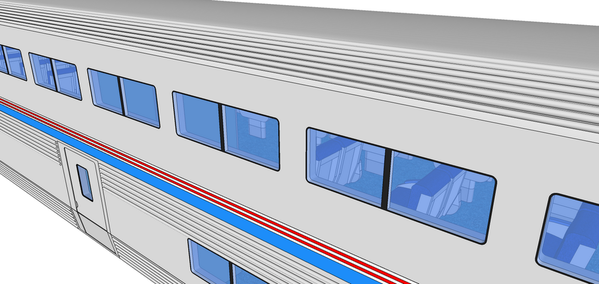

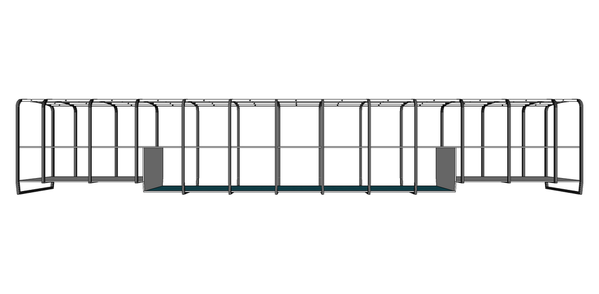

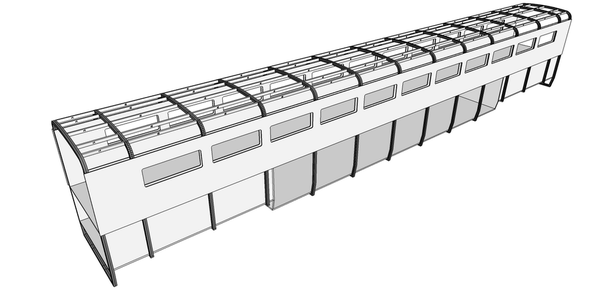

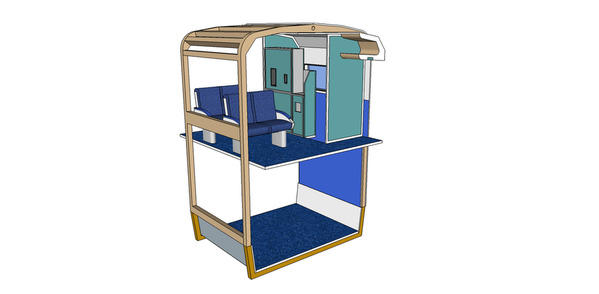

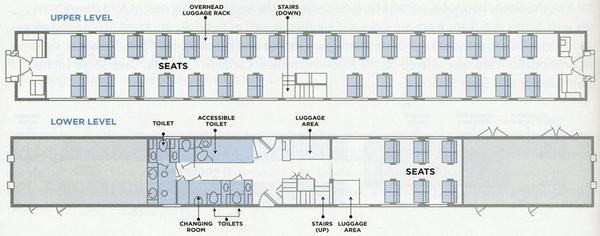

I have two more projects in my bag; the first one is in the title of this topic; I want to share with you this new idea which is for me a big challenge! why a superliner? Several reasons: these cars have an incredible style and here, in France, we have no cars like that except the TGV 2N (N = niveau = levels for you) and some commuter cars. More, I don't find a to scale model of this car anywhere. So I decided to make one! not easy but I found on the web many informations, photos and videos to have a precise idea how do build it.

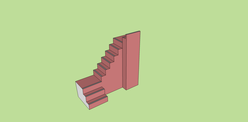

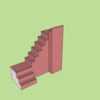

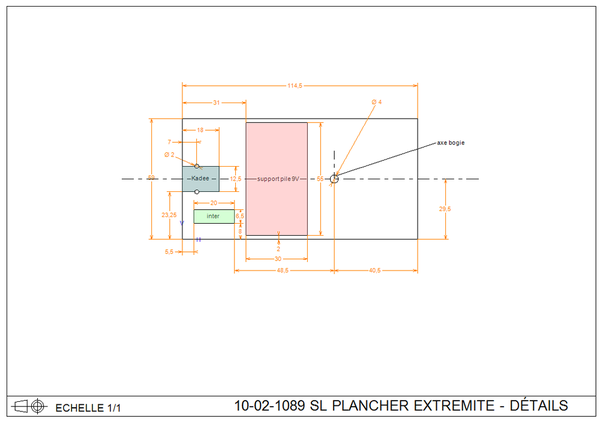

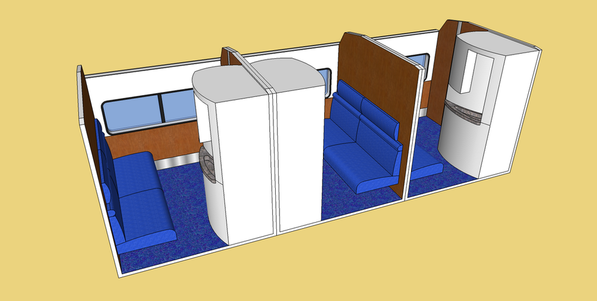

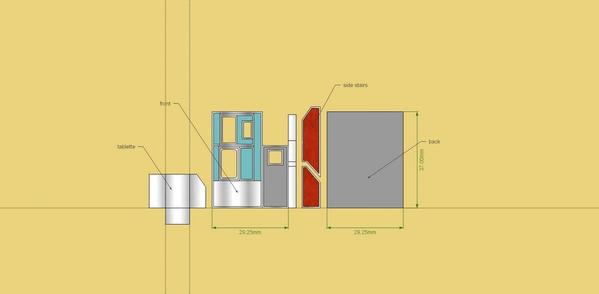

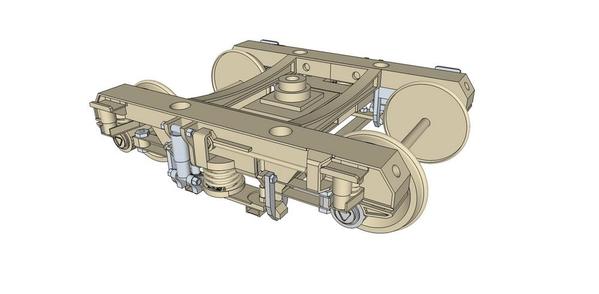

For this evening (for me!) I just want to show you some 3D drawings I made to start this project; I have also writen the complete specification which describes how I manage the whole design of this passenger car. Sorry, these documents are in french! but I can insert them on the forum if you want and it will be better than a long monologue!!

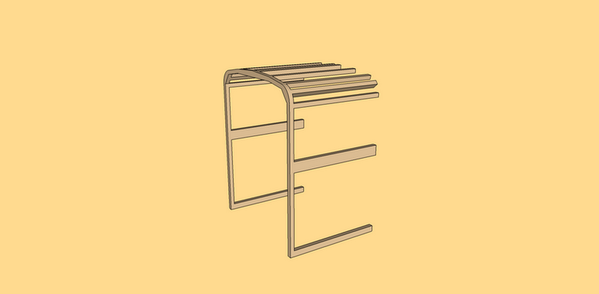

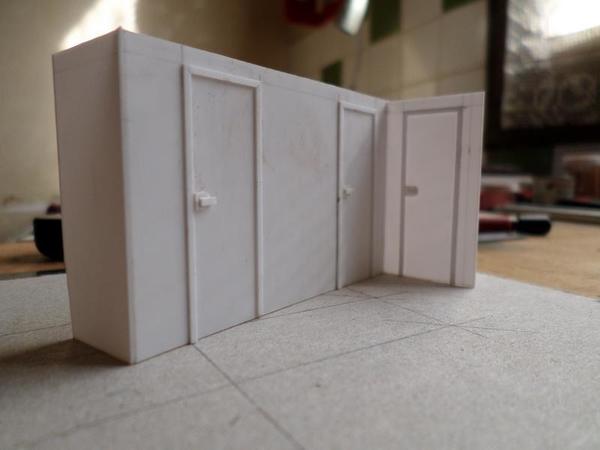

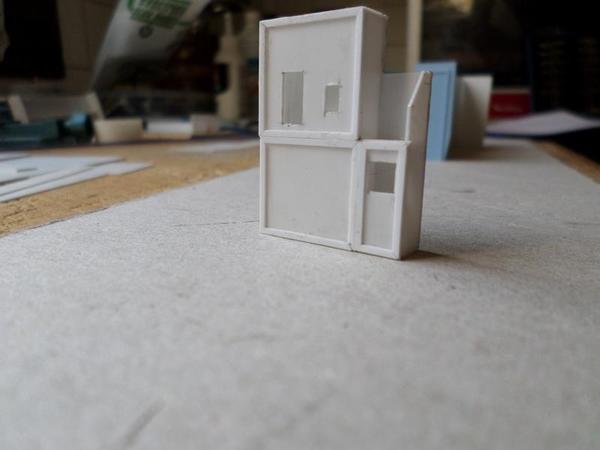

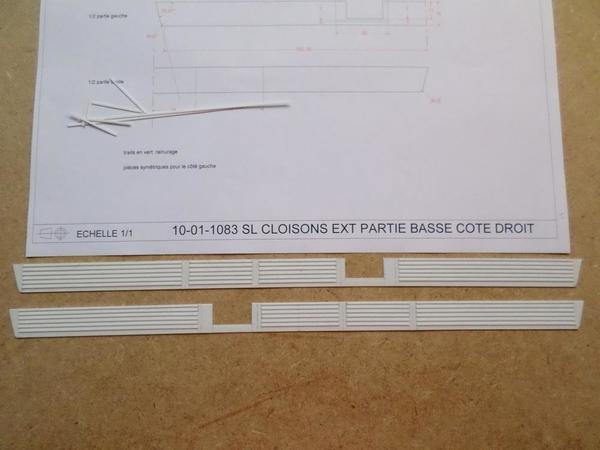

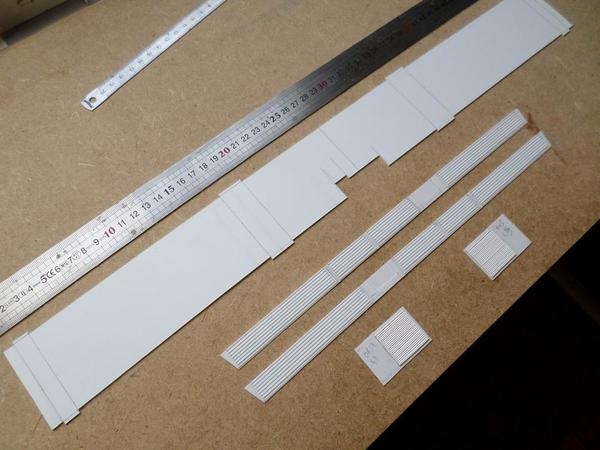

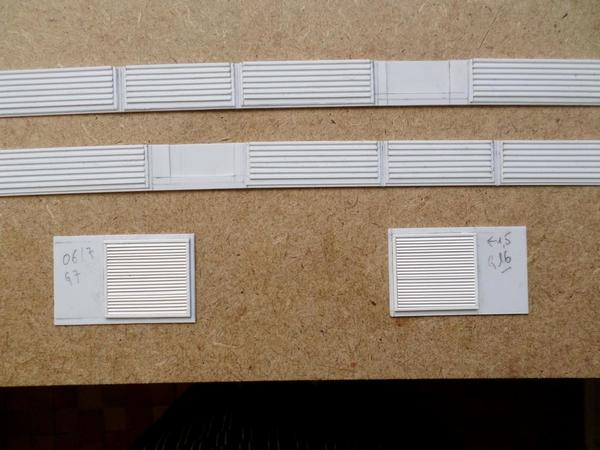

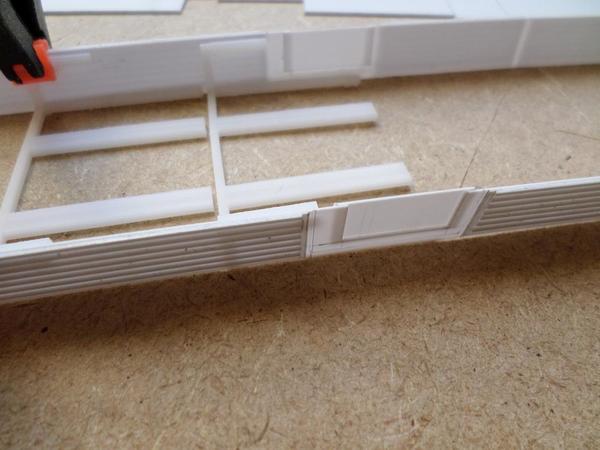

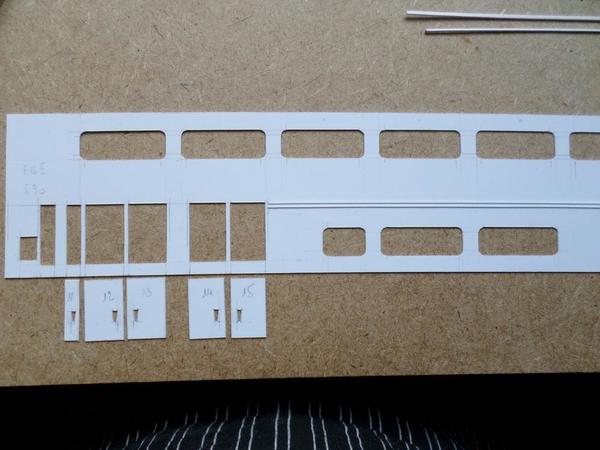

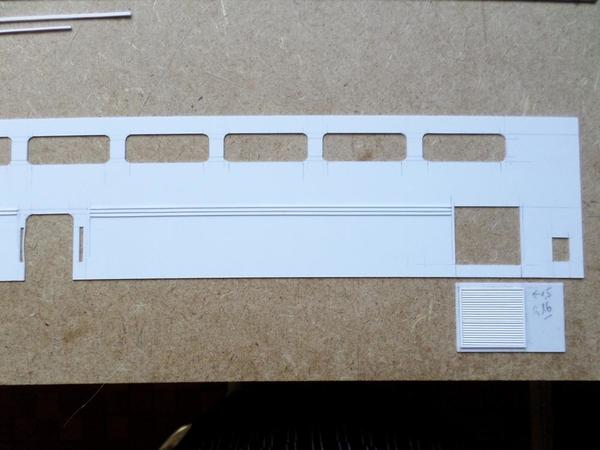

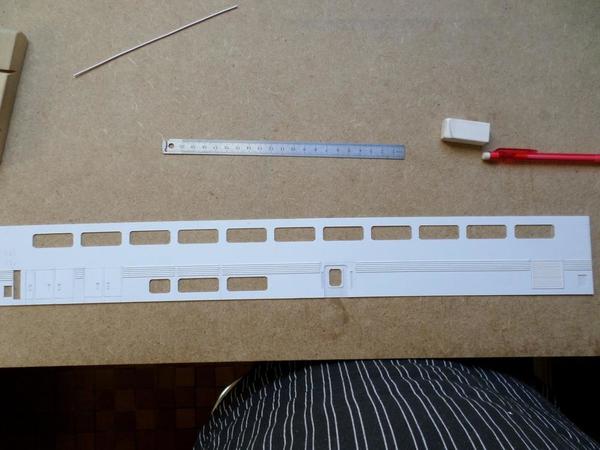

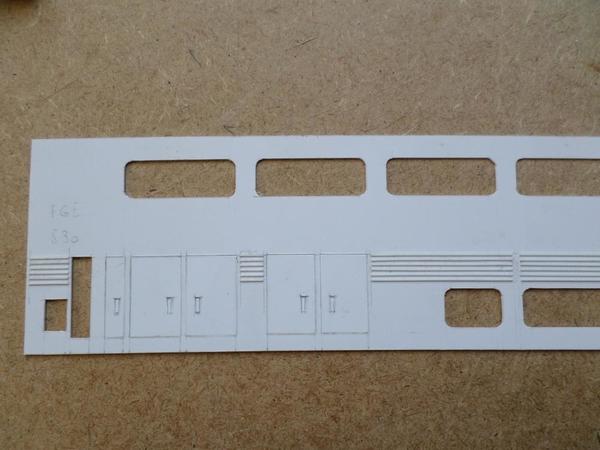

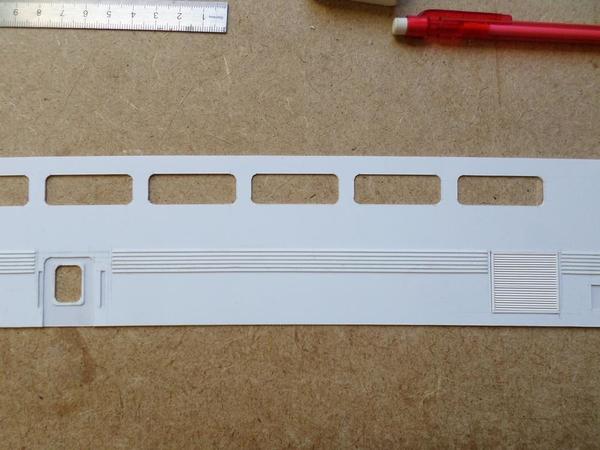

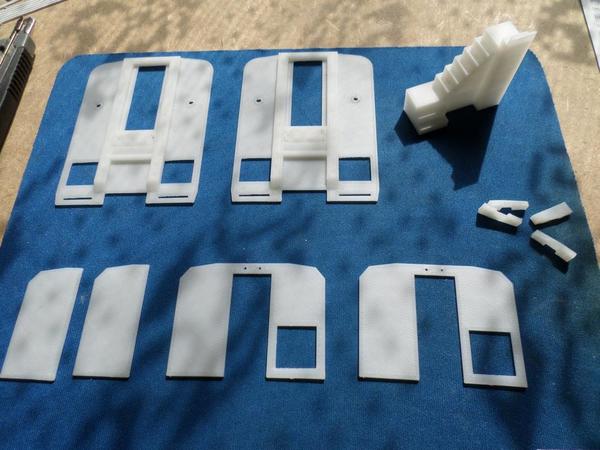

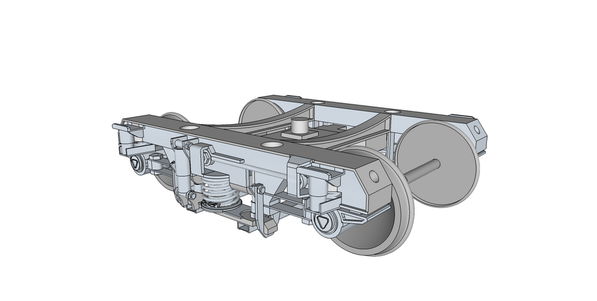

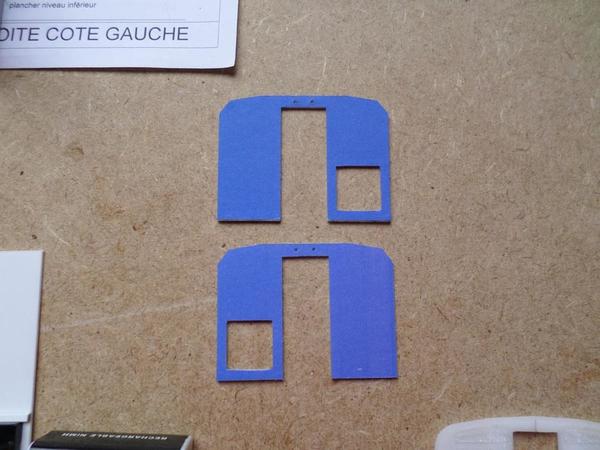

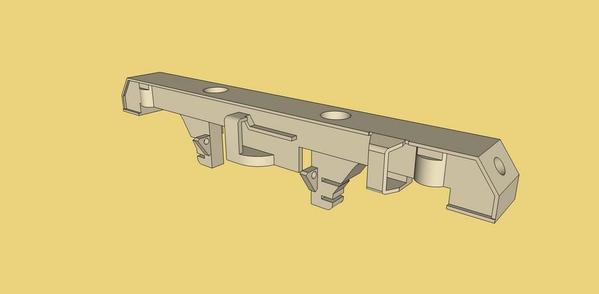

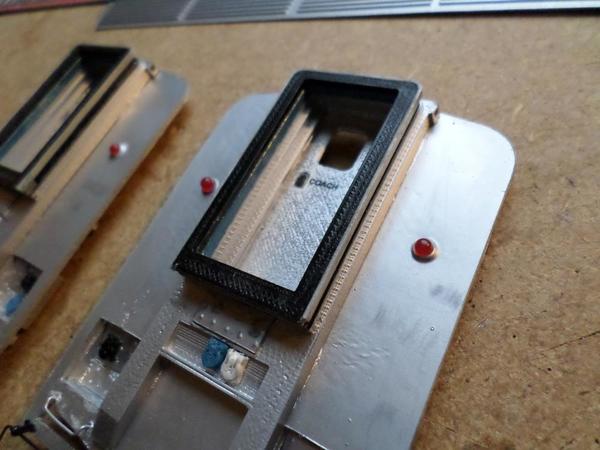

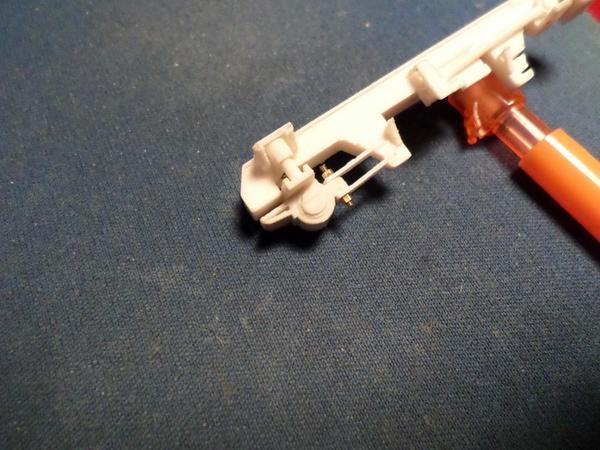

All the drawings are made with SKETCHUP software and I think that a number of parts will be made in a 3D printing way. I don't have this printer today but I found a guy near me with the 3DHUBS website to make me what I want; I will show you in a next message the first pieces he made for me.

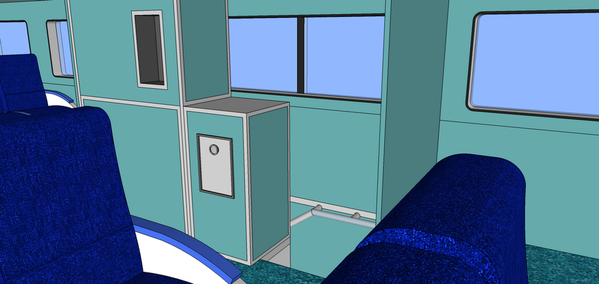

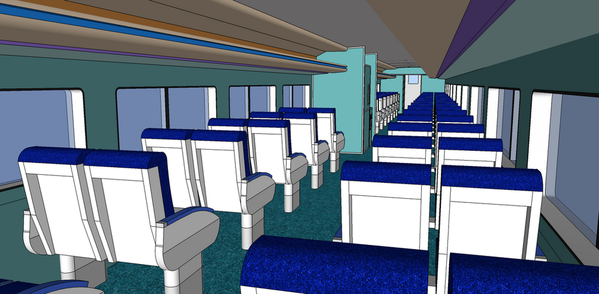

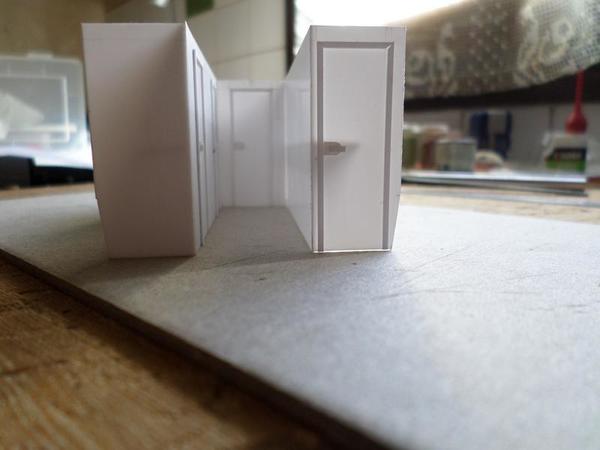

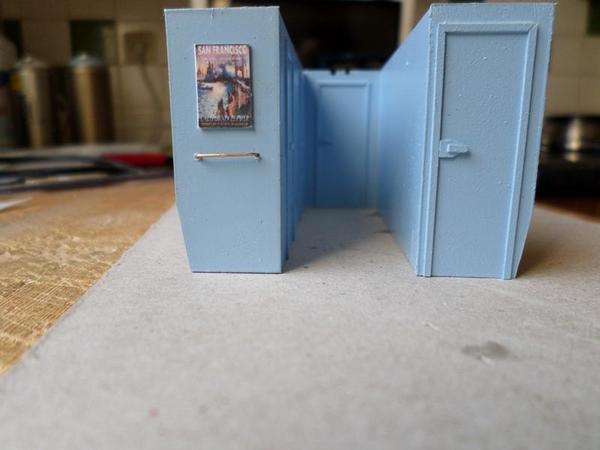

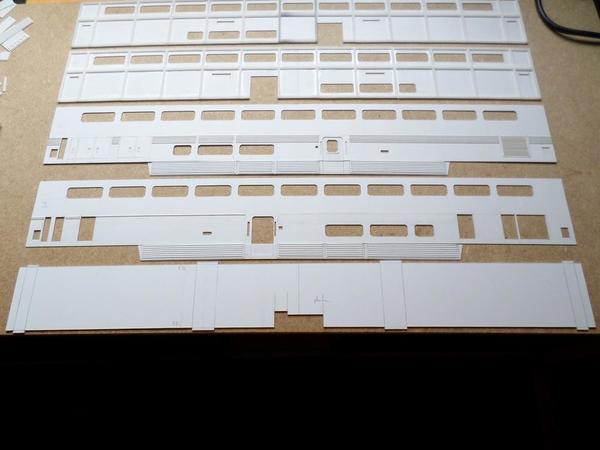

Some others drawings:

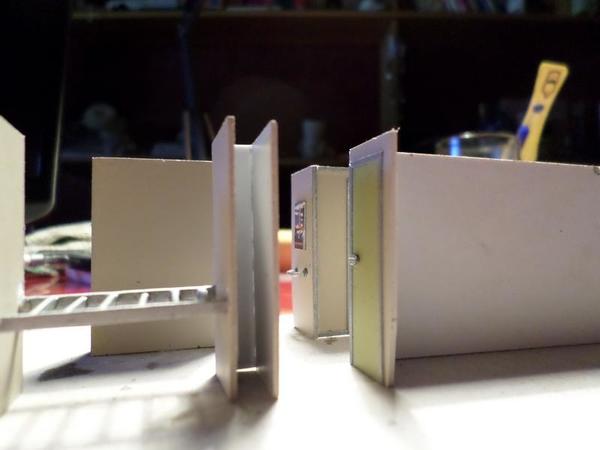

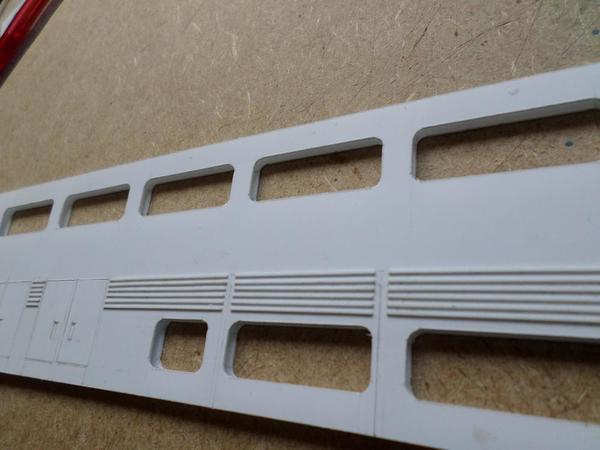

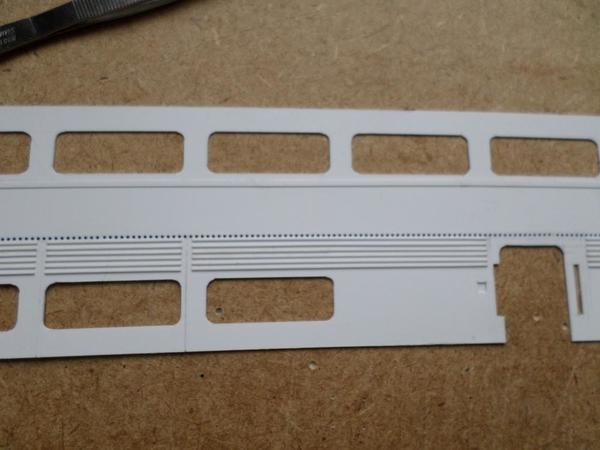

I have tried to respect the 1/48 scale for this model and it will be made like a real one that's to say: for the side faces, two partitions, inside and outside and a frame in between (other drawings showing that are in the specification). Not easy, but a very big challenge for me!

Hope you like

That's all for tonight!

jpv from France