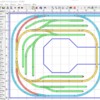

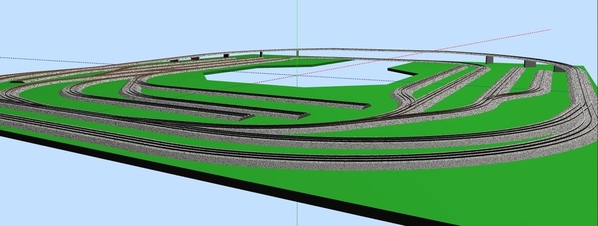

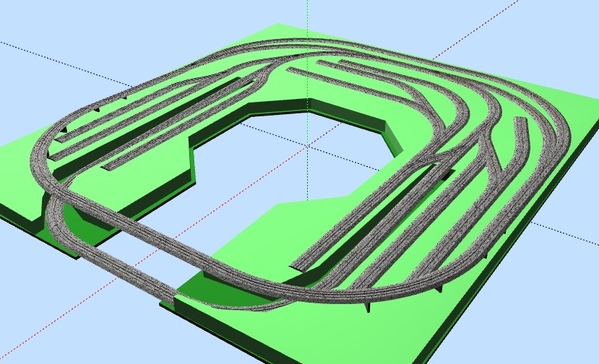

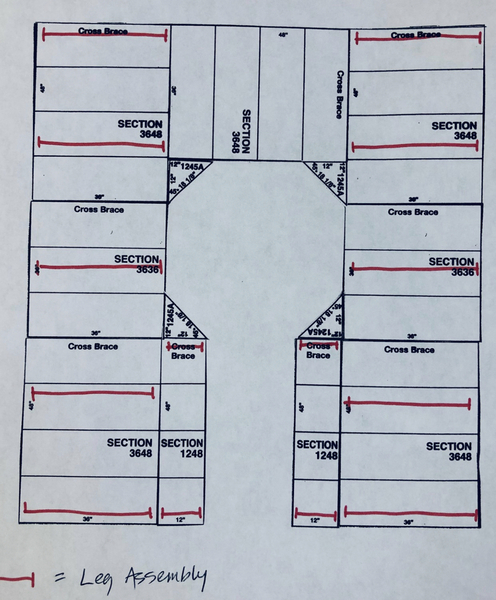

I am trying to get the best possible track plan/layout but i am a bit new at this. I am wanting to do O gauge but also have some scenery like mountains/tunnels etc. But i also want alot of switching while maintaing some continuous running lines. I am attaching my layout in any rail and pdf files. I am a looking for someone to help track plan but the last person i talked to wanted $2500 which is way out of my range. I just want something i can run my O gauge trains on and i plan to use gargraves track and ross switches. This was my first attempt to design something, maybe not the best design but it was a start. The files are attached. I would take help here or even a referral to someone that does track planning for a fee. With the 10 x 11 space i have, its kinda limitied for O gauge i know but i want to get the most out of what i have and not make some bad mistakes that will cost me in the long run.

Replies sorted oldest to newest

I'm not going to design it for you, but offer some suggestions. Hide the top part of your oval (either under mountains (sounds like your preference) or behind a scenic backdrop) so you can still have continuous running. Then use the remaining portion of your layout to operate as a port on one leg of the visible "U" while using the other "U" leg as an industrial area served by the port deliveries. The space at the bottom of the "U" could be your town area.

I would highly recommend putting your hidden area where the entrance to the center of the layout is located, and then use light styrofoam (sp?) sheets to build a removable mountain piece. Your "port" could just be a freight yard with pictures of port facilities on the walls. You might even use a port "facade" so that your continuous loop trains don't run through your port operation.

Finally, be sure to use your design software with the products you plan to use. In what you posted, you used Gargraves switches, not the Ross switches you plan to use.

Chuck

Thanks for the tips chuck that’s why i posted on here was for tips or if someone had track planning recommendations or someone who does it for a fee would also be an option since i am more of a newbie and am trying to maximize space i have with switching and scenery. The gargraves switches are being pulled out and equivalent ross switches are being added i just have not made the change yet in any rail. I would have paid one guy i talked to but when he told me $2500 i was like i’m yeah too much

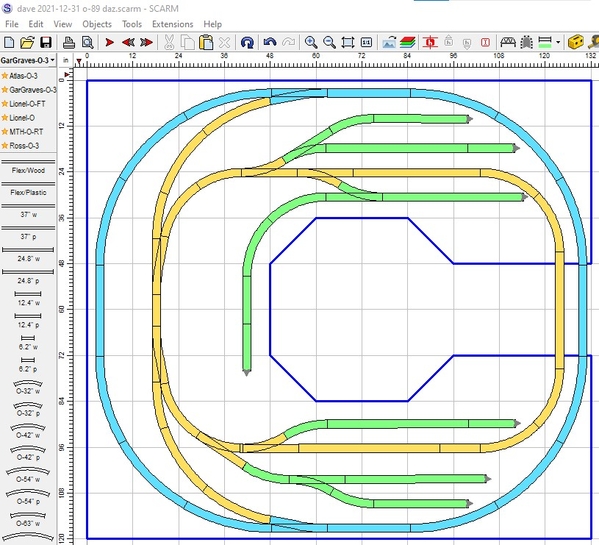

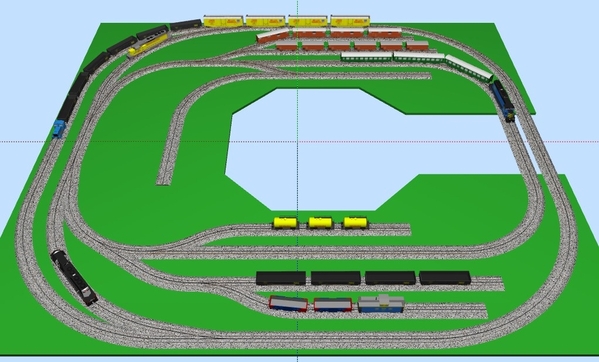

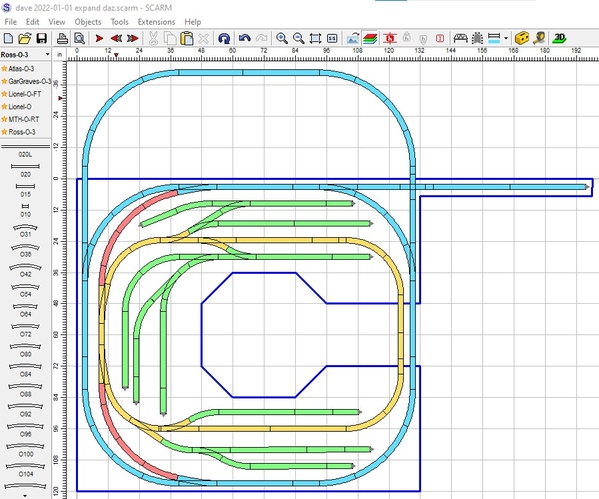

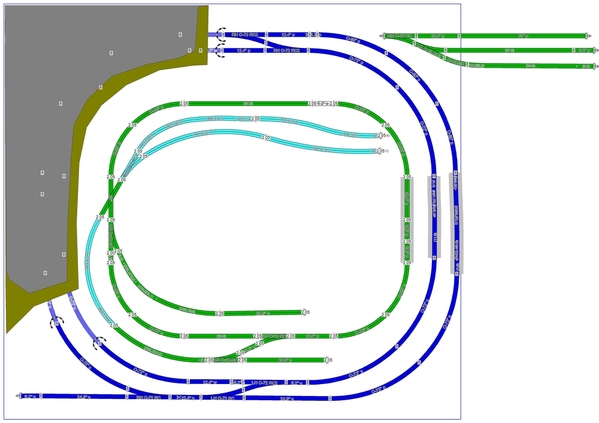

Updated track plan to reflect ross switches and gargraves track.

Attachments

@davehall83 posted:I am trying to get the best possible track plan/layout but i am a bit new at this. I am wanting to do O gauge but also have some scenery like mountains/tunnels etc. But i also want alot of switching while maintaing some continuous running lines. I am attaching my layout in any rail and pdf files. I am a looking for someone to help track plan but the last person i talked to wanted $2500 which is way out of my range. I just want something i can run my O gauge trains on and i plan to use gargraves track and ross switches. This was my first attempt to design something, maybe not the best design but it was a start. The files are attached. I would take help here or even a referral to someone that does track planning for a fee. With the 10 x 11 space i have, its kinda limitied for O gauge i know but i want to get the most out of what i have and not make some bad mistakes that will cost me in the long run.

Do what I do sit down with a legal pad and draw it out. I make many changes and then settle down with the idea.

Download SCARM (computer aided layout design) it's free and will give you a very good start. A lot of folks here use it and the learning curve is not very steep. In learning it you will learn a lot about your layout. There is a large library in SCARM that will contain the specific track you want to use and it will give you a parts list of all the track and turnouts needed for your layout. Time well spent!

OH! And, WELCOME TO OGR!!!!!@!!!!!

@Dennis-LaRock posted:Download SCARM (computer aided layout design) it's free and will give you a very good start. A lot of folks here use it and the learning curve is not very steep. In learning it you will learn a lot about your layout. There is a large library in SCARM that will contain the specific track you want to use and it will give you a parts list of all the track and turnouts needed for your layout. Time well spent!

OH! And, WELCOME TO OGR!!!!!@!!!!!

Very true, I like the pad first when I am sitting outside or relaxing I can just write it down. Latter once I decide I transfer it, then it goes much smoother.

Have you looked into Ken Hoganson's book 21 Great Track Plans for Compact Layouts? Maybe something for you to use or start with in there. I see Ken worked in AnyRail with FasTrack and Atlas O so you shouldn't have any trouble recreating his layouts. Ross and Atlas O curve turnouts are mostly drop in replacements length-wise for each other but there are some differences in curve radii so it is worth spending the time in AnyRail to fix the differences. If you plan on using sectional track I would recommend Ross over GarGraves.

Here's some food for thought.

I couldn't tell what size curves are in the FasTrack layout, but they appear to be tighter that the O-89s that are in the Ross/GarGraves version. You didn't mention what engines you plan to run and what size curves they need, but I'll assume they currently run on at least O-36.

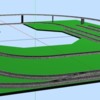

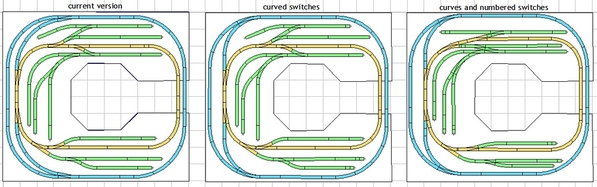

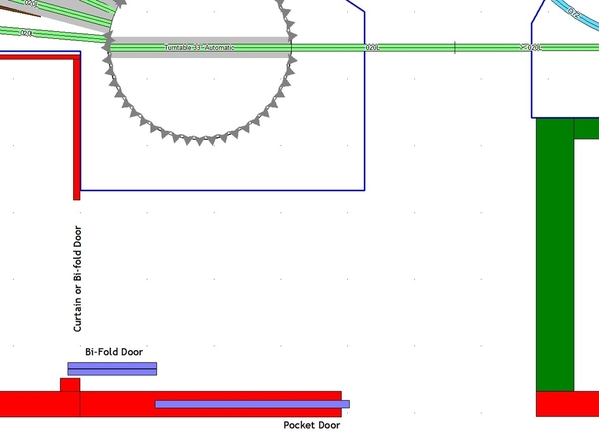

Photo 1 is a quick (and crude) rendering of Chuck's idea to consider before you go too far drawing things on paper that simply won't fit the space or trying to use curves that also won't fit. The Blue tracks are the O-89 curves in your PDF version. The Orange tracks are O-54 curves. The Green switches and curves are O-42 with several curves cut to fit.

Photo 2 shows it separated into 2 runs with more tracks needing to be cut to fit.

As you an see, the O-89 curves will fit in either version and you can probably elevate 1 bridge over the entry, but not both. As you can also see, even using O-42 switches/curves, there isn't a lot of room for switches/spurs.

Attachments

well this is certainly a cool layout you have shown me here didn’t even think of it this way. I wanted to run some engines that require O-72’s like the big boy. The fast track was just for christmas and consisted of O-72 and O-36 curves all over the place but it never got 100% working right so i plan to tear that down and put up the gargraves track with ross switches. The O-89’s with gargraves were the largest circle giving me the the best possible “outer ring” so i can run some big boys or fill scale O engines that run on O-72 min radius. The big engines will only be run on the outer ring as i know i only have space for probably one of those but like you said not so much space for switching. The rest of my engines run on O-31 or O-36 like the polar express, hogwartz express and other engines i plan to buy. The more expensive engines i get will probably be in the min O-31 to O-36 minimum radius range. But a few bigger full o scale engines i like will have to be “outer ring” only engines since they will have the minimum O-72 ring requirement but that’s something i have to live with , with the space i have unless i start making an upper and lower deck lol which may happen one day.

Mia the blue track utilizing my ross 100 and 101 switches that join the orange track? i really love this ideas and i am definitely appreciative of what you did here for me. I took a while for me to figure out anyrail but any chance you can send me these layouts so i can buy scarm and see the parts list ?

The other trick is that open bridge area is a basically a piece of plywood on a piano hinge with a latch underneath that i will have to tinker with to figure out how to get it working.

But this layout would keep me happy for the time being and i could run 2 trains if i isolate the electrical too. The wall on the top of your drawing goes into my office and is hollow if i ever convince my wife i was going to cut 2 tunnel portals into the wall and then make it look good with some scenery and portal graphic etc then i can expand into my office and have some track there too for switching and a storage/turn table yard and maybe more running track lol.

Thanks pretty far off before i do that though. I would most likely get room in the basement for a second layout before she lets me do that one

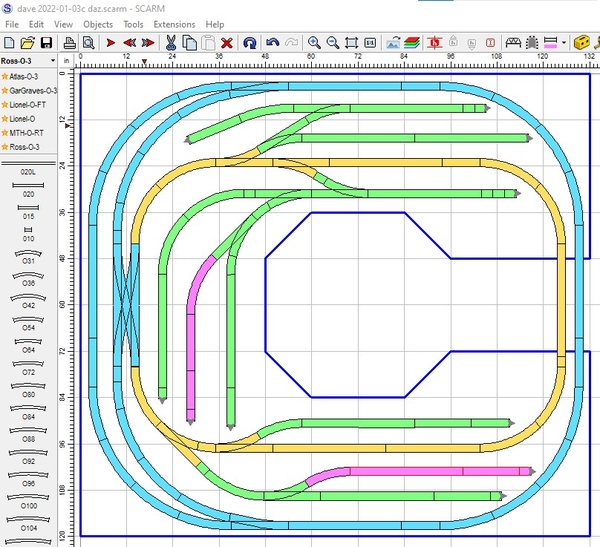

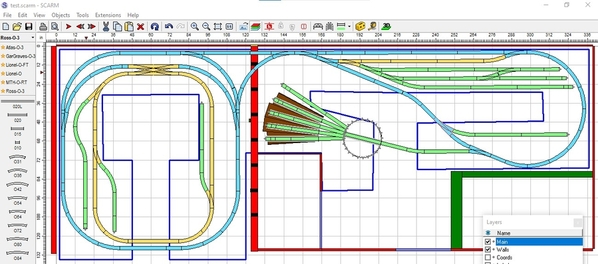

Dave, based on this new info, I’ll clean up the design some. I’m not pushing SCARM, it’s just what I use these days. If you want to use AnyRail, I’ll post a photo with track labels and a parts list so you can convert it to AnyRail. If you just have the trial version, SCARM also has a trial version. It does things differently, so be ready for a learning curve if you try it out.

ROger that, the one design on top that had a 3 way y was that a particular part? I may like the bottom design better though

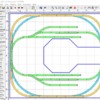

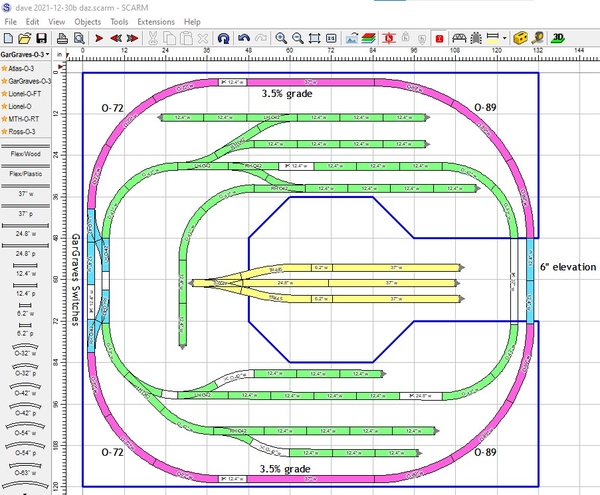

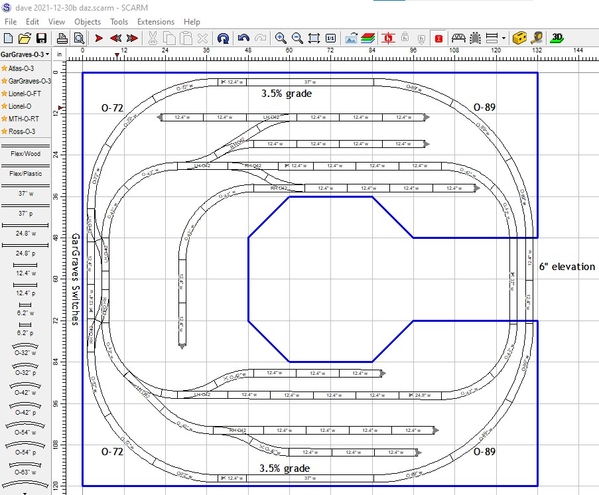

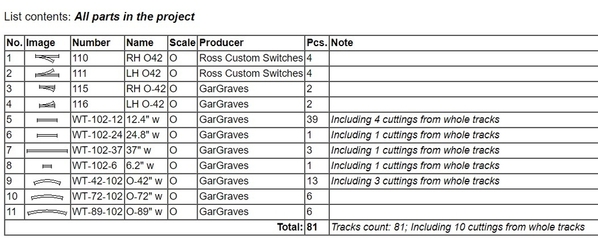

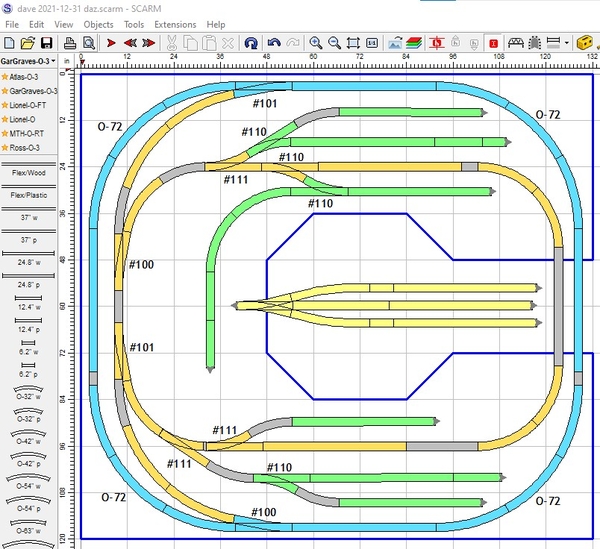

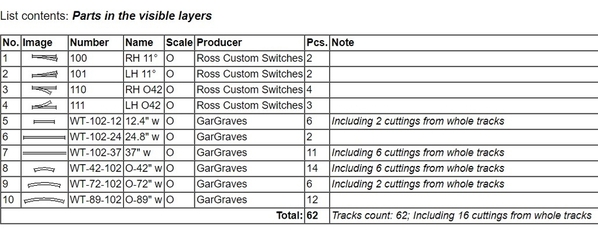

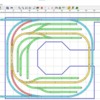

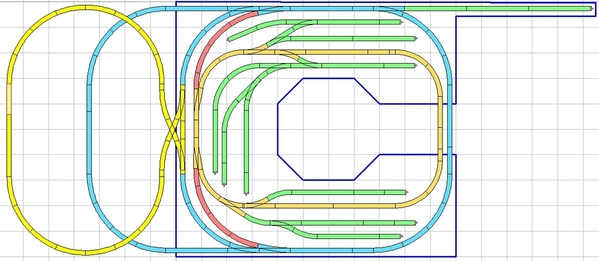

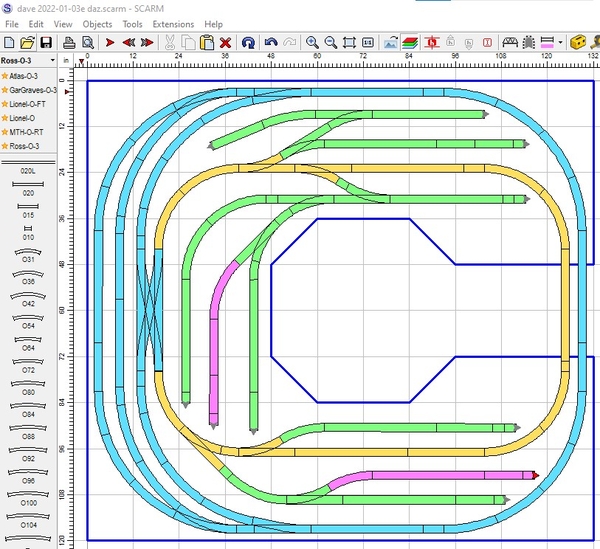

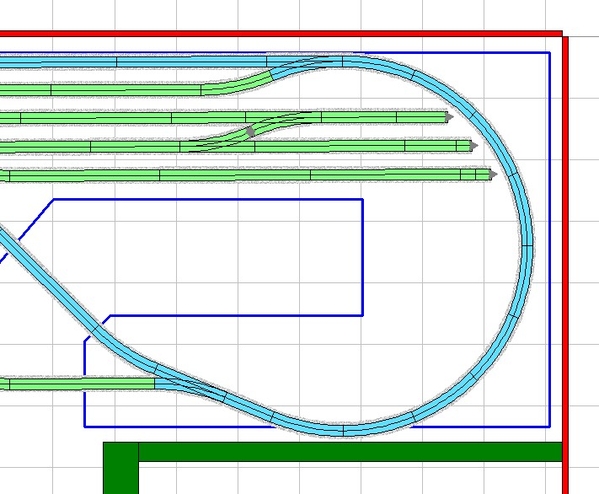

Ok, here's a version with a lot of track and switching to show different configurations. Unfortunately, the blue crossover on the left only fits using GarGraves O-42 switches, not Ross, and O-72/O-89 curves as labeled. The purple tracks are grades from 0" to 6" elevations. The clear tracks are those that had to be cut. All green switches and curves are Ross O-42. There's was no 3-way in the other photo, but I added one here to show sizing. It does limit how many spurs can be easily added, but it's something I can work on. I added the Parts List to show you that the number of pieces is under the SCARM trial limit of 100, so you can install SCARM and fiddle with the file to decide if you want to purchase it. I think AnyRail trial limit is also 100. To download the SCARM file you need to right-click and select Save As or Save Link As.

Attachments

@davehall83 Dave, your layout space is similar to what I have and what @Mark Boyce has on his Blackwater Canyon layout. Check them out for ideas.

You may want to consider having a main which will handle the BIG engines (make sure you have sidings - I've found once on, I do not want the hassle of removing them) and design the rest of layout for most of the other gear which usually handles 42 inch diameter curves. Looks like you could easily fit in several long sidings to park the long engines.

Be careful on the grade, I do not think you have enough room to get a 6 inch rise with a reasonable grade. For a 6 inch rise at 2.5% grade you need 20 feet of run. Stacking track on top of one another will not work at those sections. You can reduce the run needed by have one section rising and the other declining to meet in the middle, providing more flexibility in layout design. Of course that is assuming you want too be able to connect upper and lower levels.

If you want to do switching, you should look at the ideas of "a runaround track configuration" instead of dead ends in a yard.

The only thing is, was there anyway to keep ross switches in here and use the o-89 outer circle like you had earlier? I really want the reliability of those switches and the layout your showing. If we can figure that out, this would work out well. I saw the black water canyon very intersting layout that is something of interest. I may get rid of the trestle/elevated track here just to get the layout on a level working layout and do some upper levels later instead.

Don’t have time tonight, so I’ll see what I can come up with tomorrow, but it’s going to limit the ability to elevate sections because I’ll have to try different locations for connecting the inner and outer loops. It’ll reduce the number of spurs too.

Ok understood, if it will reduce spurs then o-72 is ok with me just mainly want the ross switches in there. The elevation stuff i may do without, i had some issues with mine on fast track

Not the O-72, using Ross switches.

I cancelled my Ross order for the 101 and 100 switches so we can figure out what i need switch wise no sense of buying the wrong switches. I just really want the reliability of the switches that ross has. The elevation i am not too concerned about and that doesn’t have to be apart of the layout. Its just that one area thats open to the floor that was in blue highlighted line which we could just run track across and use the piano hinge drop down dooor without any elevations or i can make it closed permanent as well i just have to climb under lol. The blue area is an entire piece of plywood on a piano hinge.

The gargraves switches i mean i don’t have any issues using them personally but i have no experience with them and the dz2500 switch machine. I have just heard on these forums all the horror stories of why you should avoid any other switches other than ross and people who have gotten gargraves switches have regrets and ended up tearing them out and got ross switches.

But i agree with your note saying that it’s going to reduce space for spurs because they are bigger for sure.

It would be nice to run two trains at one time by isolating electrical but that’s a secondary requirement as we gotta figure this out first lol

Just to put it out there i appreciate everyone’s input and help here. This is most certainly saving me a lot of grief and mistakes and i plan to learn from this to be able to do this on my own. I tried tinkering with the layout i had for a few hours last night and yeah i didn’t come close to the nice layout you came up with originally

If i need to keep the gargraves switch design you created because i just don’t have the space to make ross happen i will do it but my big concern was the switching derailments and reliability. For example i had another thread out here where i had a problem with my brand new polar express and this fast track. Come to find out the front wheels of the berkshire doesn’t like going into a switch unless it’s complete straight which made me have to tear up a bunch of secured fast track to put straight sections in and then it started working. I have still one section that just doesn’t work in that train but works in other trains like the wizard of oz locomotive set i have. I also watched how the lionel graduated trestle kit and girder bridge just didn’t work so well with fast track when it was suppose to and made my trains act crazy like going too fast down a steep grade and slower up in the other side of the grade and yes i expected that for sure but not as much as it did.

The topping on the issue was when i ran the N&W 612 it didn’t like fast track at all it sounded as if it were having issues with it like a small dragging noise even though this thing ran fine on the floor months ago with fast track in a basic O-36 oval with a few straight sections. The train when it got to the other side of the gutter bridge and started going down hill on an O-72 curve just fell right off the track and it wasn’t going that fast at all a picture of the locomotive i have is attached here i am not sure why it acted up maybe the turn radius wasn’t efficient for it but i know i like this locomotive and want to get it running and have a decent track with some spurs and switching

Attachments

Some engines have a lot of overhand in curves. Those 100 and 101 switches are yard switches, they are set for a 3.5" spacing and may not be the best choice for mainlines. They could work with a straight section between two of them to space things out some more.

If you want to run larger engines on the main I would suggest using Ross #4 switches, 200 and 201 if they aren't entering a curve, otherwise the 072 or larger should be fine. The #4's don't curve like 072 but they are very close in turnout angle. Facing each other they give a 4.5" spacing. They are also the same length as the 100 switches.

Dave, ordering those 4 switches changes everything, including any idea of elevating tracks now or in the future and I’m not sure how I’m going to fit an inner loop so you can run 2 trains, much less spurs for switching. Those switches let you move larger engines off the outer loop, but then what do you expect to do with them? Granted, Ross switches are arguably better than other brand switches of the same size, but if an engine doesn’t like tighter switches, simply buying Ross switches isn’t going to solve that problem. Neither is switching from FasTrack to GarGraves going to solve your problem with elevated tracks. You said you were just going to run your larger engines on the outer loop, but buying those switches suggests you have other ideas. At any rate, I’ve gone this far, so I’ll see what I can come up with, though it won’t look anything like what I posted yesterday.

Well i didn’t really have other ideas i just picked those switches to get some switches in the loop but after playing with them it looks like they aren’t going yo help us at all. Yes i would love ross witches but if we have to settle with gargraves then that’s what we have to do. I did like what you posted yesterday very much so. I’m not saying i will get rid of elevated track for good but having a level layout may be good for starters. Let’s remove my 4 ross 101s from the equation then and 100s then see what we can do with ross switches. I like what you posted yesterday it was defiantly up my alley i also looked at scouting dads layout and it was awesome the twin pines railroad with the very first post he had. a pretty good one there i’m assuming in the same space i have or maybe i am mistaken

the larger engines yes they will run in the outer loops which is fine with what we had there after tinkering with it i see why you had to go from O-89 on one side to O-72 there was no way to fit in those switches without doing that but i did like your outer and inner loop concept with spurs and things

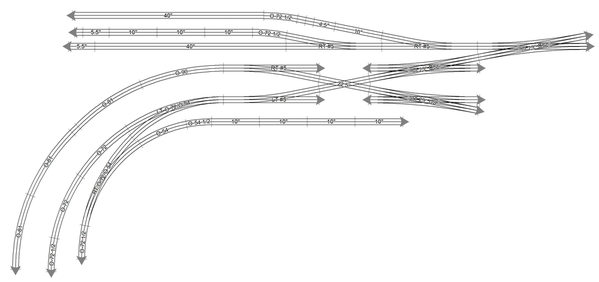

Don't forget that you can actually put crossovers on curves with curved switches. You could use either O120-O96 or O96-O72 on your curves and have the ability to run your big equipment on two mainlines, although it would obviously look better on the O120 side. Due to your room size, though, you will probably be limited to O96-O72.

Chuck

I was looking at that last night actually but got stuck with circles and couldn’t seem to get out of the circles to make something similar to what dave made but i also am being an amateur i’m probably missing some concepts or ideas in my thoughts

made some changes above to what i wrote also i have cancelled all ross switches, any gargraves track i had etc so we have a fresh start now to make it work. We can also goto ross track as well if we want. Let me know what you think

Dave, don't pull the trigger too fast, give me a chance to see what I can some up with. These designs were all done to show possibilities since it didn't seem like you knew exactly what you wanted and I obviously didn't know you ordered the switches. Twin Pines is 9x13 and I believe the largest curves are O-72. Both of these elements make quite a bit of difference. His base elevation is 4" and the lower tracks for the overpasses descend to 1" while the uppers rise to 7" accounting for the 6" differential. That means he lowered some 3" and only raised the others 3" to get grades he could live with. I assume he designed all that BEFORE he built his bench work. You've already got tabletop bench work built, so you'd have to add layers of foam board or something to raise much of the track. I don't know what Steve's lead time is for shipping, but maybe he can hold your order a bit.

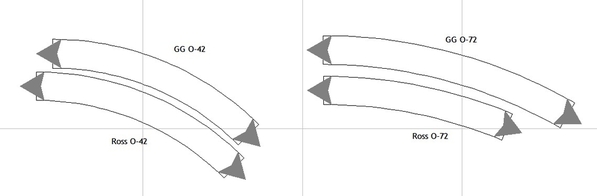

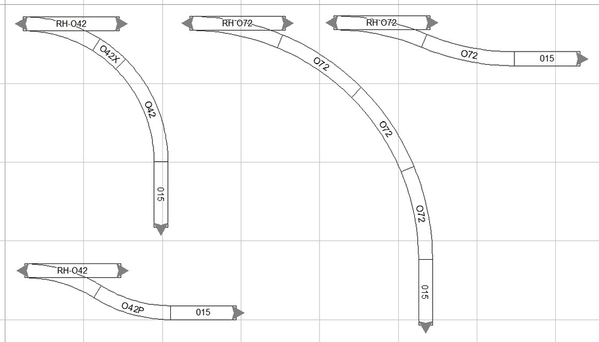

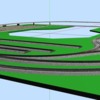

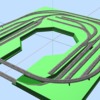

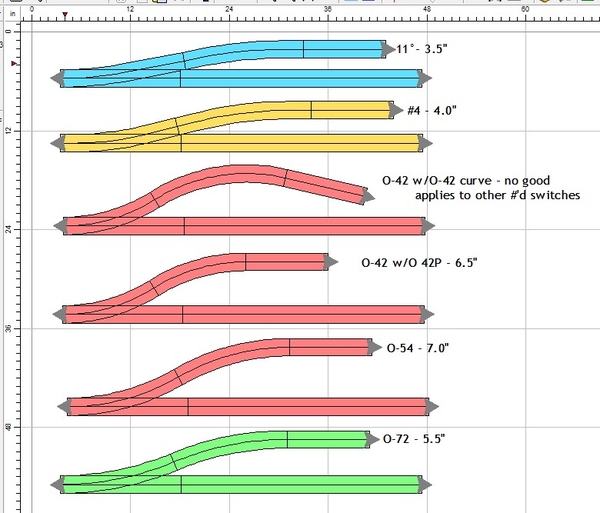

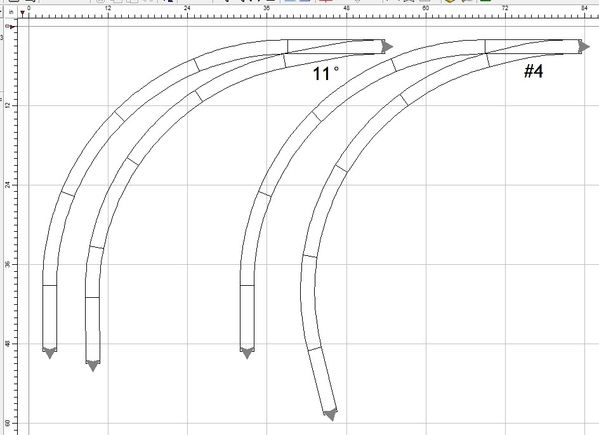

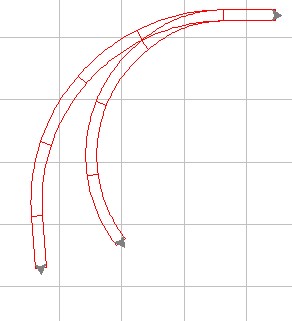

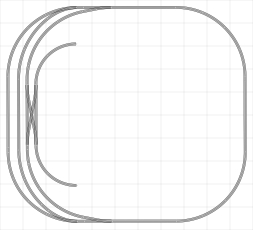

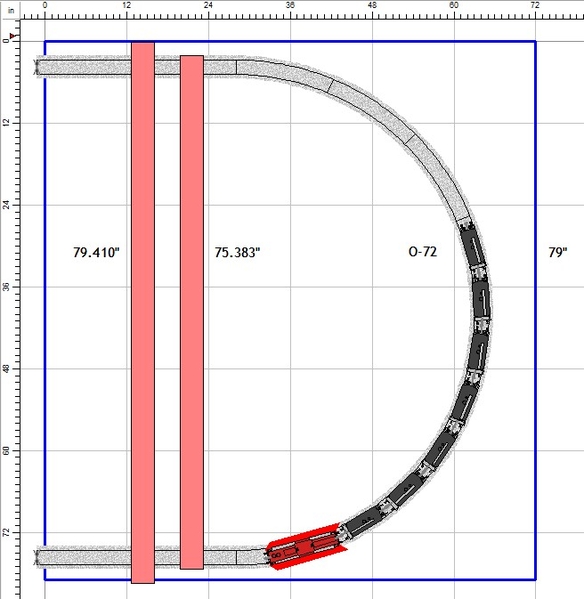

Here's some quick examples to show the difference the size curve makes. While they all fit your space, as shown in the 1st photo, note the difference they make in the length of straight sections and where switches have to be placed in the 2nd photo. Now, when you add certain switches to the mix, you limit the options even further. I added O-96 because Chuck mentioned the O-72/O-96 curved switch. When it comes to curved switches, you really have only 2 options; O-72/O-96 and O-54/O-72). I have no idea how well they operate, some users have problems, others don't. Regardless, if you want the option to move large engines that need O-72 curves between loops, you're going to have to compromise on other things. And taking large engines off/on the layout is going to get tiring real soon.

Attachments

Dont worry i cancelled the order with steve so were good to go to get this fresh start. We have all the time we need to do this right so we get something going that will work. I like having a big outer circle like the 0-96 or O-89. We can even design this with ross track and using gargraves flex if needed in places where we need flex sections. I also need to decide if i want stainless or tin rails i understand the tin you can solder wires to it which makes that a benficial factor. Your right i didn't know exactly what i wanted but the more i have seen on this post the more i start to realize what i want. So i know with that benchwork mistake i have to live with that, its sievers modular benchwork. They also have elevation studs you can buy to incorporate into the benchwork to raise the track all i have to do is pick sizes and bolt on and just get a skill saw and cut the benchwork to flex to the track. I will give you all the time you need, i appreicate you and everything your doing to help me, i owe you a case of track or something lol. If we can get ross working then we can if we cant and need to do gargraves switches then im cool with that. I found out my N&W requires min O-54 curves which makes sense why it fell off my trestle. But that could run on my outer ring and im ok with that. If i have to move the loco's and i know it gets old i will take them off and put back on if need be since my space is limitied. One day if i can go through the wall maybe ill have a storage yard and a turn table to store these guys off some spurs. I am also a bit concerned with curve switches as i have experienced with the polar express but maybe the ross stuff is good enough where they just work i havent tried them. But let ssee what you come up with but remember if we have to go back to your original idea the post with the track parts and gargraves switches we can, maybe the gargraves switches wont give me any problems which would be nice too. We dont have to do elevations either but down the road i may add that on by adding another level like you said

If we have to run the O-72 to get the right straight sections or even O-89 on one side and O-72 on the other like you did then we have to do it that way at least O-72 i think will run the big boy with a min of O-72 raidus. But if we need to do pure O-72 all the way around then thats what we have to do, otherwise i need to obtain a bigger room which i will down the road but this will at least get me into the rail roading stuff and modeling and the ability to watch my locos run, i love watching the steam thats my fav, i love loco's, i love the flashing lights, crossings , siginals i love that stuff.

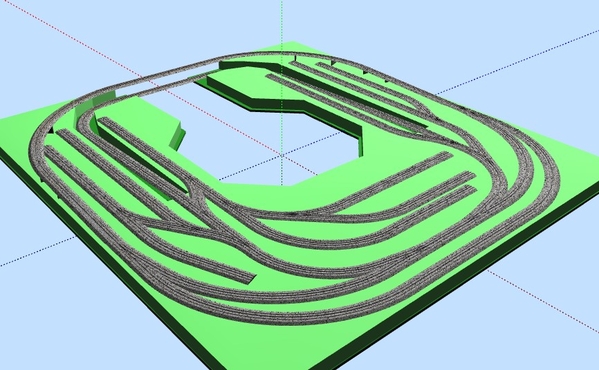

Ok, see what you think about these. Photo 1 uses the 4 switches you ordered along with O-72 curves for the outer loop and O-42 curves/switches inside. The Gray tracks are cut tracks. Photo 2 changes the outer loop to O-89 and shows what you have to give up. Ignore the 3-way, forgot to take it out. You can elevated the right side, 2" gives a grade around 2%. You can do the same on the left, but 2" gives a grade of around 3.5%.

Attachments

Wow it looks like we got a winner here so both of these uses all ross switches i see the small differences compared to the gargraves but if it where you which one would you pick gargraves option or all ross? Also would you go with stainless gargraves/tinplate gargraves or ross track? I see we have O-42 for the inner track which is cool. I take it i can run just about all locos on either the O-89 or O-72 radius? The O-72 looks a bit cleaner IMO, but what are your thoughts, i like them both lol

You might be asking the wrong person, but I favor the O-72 version because it looks more symmetrical/cohesive and makes better use of the space. The O-89 loop is too close to being a circle for my tastes and the left side seems "off" with that open space, though it depends on what you have in mind for landscaping. I also don't like the shorter spurs. Bear in mind, I added the spurs mostly to fill the space and show possibilities.

Here are a few thoughts:

- The Red crossover tracks will let you store a large engine set to run in opposite direction while running a 2nd on the outside loop. That way you can keep 2 large engines on the layout and not have to manhandle them each time you want to run 1. You could also add 1 or more spurs to the 4 corners of the Blue loop to store even more spare engines and hide them with tunnels.

- The Orange track lets you run another engine on the inside loop.

- The Orange tracks also let you switch cars around on the Green tracks while a train is running on the outside loop.

- The Green tracks that loop around the center let you service a factory, though the spur is only long enough for maybe 1 car and the engine. It could also be used for engine storage by adding another switch to 1 of the curves.

- a train going clockwise on the Orange track would service the lower spurs by backing in.

- a train running counterclockwise on the Orange track would service the upper spurs.

Attachments

Oh, and here are the parts lists for the O-89 version and the O-72 version. You can see all switches are Ross and all tracks are GarGraves stainless with wood ties. I honestly don't know which tracks is better, but I do know the lengths of some are different, so if you want Ross, changes will need to be made. The layout won't change, but tracks aren't a straight swap.

Attachments

Got it, this looks great, what kinda switches would be needed to add spurs off the blue loop or would it create problems with trains running across those switches? I imagine your thinking the curve section going into each corner of the table for that blue spurs. For the green spur for the factory area where you thinking adding a curve type switch to the curve? The top of the layout the upper most spur could it be extended to the left as well have it going to the right like we did on another layout you did or is it limitied by type of switch?

Overall this looks really nice. Now its just down to parts/type of track. Ross track? Gargraves stainless/tinplated? If you send me the scarm file i can open it too. How did you get the nice look in scarm that shows the blocks instead of just track lines? Its definitely an adjustment i think thats why i went with anyrail as scarm is really advanced lol

Admittedly I just tried an O-72 switch with the straight going out. But, you're right, going through the curve all the time might cause problems. I tried the O-72/O-96, but that has the same problem and because the curves are close doesn't really add enough space to store something large. I'm not sure the O-72 switch does either depending on how long your engines are.

Here are some different ways of adding spurs to the center Green tracks. You don't need to do both. I don't know if you plan to landscape and add accessories, just note how little empty space there is if you do all of this.

I didn't realize you installed SCARM, so here's the file.

Attachments

Got it at least i can delete or take all on this i really appreciate your help, if i ever bust through the wall which would be at the top of the layout perhaps on the very left side since that's where the portal would be maybe that would be an option for a curve switch or a way into the next room. I am not worried about that right now though thats like an after thought. I could also experiment with a second level in this room to get more going if i can get some type of shelving to go up above this benchwork which would be a totally separate layout wont be connected

If you ever go through the wall, the current left side can become a passing siding or storage and then standard O-72 switches would be fine.

If you need any help with SCARM don’t hesitate to ask.

Did you have an opinion on tin plated vs stainless gargraves and same on ross track what was your opinion ? By the way you must have alot of time outside of your railroad to help folks like me but its much appreciated, i dont know what i would have ended up with if it wasn't for everyone on this forum so much thanks to all.

I see on what you mean on the left side that would be cool.

My scarm looks like this instead of the nice easy to see sections you have, is that a setting?

Attachments

I could be wrong, but I believe GG stainless with wood ties is what most seem to use, possibly based on price, I don’t know.

As for time, I’m retired, this stuff doesn’t take me long after years of using SCARM and I don’t have a layout at the moment. I’ve had temporary layouts, but a number of factors have kept me from building a permanent one. I may get to it next year, but it’ll only be a display layout for our collection of Bedford Falls buildings, etc. I don’t have the space for anything more than a 4x8x11 L-shaped layout. I always wanted to use ScaleTrax, I have 10 pieces of Flex, but nixed that idea when I had to downsize and the lack of availability. Atlas would be my choice because it’s quiet and looks nice, but I’m actually thinking of going old school with Menards track to support them for supporting the hobby.

@davehall83 posted:My scarm looks like this instead of the nice easy to see sections you have, is that a setting?

Yes, Tools/Settings/2D View. Uncheck all but Outlines and Separators.

Attachments

Many find it difficult to solder track power feeder wires to stainless steel rails. Tin plated rails are much easier to solder. Here's a link to more info on this:

Good point Steve, that’s why I said I don’t really know. 🤣 I should have also mentioned that GG and Ross libraries don’t have the same curves. They both happen to have O-42 and O-72, but they’re different lengths, so they aren’t a 1 for 1 swap. I have seen more lately who have chosen Ross track, presumably so everything looks the same. I once visited a layout in Texas that used virtually every brand and it was all weathered, so it wasn’t that noticeable.

Ross and Atlas use 22.5 degree curve sections, or 16 sections per circle. GG uses 30 degree sections, or 12 sections per circle. GG 054 and smaller use 45 degree sections. If you buy curve sections from Ross or Atlas they will all be uniform, GG will vary. Many people need the uniformity and buy Ross or Atlas. Still others use GG flex track and bend whatever curves they need. This is also pretty cost effective.

Atlas O is nickel/silver with plastic ties so it can be used outdoors. I would think stainless steel GG is for outdoors as well but not with wood ties.

I have about 150' of Atlas and close to the same amount of GG tin plate flex track down with another 200' left to go. Cost and availability led me away from Atlas. Atlas, Ross, and GG all mate up well together.

Yeah i guess i shouldn’t complain about my space then , seems like we all have wants and ambitions but need a warehouse size building to get it but this will keep me busy for a while for sure. I have also heard of some folks who prefer the solid atlas tracks because the rails aren’t hollow there just so many choices but your choice for supporting menards that’s definitely honorable for sure i hope you get a layout you well deserve especially since you design everyone else’s but your own but i can see it being fun when you know the software and have done it so much

Yeah i see what you mean on the track. Thing is people praise the solid rails on atlas over hollow rails on others. But then people love the looks of the ross and more uniformity and all and some like the wood look of gargraves. But the stainless i was wondering if it’s better for keeping rails clean and tidy but there is the soldering thing that was brought up but i plan to run the pigtails that gargraves made on pins but i hear a solder is more durable and less problematic which i can agree. But stainless may add durability or better looks it’s slot of choices and they are all nice looking tracks

Dave, I have designed no less than 10 layouts for myself, but something has always come up before the build starts. Then we decide something else is a priority, so the available space and location change. I’m not a railroader, so I just want to watch some trains go through Bedford Falls when we eventually get it set up. It’ll basically be a temporary Christmas layout that will stay up year round.

I think Atlas is the better track, but it gets pricey compared to others. The solid rail is why it’s quieter than the others, it also seems to stay clean longer. I’m originally from Wisconsin, hence my loyalty to Menards. I had planned on Atlas until the design got pared down. One thing I’ve heard about GG is there’s quite a bit of variance from track to track, like 1 rail being slightly longer than the others, so you need to take your time assembling it. Just don’t expect to lay a track, tack it in place, lay the next ones and everything will match up perfectly, dry fitting is best. Cutting the curved tracks take particular care because if they’re not cut at 90°, the straight spurs might not end up straight.

I actually lIke designing. I did programming in my former life and using SCARM takes a lot of the same skills as writing a program. A lot of modelers enjoy building more than operating trains, I enjoy designing, or at least helping when I can.

Dave, I just noticed your location. We have friends in Indian Head MD and Woodstock, not that far away, and we’ve been though your neck of the woods along the river.

Wow i know indian head very well i grew up in waldorf, md over 28 years living there and indian head is a frequent visit when i lived there. Woodstock isn't too far away either. Do you come this way often? I see your in IL. The river is definitely the nice part , i live close to the river which is nice just not too close to be in a flood zone lol, kayaks are definitely fun not to mention the mountains are really nice and trains as well. By the way how do i get the print and digital subscriber/support on my banner i paid for digital and print o gauge railroading magazine but it didn't update my profile.

@davehall83 posted:...By the way how do i get the print and digital subscriber/support on my banner i paid for digital and print o gauge railroading magazine but it didn't update my profile.

Sometimes it takes a day or so for your subscription to be updated so that your profile has the Digital Subscriber tag added along with the ability to view the included OGR videos. I'm sure it will get sorted soon, but since this is a holiday, maybe by this Monday at the latest. If this isn't resolved by then, you could contact Alan @OGR CEO-PUBLISHER

I think it is all good track each with their good and not so good points. Atlas may be a little quieter, but I also think some of that is perceived because what I do hear is lower in frequency because of the solid rails. That's what I hear in my smallish room. What one might hear in a large club layout may be different. Road bed makes a big difference also.

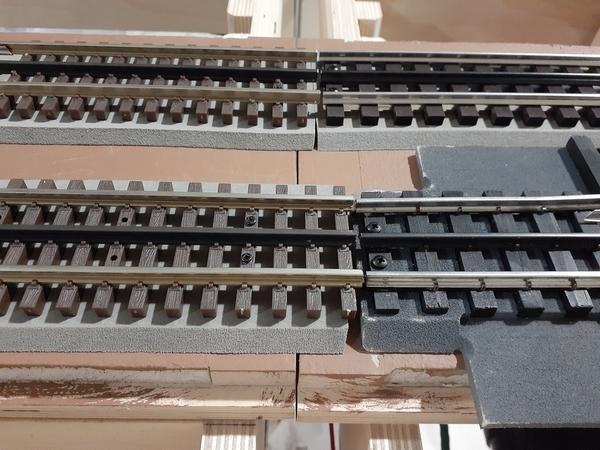

This is GG tin plate flex on the left, Atlas O on the right, coming off of a Ross switch.

Attachments

Thanks for that i just have to decide now what i want stainless or not the soldering thing is a good point i just dont know what advanatage stainless has. I also have to consider ross track too because turnouts are black plastic and wood phantom track is not but i like the wood phantom track too lol.

Thanks for the help there, i sent him a note because it was created on december 27th i think the issue is i didn't use the forum link to purchase the digital archives/supporting member. I went directly to the o gauge rr magazine website and bought it there, i got an account id and all that but it never updated my account here probably a mix up unless that is different than the subscription offered here and if it is, i will gladly pay the $12 to support this forum, this is quite frankly one of the best forums i have ever been on there are lots of good people here and its very encouraging.

Not sure where you saw IL, I’m in Peoria AZ (Phoenix). My first visit to Indian Head was in 1993 when I retired from the Air Force. My friend, Arlo Bowie, also grew up in Waldorf and La Plata. Our next visit was in 2009 when I retired from the post office. We’ve probably visited half a dozen times since and I’ve been to DC 10 or so times. My friend passed away in June 2020, so we’re going to try to visit his wife again in 2022, but that’s subject to how worried she is about covid.

Dan, that’s a good shot showing the differences.

Sorry i meant AZ, if your ever in the neighborhood let me know we can always talk trains lol. I am also very sorry for your loss and hopefully your friend is doing ok despite the covid and all the craziness in the world right now. I just wish it would go away to tell you the truth so we can all go back to normal lives.

Air Force is my favorite every time i think of them i think of all the air shows and blue angels i used to watch when i was a kid it was neat and still is.

I was going to ask maybe i already did but what should i lay cork under the track? If so whats a good brand of cork theres so much out there. I know midwest had one that gargraves sells as theirs.

What kinda road bed do you have in the picture there it looks good! All these tracks seem to have a good point to them and they all look good, can i just have them all lol.

My story here so everyone knows my dad when i was growing up setup my very first train table when i was about 6 in the 1988 era and we ran HO scale. He used a 4x8 plywood with some legs on it and green grass covering that they sell at hobby shops and away we went. We had just the basic dog bone circle and maybe 2 switches it was atlas track and we nailed it down with finishing nails and had some RR crossings and buildings but i always loved playing with the switches on the switching part of it and also loved RR crossings, the lights and all that and i always wanted to do more and i would get out those big atlas catalogs from the hobby shop and just dream of the bigger layouts and more switches. I never did get to expand on it. I visited my grandfathers home town about 2 years ago in Altoona, PA horse shoe curve and visiting the horse shoe curve was the best thing i ever did it sparked my model railroading memories and then i started collecting items from shows like the greenberg train show and other shows that are in MD. Ever since i have been a fanatic. I really love the bigger engines on O gauge and i love the HO scenery so its always been a hard choice between which one but i fell in love with these toy trains and everything i have seen at the shows so i just had to build my own layout and here i am

looks like i finally got my badges all good now digital subscriber + supporting member, love it!

Would you mind doing a version 2 of the most recent layout with using ross track and switches and i guess gargraves flex where needed to create custom sections, i am having a heck of a time trying to cut the flex in any rail (i know you use scarm) without getting errors that my radius is too small or it just doesnt look right see screen shot. I am recreating the drawing in any rail just so i can try it out on this software since i know it. It looks like in scarm you ended up cutting one of the gargraves o-72's to fit that inner circle section to get it straight. At least thats what i think you did. I didn't know you could cut the regular track, if you can maybe i can cut the gargraves O-72.

Attachments

Happy New Year!

The road bed is Ross under the switches. All the rest is Flexxbed from Hobby Innovations. Good stuff. Not necessarily cheap and a little different experience to order but I'm happy with it.

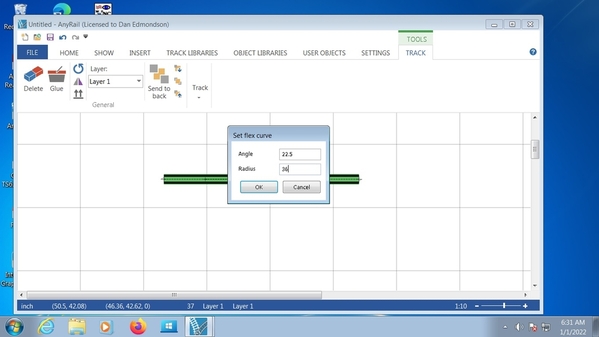

I don't know SCARM but I can help with AnyRail. Here is how I make curves with flex track. I'm using GG but this works with atlas flex in AnyRail also.

Highlight and right click on a piece of flex track. Select "Curve flex".

You'll get a window for entering the angle and radius of the curve you want. I'm using 22.5 degrees and radius of 36".

This will create a curved piece already sized to length.

Cutting is just as easy. Put your cursor where you want to make the cut and right click for the menu. Select "Cut flex here".

Now you have two pieces of track at the length and radius you want.

Attachments

Dave, I can convert the design to Ross track, but I didn’t use any flex track. While it’s easy to use flex in software, I think you’ll find it difficult to bend and align flex in reality, especially short pieces like the one in your photo. You have to take special care to align the joints to avoid kinks and that’s a lot easier with longer pieces. It’s also easier to bend to O-72 than it is to O-42. O scale flex is not at all like HO scale flex, I’ve played with ScaleTrax flex (arguably the easiest to bend) and used flex on one of my HO layouts in the past

At any rate, I followed Dan’s AnyRail instructions to bend flex to 22.5°/36” and how to cut it, but that didn’t show how to fill a gap with flex. I don’t know if AnyRail lets you measure the gap and use that in place of 36” to get a perfectly sized 22.5° flex curve. I assume you cut sectional track the same way. In SCARM, you add a flex track to one end of the gap, then move the cursor to the other end and right-click. The hard part is maintaining the O-72 or O-42 curve when installing real flex track on the layout. And, yes, I see the “kink” in your example and that’s the problem when laying actual track.

.

Dave, if the piece is flex you can disconnect it, grab the end with the cursor and drag it where you need to. If you pull it longer than an unmodified flex length it will turn red to warn you.

All of my straight Atlas track is flex but I don't recommend it for bending curves because it is very difficult to bend even with large radii. It will constantly try to return to straight. I struggled to get a 5 degree bend with a radius close to 088. Note also that even with this small bend it was necessary to trim the rails even on one end. That's just how it works making curves with any flex track.

Most all of my curves are close to 080 and 088. I made a plywood curve template to match the radius at the inside edge of the ties. This made bending the curves much easier and avoids kinking even across joints. The GG flex is 37" so it is not too difficult to get 30 degree pieces and cut down on a few joints. People have reported bending flex around the bottom of small trash cans. No matter how you bend flex it will always need to be trimmed even. That's pretty easy with a dremel but there are many ways to do it.

I believe this is why GG sectional pieces are not uniform, they are bent in a similar manner. Most GG users are used to laying a piece, trimming it, laying the next. . .

There is also the choice to use sectional track in curves as they can also be cut to whatever you need.

I don't think AnyRail will cut sectional track.

Wing it

I did my outside loops including my elevated up and downs,

All the rest has been changed many times and evolved over the years,it was part of what I enjoyed.

Sitting up there and dreaming of what I would do next.

Yes please can you convert to ross track for me so i can see that version. I did what others said and that’s how i ended up putting flex in the design but your right and i rather not have to try and bend flex track. It looked like on the gargraves version you used regular sectional curves and cut them which anyrail won’t let you do it only allows it on flex track. But i much rather if your able to take sectional track and cut it, do that instead of dealing with flex. i just didn’t know you could do that, but in the drawing world scarm is the only one i found out that will let you cut sectional track so i used flex track as a “filler” to make the software happy but i made notes to just buy the sectional track pieces and cut them.

I much rather stick with ross sectional track 100% that’s my preference and not use any flex track if i can help it just less headaches as me i much rather cut a sectional piece of i had to choose a piece o had to cut.

One piece that’s not even in any rails track library is the O42X i saw you used which i didn’t even know existed and i couldn’t find it on Ross website but that sure makes things easier if he has transitions like that.

I guess this is telling me i need to learn scarm and use it and don’t look back lol.

One question had and it looks like ross track is all tinplated steel is that the same tinplated as gargraves tinplate or is it a bit different material ?

I believe ross switches are also tinplate steel or are they all steel?

I was assuming at first the ross track was more of a plastic wood tie because of the black color but their web site says they use real wood ties. I was like well if i had to buy for say a bumper or just a piece of gargraves track does the phantom wood or phantom plastic match the ross better?

Also i do have a bunch of gargraves track pins, their #4 screws, pigtail wires that go between the track pins and all that mess do you think that will work with ross track? I see ross track when you buy it you can ask for sectional wires to be added to each piece for $4.95 but is that the same thing it’s just a pin that slides in one of the rails with a pigtail that hangs down?

I wonder what ross wants you to do to secure their track to a permanent layout like is it the same as gargraves where you drill a 1/8 hole in the wood tie and use an #4 pan head screw

The other part is i would definitely like to use ross bed because it looks easier to lay than regular cork with the track grooves in there.

Happy New year to everyone here!

Thats exactly what i did in anyrail which works fine with flex but i can’t cut sectional track like scarm. I wish they wills add some things scarm could do because any rail is easy to use but most folks like scarm i noticed so i may be having to switch to that if i need to cut sectional curves and straights. I got a dermal 4400 for christmas as well as gyro wheels for gargraves that should do it for cutting and also got the dremel reinforced wheels as well

@turkey_hollow_rr posted:I believe this is why GG sectional pieces are not uniform, they are bent in a similar manner. Most GG users are used to laying a piece, trimming it, laying the next. . .

There is also the choice to use sectional track in curves as they can also be cut to whatever you need.

I don't think AnyRail will cut sectional track.

That is what the folks at GarGraves told me. Trouble is folks tend to think they can just lay GG tracks and things will match the software, they’re used to FasTrack just snapping together.

I played around with your instructions and figured out what Dave was doing wrong. All he needed to do with his short piece of flex is select it, then right-click and select the “Smooth flex” option. And you’re right, I also don’t see an option to cut sectional track, so gaps need to be filled with flex.

BTW, is there any way to change the dimensions from cm to inches? I didn’t see one.

EDIT: I found it.

You can still do the design in scarm i’m fine with that. I was just trying it out last night and i did do the smooth flex option but i still had a very nasty curve joint lol. I rather use 100% ross and cut sectionals trust me i see what your saying i bought a few pieces of flex to see how it worked and i said to myself you know if i can get away cutting sectional track that would be ideal lol

Its under the settings area i believe in measurements you can change from cm to in

Dave, I found the cm to inches setting.

I also retried the smooth flex option and saw what you meant. I think the difference is I lined things up using an O-42 curve, so the flex was replacing a section of O42 curve and it came out smooth. I offset the switch a tiny bit and got the same result you did.

I also don’t see the O42x in the AnyRail library, but both SCARM and RR-Track list is separately. I don’t see it or the O42p on the Ross order sheet. Maybe they come with the O-42 switch like the makeup curves for some FasTrack switches. FWIW, the O42 switch design serves a dual purpose. Adding the O42x gives you a complete O-42 curve while adding the O42p gives you a parallel spur. That’s not the case with the other switches.

I have no idea about the pigtails, type of track or how to secure them.

If you’re comfortable with AnyRail, I wouldn’t switch just because of the O42x. I would check with Steve to see if it’s actually sold separator cones with the switch.

Attachments

ok got it. The Other reason to switch is the scarm can cut sections which we needed for this. Would you be willing to draw up ross sectional track in scarm ?

I’m starting the conversion now.

davehall83, I think you would be very happy with Ross sectional track. Many consider Ross switches as the best you can buy. Those other 042 pieces don't exist but you can cut them from 042 curves as you lay the track. Those are 45 degrees so you should be able to get two pieces to do what DoubleDAZ designed. In software you can fill these in with flex if you really need to.

Yes, use the #4 screws. You can buy them from Ross or from McMaster-Carr.

I don't have any experience with the Ross wire drops. For Ross and GG I flip the piece over and solder wires directly to the rails. One drop covers 12 feet or more of track. I solder directly to the Atlas track clips, much like the ones they sell, because it is difficult to solder to solid rails without melting the plastic ties.

Dan, they had them 4 years ago, but if you're sure they don't have them now, I'll inform Milen and get the SCARM library changed, or at least have him check with Steve to confirm.

I see i thought maybe the O45X was a piece that they sold but now that makes sense just cut it but i have a question out to steve at ross to see if they come in the O42 turnouts like doubledaz suggested they possibly may come as a package thing to help complete that curve.

Its nice that it covers at least 12 feet of track but if i wanted to be really careful to ensure no voltage drops maybe every 6 feet or is that over kill?

When you solder the wires are you doing it on the side of the rails at the bottom of the rail? Thats my worry too is i got a good weller and it has plenty of tips just wasn't sure if i risk melting the track ties.

Does anyone have a suggested transformer to use i have a CW-80 and a GW-180 (but may sell the GW-180). I was thinking a ZW-L at some point or the MTH equivalent i just want something nice and that has plenty of power to push multiple locos especially if i isolate track.

Dave, assuming Dan is correct, I went ahead and cut replacements for the O42x and O42p tracks. I left the originals in (clear tracks), just moved them out of the way. One thing to note is that the track center rails are about 3" from the edges, so you need to check the clearance needed for the engines you plan to run. The design can be shrunk 8", the length of the Orange straight track on the left side. If it needs to be shrunk, the spurs will have to be shortened a bit.

Attachments

Thanks again for doing this so track center rails are about 3" from the edges, your saying the orange line on the right side is the 3" issue? Do you think i will have issues with a big boy or something like that running? I think if i am looking at this right the potential 3" issue track is the right side where they go over the opening? What made the center of the rails different i guess thats something new for me to understand ![]() Just want to make sure i do this as trouble free as possible

Just want to make sure i do this as trouble free as possible

Even if Ross doesn't offer it as a package with the s 042 switch I wouldn't be surprised if he cut a curve sectional to what you want if you asked him.

Sure 6 - 8 feet between drops is fairly common. Voltage drops are going to be determined more by distance from the transformer and wire size.

I use a Weller, around 675 degrees with a 3/32 wide tip. I tin the wire and bottom of a rail, then solder the wire to the rail. This helps cut down on the time the heat is applied. Other than getting in between them, the wooden ties shouldn't be a problem. I don't use flux but I do scuff the rail a tiny bit with the dremel, especially the center rail.

Once steve gets back to me if the answer is no on the O45X and P's then i will ask if he minds cutting me some save me some time lol. I am running 14 gauge copper wire for all my power drops. I do home runs to a break out panel that has the + and - Side with screw terminals. Then it has a bus bar connection for the + and - off the transformer.

I wanted to use 14 gauge to alleviate any issues with voltage drops and have a good solid connection and i totally believe in solder. I have this weller kit i just purchased just for my train hobby and i always need a good solder gun when i want one i never seem to have one so i got a good one.

Weller WE1010EDU Soldering Education Kit, Multicolor, 8-piece kit

https://www.amazon.com/gp/prod...00?ie=UTF8&psc=1

What percentage or type of solder is good for this 60/40?

Got a response from steve on that O42X and P this is what he said basically its cut my own.

No its easily cut to any length with the dremel

You add the P to any section of track and we will solder the clips to it

I asked him about cutting one for me and this his statement

Probably cant cut it to the exact length you want. Your drawing you will find is an approximation and everything most likely will not fit without some adjustments

@davehall83 posted:Thanks again for doing this so track center rails are about 3" from the edges, your saying the orange line on the right side is the 3" issue? Do you think i will have issues with a big boy or something like that running? I think if i am looking at this right the potential 3" issue track is the right side where they go over the opening? What made the center of the rails different i guess thats something new for me to understand

Just want to make sure i do this as trouble free as possible

No, I'm saying the short Orange track (red circle) on the left between the 2 switches is only 8" long, so you can only shrink the layout that much. I took 8" out of all 4 sides and the photo on the right shows those changes. I'm not suggesting you do that, I'm just saying that the maximum because once the 2 switches join, you can cut any more.

The little Yellow box at the top of the photo on the left is 3" deep showing the distance from the center track to the wall. We tend to measure from center track to center track when discussing track separation. Dan mentioned the spacing for the 11° and #4 switches as being 3.5" and 4.5" respectively. The 3" I'm talking about is not exactly the same because it's to a wall, not to another track, so it's actually equivalent to 4" or so. The general rules of thumb is 3.5" separate in yards and 4.5" on mainlines. However, when curves are involved that may need to increase because of the overhang of the cowcatcher and the midsection of long cars, like passenger cars. Unfortunately, there is no standard for cowcatchers and the amount of overhang depends on the curve, the tighter the curve, the more overhang. It also depends on the specific engine because there is more that one version of a Big Boy. The only way to know is to lay some tracks and place the engine on them to measure the maximum overhang through the curve. If you know the specific engine, someone might be able to tell you how much there is with O-72 curves. Some modelers play it safe and use a separation of 6" or more because they don't know what equipment they'll buy in the future.

Attachments

Got it that makes sense so the good thing is i have 2 to 4 inches from the edge of the blue line to the wall so the table isn’t exactly but up against the wall so that will help with that. Thanks again now i think i’m ready to start building and buying track lol! now the fun begins but this will evolve slowly as i’m sure there probably is at least $2500 in track between switches , road bed and sectional track but the good thing is i can do the outer circle first get those switches in place then keep going and test as i go

@davehall83 posted:Got a response from steve on that O42X and P this is what he said basically its cut my own.

No its easily cut to any length with the dremel

You add the P to any section of track and we will solder the clips to it

I asked him about cutting one for me and this his statement

Probably cant cut it to the exact length you want. Your drawing you will find is an approximation and everything most likely will not fit without some adjustments

He probably didn't understand that the only reason it's an approximation in the drawing is because he no longer offers those tracks, so we substituted cut tracks. He may not have the dimensions he used when he did offer them, but they were both standard pieces at the time. SCARM says they're 4.76"/11.73" respectively while RR-Track says 4.62"/11.38", maybe they're both using different rails for the measurement. He's right though that you have to cut carefully or the tracks connected to it will not be straight.

Here's an example. for the design. The lower cut is correct and the connected track is straight. The upper cut is off by just a bit even though it looked right, but you can see the connected track is not straight. Now, if you lay that switch, then the cut track and subsequent straights, they are not going to connect where they need to. That's why it's important to lay sectional track and dry fit things before cutting, especially curves.

Attachments

Yeah i get that for sure now, thanks for pointing that out. I was just thinking how easy it could be to throw off an entire circle or layout just by once piece not being cut right so laying it out and pushing the sectional together maybe the best bet then cut the pieces last, the other thing is im sure this is common but when i did it on fast track its always that last piece that completes a circle that i have to bend twist and curse at to get it to go together and sometimes i get worried im going to bend it too much or put too much force im going to break it or get it out of alignment i like to do things carefully and right so i guess im in for the learning curve on this but the dremel with the gyro cutoff wheel will be my friend on the O42's, i have learned so much just on this forum alone its amazing like the fact that i can cut sectional track and put pins in it to connect it was something i didn't know i could do that changes everything. I thought you could only do that with flex but now i know its done made a world of a difference and it would be much easier IMO to cut something thats already curved to the radius i need

FWIW, I found that it was far easier to achieve the results I was looking for by using flex track for much of my track.

As for uniformity between Gargraves & Ross, I personally don't think there's so much difference that I need to sweat it.

Ross switch on the left, Gargraves FLEX on the right. Both are tin plated rails with wooden ties. Some of my Gargraves has ties much closer to the Ross shade, other pieces are lighter like this one. This is older track, probably why it's lighter.

Attachments

Thanks for putting that up there for me to see that, thats exactly what i needed to see and realize. I am definately going all Ross on this layout but if i ever had to use some ross flex at least i know how close they look as far as color and all that and after doing some ballasting and things im sure it just blends in. I have read some of your other threads on gaps like that with the track, i used to be real worried about any gaps but realized after reading things on here as to why the pin stops are there and why its good to have a small little gap for thermal expansion/moisture differences in the winter/summer that it needs room to expand and contract. Also you get that neat clickity clack i believe as well which thats something i want to hear. After doubledaz and turkey_hollow_rr and other folks on here did some comparisons on track and noticing the differences they all seem to have something unique and cool about one over another but the good thing is between the brands cant go wrong and even atlas i have considered but settled on ross as my final decision since from the postings and what i have seen atlas switches are hard to get especially with supply chain shortages im sure. But i know for sure i will be happy with this and if it wasn't for all that have contributed to this forum i wouldn't have made some expensive mistakes. Its one thing to make a mistake and learn from it and correct it, but another when you put out hundreds of dollars on things and have to trash it all and buy it all again thats what i dont want to do because then i look at it as well i could have used that money to buy a nice locomotive, more track , scenary, a building or something lol. But i know sometimes you will have mistakes that cost but if i can avoid them awesome. My goal is here to learn from everyone, i am learning scarm and anyrail at the same time but i think im going to convert to scarm the biggest thing is for cutting straight sections thats a big deal for me now and also i notice alot of folks prefer it and i like it too just a bit harder to use. Once i learn and become efficient at this , my contribution is to also help someone else just like me in these forums where i was at today so others can enjoy this hobby so right now i may be taking help but at some point i will be offering help as well so this forum can continue to thrive and get more people involved into model railroading. I also want to see younger people getting involved more too because i think that the "computer age" while it has helped us alot, it also is taking away from the hey lets get out a board game or family time or run some trains and build together as a family so your involved with others and not isolated to a phone or ipad. I am trying to push this concept in my home now so my kids can learn to appreciate this hobby and others. I think its healthy to take a step back from the digital age and do things like this. I want the generational hand down to keep going with this hobby so that it just doesn't get put on a back burner for an ipad or computer theres just so many things to appreciate about this hobby.

Here's a better shot of some the newer Gargraves and the end of a Ross switch. The colors are a bit closer. The gaps you see here are because that line between the sections is a power lift bridge, to that track on the right comes up over two feet to allow me to walk under to the inside of the layout.

Truthfully, unless you're really looking for it, a couple feet away you usually don't even notice the color variations.

Attachments

Ah you just peaked my interest here with that power lift bridge, so i have a use case right now on my layout where i have a fold down piano hinge piece of plywood with a latch on the right side of my layout which allows me into the space. I plan to have straight track across there but i have the issue where i need to figure out how to have a drop down piece of track that goes back into place once the plywood is latched back into its normal position. I have been doing research and looking at all the different ideas but the one thing that stumbles me is ok how far away or how close to but the tracks together on each side so i can let the plywood drop down and go back into place without breaking anything and not having too much of a gap that it derails something. Its also on my big outside loop and inside loop which means theres no way around it unless i decide to make it a fixed plywood door or something and just duck under

Well i just purchased scarm so now i have both anyrail and scarm to play with, i actually am starting to like scarm more i mean i like it all but at least i have choices now to use to model things im going to play around with it and i see alot of youtube video tutorials out there on how to do things im going to start watching some videos and training myself on this so i know it more. One thing i been wondering if your doing any elevations in scarm and you get the 2.5% grades and all that like we looked at before, not that i am going to do that for this layout but i just wondering how do you take the elevations from the scarm drawing you do IE translate it from paper to the benchwork? Thats one thing i think i should learn at some point is how to take whats on paper for elevations and make them. Like where to start, how tall of a piece of plywood/board do i need and how much bigger does each board need to be as it elevates etc to achieve the grade that its suppose to be and all that stuff

Also i noticed my paypal said that its milen is the owner of scarm its amazing you even know that person to influence scarm updates/changes thats actually kinda cool!

My benchwork started out as Mianne benchwork and then it was "embellished". This is the Mianne power Lift-Bridge, it's the largest size they offered, 4 feet wide by 4 feet deep.

This is my whole layout build thread, if you need something to put you to sleep. ![]()

New Train Room Finally Getting A Layout!

Attachments

Milen actually beta tested the early versions of his software by giving it away on this and other foras. He still maintains a thread on this forum to announce product updates and new features. For what you are building, you probably could have used the current free version (limited to 100 pieces of track), but I'm always happy to see a model railroad vendor get rewarded for his work.

You mentioned that there is some room between your table edge and surrounding wall. While that may eliminate any scraping or gouging caused by larger engines, it raises another issue to consider. If one of your big engines derails at a point where there is too little table space to "catch" it, it will go to the floor and may be severely damaged. Such a fall will not be covered by your homeowner's insurance, so leave a good 4 or 5 inches of space outside your outer most loop in an effort to minimize the likelihood of such an accident. The other alternative is to attach a raised lip, probably about 2 or 3 inches up, all around your table to protect your equipment from such a fall.

Chuck

The trick to a flip up is to have the hinge above the rail, obviously, a flip down needs the hinge below. I shoot for the width of a saw blade for track cuts along seams.

I believe John has a Mianne lift. I built a DIY version.

I also overlap the table a bit, hopefully scenery will help hide the seams some more. If you look close here, these are different cuts of Atlas "placed" next to GG flex on the top route and atlas next to another Ross switch.

Attachments

Wow yeah so i wanted mianne benchwork as my first choice but the guy never responded to me or was very sporadic he wouldn’t return calls and then he would reply to emails then when i got him on the phone he would say yeah i’ll have it to you tomorrow my bench work plan but every few days i called i got the same story i think he’s overwhelmed with work but his product is solid and i wanted his benchwork but since he never replied o ended up with sievers which it’s very good as well maybe i can find that power lift section on his website to order

Dave, there are all kinds of techniques for building grades. You’ve used the trestle sets, but they’re designed for grades around 5%. Woodland Scenics sells readymade 2%, 3% and 4% foam Incline Kits than can be shimmed for other grades. Google “cookie cutter benchwork” and you’ll get examples of all kinds of methods used.

Thanks for the tip, so far with the layout the track total in materials is around $2525 which is about where i thought it would be thats just estimating the track only on ross's website and i will probably order some extra pieces in case i make a mistake, break one all that good stuff. I will check out the cookie cutter stuff see what i can find, now that i have seen scarm and purchased it i am having fun with it, i actually prefer it over anyrail i been playing around with it and see why scarm is preferred and it does things anyrail just doesn't do

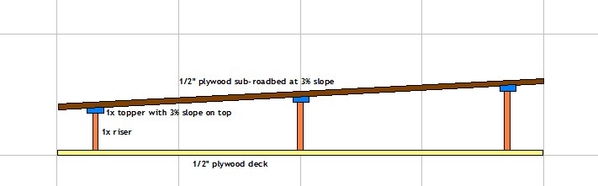

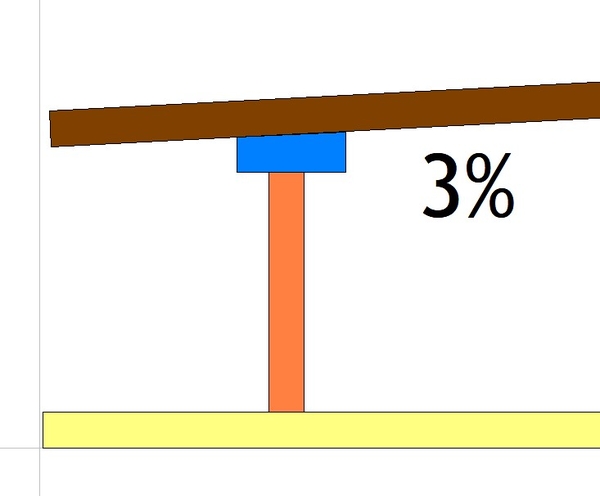

Risers are probably the only thing I really lean on software to help with. Find a few strategic points along the way and cut as close as I can to the heights in AnyRail given from the slopes. The tops of the risers are cut at about 1.5 degrees.

Attachments

Dave,

Dan's photo is an excellent example. It shows both tabletop decking and open framing with cookie cutter sub-roadbed on risers. He has attached his risers to the top of the framing using pocket holes and some of the riser are notched at the bottom with part sitting on the decking and part on the framing. You already have a full tabletop, so your risers would sit on the tabletop just like the trestle set supports you had with the FasTrack. Instead of the track sitting directly on the supports though, you'd add sub-roadbed like Dan's and the risers would support that. I don't show it, but on top of the plywood sub-roadbed would be whatever roadbed you choose (cork, foam, Ross, etc.) and then the track.

Here's a closeup the support. Note the 3% angle on the topper.

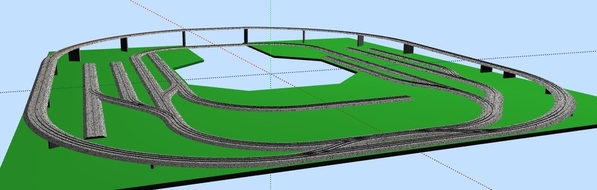

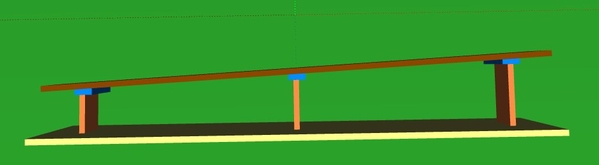

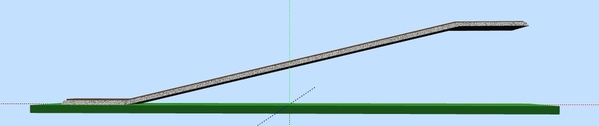

3D view.

Here are the heights at the track joints. They can be used to guesstimate how many risers you need and where to place them. Since folks tend to build framing with 16" centers, placing risers every 16" or so seems reasonable, but that depends on the thickness of the sub-roadbed and the weight of the engines you plan to run. One thing to think about is the easements going into and coming out of the rise. You don't want to immediately go from 0" to a 3% rise with your first support. Here, too, the length and degree of easement depends on the engines you run and how far out the cowcatcher sticks. If you rise or drop too quickly, the cowcatcher will hit the rails.

Just a 3D view with a 3" rise over the entry. A 3" rise gives you a 3.1% grade.

Attachments

Dave DoubleDAZ I should have explained that the little 1/2" pieces on some of the risers were added when I decide to make the upper level 10" instead of 9". I added 1/2 on some risers and extended the transition to level on the upper level to get the additional inch. Not that the risers can't be built that way.

One thing to keep in mind when going from software to reality with grades is that in software all of the measurements are relative to the top of the rail. That is the zero reference and it is really 1 7/16" higher than the framing in my case. (Plywood, homasote, roadbed and track.) You just have to remember when you go up X inches there is some structure below that, but the height dimension in software will still give the proper cuts. If the software said that point in the curve needs to be at 7", that's what I cut the riser to. If there is plywood and homasote on the framing below that point I have to compensate for that to keep the reference correct. This case is a little easier since all of the surface is in place. You just need to account for roadbed and track. I don't see any overhead crossings in Dave's design but if there ever are it is really important to understand this so you have enough overhead clearance.

Dan, got it. That explains why it looks like there's a notch in some of the risers. Good points about the clearance. In this case, there are no overpasses, but I did put together a version where I swapped the Blue and Orange tracks on the right side to create 2 overpasses. Since Dave already has a full tabletop and rigid foam sheets come in 1" and 2" thickness, I raised the whole layout 4", then added a 3.5" downgrade to the Orange loop and a 3.5" upgrade to the Blue loop, a total of 7". Those result in grades of 3.7%, not ideal, but doable with modern engines.

Attachments

Dave, you're probably going to ask for it ![]() , so here's the file with the grades. The deck is on a separate layer, so turn that off/on in the Layers box to edit the tracks, otherwise you won't be able to see the tracks.

, so here's the file with the grades. The deck is on a separate layer, so turn that off/on in the Layers box to edit the tracks, otherwise you won't be able to see the tracks.

Attachments

@DoubleDAZ Nice update to the track plan.

I understood Dave to want to run large engines so he needed 072 for at least one loop. Right now it looks to me like he has no place to park an engine and cars. His room should have space for a narrow dead end "shelf" which could come off the upper track to the right of the entry keyhole - which I think is a solid wall.

All - regarding the risers - I've taken this approach on my layout and even went to the extent that I precut my risers with the slope on one end and flat on the other. I only did this because I did not know any better and I already had a plywood deck in place. This worked fine for the install, but as time went on I needed to make changes and the (cheap) 1/2 ply I used warped in places. (Supports were 12 to 16 on center and it still warped screwed down.) This made making adjustments really hard, one because I had already installed hardscape and two I had no access from below. When I do this again, I would use Wescott's method of attaching risers to the bench work and not a plywood deck. But given what Dave is trying to do, the approach suggested will work fine, provided he puts in enough large holes (hand sized) in the deck for wiring of track, switches and other goodies. Cutting holes in my underlying plywood deck has created nothing but headaches as the vibration causes all kinds of things to loosen and move around. Adding switches or signals later is not fun.

As far as the transitions to a new grade, I found cutting a section of plywood long enough to to start the transition and get into the grade was critical for smooth operation. (Wescott uses the cookie-cutter term for this.) The plywood is going to have to bend into an "s" shape - which it will not want to do. However for our purposes that is a good thing.

So don't use cheap plywood. All of my framing, lift table, and legs are made of 3/4 and 1/2 arctic birch plywood.

Attachments

Okay Jeff, you have gotten my curiosity up. How are you going to bend plywood into an S curve?

Enjoy reading this discussion. We are all Ross and use RRTrax which has been accurate to within 1/4” and is usually dead-on. As someone suggested earlier, after measuring carefully and going thru the gyrations, we found that dry fitting and winging it works pretty good. As you gain experience, it gets fairly easy.

Ross doesn’t make flex track. Steve sell Gargraves, track screws, cork, etc and has been great to work with. We are on level 2 and have installed 40+ Ross turnouts. If you are going to have a large number, you might want to do the soldering yourself if you are good at soldering and save the $$$.

Good luck.

@ScoutingDad posted:@DoubleDAZ Nice update to the track plan.

I understood Dave to want to run large engines so he needed 072 for at least one loop. Right now it looks to me like he has no place to park an engine and cars. His room should have space for a narrow dead end "shelf" which could come off the upper track to the right of the entry keyhole - which I think is a solid wall.

Dad, if you look back a couple of days (post #34?), you'll see I posted a photo with a switch in the upper right corner going to the right. I couldn't tell from the photos that have been posted what was to the right of the layout, so I ended the spur at the end of the table.

However, there are problems with adding a switch to any of the corners. Dave doesn't like the idea of running large engines through the curved part of switches, and I agree with him as a general rule. However, I'm not sure how big a deal that is with O-72 switches at reasonable speeds.

In any event, Dave then he goes on the suggest a future expansion into the room on the left which would require switches in the corners. I'm not exactly sure what he has in mind, so I drew up a plan with a loop of O-72 tracks going into that room as well as a spur onto a shelf in the upper right, assuming I understood what you're suggesting. He also suggests he may want to elevate sections of Blue loop on the right and I've posted suggestions for how to do that.

So, assuming he doesn't want to add the shelf to the upper right, my "idea" for parking large engines is to park them on the Red tracks. Both are 50" in length and should hold at least 1 engine each allowing 3 large engines to remain on the layout. Rolling stock and smaller engines would be stored on the Green tracks. When he wants to run a smaller engine around the outside, the Blue track on the left would become a passing siding. He'd move the large engines to the passing siding and run the smaller engine around the Blue/Red/Orange loop. I realize that's not ideal, but little is when trying to cram so much with special requirements into a relatively small space.

Bear in mind, these are just my thoughts on how to make things work. I don't advocate any particular way to do things.

Attachments

@DoubleDAZ @Bill Webb I love this forum - great comments and thoughts.

Bill - the second article I started to write addressed this. However since that is not going to happen, Westcott's book on page 10 has 2 photos on how this happens/works. (no photos - copyright) Plywood is resistant to sharp bending so for our purposes this works to our advantage. If we were going up the lower section is firmly secured to a base. Then we start bending an upwards curve, then we insert a support and then bend the plywood back down. This forms an "s". This is the only place where cheap 1/2 plywood works, since it bends easier. BUT - if bent too much, the transitions will be too steep and the bigger engines will not be happy. Think about when you cut a plywood sheet on sawhorses - the unsupported section will bend by itself. I'll have to measure mine, but I think I was getting about a 1/2 inch rise over 24 inches ( roughly 2% ). I do not think you can get that degree of bend out of a 3/4 sheet, especially baltic birch type. Of course that is a good thing if you are trying to run scale wheel sets.