole in the coupler mount (a pin vise will work; the part is plastic). You will need to shim it to the correct height. Because of the differences in the coupler box width, I also shim the Kadee box on the side to keep it in position.

5. For hand rails, you can order new ones from Atlas (if in stock -- they are not always) or make your own from wire or even paper clips. In addition be prepared to paint the parts to match the locomotive.

Most of the parts for the Dash 8s are available on the Atlas website, but be aware that the wide cab Dash 8s use a different spacer, and that is not available. Bill Serratelli at Atlas was kind enough to scrounge me some for my projects.

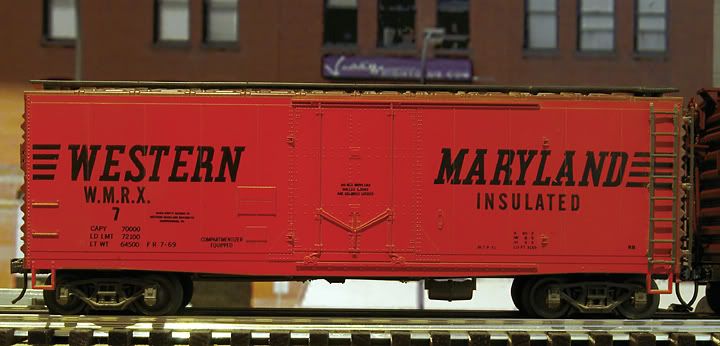

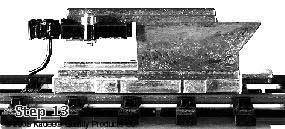

For the GP 60s, 60Bs and 60Ms as well as the SD40s, no spacer is used. Instead you buy a new full pilot, which you may have to paint. You also need to order the top steps. The other steps and most of the detail parts can be reused from the three rail pilot. Be aware that for the GP 60 series of engines, the front and rear pilots are slightly different. The rear pilots seem never to be in stock, so I used from pilots. The difference is where the MU recepticles mount. Its hard to explain, but they will be off slightly if you use a front pilot on the rear, but you can trim the MU recepticle parts to fit and look good. The MU recepticles are separate parts (three front and three rear) for the two rail model. Look close and you can see them in the picture above of ATSF 116.

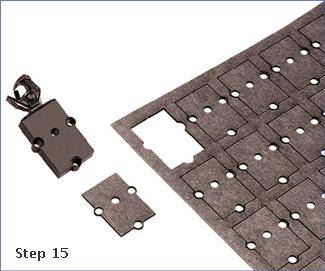

In addition to the pilot and other parts, the GP 60s use a coupler mount or spacer. Its basically just a thick shim.

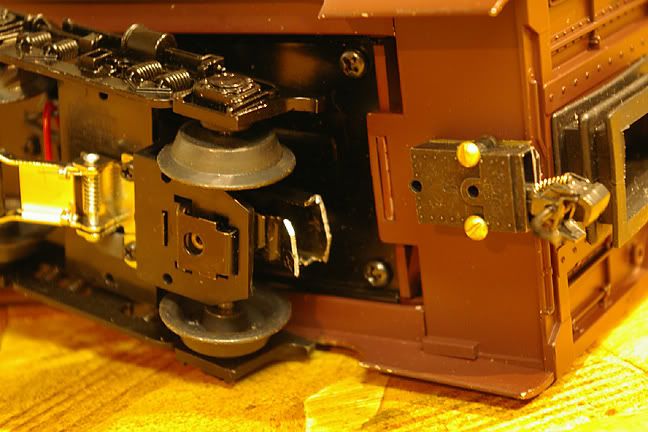

To mount the pilot you tap the holes in the frame (2 mm) this time. I can't recall the length of screws involved; about 6 or 8 mm, I think. Locations for the coupler are already tapped in the pilot. Like other Atlas products, the mount holes are off for Kadees, but you can use them anyway just by carefully working down the screws in alternate fashion. This comes out at the correct NMRA recommended height. To take off the three rail pilot you likely will have to drop the trucks.

The SD 40s also use a separate pilot (again order the needed top steps). The coupler mount piece is both a shim and it fills some of the pilot front. This one attaches to the pilot with its own set of screws (I don't recall the dimensions). Again, you have to tap holes in the frame (2mm again). I believe I mounted mine with 2 by 4 or 5 mm flathead screws. For the SD 40 you absolutely must cut off the large three rail coupler mounting lug at the front of the truck or it will foul on the fixed pilot. Like the Dash 8, I drilled my own hole to mount the Kadee; the Atlas scale coupler extends too far out in my view and Kadees are better in any event.

RM

It has been mention about truck mounted KD couplers. Dave C did a very nice post a few months ago on this subject.

It has been mention about truck mounted KD couplers. Dave C did a very nice post a few months ago on this subject.