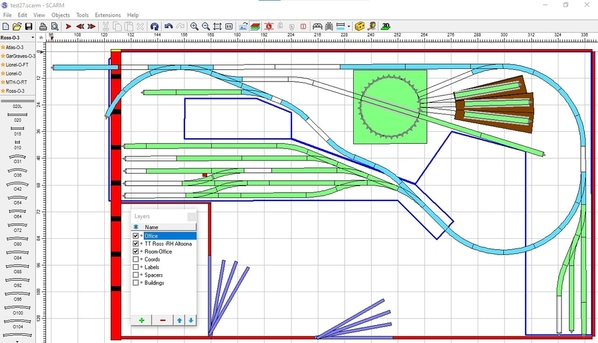

Okay, here are the 27" and 33" designs I've been working on, hence the "test" in the filenames. The loop on the right in both can be pretty much swapped, I just wanted to show different options. The negative is what the 33" TT does to the yard and lead on the left as well as the reach. I expanded the access area so more will be within a 30" reach, but it's awfully narrow, so I don't know if you can fit to deal with problems. I'd still like to work on the track above the yard to see if I can't work it more around the TT and expand the access area more.

I've been trying to avoid having the mainline run through the turnout portion of a switch, but I'm still not sure how big of a problem that really is, so I added a curved switch to the 33" version. If it's okay to have curves switches, why isn't is okay to have trains run through the turnout of regular switches?

I'm also still concerned about designing this for large engines, so I made sure there was a path across the TT to a whisker track without the need to turn a large engine. Unless you plan on buying a bunch of expensive large engines, I just don't get it. If my main inventory was "normal" sized equipment I'd design with that in mind while adding the capability to run a larger engine or engines. And if I wanted to show off my large engine, I wouldn't hide it inside a roundhouse, unless the roundhouse had no roof, just a personal opinion. Trouble is, other than the TT/RH, I don't see much that can be done differently. Oh, and the TT/RH won't fit in the lower right corner, at least not the large 63" version, so I've given up on that idea.

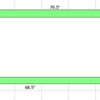

But, I'm not giving up trying a 27" TT with Altoona's 55" RH. The 27/55 is 68.5" deep. The 33/63 is 79.5" deep. The last photo shows the difference in minimum real estate, but I'm not sure how much difference that makes given the location. I just think the larger TT/RH is oversized for the space, that's all. But, that's also a personal opinion and based more on the fact that it's ONLY a TT/RH without the usual lead tracks, water/coal stations, engine house and adjoining yard.