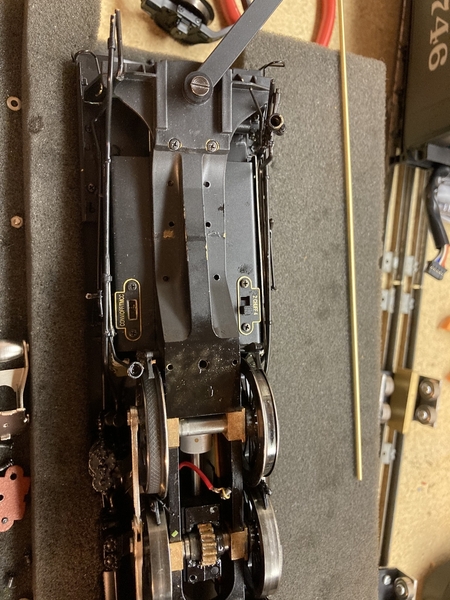

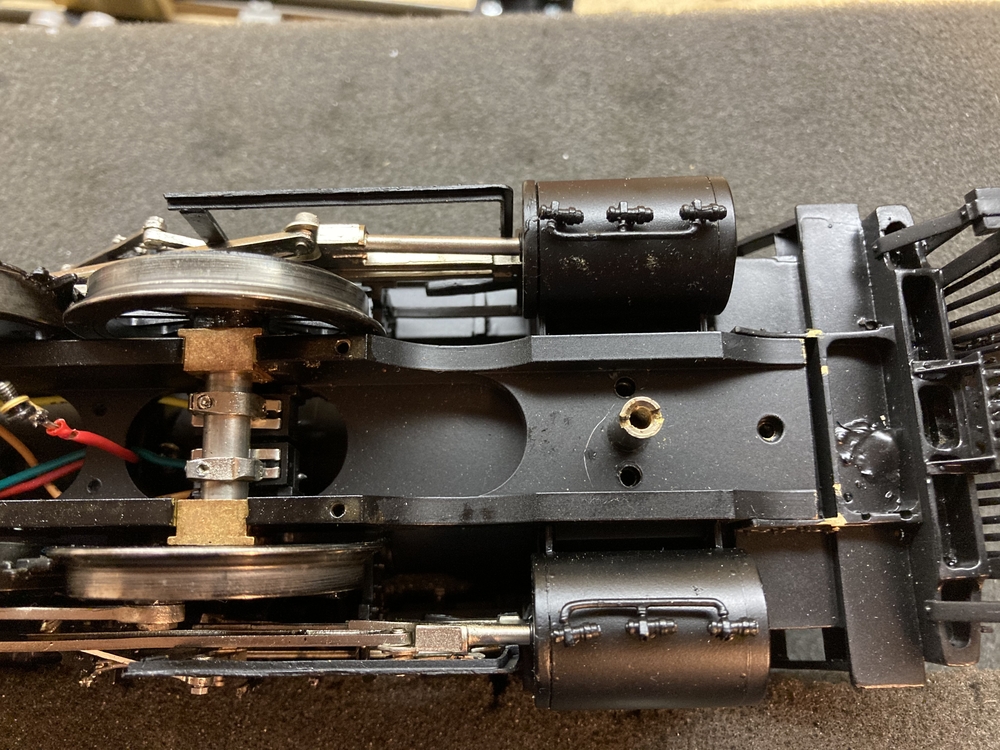

I am working on a Sunset Model engine for a friend. The issue he had with this engine is it would not seam to go very far, it would stall. I concluded that it was most likely binding up. The traction tires are old and need to be replaced I figured that’s all it was. Still need to find tires if anyone has recommendations. But when I put it back on my rollers I noticed that it wobbled quite a bit. Figured it was my rollers then it bound up and I started looking elsewhere. What I finally noticed is the riser from the frame to the bronze bushing on Fireman side of the locomotive was missing in both the rear and front drivers. The two middle ones have springs. Is there anyway I can get something to replace them with?

Also if anyone could guide me as to how to remove the shell from the frame that would be appreciated.