AMFLYER (Tom) - thank you for the experienced insight!

Russell - based on Tom's wiring information, it would seem a modular layout would be difficult. The problem could be solved by fabricating two wiring harnesses - one for track power and one for accessory power. Using a combination of D-Sub connectors and Anderson Power Pole(for track, heavy gauge wire) one could build the harnesses with the accompanying attachment connectors from the transformers.

All of that seems a bit much for what you want to accomplish.

Item#2 - the CTT plan is O and has a reversing track on the inner loop. Again, you don't want to go there for this project.

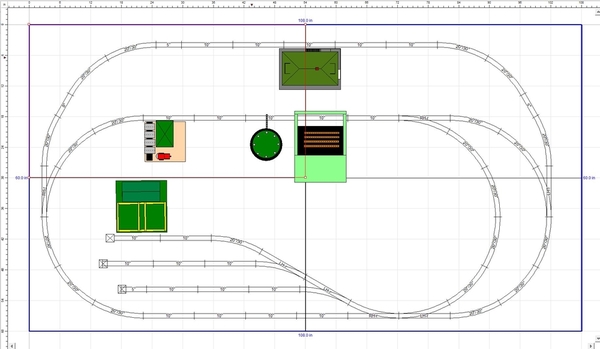

Item#3 - some SCARM help - in Tools -Toolbox or the icon on the menu bar there is a rectangular baseboard tool. I used it to create a rectangular baseboard with exactly 60" x 108". View - Show size and area.

Item#4 - In the library panel there is a figures library. I used the rectangle figure and created 4 - 30" x 54" rectangles, set the Vertical position at -.25" and the height at .20" and selected Translucent for the color. Then, copy and paste three more and move them to position.

Now you have four outlines that would represent each module.

This will enable you to see were the breaks for the track are located. The current layout would need some repositioning of switches.

I would suggest a two line layout that doesn't have the lines joined or keep the plan that you have and tweak it for the modules . It will greatly reduce the wiring and potential electrical issues.

I have attached your first attempt with the modules outlined. You can use the file and rename it with each layout change to keep the modules.

I also found a 60" x 90" track plan from a 1953 book that sets up nice for accessories. See attached. The spur at the bottom looks like it may work for log loader.