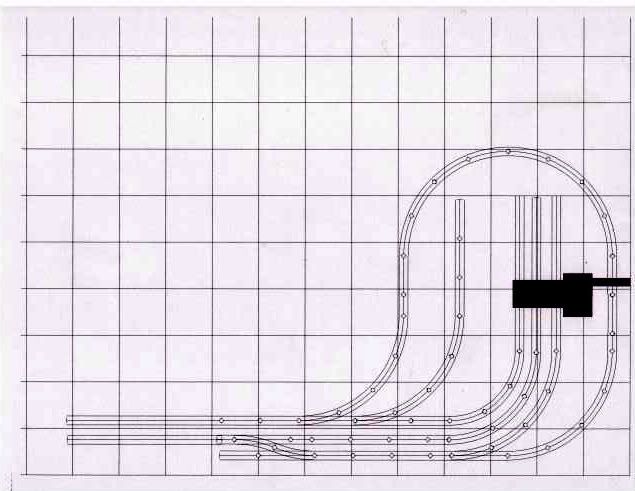

Follow the thread to see the track plan variations and grade/elevation options for this plan:

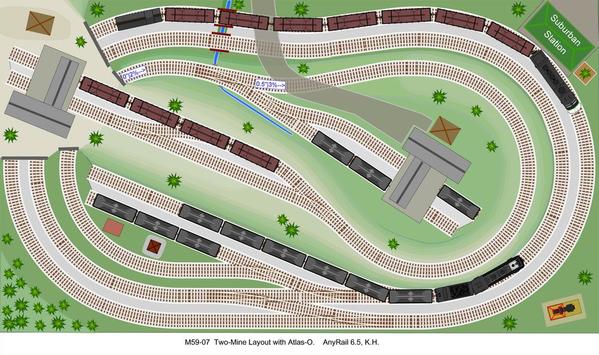

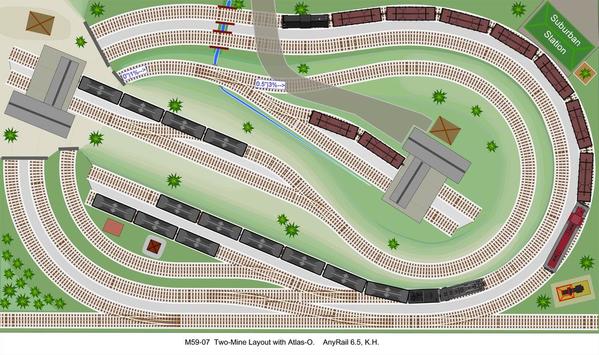

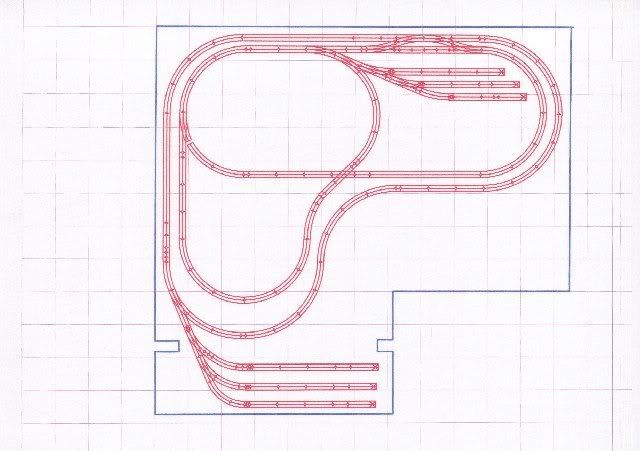

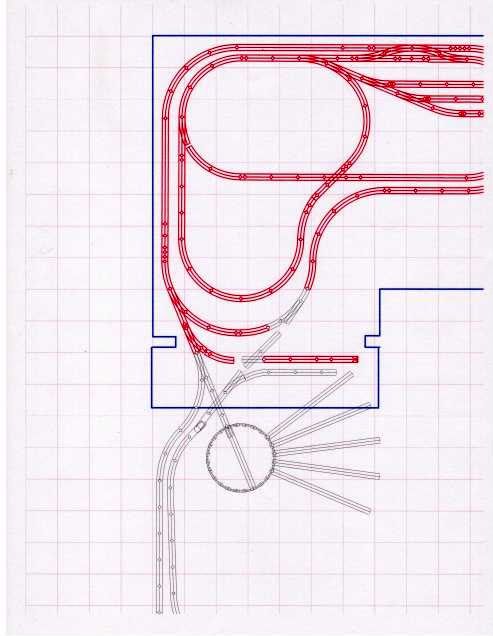

This is a 5' X 9' layout plan with two mines, using Atlas-O track. The outer mainline loop is O-54 minimum, with O-72 easements, which will accommodate larger equipment. The inner mainline loop is O-45 minimum with O-63 easements. The two mains are connected with a nice #5 crossover. All other turnouts are O-54.

The run up to the mines is O-36 with some easements. The line runs through the tunnels, and as it exits the tunnel, starts a 2% grade, climbing through the turnout serving the first mine at 1/2" elevation. The run continues at 3% up to the mountain-top mine, which is at 5" in elevation (or higher). [See the grade option discussion in subsequent posts]

This is based on an HO plan from Model Railroader, which has appeared in their magazine twice with variations, each time as a 4' X 8'. Compared to that plan, this O gauge layout plan has two mainline loops as compared to one for the HO plan; which allows servicing and switching the mines while a second train runs the outer loop.