Had to rewire some Lionel original uncoupler/unloader switches. You know, the ones with the flat 4 conductor rubber cord that always cracks. As I was doing that I thought why not, so here is the results. The picture of the shows a new wiring system. Basically, the heavy black wire goes to center rail track power, the heavy red lead then goes to transformer accessory power. The black wire to no 1 screw on the track, no 2 green, no 3 red, and no 4 white. This will give you full accessory power for the track and provide another power tap for the center rail, which we all know you can't have too many of. The next picture is replacing the original Lionel with a dpdt center off momentary switch, which gives you the advantage over the original Lionel version that you can short out the transformer if you push both buttons at the same time, plus takes a lot less control panel space. The px is of a full sized switch but a mini switch also works fine. The color coding is the same. Does anyone know where I can get a reasonably priced software for doing simple wiring diagrams, I am not really very good at that.

Replies sorted oldest to newest

I have been fiddling with a program called Tiny Cad. It is free and not too bad after you get used to it. I don't quite get all the symbols though. If you find a better one please post and I will do the same.

Some folks use Paint and some use Power Point. Paint and I don't play well together and I have just recently tried Power Point and don't know how to use it. Going to give PP some more time though, it was also recommended by another forum member.

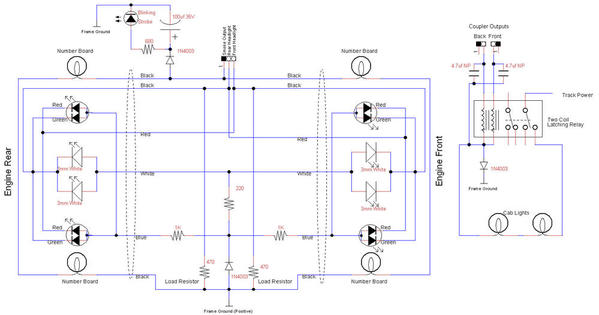

I use TinyCAD as well, here's an example of something done with it. This is a wiring schematic for a BEEP I upgraded.

Attachments

Thanks so much, I have got to get some track cleaned now, but will try this later today, once I get it right I will post the schematic for the switch.

thanks, I already downloaded the program, I was fascinated by Gunrunners lighting scheme. Puts a lot more action in the engine. Quite ingenious. Like it a lot. I was working on an led scheme for the O22 switches, but reached a stumbling block as to how to fill the big holes in the remote control. Benzes are not available at a reasonable price anymore.

Yeah, I understand, re not energizing the magnet. I did think about that, and concluded that the cars are going to be parked anyway on the track, so what difference does it make? I have some weird switches that I bet you would like to have for that project, they are center off, momentary one way, and fixed the other. Let me know if you can use some like that.

thanks, I already downloaded the program, I was fascinated by Gunrunners lighting scheme. Puts a lot more action in the engine. Quite ingenious. Like it a lot. I was working on an led scheme for the O22 switches, but reached a stumbling block as to how to fill the big holes in the remote control. Benzes are not available at a reasonable price anymore.

The lanterns are available for around 75 cents last time I checked. The easiest way is to find one of the LED replacements that has the lighting to the sides and just replace the bulb.

The controllers are another matter, I guess it depends on which ones you have.

The LED in the switch is not too bad of a problem, the lantern will cover up any construction ills. The problem is how to fill the very large holes in the remote switch, that the big light bulbs stick thru. An LED as you know is less than 1/4 the size of the bulbs. I noticed a control I had from somewhere, that the factory glued a piece of black plastic over the holes and re-drilled for a smaller bezel. I am not really very neat when it comes to that kind of work. I tried to find LED mounting pieces but could not find any large enough. I am really close to this solution, but have run into this stumbling block. I even thought of black silicone, but that is kinda hokey.

I figure I could supply an external 16 volt dc (laptop style) power supply that could potentially power up to 40 switches, if we can use led's. There are lots of those on the surplus market with really odd power connectors.

I have 39 switches on my layout, and cannot believe how much juice all those little light bulbs take.

Up more your alley then mine Gunrunner, but once we get this perfected, doing the conversion for example an O22 switch over to the new style wireless programmable controllers should be a snap, due to the dc switching. I have heard from a lot of guys who feel they are being held up for ransom to change everything over, ie track transformers etc, to accommodate the new systems. As said, more your field of expertise than mine, I am having enough problems just perfecting systems for cleaning track!

It depends on what your goal for the switch controllers is how you'd approach it.

It would probably be easier to simply come up with your own replacement, it's just a toggle switch the LED's and a couple of resistors. When you get a lot of switches in a layout, the old Lionel control start to take up a lot of panel space.

Another point is many people want the toggles in a panel that represents the layout.

excellent idea, I am glad I thought of it!

Can't I take a little credit? ![]()

![]()

ok, a little bit!

Thanks for the lead to Tiny Cad. It's a great program and the price is right.

These tracks can, and should, be wired so that the magnet is not energized when Unloading is done. The magnet can overheat if the unloading car must be energized for awhile, plus it adds to voltage drop. I don't use controllers, so for dual purpose (uncouple-unload) tracks, I use a push button to uncouple and a momentary contact DPDT to unload.

When I get time, I'll make a TinyCad schematic and post it.

Do be aware that wiring differs between RCS and UCS tracks.

If this is important to you, what I would do (because I want to keep to a 4 wire cable and use the screws)I would isolate the coil from the 2 right hand control rails, eliminate the ground (outside rails) tap from pin no one, and then use pin no 1 to feed power to the coil. You will then need to add a ground lead from the transformer to the switch. This will still enable you to feed a track power connection to pin no 3.I bought some dpdt center off switches by mistake, that would be ideal for your setup. One side of the switch is momentary, the other non-momentary. If you like, you can have some for your layout, I don't think I would ever use them.

I really don't think we are in any danger of overheating the coils in the track for uncoupling, they seem to be pretty robust. We buy a lot of these tracks, and as of yet, I have never had one where the coil was burnt out. I have had many where the red is discolored from heat, but they still work.

Hey Gunrunner!

I also liked the tiny cad, but do you know how I can save the drawings so I can insert them into a word doc? I also would like in some cases to make the drawings a little bigger.

I'm on the Outer Banks today, and can't check the way my layout is wired, but the attached schematic, drawn from memory, should do it. Note that the switches can be replaced by an AIU, but you cannot have both AIU and switches.

[Edit: how do I get the schematic to appear in the post itself?]

Attachments

You could print the Tiny Cad drawings to a pdf file then possibly use with Word? I was thinking Word would work with PDF's but not sure? Also I was thinking you could re-size the drawings in Tiny Cad, but don't recall how? Maybe GRJ will be along with assistance, looks like he knows how to use it a bit better than I do.

Yup that will doer very nicely done, how did you save the drawing to be able to use it. Whenever I try it will only save as a bit something or other.

Tin Man, I assume your question is to me. I have Acrobat Pro installed on my computers, which enables me to print to Acrobat. So in Tiny Cad, I select Adobe Acrobat as the printer and check the box to print all on one page.

You can print to PDF, which will certainly work.

You can also do what I do. I simply use my screen capture program to create a JPG from the screen image. Since I have a 28" main monitor at 1920x1080, I get good resolution for the schematics in my JPG files. It's simple, and you can directly insert them into any word processing program, post them here, etc.

You can also export as an image file directly from TinyCAD.

Ok, I will try to figure this out. Definitely not my field of expertise.

I forgot to mention that if you want a PDF, there are a number of free PDF printing solutions, no need to buy Acrobat Pro.

CutePDF, PDF Creator and many more.

Agreed. I use Acrobat Pro for business, so I have it.

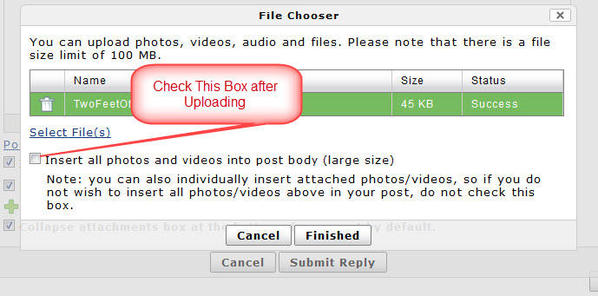

GRJ, how do you get the schematic to show in the post, rather than as an attachment?

Attachments

GRJ, ok, so you had the schematic as a photo, rather than an Acrobat file. The box you show only relates to video and pix.

Correct, you can't get a PDF to display in-line.

BullZip is another free pdf printer to add to the list. They also have one that prints to Word files and some other interesting items. However, not sure this print to Word would work with Tiny Cad? Might just be for text files, but I have never tried it.

I'll endorse BullZip - it's great.

Lots of choices. ![]()

yup, I was really blown away!

Having trouble with a brand new fastrack remote operating track. My postwar milkcar works fine on a tubular track remote operating track, but when I use the same car on the fastrack the solenoid operates backwards. Instead of the solenoid shifting to push the milkman and cans out it wants to pull him in. Please advise how correct or how to trouble shoot

Sounds odd. The solenoid is AC, and when powered only goes one way. Or it should. Have you opened the car and checked the linkage?

RJR posted:Sounds odd. The solenoid is AC, and when powered only goes one way. Or it should. Have you opened the car and checked the linkage?

Yes I have opened the car up that's how I know it's operating backwards compared to the tubular track remote operating track, so wires on the car are correct. The fastrack controller and/ or track wiring is suspect. I don't what to look far. Please advice on troubleshooting procedure.

There is, or should be, a spring on the solenoid. Is it there? If yes, and you push the armature against the spring. observe how the mechanism works.

I suggest leaving the body off, and trying it on both types of tracks, and observing what happens differently.

The spring is there. On the tubular operating track the milk car works like is should. The same milk car on the fastrack operating track operates backwards the milkman pull back into the car. I'm claiming faulty wiring in the track and/or controller. It doesn't which way the car is facing. My electrical knowledge is very weak when it come to troubleshooting. The uncoupling button works fine i.e. press it and couplers open. So I'm getting power and ground through the shoes on the trucks. There's got to be a way to test with a multimeter either countinuty or a with a power source?

Please advise

Doesn't make sense. Fascinating issue. What part of VA are you in?

Like RJR, I’m a little baffled by your problem. In theory it makes no difference what power is applied to the solenoid. The coil becomes a magnet pulling the core in. In order for the core to be pushed away from the coil, the core would need to be a magnet in which case opposite poles would repel. I have couple of milk cars and they work with tubular track as well as FT.

Can you take and post videos of the operation, with body off?

I suppose there could be a poor connection somewhere and solenoid doesn't move completely.

This train was not wired by me. The train fine, but I'm finding continuity between all three rails on the fastrack loop. This is not right. On the tubular track loop everything is correct the two outer rails are connected with the center power isolated. I believe this why the milk car works fine. Could it be possible that on the fastrack be be wired backwards where the two outside rails are my power and the center is my ground? Motors, light bulbs, and switches don't care which way the power flows as long as the circuit is completed? My next step is test the uncoupler/operating track by taking it off the table and connecting a terminal track and separate transformer to see what my results are and see if my theory is correct by correctly and then reversing the leads.

Mike, I don’t know what your layout looks like but, it is difficult to test continuity on a layout. There are many things that would show as continuity such as the power supply, switches (lights) and any locomotive or rolling stock with a center rail pickup roller. By all means, remove the operating track to a test bench to see if you can replicate the issue. Next take the tubular operating track and repeat the test.

I think RJR and I are having difficulty seeing this as an electrical problem. AC current does not have polarity in the same way as DC and the mechanism is ridiculously simple. I can’t speak for RJR, but inclined towards a mechanical issue. That why I am suggesting that you test the milk car on both the FT operating track and the tubular track. Also a little video of the mechanism would be really helpful.