Hi, All. As I introduced myself in the electrical forum, I’m a life time 3 Railer, long time forum lurker, and recently joined the board.

I’ve had Lionel layouts since I was 7 and actually have my first 027 train set yet. My last layout was a 25’x15’ basement layout back in 2006 – a double mainline with a branch line and a small yard on each end to do some switching when I wasn’t loop running. The layout was focused on the branch line, “Valley Junction,” which is a fictional town somewhere in central-ish PA. The mainline that passes thru is of course the PRR. Thus “VJ&P”, which also happens to be my initials. The PRR double mainline were the outer most loops. I could switch cars from the mainline to the VJ branch line and deliver them to the local industries. There were 2 smaller loops in Valley Junction so I could let 4 engines in total run amuck on their own. The entire layout was conventional engines with old school blocks.

I had laid the track and got thru most of the power wiring and started with some signals and accessories but as life would have it, I had to stop and tear everything down. I moved from PA to NC at that time. I kept everything in storage for years but never had the time or space to get back into it. I sold most of it except for a few pieces.

Fast forward to a couple of months ago, and 2 things happened: My wife surprised me on our anniversary with a Pennsy Flyer LionChief set and we made the decision to build a new home. I don’t think she realized what she unleashed when she got me the Pennsy Flyer :-D I realized how much I missed it. And since we made the decision to build, we’re adding a bonus room above the garage specifically for a new iteration of the VJ&P. Stairs will come up in the middle of the room so the layout can run around the perimeter, most likely with one or 2 peninsulas. We’ll build in lighting, ventilation, and a few other things to tailor it specifically for a model RR.

But I’m getting ahead of myself. I won’t start designing the new layout until we lock in the plans with the architect so I know the room size and shape. It will definitely be a new version of the VJ&P with focus on Valley Junction and Pennsy passing through.

In the present, I’m working on finalizing a small layout. The goal is specifically to start learning about Lionel Legacy and all the cool new technology for the hobby that has come around in the past 10 – 15 years. I’m not concerned about prototypical operations or scenery. I’m starting out with a couple of “boring” loops and sidings so I can figure out how all the new tech works with the intent of applying everything I learn to the future 35’x25’ layout in the next year or 2.

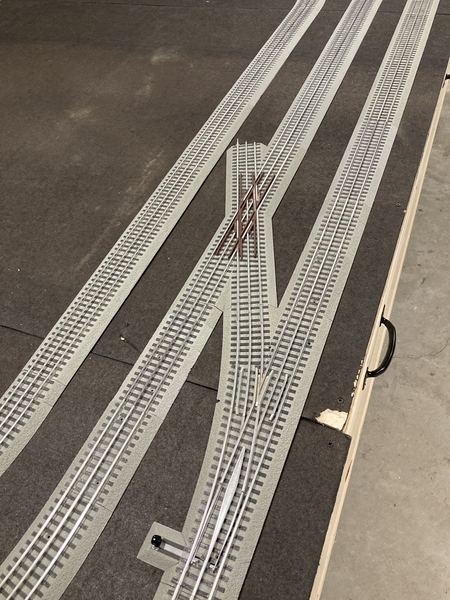

That said, I’ve attached what I’ve been working on. I’m new to SCARM, and Fastrack, so please excuse the rookie mistakes and gaps in the design. Since the new layout will be a few years away, I wanted the 072 outer loop so I can purchase a big engine or two and begin to build my collection again. I originally had 048 curves for the inner loop and outer loop passing siding, but @SteveH is a bit of an instigator ![]() and made me rethink what I was doing. In the same space, I can use 060 curves which will allow me to run engines with a min 054 requirement. I added a reverse loop and a few sidings. I have a couple conventional control engines but decided to added an elevated loop to run them. The double loop layout will be all Legacy control.

and made me rethink what I was doing. In the same space, I can use 060 curves which will allow me to run engines with a min 054 requirement. I added a reverse loop and a few sidings. I have a couple conventional control engines but decided to added an elevated loop to run them. The double loop layout will be all Legacy control.

Again, this layout is a learning exercise for setting up and getting familiar with all the new tech. The track plan itself isn’t the priority but I wanted to be able to run a couple engines and have some on table storage. I’ve started a discussion about the wiring and power set up in the electrical forum but wanted to introduce myself and share what I’m working on as far as the track plan goes.

Any feedback on the layout or tips for using SCARM are welcome.

One initial question about Lionel Fastrack... I understand it doesn’t have as much “give” as the old tubular track which you could fudge and shift stretches of it to put everything together. How unyielding is Fastrack? In my plans, I have lots of the tiny connector sections and also areas where I couldn’t quite get SCARM to connect pieces. In the real world, will I be able to pull the gaps close or do I really need to have the exact combination of pieces?

Thanks in advance for the input and discussion. And thanks to all of you who have been posting in my other thread. Looking forward to getting to know everyone.

- Vin