I am new to TMCC, I cant get my engine to complete a loop on 10 x 24 layout. It never looses power, there is only 1 transformer. It stops in the same spot every time. Not sure where to even start looking for this problem, any trouble shooting tips would be great

Replies sorted oldest to newest

Can you disconnect the TMCC base and run the loop in conventional mode? If the loco still stops, you have a power connectivity issue with a section of track.

Does the headlight flicker when the loco stops? If so, you have a weak TMCC signal problem. Search the forum for discussions on how to diagnose and resolve weak TMCC signal.

#1 attempt to blow the horn repeatedly (don't hold the button, but instead multiple rapid presses) to ensure the engine is responding before and passing through the problem area. If you see the headlight blink or it just stops responding- then you have a TMCC reception problem.

#2 Walk over if possible and place your hand just above the engine where it stopped. Your hand can increase the signal and if the engine now responds where it did not before you have a reception problem. Again do not touch the engine, but placed just above it.

#3 Ensure your base power supply is grounded (power supply has a 3rd ground pin) and is plugged into a know grounded outlet.

#4 You may need to run a ground wire (actual earth ground) wire to increase signal strength in that area.

I have a Lionel USRA light mountain type with Legacy. It has run flawlessly since I obtained it. At an operating session this weekend, it decided to stop running. Another skilled operator was running it. what it does now is power up fine. Whistle, bell and smoke all work fine but the engine won't move. It seems there is something holding it back. If I hit the boost, it will run for a short distance and stop. I have read these manuals until I think my eyes are crossed. Can anyone suggest anything? Thanking you in advance. Bill Park

Since it moves a bit with boost, are you saying it won't move no matter how many turns you do on the big red knob?

Bill, most of these "smart" locos can be reset by pressing a sequence of buttons on the CAB-1 or CAB-2. Think of it as "rebooting" the train's on-board computer. I would try a reset, reprogramming the Legacy engine ID, etc., even before I would take the shell off. Good luck!

@Bill Park posted:I have a Lionel USRA light mountain type with Legacy. It has run flawlessly since I obtained it. At an operating session this weekend, it decided to stop running. Another skilled operator was running it. what it does now is power up fine. Whistle, bell and smoke all work fine but the engine won't move. It seems there is something holding it back. If I hit the boost, it will run for a short distance and stop. I have read these manuals until I think my eyes are crossed. Can anyone suggest anything? Thanking you in advance. Bill Park

See if a traction tire has come off and jammed underneath where it is hard to see. Or a bolt loose or fallen out of the linkage.

Thank you gentlemen, I will investigate those possibilities

@Bill Park posted:I have a Lionel USRA light mountain type with Legacy. It has run flawlessly since I obtained it. At an operating session this weekend, it decided to stop running. Another skilled operator was running it. what it does now is power up fine. Whistle, bell and smoke all work fine but the engine won't move. It seems there is something holding it back. If I hit the boost, it will run for a short distance and stop. I have read these manuals until I think my eyes are crossed. Can anyone suggest anything? Thanking you in advance. Bill Park

What system are you using? Legacy or Cab1?

Gun Runner John, The engine powers up fine, smokes, railsounds, bell and whistle, but no matter what I do with the throttle wheel, no matter how many turns I make, the engine doesn't budge. I can get it to move by using the boost button, but it goes maybe a foot and stops. I have also had it start and just run away with speed and only way to stop it was close the transformer throttle. Is there any strategy that holds the engine from accepting the speed commands?

What is the exact Lionel product number?

If you are using a CAB1 try installing fresh batteries. As the batteries start to get weak the first function that fails is the red knob. The red light on the base should should flash when the red knob is turned.

@Bill Park posted:I can get it to move by using the boost button, but it goes maybe a foot and stops. I have also had it start and just run away with speed and only way to stop it was close the transformer throttle. Is there any strategy that holds the engine from accepting the speed commands?

Another possibility. I have experienced 2 TMCC remotes were the throttle knob was defective. One was bad out of the package. Assuming there are few if any "new" Cab 1 remotes, the risk of issues is always there.

Throttle response was all or nothing. Once the engine took off a full speed no amount of throttle turns would stop it. It was like the rehostat would lose its "zeroz' point.

If you had another TMCC loco to try, it might help with the process of elimination.

@RickO posted:Another possibility. I have experienced 2 TMCC remotes were the throttle knob was defective. One was bad out of the package. Assuming there are few if any "new" Cab 1 remotes, the risk of issues is always there.

Throttle response was all or nothing. Once the engine took off a full speed no amount of throttle turns would stop it. It was like the rehostat would lose its "zeroz' point.

If you had another TMCC loco to try, it might help with the process of elimination.

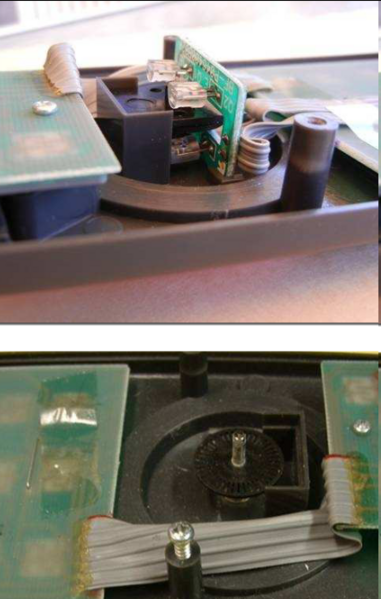

I just fixed a CAB1 remote with a bad throttle. The fix was stupidly simple. When someone had the remote apart (evidenced by the wrong screws being used to hold the remote together) the throttle red dial encoder circuit board got angled rather than being vertical in it's holder brackets that are in the front and back halves of the remote. This is turn also slightly bent the optical LED or receiving photodiode so even when the board was put back in position,the beam through the encoder wheel was slightly off. Slight pressure and bending and careful assembly and it's like new.

Again, Cab1 uses an optical encoder wheel- not a throttle pot. If one or both of the beams are out of alignment or damaged it cannot identify rotation. https://www.machinedesign.com/...atureencoder-signals

Check that out, I didn't take pictures but google found an archive of the old Trainfacts website.

Again, I found when someone before me assembled the remote, that little vertical PCB with the LED and photodiodes was angled rather than vertical causing complete lack of reading the encoder wheel.

I hope this isn't the problem in this topic, but just answering since I recently just last night encountered and fixed one of these. -Fresh on the mind.

Attachments

The problem developed when we were running two Legacy engines at once on a Legacy system. One engine suddenly stopped and refused to move forward. I followed the recommendations posed here. The suggestions were checking to see if a rubber tire had come off and none had, and to do a complete reprogramming of the locomotive. Programming didn't change anything. A further test was conducted on another Legacy locomotive and it performed per manual. I disconnected the Legacy line to the track and tried running it conventionally. The engine took several tries with the throttle on the transformer but eventually would run in forward with the speed being able to be controlled with the throttle. However it would not run in reverse. Again using the boost, it moved about a foot and after several tries, it took off uncontrolled until I shut down the throttle. It sounds like it needs a repair shop. My ambition here was to just identify if it was something I programed by mistake or does it need help from a service person. Again, any thoughts are appreciated. Bill

Again, what is the specific Lionel product number for the problem locomotive?

The product number is 1931090