First - its been great seeing all the work being done, the trains run, the building details added ... WOW

One of the things about starting with a blank canvas is there are so many options. They just get reduced as we go along. I finally decided to go ahead and build out the incline section thinking I can always change it later. I'll post photos later, not much to see from the previous posts.

My total run from upper section to lower section is about 399 inches and encompasses nearly 3/4 of the way around the outer edge of the layout. That was me wanting a large passenger station and freight yard on a lower level.

In order to make sure the grade was consistent across the distance, I measured distances and heights off the floor at key sections. Since I am building this in sections, each corner is a section and the straights connecting them are sections. In the long straight runs, the 1/2 ply is supported at the edges with 1x2 pine strips for rigidity. That means I only need to support at the ends ... no sag in the middle. Sections are screwed together at the sub-road bed to limit movement relative to each other. Remove the screws and the sections come apart.

After that, it was to the spreadsheet to model the slopes. For the most part I tried to keep changes to the 1/4 inch. Happy to report I was able to have a 2% grade (roughly)

| HIGH | | | | | | | LOW |

| SEGMENT Length | 0 | 80 | 63 | 50 | 83 | 55 | 52 | 16 |

| TOTAL Length | 0 | 80 | 143 | 193 | 276 | 331 | 383 | 399 |

| Height | 40.5 | 39 | 37.75 | 36.75 | 35 | 33.8 | 32.75 | 32.75 |

| Increment Height | | 1.5 | 1.25 | 1 | 1.75 | 1.2 | 1.05 | 0 |

| Grade SEG | | 1.88% | 1.98% | 2.00% | 2.11% | 2.18% | 2.02% | 0.00% |

| Grade Run | | 1.88% | 1.92% | 1.94% | 1.99% | 2.02% | 2.02% | 1.94% |

I also wanted to see if the grades were fairly consistent. A scatter plot shows a pretty consistent slope, although you can see that from the table data.

The graph below shows the initial build - note the change in slope in section 3. The end section is a short level section which holds 2 switches where I wanted a flat lead to avoid operating problems. It was just a matter of playing with the elevation at each section to obtain the slopes. Once the slopes were as I wanted, I went back to the layout and raised or lowered the sections as needed.

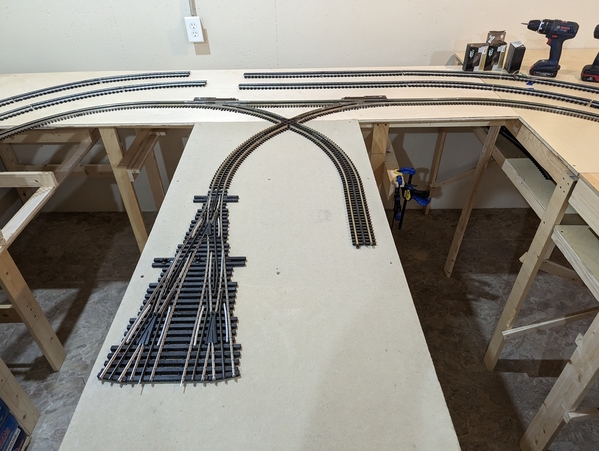

Now its lay down some track and see if a car will coast down the grade into the yard.