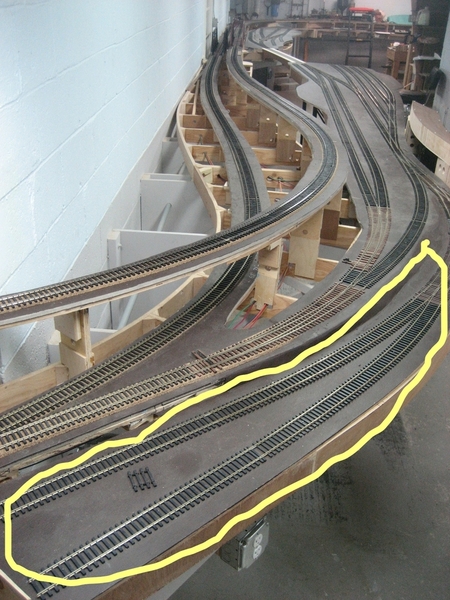

There was this tight situation that my original build did not accommodate very well. I had intended for one siding but had this turnout I wanted to use but alas, when added it was too crowded. So I bumped out the initial benchwork as shown below:

Area Too crowded

Area Too crowdedBasic supports added

Initial foot print

Feather finish the seam

Blend in with sander

Base coat

Finally have the space for the nicely detailed Morrison's Doors factory. I attached an extended bottom ledger board as a floor for two cans of expanding spray foam. Note the positive bumper posts. 1" of Toyota vacuum hose with small square drive trim screws. it's 42" to rock bottom otherwise. They grab the rear most wheel set on each side of the coupler. I needed 85 bumpers a.s.a.p. so these are only a "temporary" fix, riiight.

Here is the foam after basic profiling. There is a rumor that scenery may start any year now, but running the RR takes precedent.

Since switching a portion of the locos to battery R/C a lot of layout work ground to a halt.