Well folks, into the vat again. The front stack on the BB stopped smoking with no fan air and no heat and I got the 4 blink sequence in the cab light. Up to that time, both stacks were smoking bellows along with the whistle after Mike's overhaul. Got about 20 minutes of run time.

So, I bit the bullet and took the boiler off and snapped the following pics. I disassembled the dual smoke unit and you can see the innards.

Learned the following: The left side of the board and left fan and left heating element is designated smoke 1 on the board and is for the rear stack. The right side of the board and right fan and right heating element is designated smoke 2 on the board and is for the front stack.

Noticed the following:

Both funnels feeding the heating elements were charred a bunch.

The heating element for the front stack was more black than the one for the rear stack.

The thyristor for the heating element for the front stack was 1/4 inch from its heating element.

The thyristor for the heating element for the rear stack was 1/8 inch from its heating element.

The wick for the left side for the rear stack looked burnt - don't know if that is normal.

The wick for the right side for the front stack looked more burnt.

The black reservoir containing the wick was bubbled out on both sides due to over heating.

So, now for questions:

What component failed - fans, heating elements, thyristors, entire board. How does one check each component? Any help would be appreciated.

Replies sorted oldest to newest

one thing I noticed is not enough smoke fluid, which caused the wicking to burn.

bigdodgetrain posted:one thing I noticed is not enough smoke fluid, which caused the wicking to burn.

Thanks BDG, I have fallen into my nemesis - that being starving the units. Smoke was bellowing out of both stacks before the front one stopped; so, now I am thinking that volume of smoke is not the only indicator; time is the other factor. After 10 minutes of running, I should have added more fluid. BUT the gotcha is if you add too much, you mess up the fans and any other circuit boards around.

Have been searching for topics on the forum regarding what I called the thyristor - don't know if that is the right name for the component next to the heating element. A spec was mentioned in the forum for how close it had to be to the heating element. I think I saw somewhere where Jon (retired) of Lionel mentioned it.

The thermistor should be vertical off the board parallel to the smoke unit. That seems to produce good results for my VL-BB. When I had very poor blowdown smoke, I checked that smoke unit and the whistle smoke unit. The whistle had it parallel with the smoke resistor, the blowdown had it leaning in right next to the resistor. I adjusted it to be like the whistle, problem solved.

Thanks GRJ, as a first step to find out why the smoke unit has failed, is there a way that I can test the fans when they are still connected to the board?

You need to disconnect the fans from ANY electronics, then you can try powering them with a 1.5v battery. Any smoke fan that's good should spin on 1.5 volts. I believe the smoke motors for the VL-BB don't have plugs, so that complicates it a bit, you have to take the leads off the motor, note where the red one goes before you do. ![]()

Another question, when putting new Lionel wick 691SMKP008 in each compartment, how many ropes after shredding per compartment?

gunrunnerjohn posted:You need to disconnect the fans from ANY electronics, then you can try powering them with a 1.5v battery. Any smoke fan that's good should spin on 1.5 volts. I believe the smoke motors for the VL-BB don't have plugs, so that complicates it a bit, you have to take the leads off the motor, note where the red one goes before you do.

Thanks GRJ, per the pictures below, do I still have to disconnect the leads:

Attachments

If you have it out like this, you still have to disconnect one lead to make sure you don't cook the circuit that normally runs the fan motors. As long as the PCB is totally isolated otherwise, you can leave one lead on the PCB.

There has got to be a reason for Lionel wick premature burning other than not enough fluid. Looking at the pictures posted I think we can see the reason. Looking at the smoke unit housing the cut out for air flow would make me think that the impeller needs to spin CCW to allow more air passing through the cutout over the resistor. Too me, looking at the impeller the way it’s mounted, it would need CW rotation for air to be pushed away from the impeller allowing maximum air flow. If I’m correct on the CW rotation the air would hit the casting in the opposite direction needed and not allowing the air to fully excape in to the resistor area causing overheating.

RickM46 posted:Another question, when putting new Lionel wick 691SMKP008 in each compartment, how many ropes after shredding per compartment?

Any ideas?

One rope per compartment should do it.

Just found some comments in my Lionel notes by Jon Zahornacky regarding the placement of the thermistor to the heating resistor; found them somewhere in the forum (have been looking for them again for hours but no luck) and put the comments in my notes:

Jon Zahornacky, aka SanaFeFan (smoke unit engineer for Lionel, retired) said that the smoke units were engineered for the factory block of wick to work with the heat resistor, a thermistor located 1.6mm from the heating resistor and with the wick block a certain distance and density to the heating resistor. You cannot buy the factory block of wick. So, it is critical that you locate the replacement wick and its density and thickness and depth as close as possible to the original factory block and not block the fan air holes.

1.6mm converts to 0.0629921 inches which converts to 1.009/16ths.

Correction to the description to Jon's career: Jon was more than a smoke unit engineer; he was a great engineer and inventor and held many patents for his work; happy retirement Jon!!

RickM46 posted:RickM46 posted:Another question, when putting new Lionel wick 691SMKP008 in each compartment, how many ropes after shredding per compartment?

Any ideas?

Thanks Rod!! Am waiting for comments on your fan rotation above.

romiller49 posted:There has got to be a reason for Lionel wick premature burning other than not enough fluid. Looking at the pictures posted I think we can see the reason. Looking at the smoke unit housing the cut out for air flow would make me think that the impeller needs to spin CCW to allow more air passing through the cutout over the resistor. Too me, looking at the impeller the way it’s mounted, it would need CW rotation for air to be pushed away from the impeller allowing maximum air flow. If I’m correct on the CW rotation the air would hit the casting in the opposite direction needed and not allowing the air to fully excape in to the resistor area causing overheating.

I see the point you are making and I noticed the same thing in another VL engine, the Baldwin Centipede, which has four single smoke units. In those units, however, the fan motor was wired so that the impeller would spin CCW so as to propel air directly into the cut out leading to the resistor.

However, I'm not sure that this would account for the sort of heat damage caused here, which is not minor. Also it would be a design defect, meaning that it would have appeared in other VLBBs and (a) I have not seen any reports of that and (b) it has not happened in mine. Going back to the OP's original post, everything (fan, heater) failed, which might indicate a main board failure.

As this engine was serviced by Mike R. I'd email him to ask what he thinks. I would not discount lack of smoke fluid as a cause of overheating as in my experience these units use up fluid very quickly. Mike R. also referred to this in the instruction video made in connection with the issue of engine, which I took as a kind of warning to keep them topped up.

In the pictures above if the impeller spins CCW the air is being pushed via the concave portion of the impellers. The air needs to be pushed via the convex portion of the impeller. I checked this against an MTH unit and they engineered the air to be pushed via the convex portion. There is no way to get this with the Lionel unit as is. You may try pulling the impeller out and turning it over so as to push air on the convex side of the impeller. I’m not trying to discredit the Lionel engineer that designed his smoke unit but I think it is a flaw.

Gentlemen, thanks for all the help on the smoke unit. I am now thinking about what components I can check to determine which one is at fault. I can test the fans but would like any advice on how to check the resistors and thermistors.

The Smoke Elements should read about 8 ohms. You can measure them right on the PCB since you have it disconnected from the loco. The fans should spin at 1.5v. They can take up to about 6v without damage. I usually put ~3v using a couple of AA cells to check them out.

The damage to the smoke funnel looks like things got very hot. The batting looks charred, but in reality it is not charred, it is the fluid that burned and produced the burnt residue on the batting. This is a common misconception that the batting burns, the matted batting in this loco does not burn or char. It is the burning of the fluid (it is a lamp oil) that produces the residue. Using the newer "string like" batting does melt however, and the reason it smokes more is the temperature is hotter with the less dense material.

Having designed the electronics system in this loco, I believe the reason your loco failed is the thermistor could not sense the temperature created by the element due to the residue. The temperature path for the element to the thermistor is through the fluid dampened batting. When the batting is not saturated, the temperature rises on the element, but the air between the thermistor and the element is a poor conductor of the heat, relative to a saturated batting material. Low fluid level will cause this condition to happen, and then the element will overheat. The smoke unit can handle this for the most part, but repeated power cycles with low fluid levels will cause the damage you have. Again, I am guessing a bit here, it may be you just have a failed RCMC smoke circuit...

You may have damaged the RCMC, but the only way to know is to repack the smoke unit and try it. If the element is ~8 ohms, then you should not get a 4 blink. It is possible the thermistor failed, it should read about 50k ohms cold, you can measure it with a meter as well. If the thermistor fails, you will also get a blink code.

I also suggest Lionel premium smoke fluid, as it is non-conductive. Unless you get the RCMC fully saturated with Lionel premium fluid, RCMC should not be damaged. Just wipe it off best you can.

Hope you get your loco back running!

Jon,

Thanks as always for your detailed explanation and insights. Is the original "block" style batting material available anywhere for purchase? I think Lionel no longer sells it and switched over to the angel-hair or I believe you referred to it as "string-like" batting. Thanks.

Glad retirement hasn't taken you off the Forum, but do hope you're enjoying it (and your trains).

Dave

Jon, thanks a million for your explanations above. They certainly bring to light your engineering technology and thought that went into the smoke unit and even the rest of the design of the components of the VL Big Boy. At this point, in my use of the stack smoke units, I think I am the 500 pound gorilla that kicks around Samsonite luggage in that commercial totally ignorant of what it took to create that marvel. I have always been too conservative in feeding my smoke units fearful of overflowing and ruining circuitry and then drowning others - the aforementioned gorilla.

I am only using Lionel smoke fluid now and glad to know it will not harm circuitry.

Also, this needs to be said, due to my mistreatment of smoke production, Mike R. rebuilt all the smoke units in my engine and replaced the RCMC located way rearward of the stacks (I drowned that by overfilling blow down way back). His repairs were first rate; he did them so that you can't even tell the original fixtures were touched and still look like factory; very neat and precise. But, enter the aforementioned gorilla again.

However, I have noticed that the whistle unit shows no charring and the resistor looks clean - yet another clue.

I have no electrical/mechanical skills and would not know how to use a meter; but, really want to get the BB stacks going again - only the forward stack failed; the rear one was still functioning. To that end, I have ordered all available components from Lionel parts for the dual stack smoke unit including reservoir, both fan motors and fan blades, divider, wicking, and the complete board with funnel, resistors, thermistors. I do not plan to assemble it myself; am hoping for the skills of someone on the forum - anyone care to help?

Two questions: You mentioned that the new RCMC located way rearward may have been damaged due to the front stack failure; didn't know that could be a result? In some previous threads, you mentioned that the thermistor should be located 1.6 mm from the resistor, is that true for the stacks?

Thanks immensely for your help!

BTW, the RCMC was never under the main stacks. It's always been in the middle of the boiler under the cover with all the switches.

As for repacking these things, I need to do that to mine as well as it has never smoked well at all. So the thermistor needs to be down in the wicking as does the resistor so that it does what it suppose to do? That's good to know as I would have probably moved it closer to the PCBA.

Sinclair, as you know, I have been knee deep into my VL BB since April. With each step, I have learned a bunch. Now, as this goes on, with smoke units: wick must be wet enough and firmly packed enough to allow the thermistor and resistor to work using the wet wick between them as a means of temp sensing; the distance between the thermistor and resistor is critical; smoke fluid used must not obstruct the latter; char must not obstruct the latter; the thermistor and resistor must rest enough onto the wick but not covered by the wick (resistance felt against the wick when mounting the board) ; lastly, density of the smoke plume AND run time is critical.

Per Jon's advice, I put a True RMS meter on the components of the smoke unit board and got the following results:

Smoke 1 - left side of smoke unit - rear stack - still working: Resistor has 8.5 ohms, thermistor 49.6k ohms.

Smoke 2 - right side of smoke unit - front stack - not working: Resistor has 12.8 to 13.5 ohms, thermistor 50.5k ohms.

Don't know what the readings mean.

RickM46 posted:Per Jon's advice, I put a True RMS meter on the components of the smoke unit board and got the following results:

Smoke 1 - left side of smoke unit - rear stack - still working: Resistor has 8.5 ohms, thermistor 49.6k ohms.

Smoke 2 - right side of smoke unit - front stack - not working: Resistor has 12.8 to 13.5 ohms, thermistor 50.5k ohms.

Don't know what the readings mean.

The Smoke2 resistor is not in spec. and why it flashes an error code.

RickM46 posted:Sinclair, as you know, I have been knee deep into my VL BB since April. With each step, I have learned a bunch. Now, as this goes on, with smoke units: wick must be wet enough and firmly packed enough to allow the thermistor and resistor to work using the wet wick between them as a means of temp sensing; the distance between the thermistor and resistor is critical; smoke fluid used must not obstruct the latter; char must not obstruct the latter; the thermistor and resistor must rest enough onto the wick but not covered by the wick (resistance felt against the wick when mounting the board) ; lastly, density of the smoke plume AND run time is critical.

Absolutely correct!!!

Thanks a million Jon; with all your help, now we will know how to diagnose the components. I take it that my RCMC board may still be shaky but only way to know is to fix the smoke unit????

Last question: Does your spec of 1.6mm space between the thermistor and resistor still hold for the stacks?

Thanks for your patience.

Hello Rick; "tuned" my VL BB smoke smoke units (blowdown/whistle/main smoke) about two weeks ago with the strand wicking. Left the gap between thermistor and element as I found it; about 3/32" to 1/8". Checked elements and fan motors; all good; elements had brown residue and cleaned each VERY carefully with denatured alcohol and toothbrush. Really was generous on the Lionel premium smoke fluid in soaking the wicking (40 drops?) before assembling. The best tip as per Jon Z is to simply ensure the element and thermistor use the wet wicking as a "pillow" to rest on and conduct heat as necessary to the thermistor. There are some great youtube videos on the VL BB smoke units: "120 drops of Lionel Premium smoke fluid" is good info. I am not a newbie to this as I have a lot of scar tissue on these "tune ups"; you have some great info above. Wish you well; you will do fine; Falcon70

RickM46 posted:Last question: Does your spec of 1.6mm space between the thermistor and resistor still hold for the stacks?

Thanks for your patience.

The spacing is not that critical, I usually recommend the element and thermistor leads are 90 degrees to the PCB mounting surface. I really never measured the distance the PCB mounting holes are in the correct spacing for the sensing.

Jon, thanks a bunch for your help; you have certainly put us in the right direction for maintaining our smoke units. In my own experience with my board, the thermistors when perpendicular and parallel and at the same height to the heating elements have a gap of 1/16 inches exactly. When installing the board for them to meet the wick, be careful not to bend them out of alignment.

Now for the wait for the new parts to arrive. Many thanks to the gents on the forum for participating in solutions!

FWIW, that's what I did with mine when I had an issue with the blowdown. The thermistor was bent up really close to the resistor, and I got very little smoke. I just straightened it out like the whistle smoke, and it works great now.

I add my thanks to Jon for continuing to contribute here and in particular the explanation of the thermistor sensing function, which is news to me.

In RICKM46's position I'd hope replacing the front stack resistor would do the trick without having to replace a board but all you can do is try. But if you are getting the complete smoke unit PCB with resistors already installed it's a relatively simple job to screw that to the existing reservoir with a proper amount of smoke fluid in it and see if the front stack functions. Obviously if the existing reservoir has heat damage you'll want to replace that but again what you need to do is pretty self-evident from just looking at the way the smoke unit is assembled. Good luck!

Thanks GRJ; straight up gives a gap of 1/16 inch on my old board.

Thanks Hancock52; with the new board, I will also still have to install the fan motors into the reservoir, install the fan blades on the motors, and then solder the red and black leads to the board. Don't know if the board has holes in it for the leads. Don't know how the fan blades are fixed onto the motors. When they arrive, I will be consulting the forum on them. If all goes well with the new board, I may just order new resistors for the old board and install them - nothing like spare parts.

I will keep the forum up on my progress. Got a real charge out of using my meter for the first time and getting the ohms on the components. Also, taking the boiler off to get at the components is easy - be mindful of the wires for the lights at the front - they are short. However, there are boards that are buried - I would not attempt to replace the RCMC.

RickM46 posted:Got a real charge out of using my meter for the first time and getting the ohms on the components.

You're easily amused. ![]()

gunrunnerjohn posted:RickM46 posted:Got a real charge out of using my meter for the first time and getting the ohms on the components.

You're easily amused.

In that case, so am I! I'm never so delighted as when something I try actually works.

RickM46 posted:I would not attempt to replace the RCMC.

It's not that hard as long as you take your time and lots of photos (Hence why the top is off of mine and why I know where the RCMC is.). But then I've never been afraid to dig in.

sinclair posted:RickM46 posted:I would not attempt to replace the RCMC.

It's not that hard as long as you take your time and lots of photos (Hence why the top is off of mine and why I know where the RCMC is.). But then I've never been afraid to dig in.

I hear you. I never considered taking apart any of my locomotives - thought they were too complicated. Now, since I have gotten into the Big Boy - right into the jaws of the behemoth - I would give the others I have a shot once out of warranty. Nothing like having the guys on the forum for help. The innards of the Big Boy were masterfully constructed.

gunrunnerjohn posted:RickM46 posted:Got a real charge out of using my meter for the first time and getting the ohms on the components.

You're easily amused.

Yes, easily amused; never used my small 1987 Radioshack meter for anything other than voltage and continuity; was amazed when my new meter (True RMS) automatically switched from ohms to K ohms for the thermistor. Management of electrons has always amazed me.

RickM46 posted:gunrunnerjohn posted:RickM46 posted:Got a real charge out of using my meter for the first time and getting the ohms on the components.

You're easily amused.

Yes, easily amused; never used my small 1987 Radioshack meter for anything other than voltage and continuity; was amazed when my new meter (True RMS) automatically switched from ohms to K ohms for the thermistor. Management of electrons has always amazed me.

Just havin' fun with you Rick. ![]()

gunrunnerjohn posted:RickM46 posted:gunrunnerjohn posted:RickM46 posted:Got a real charge out of using my meter for the first time and getting the ohms on the components.

You're easily amused.

Yes, easily amused; never used my small 1987 Radioshack meter for anything other than voltage and continuity; was amazed when my new meter (True RMS) automatically switched from ohms to K ohms for the thermistor. Management of electrons has always amazed me.

Just havin' fun with you Rick.

Ha!! More fun with electrons: Just tested Smoke 2 fan with a cobbled up 1.5 volt battery that I soldered wires to. Disconnected the red lead from the old board and connected the battery - it ran fine; so good spare parts.

Ordered my parts last Tuesday; called to see if they shipped yet; they haven't due to personnel constraints at Lionel for the summer; will ship later this week; no worries; Big Boy is apart and sitting on my work bench (dining room table) looking all kinds of forlorn with its hat off; will keep the forum up on progress.

Valhalla - my parts for the smoke unit showed up yesterday; excellent response from Lionel's parts lady Katie. Now, I have a series of questions which I will post.

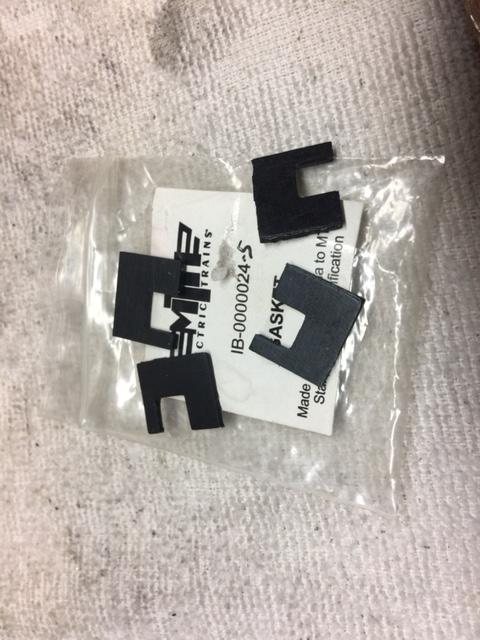

First, regarding the fan motors (see the motors in the reservoir below): each fan motor fits into the reservoir and are attached to it by 2 micro screws (DOH, I didn't order the screws); each motor has 2 terminals; one terminal is marked with a white dot. On the old motors, that white dot terminal is used for the black ground wire, the other unmarked terminal is for the red power wire. Just looking for verification from the forum.

Attachments

Look for the + and - as to the original. That may be what the white dots are for. Good luck and let us see the results.

Thanks Rod! Now I have 2 more questions regarding the fan motors:

1. How are the fan blades attached to the motor shaft? Is that just a press fit onto the shaft or are they glued on? 2. One member of the forum suggested a drop of oil into the top bearing supporting the shaft - should that be done? Thanks for any advice.

Attachments

RickM46 posted:Thanks Rod! Now I have 2 more questions regarding the fan motors:

1. How are the fan blades attached to the motor shaft? Is that just a press fit onto the shaft or are they glued on? 2. One member of the forum suggested a drop of oil into the top bearing supporting the shaft - should that be done? Thanks for any advice.

Any info on the above??

Yes, those fans are a press fit, don't glue them on! Be sure to not press them down too far and seat them on the bottom, you should have them low enough to not hit the circuit board and high enough to not scrape on the bottom. So spinning freely would be correct. As to the drop of oil, you can put the smallest drop you can do onto the shaft before you put the fan blades on if it makes you feel better, I don't usually oil my new fan motors but I don't see how that could hurt. Perhaps other member with more experience in that area could be of assistance.

Follow what Davety posted.

Thanks Dave and Romiller49!! I will just press them on as you advised; I think I will forego the glue and the oil. I am guessing that they can be removed from the motor shaft if necessary by gently prying them up thru the air channel in the reservoir.

Now, on to another question: I will have to solder red and black leads to the fan motors; I am thinking 20g or 22g wire. The board has very short red and black leads coming out of it for the fan motors (they couldn't have made them shorter) and those leads are soldered on the top side and bottom side of the board. Is splicing/soldering the leads from the fan motors to the short leads on the board the right way??

Attachments

RickM46 posted:Thanks Dave and Romiller49!! I will just press them on as you advised; I think I will forego the glue and the oil. I am guessing that they can be removed from the motor shaft if necessary by gently prying them up thru the air channel in the reservoir.

Now, on to another question: I will have to solder red and black leads to the fan motors; I am thinking 20g or 22g wire. The board has very short red and black leads coming out of it for the fan motors (they couldn't have made them shorter) and those leads are soldered on the top side and bottom side of the board. Is splicing/soldering the leads from the fan motors to the short leads on the board the right way??

Don't pry them up from the side, that is how you bend the shaft and ruin the motor. Using small needle nose pliers grip the center and pull them up that way.

Some of the boards that I get don't even have those wire leads on them, consider yourself lucky yours came with them. Yes you solder to those wires using an appropriate gauge wire.

Personally, I'd just remove those wires and solder direct to the PCB, much neater installation.

GRJ, if I wanted to remove those wires, then I would have to un-solder them from the board first?

Yep, you just touch the iron to the joint and pull the wire out. Then, to clean the hole, just heat it again and tap the board straight down on the bench quickly, the solder will pop out. Obviously, we're doing this with the proper sized soldering iron. ![]()

You can use much finer wire, the motors only draw around 30-40ma, so any size wire up to around #30 is fine.

Thanks GRJ, I plan on using a Hakko fine tip set to 550F. So, after the wires have been detached, a second heating and a tap of the board while the iron is on the solder or do you withdraw the iron first and then tap?

Davety posted:RickM46 posted:Thanks Dave and Romiller49!! I will just press them on as you advised; I think I will forego the glue and the oil. I am guessing that they can be removed from the motor shaft if necessary by gently prying them up thru the air channel in the reservoir.

Now, on to another question: I will have to solder red and black leads to the fan motors; I am thinking 20g or 22g wire. The board has very short red and black leads coming out of it for the fan motors (they couldn't have made them shorter) and those leads are soldered on the top side and bottom side of the board. Is splicing/soldering the leads from the fan motors to the short leads on the board the right way??

Don't pry them up from the side, that is how you bend the shaft and ruin the motor. Using small needle nose pliers grip the center and pull them up that way.

Some of the boards that I get don't even have those wire leads on them, consider yourself lucky yours came with them. Yes you solder to those wires using an appropriate gauge wire.

Thanks Dave for the tip on the needle nose pliers and the fan blades.

Now, I have one last hurdle: There is a mounting screw in the center of the board that goes into the reservoir. You can see its threaded end below. However, the funnel is press fitted into the board over the mounting screw so you cannot get at it. Tried to pull the funnel off with my finger tips but it is pressed tight into the board. You can see the two black funnel ends just emerging out of the board under the heating elements. There are 4 other mounting holes at the corners. I guess I could just drill out the receiving hole in the reservoir and not use the center mounting screw. Any suggestions???

Attachments

That funnel comes out it can just be stiff in there. I don't have a very good suggestion on getting it out, only to say be careful. Perhaps some others here have some good advise on how to get it out.

It’s pretty clear from the photos that the funnel is a really tight press fit into the holes in the PCB board as the edges of the holes are bent in the direction the funnel inlets would have been inserted. I’d use the flat side of a screwdriver blade to gently nudge the funnel inlets out of those holes.

Regarding the white dots on the fan motors: I think that these actually indicate the + terminal but these motors originally may have been wired to spin CCW so the - lead would be wired to the white dot terminal. Check the original motor wiring to be sure but a couple of posts on the first page of this thread explain the reason for the reverse wiring.

Yes, Hancock52, the funnel nozzles are a really tight fit into the holes - when I first took the board out of its bag, there were very small strings of fragments of board resting against the funnel nozzles protruding over the heating elements - they must have used some sort of press to insert the nozzles into the board causing the fragments - that has got to be a headache for those repairing the units.

Regarding the fan motors, the old units have the negative black leads soldered to the white dot terminals and I am thinking that would make the fans spin CW with the convex part of the blades facing the direction of spin - I will verify that before soldering.

Update: upon later investigation, the NEW motors produce CCW rotation with the black lead attached to the white dot terminal with the concave part of the fan doing the pushing thru the air channel to the wick chamber. Am not sure what direction the fan spins on the old motors with the black lead currently attached to the white dot.

The convex part of the blades should face in the direction of the spin. That's an air noise reduction measure for the fans.

When I remove the solder, I hold the board above the bench a couple inches, heat it with the iron, and then quickly tap it on the bench. You don't try to keep the iron in contact with it, if you immediately tap it after removing the iron, it works fine.

GRJ: Thanks for the tips on de-soldering - will do.

And just tested the NEW fan motors with significant results: Attaching a red + battery lead to the white dot terminal and the black lead to the other terminal produces CW rotation with the convex part of the blades facing the direction of rotation. This is the opposite to the way the old motors are connected - black lead to the white dot terminal. On the new motors, I will attach the red lead to the white dot to get CW rotation.

I hate to contradict myself, but maybe CW is wrong for this smoke unit. Looking at the picture, it's obvious from the positioning of the fan exhaust that the motors probably should run CCW. I think CW would result in much less airflow with that air chamber design. Obviously, the folks that designed the impellers and the folks that designed the smoke unit don't talk. ![]()

GRJ, I think you hit the nail on the head as others in this thread have written - there is some disparity in design. Right after I said 'On the new motors, I will attach the red lead to the white dot to get CW rotation' I had second thoughts. As Mike R wired the motors for CCW by attaching the black lead to the white dot, I will do the same - at least air will be pushed through the exhaust channel of the reservoir to the wick chamber by CCW rotation with the concave part of the fan blade doing the pushing. I think the design of the exhaust channel of the reservoir to the wick chamber trumps concave vs convex of the fan.

RickM46 posted:GRJ, I think you hit the nail on the head as others in this thread have written - there is some disparity in design. Right after I said 'On the new motors, I will attach the red lead to the white dot to get CW rotation' I had second thoughts. As Mike R wired the motors for CCW by attaching the black lead to the white dot, I will do the same - at least air will be pushed through the exhaust channel of the reservoir to the wick chamber by CCW rotation with the concave part of the fan blade doing the pushing. I think the design of the exhaust channel of the reservoir to the wick chamber trumps concave vs convex of the fan.

As I said in an earlier post in this thread, I have come across this apparent mismatch of the impeller blades' shape and exhaust channel configuration before on another VL engine with plastic smoke units, the Baldwin Centipede. Lionel has never mentioned anything about the difference between these and "normal" smoke units where it's CW rotation of the impeller blades that will push air directly through the channel.

But incidentally, when I re-wired my Centipede fan motors to spin CW instead of CCW (as originally wired), it made no discernible difference to the smoke output; it was neither obviously better nor worse.

Hard to believe that the designers of these units did not recognize that stock impellers have always had the convex side of the blade run CW to propel air (but I'll be corrected if someone has ever seen an impeller made to run the other way). I did think about turning the impellers in my Centipede's units upside down but decided it would be too difficult to get the spacing on the fan motor spindle right. Besides, the bottom of the impeller is a solid round piece and having it on top might have impeded the airflow to the blades.

gunrunnerjohn posted:I hate to contradict myself, but maybe CW is wrong for this smoke unit. Looking at the picture, it's obvious from the positioning of the fan exhaust that the motors probably should run CCW. I think CW would result in much less airflow with that air chamber design. Obviously, the folks that designed the impellers and the folks that designed the smoke unit don't talk.

Here’s a picture of MTH impeller. Their fan spins CW with air being pushed via the convex part of the fan allowing total air escape into and across the resistor area. Unfortunately the Lionel design does not allow this to happen no matter what you do. If theirs spins CW the air smacks right back into the fan housing greatly limiting proper air flow. If theirs spins CCW as designed the air is trapped inside the fan housing via the concave shape of the fan greatly diminishing the air flow out to the resistor side of the smoke unit. Lionel needs to re- design their fan and this just may solve all the burnt batting issues.

Attachments

I guess if one wanted to be adventurous with a Dremel, you could cut that upper corner portion of the exhaust channel to be like the lower portion; I looked at my new reservoir and it looks like that shoulder is solid material; but not an effort for my unsteady hands.

Rod, there is an interesting feature of the design of the MTH smoke unit: there is a gap between the wick chamber and the fan chamber; if you overfill, the fluid will not back feed into the fan motors; of course, it will go somewhere.

Rick, there's a rubber gasket between the two, the fluid still goes into the fan chamber. ![]()

To be blunt, if Mike Reagan wired this unit - and indeed it originally came wired - so that the impeller spins CCW, that would be good enough for me. What the thinking was behind this design only someone who was involved in it can tell us. It looks like a mistake or at least very odd to me.

RickM46, your idea of widening the airflow outlet is very interesting to me but again, what the thinking was behind the original design would help in deciding whether to try this experiment. Also whether another replacement part is available in case the cutting goes wrong!

For purposes of comparison, I have looked out the thread I posted on the VL Centipede units, which also concerned a completely separate oddity about a Lionel spare part for those units, an internal metal heat shield that was not part of the stock unit. The thread is here: https://ogrforum.ogaugerr.com/...onel-smoke-unit-part

I never found out what that part was designed to do and how it was meant too fit in the plastic smoke units. If anything, the units were even odder than the one you are working on; as the photo below shows, the airflow from the impeller to the resistor has to go through at least a full 90 degree bend, which I can't think is very efficient:

These units also came from the factory with the fan motor wired to spin CCW (negative wire to terminal marked with white dot) so that the concave side of the impeller blades was pushing the air towards the resistor:

It would be interesting if someone from Lionel (or Mike R.) explained the theory behind this arrangement but short of asking them or him I don't see the logic of it.

Anyway, as I have said in my last post, wiring the fan motor to spin CW in these units had no effect on the smoke output, good or bad, and so maybe the motor and impeller generate enough airflow for the unit to operate as designed whichever way you wire them.

Attachments

Hancock52, great presentation of your smoke unit - yep there is some design logic that is not obvious. In my case with mine, black wire to the white dot it is.

GRJ, Darn, I thought there might be some smoke unit I can't drown.![]()

RickM46 posted:GRJ, Darn, I thought there might be some smoke unit I can't drown.

Probably not. ![]()

![]()

RickM46 posted:I guess if one wanted to be adventurous with a Dremel, you could cut that upper corner portion of the exhaust channel to be like the lower portion; I looked at my new reservoir and it looks like that shoulder is solid material; but not an effort for my unsteady hands.

I wouldn’t do that. You’ll definitely ruin the unit. Put it back together as is and just keep it loaded with fluid.

Rod is, of course, totally correct. Changing the airflow won't make up for too little or too much smoke fluid.

I am grateful for the patience of the forum; however, I have yet another situation with the New PCB board as delivered and as compared to the old board. On the old board, the tops of the thermistors are even with the tops of the heating resistors. On the new board, the tops of the thermistors are even with the bottoms of the heating resistors. See pics below. That can't be right or is it?? The top pic is the old board. BTW, I woke up at 4AM and this disparity was the first thought that hit my mind --- I need to get a life.

Attachments

Gently pull them up to be even with the top of the resistor, problem solved. I'm sure they get bent at times in shipping.

Interesting to me (and maybe need to get a life too) is that it's the resistor in the new unit that looks to be out of place i.e. too high whereas the thermistors are at the same level as the original. It's also at a slight angle. So pulling up the thermistors to be at the resistor height means that they and the resistor will be seated slightly deeper in the smoke wadding than in the original, which may make no difference but you won't know without testing the unit.

More generally, the whole assembly looks kind of bodged together with the wire leads to these components being as long as they are. But that's just my amateur opinion. ![]()

Hancock52 posted:Interesting to me (and maybe need to get a life too) is that it's the resistor in the new unit that looks to be out of place i.e. too high whereas the thermistors are at the same level as the original. It's also at a slight angle. So pulling up the thermistors to be at the resistor height means that they and the resistor will be seated slightly deeper in the smoke wadding than in the original, which may make no difference but you won't know without testing the unit.

More generally, the whole assembly looks kind of bodged together with the wire leads to these components being as long as they are. But that's just my amateur opinion.

They are that long so the components are in the wick and there is still room between the board and component for air flow.

Gene Anstine

Thanks GRJ, Hancock52, and Gene; yes, that new assembly has 2 flaws - press fitting the funnel into the board so it cannot be removed and thus orphaning the mounting screw under it and the positioning of the thermal elements - so much for precision; but, it is what it is.

I was thinking I could take a measurement of the distances of the elements from the old board and make the elements of the new board the same; either gently pressing down or pulling up. Per Jon Z., it is critical that there be wet wick between the thermistor and resistor.

grfd59 posted:They are that long so the components are in the wick and there is still room between the board and component for air flow.

Gene Anstine

I see your point but would just add the following.

The VLBB smoke unit issue I have is with the blowdown unit, not the dual stack unit Rick is working on but the same basic issue seems to arise. I have not opened up my engine yet but I know the blowdown unit is equipped with a thermistor that might be misaligned. Lionel stocks some different variations of the PCB for this unit. The first one below has the thermistor mounted on wiring that is similar to old TAS smoke units and those used by 3rd Rail; the wiring is rigid and bent in a U shape that fixes the position of the thermistor relative to the resistor. The second one has the extra wire. Possibly just a difference in the way that these were assembled at the factory but the first option seems better constructed to me (thermistor less likely to be moved out of correct alignment when the unit is screwed on to the reservoir and presses into the smoke batting) :

I should also note that this particular unit as a whole is very similar to the problematic ones in my VL Centipede but I don't recall those being equipped with a thermistor.

Attachments

My VL-BB had poor blowdown but the regular smoke and the whistle smoke worked fine. I just positioned the thermistor for the blowdown the same as the whistle smoke, problem solved.

GRJ, do you remember what the position of the thermistor was to the resistor?? Was the top of the thermistor even with the top of the resistor and gapped at 1/16 inch?

It was at least 1/8" between them for my locomotive.

FWIW, when I have looked at thermistor placement on TAS and 3rd Rail units, it was nearer 1/8th than 1/16th. However I did not know before reading this thread that the heat transfer was through the wadding and it has to be saturated for this design to work correctly.

Hancock52, you mention an extra wire on the second one - what extra wire??

RickM46 posted:Hancock52, you mention an extra wire on the second one - what extra wire??

I only meant the extra length of wire forming the leads to the thermistor, not that there is a whole other wire.

Hancock52 posted:FWIW, when I have looked at thermistor placement on TAS and 3rd Rail units, it was nearer 1/8th than 1/16th. However I did not know before reading this thread that the heat transfer was through the wadding and it has to be saturated for this design to work correctly.

Since the Legacy system is a totally different design, that probably has little bearing, though I think that's what I see when I look at these. The TAS sensor was open-air, it didn't sit in the wick.

Per Jon Z in a previous post re my Legacy smoke unit: 'The temperature path for the element to the thermistor is through the fluid dampened batting. When the batting is not saturated, the temperature rises on the element, but the air between the thermistor and the element is a poor conductor of the heat, relative to a saturated batting material.

gunrunnerjohn posted:Since the Legacy system is a totally different design, that probably has little bearing, though I think that's what I see when I look at these. The TAS sensor was open-air, it didn't sit in the wick.

Agreed. I have just looked at an old TAS unit I have on hand and the thermistor was mounted above and slightly behind the resistor. The 3rd Rail units have the same basic design but with a ceramic-coated resistor. I recall that in one of those, when (per advice from Scott Mann) I moved the thermistor further away from the resistor, the unit smoked as you'd expect. He told me that at the factory they sometimes don't ensure the clearance is sufficient. It was originally within 1/16th inch and I backed it out to about double that.

Lionel's system is obviously more complicated and maybe has something to do with substituting plastic components for metal. Anyway, now the VLBB blowdown issue has gone to the top of my personal irritation list and I'll check it out next week.

Thanks gentlemen for the discourse and info; I have adjusted the resistor and thermistor to be the same as the old unit; gap is sitting at 1/16 inch; the first picture is the un-adjusted new unit; the second is the adjusted new unit. The adjusted unit matches the old unit.

Attachments

Folks, thanks to the help from so many gents on the forum, I finished building the front main smoke units - 2 chambers and fans; all new parts. Primed each wick with 70 drops of fluid; made sure I didn't overdo it by turning the unit up side down and looked to see if any fluid drained out - none did. I am working on a smoke unit document consolidating all that I learned for each component. Oh, yes, the Big Boy is back on the tracks and smoking up a storm. Its internals ain't factory anymore but it works; note the 10mm SS screw holding down the PCB.

Ran into a few assembly problems: the smoke unit funnel was pressed into the PCB to be un-removable and orphaned a mounting screw under it; one of the reservoir chassis bracket holes was not tapped; one other reservoir mounting hole for the PCB was stripped; one wick was 12 inches long - all others were 8.

Learned a lot: bought a whole bunch of parts and tools: namely a multi meter, Hakko FX888d soldering station, Hakko FX100 temperature unit, screw driver magnetizer, soldering tweezers (helped installing the 5 pin plugs into their recpticals), 20g, 22g, 28g, 30g wire, wire nippers, wire strippers, .5mm solder, Helping Hands work station, heat sinks, electrical tape, all the smoke unit parts I could get from the Lionel parts page, micro screws, 8 inch wick.

In the 2nd pic, notice the 10mm long ss screw to the lower left; got it from Micro Fasteners to use in a stripped hole.

Attachments

Now you're all set to go into the repair business! ![]()

![]()

gunrunnerjohn posted:Now you're all set to go into the repair business!

Yeah, it’s all just a matter of having the right tools, isn’t it? 🔧🛠🔩🔬🍸

Hancock52 posted:gunrunnerjohn posted:Now you're all set to go into the repair business!

Yeah, it’s all just a matter of having the right tools, isn’t it? 🔧🛠🔩🔬🍸

Yep, spent a bunch on all the stuff; but, now I can overhaul my units; Mike R's service of the loco left it in factory condition and that provided a good base.

Tinplate Art posted:GREAT work and results! Of course, the "elephant in the room" is why could Lionel not have included a better designed smoke unit in such a premium, high end model in the first place? This question, unfortunately, is never answered!

He restored the unit to factory condition and it smokes great, so what do you recommend to be designed better? Seems like it works as expected after rebuild. Smoke systems have consume-able batting material, and they need serviced. Please don't confuse maintenance with design. And since you believe the smoke unit is not designed well, please explain what your expertise indicates is in need of improvement? Constructive feedback is always a good posture.

BOTTOM LINE: I am VERY GLAD the gentleman got his smoke unit repaired!

I've replaced a ton of MTH smoke unit wicks, so I can only assume you've not run these locomotives a great deal. I've never tried to quantify whether the MTH or Lionel wick lasts longer, but both need regular replacement.

Lionel got a big black mark with the run of bad fan motors, but I believe that's all behind us now.

Just sayin... ![]()

GRJ: GOT IT, and THANKS! (smile)

Gents, am very happy to see the good ol Big Boy lumbering around the track again with everything working; especially since the smoke unit was fixed with my own 500 pound gorilla paws. Now, I am fat, dumb, and happy - a dangerous condition. I have destroyed a number of smoke units - usually either drowning or starving. I did starve the BB right out of the box using a micro dropper. Now, lesson learned; the object is to keep the wick saturated; hence, I will keep track of minutes run. There has to be a correlation between that and drops to replenish.

One last thing; the funnel to the heating elements on the BB has 2 chambers - one feeds the front stack, one feeds the rear. I think when dosing with a small number of drops, you are only wetting the chambers.

SantaFeFan posted:He restored the unit to factory condition and it smokes great, so what do you recommend to be designed better? Seems like it works as expected after rebuild. Smoke systems have consume-able batting material, and they need serviced. Please don't confuse maintenance with design. And since you believe the smoke unit is not designed well, please explain what your expertise indicates is in need of improvement? Constructive feedback is always a good posture.

Jon,

It is good of you to post here and I am replying with no small amount of appreciation; you have assisted me in the past (re: Acela). I don't intend to hijack RickM46's thread but since you ask . . .

Speaking as a pure amateur, it's difficult to comment on the current generation of Legacy smoke units without knowing why various design changes were made: plastic components for the smoke unit reservoirs (which in my experience don't hold up to ordinary maintenance disassembly because screw threads are easily damaged), air channels that require the fan motor to be wired the reverse of the norm (no change being made in the impeller design), pads instead of rope wicking, use of thermistors that can easily be put in the wrong position during factory or later assembly are examples that occur to me. All I can say is that up to the changes that were in the Legacy AC-9s smoke units, which I understand involved changing the code used to control their operation, later model Legacy smoke units just do not perform up to expectation and are not easy to maintain.

I have a feeling that most or all of the changes are related but explanation of this has been in short supply.

I will say that when the VLBB was issued, Mike R's video on its operation emphasized that the smoke units use up fluid rapidly. In mine, I have only ever used Lionel premium fluid and been careful to watch for signs that the fluid was getting low - which tends to happen after no more than about 10-12 minutes of continuous operation. Warning people off of overfilling smoke units (as the relevant owner's manuals all do) can itself create the problem of these units really not having an adequate fluid supply - particularly dual chamber units where there is only one filling point.

I for one would like to understand the theory behind the operation of these units.

P.S. I am nostalgic for the VL GE Evo smoke system, which for me always worked exactly as advertised!

Hancock52 posted:SantaFeFan posted:He restored the unit to factory condition and it smokes great, so what do you recommend to be designed better? Seems like it works as expected after rebuild. Smoke systems have consume-able batting material, and they need serviced. Please don't confuse maintenance with design. And since you believe the smoke unit is not designed well, please explain what your expertise indicates is in need of improvement? Constructive feedback is always a good posture.

Jon,

It is good of you to post here and I am replying with no small amount of appreciation; you have assisted me in the past (re: Acela). I don't intend to hijack RickM46's thread but since you ask . . .

Speaking as a pure amateur, it's difficult to comment on the current generation of Legacy smoke units without knowing why various design changes were made: plastic components for the smoke unit reservoirs (which in my experience don't hold up to ordinary maintenance disassembly because screw threads are easily damaged), air channels that require the fan motor to be wired the reverse of the norm (no change being made in the impeller design), pads instead of rope wicking, use of thermistors that can easily be put in the wrong position during factory or later assembly are examples that occur to me. All I can say is that up to the changes that were in the Legacy AC-9s smoke units, which I understand involved changing the code used to control their operation, later model Legacy smoke units just do not perform up to expectation and are not easy to maintain.

I have a feeling that most or all of the changes are related but explanation of this has been in short supply.

I will say that when the VLBB was issued, Mike R's video on its operation emphasized that the smoke units use up fluid rapidly. In mine, I have only ever used Lionel premium fluid and been careful to watch for signs that the fluid was getting low - which tends to happen after no more than about 10-12 minutes of continuous operation. Warning people off of overfilling smoke units (as the relevant owner's manuals all do) can itself create the problem of these units really not having an adequate fluid supply - particularly dual chamber units where there is only one filling point.

I for one would like to understand the theory behind the operation of these units.

P.S. I am nostalgic for the VL GE Evo smoke system, which for me always worked exactly as advertised!

I could write a book on smoke systems. Since the introduction of the RCMC system I designed, the smoke system controller and its subsequent tuning was my responsibility, and my nemesis. I spent many long days in China, at the design center, working various smoke bowl and assembly designs with the team. Making a better smoke system has been studied by the brightest folks I know of in the industry, there is not much more, if anything, left to improve. The current designs are pretty good if the smoke unit is built properly and maintained, and it should work nicely for some time.

I really can't comment more as I am not sure what would be confidential in an explanation of the design work to make these smoke systems function. I still have to respect the confidentiality agreements of the company I worked for, and I actually doubt a book would solve the problems 100%.

Still, the forumites are a bright group of folks. And as I stated - any constructive feedback means a lot to the designers.

SantaFeFan posted:Hancock52 posted:SantaFeFan posted:He restored the unit to factory condition and it smokes great, so what do you recommend to be designed better? Seems like it works as expected after rebuild. Smoke systems have consume-able batting material, and they need serviced. Please don't confuse maintenance with design. And since you believe the smoke unit is not designed well, please explain what your expertise indicates is in need of improvement? Constructive feedback is always a good posture.

Jon,

It is good of you to post here and I am replying with no small amount of appreciation; you have assisted me in the past (re: Acela). I don't intend to hijack RickM46's thread but since you ask . . .

Speaking as a pure amateur, it's difficult to comment on the current generation of Legacy smoke units without knowing why various design changes were made: plastic components for the smoke unit reservoirs (which in my experience don't hold up to ordinary maintenance disassembly because screw threads are easily damaged), air channels that require the fan motor to be wired the reverse of the norm (no change being made in the impeller design), pads instead of rope wicking, use of thermistors that can easily be put in the wrong position during factory or later assembly are examples that occur to me. All I can say is that up to the changes that were in the Legacy AC-9s smoke units, which I understand involved changing the code used to control their operation, later model Legacy smoke units just do not perform up to expectation and are not easy to maintain.

I have a feeling that most or all of the changes are related but explanation of this has been in short supply.

I will say that when the VLBB was issued, Mike R's video on its operation emphasized that the smoke units use up fluid rapidly. In mine, I have only ever used Lionel premium fluid and been careful to watch for signs that the fluid was getting low - which tends to happen after no more than about 10-12 minutes of continuous operation. Warning people off of overfilling smoke units (as the relevant owner's manuals all do) can itself create the problem of these units really not having an adequate fluid supply - particularly dual chamber units where there is only one filling point.

I for one would like to understand the theory behind the operation of these units.

P.S. I am nostalgic for the VL GE Evo smoke system, which for me always worked exactly as advertised!

I could write a book on smoke systems. Since the introduction of the RCMC system I designed, the smoke system controller and its subsequent tuning was my responsibility, and my nemesis. I spent many long days in China, at the design center, working various smoke bowl and assembly designs with the team. Making a better smoke system has been studied by the brightest folks I know of in the industry, there is not much more, if anything, left to improve. The current designs are pretty good if the smoke unit is built properly and maintained, and it should work nicely for some time.

I really can't comment more as I am not sure what would be confidential in an explanation of the design work to make these smoke systems function. I still have to respect the confidentiality agreements of the company I worked for, and I actually doubt a book would solve the problems 100%.

Still, the forumites are a bright group of folks. And as I stated - any constructive feedback means a lot to the designers.

Jon stop posting on forum! and go traveling without smartphone laptop tablets just you and scenery laughing loudly hope you do get to enjoy retirement

Jon, I appreciate immensely the help you gave me in the re-construction of the new smoke unit for my Big Boy. For me, it was a rush when after help from you and the others in the forum, it worked immensely well - my BB lives! I don't know if you can stay away from the forum; and, selfishly, appreciate your participation.

Now, per direction from the forum, I am looking for a place to hang a document. I have created a Microsoft rich text document from a pedestrian standpoint showing everything I learned about a smoke unit; it might help others when it comes time to maintenance a unit. I would gladly email a copy to someone who can review it and suggest corrections.

SantaFeFan posted:I could write a book on smoke systems.

I'd buy that book Jon, and I don't buy many books. ![]()

gunrunnerjohn posted:SantaFeFan posted:I could write a book on smoke systems.

I'd buy that book Jon, and I don't buy many books.

So would I - as long as it’s autographed. 😁

OK, no takers on my Smoke Unit document; so, don't know if I am flooding the forum but here it is:

Lionel Legacy Smoke Units

June 2018

The following information was accumulated from the OGR forum during the repair of a dual stack smoke unit of a 2014 Lionel Big Boy 6-11437. Information came from Jon Z., Mike R, MartyF, GRJ, Sinclair, Hancock52, Falcon70, Romiller49, Davety, and others on the forum.

See OGR thread:

https://ogrforum.ogaugerr.com/...opped-working?page=1

Smoke Unit Components.

Reservoir - metal or black composite plastic, home for the wick, smoke fluid, fan motor secured to the reservoir, fan blades, fan air passage channel to the wick, PCB board secured to the reservoir by micro screws.

See info from MartyF below on metal reservoirs and centering the heating elements.

Stack funnel - allows supply of fluid to the wick; mounts to the PCB board over the heating element; in the case of the Big Boy, the dual stack funnel has 2 separate chambers - one that delivers smoke fluid to the front smoke unit, the other to the rear smoke unit; putting small doses of fluid into a funnel may only wet the funnel especially those funnels that are composed of multiple chambers; the Big Boy funnel with its chambers does not allow the insertion of a long syringe to wet the wick directly with fluid.

Fan motor - mounted to the reservoir; has 2 electrical terminals - one with a white dot; the rotation direction of the motor shaft is determined by which of its 2 terminals you connect the red plus power lead and the black negative ground lead; in Lionel motors, connecting the black lead to the white dot terminal will produce CCW rotation; the fan motor is attached to the reservoir via 2 micro panhead screws - 1.3mm X 2.8mm X .2 thread; the red and black wires connecting the motor to the PCB board are 28-30 gauge and soldered to the board (with my unsteady hands, I found 22 gauge easier to solder); the fan motor can be tested with a 1.5 volt battery if the motor is not connected to the PCB board; 1.5 volts easily runs a good motor.

Fan blade - mounted on top of the fan motor; the fan blade is press fitted onto the fan motor shaft; it should not be glued; it can be removed using needle nose pliers and pulling gently upward; ideally, the motor should spin with the convex part of the blade pushing air through the air channel into the reservoir wick chamber; however, the position of the air channel will determine which direction the fan blade should spin; some say there is no difference whether the concave or convex side of the fan pushes the air.

PCB board - mounts on top of the reservoir via micro panhead screws 1.9mm X 8mm X .4thread; contains a heating element resistor, heat control thermistor, white plug recepticale with 5 pins (sometimes black) for a white 5 position plug (sometimes black) from the RCMC; air intake hole for the fan; smoke exhaust hole over the heating resistor to a funnel that leads to the stack, funnel may be press fitted into the board (Big Boy main stacks), 2 holes for soldering the red and black leads from the fan motor, embedded printed metal circuits connecting the components to the recepticale for the 5 position plug to the RCMC; the recepticale for the 5 position plug from the RCMC has these 5 pins and with the recepticale pins facing upward from left to right are labeled: SENS, COM, FAN, HTR, RAW; when soldering new motor leads to the board, test continuity using the COM and FAN pins.

Heating element resistor - should be soldered perpendicular to the board; must be centered in the reservoir chamber and not touch the sides of the reservoir; its height off the board should be enough to allow it to sleep on the pillow of the wick and not be covered by the wick; be careful not to bend the resistor when installing the resistor into the wick; there should be some resistance from the wick against the resistor when attaching the PCB board to the reservoir; can be cleaned with isopropyl alcohol and a soft tooth brush; can be tested on the board for ~8 ohms; if ohms are higher than ~8 ohms ie. 12 ohms, a cab light error blink will occur and the unit will be disabled by the RCMC; in the process of overheating, some say the burnt resistor may damage the RCMC.

Heat control thermistor - should be soldered perpendicular to the board, parallel to the heating element resistor, its top should be even with the top of the resistor, adjacent to the resistor with a gap from 1.6mm or 2/32 to 3/32 to 4/32 inch between it and the heating element (Big Boy gap is 3/32, some say 4/32 inch is better, mine is set to 3/32); can be tested on the board for ~50k ohms; if ohms are higher than ~50k ohms, a cab light error blink will occur and the unit will be disabled by the RCMC; air between the thermistor and the resistor is a poor conductor of heat when compared to a saturated wick; charred wick and dry wick are also poor conductors of heat to the thermistor.

RCMC board - controls the smoke unit; a 5 position plug comes from the RCMC to a 5 pin recepticale on the smoke unit PCB; at cold startup on a Big Boy and with a medium smoke setting, the amp meter on a ZWL shows a current draw of 6 amps for ~8 seconds, then 4 amps for ~8 seconds, and lastly drops to about 1.7 amps; the RCMC for a Big Boy brings the main stack smoke units online before the rest.

Question: does the RCMC sense when a fan motor is not working??

Fluid - Lionel Premium fluid is recommended for Lionel smoke units; it is thinner than some others; it is not a conductor; it is used in proper amounts (drops) to saturate the wick for smoke production; since it is not a conductor, if a board gets wet with it, you can usually wipe the board dry without damage; too much fluid may also wet the fan motor and damage it.

Fluid dosage - is measured in drops; the Lionel Premium fluid dropper is graduated in .25ml increments; .25ml is about 10 drops; there are some droppers that measure out smaller size drops; Mike R recommends 20 drops per chamber for the Big Boy main stack and 10 drops for whistle and blow down; when installing new wick into a smoke unit, I used 70 drops to saturate that chamber's wick before I screwed down the PCB board - turned the unit up side down to see if any fluid ran out - none did; putting small doses of fluid into a funnel may only wet the funnel especially those funnels that are composed of multiple chambers; after a dose, blow gently thru the stack to break a miniscus; some say to only add fluid when the unit is cold and to let it soak into the wick. some say you have to consider run time and density of the plume to determine when to add fluid; some say to add 20 drops of fluid after 10 minutes of run time.

See more info on dosage:

https://www.youtube.com/watch?v=WRcpFRtA6IY#t=180

https://www.youtube.com/watch?v=1asUWbJtfok

Consider the path of the smoke fluid when you add some: the fluid will have to wet the stack, then funnel, then heat resistor, and then finally the wick; what gets to the wick may be less than the full dose; I have seen excellent smoke after a dose and now know that is because the resistor itself is wet.

String Wick - replacement part number 691SMKP008 (8 inch long string); wick receives smoke fluid thru the stack and funnel; is packed into the reservoir; the string wick is less dense than the original factory block wick and thusly gets hotter, but, must be dense enough (as close to the original factory block wick) and wet enough to accomodate the vaporization of smoke fluid to produce smoke by the heat of the resistor; must not block the air channel in the reservoir from the fan to the wick; must be wet enough and dense enough to provide passage of heat from the resistor to the thermistor so the thermistor can control the temp of the resistor; if the string wick is not packed as dense as the original factory block and is not wet enough, it will melt (per Jon Z.); usually one 8 inch length of string wick is sufficient for a chamber after it has been pulled apart and balled up; I use an 8 inch string wick + 4 inches from another string; use the flat butt end of a micro screwdriver to compress the wick after it is pushed into the reservoir; wick preparation for packing into the reservoir can be seen at:

https://www.youtube.com/watch?v=ZkDlQ5Cwwlk&t=12s.

Charred Wick - charring is the hydrocarbon brown residue on the wick produced by vaporization of the fluid; too little fluid and high temp will cause charred wick; charred wick is not burnt wick; dry wick or too big a gap between the resistor and thermistor will result in charring and overheating and damage to the resistor or thermistor; charred wick between the resistor and thermistor is also an impediment to the sensing function of the thermistor; overheating can also distort the reservoir itself.

Smoke Plume - when the smoke plume begins to get anemic, add fluid; if you smell plastic burning, the wick may be charring.

Dual Chamber Divider - in dual chamber smoke units, the divider separates the chambers; has a cut out passage on the bottom of the divider to allow fluid migration from one chamber to the other.

Micro Screws - black oxide phillips fasteners used in the smoke unit; if not in Lionel parts, stainless steel versions can be found at:

https://www.microfasteners.com...rection=0&page=1

http://www.fastener-express.co...crews-stainless.aspx

https://www.boltdepot.com/Cata...5EAAYASAAEgLkL_D_BwE

however, consider that these screws are stainless and non-magnetic and have phillips heads that are a tad bigger but work in a pinch.

Tools and Parts - a multi meter to check for continuity and ohms, Hakko FX888d soldering station with tip assortment (may require recalibration after testing the soldering iron tip using a Hakko FX100), Hakko FX100 soldering iron tip temperature meter, micro screw drivers, screw driver magnetizer, long soldering tweezers (helps installing the 5 pin plugs into their recpticals and retrieving screws dropped into the chassis), 20g, 22g, 28g, 30g wire, wire nippers, wire strippers, .5mm 60/40 rosin core solder, Quad Hands work station, heat sinks, electrical tape, all the smoke unit parts you can get from the Lionel parts page, micro screws, 8 inch wick, an extra hand to hold your shaky hand steady, long lead time on ordering parts, soldering tutorials on Youtube, unlimited patience; help from the OGR Forum.

Per MartyF (June 17, 2018):

Metal Smoke Reservoirs and Centering the Heating Elements.

Guys, one pointer that you want to keep in mind when working on Lionel or MTH smoke units. Both Lionel and MTH have many smoke units with a metal smoke reserviors where the heaters and wicking reside. Before putting the PCB with the heaters or heater back inside, be sure the heater is centered so it will sit as close as possible in the smoke reservior. Doing this has nothing to do with smoke output. What you do not want is the heater to touch the side of the reservior and ending up doing damage.

Here is what I always do. Take your continuity meter and with one probe hit the heater pad or screw on top of the PCB. Take the other probe and hit the reservior and hope you see no continuity. If you have no continuity, you did the job right and are good to go. If you see continuity, open the unit up again and re position the heaters and repeat the step until you see no continuity.

Today, many of the smoke reserviors are plastic. That makes life easy. Lionel is always a bit easier to do with the single heater. You have all read some of the great info on updating smoke units by GRJ and Alex. Even with modifications to the smoke unit, always make sure the heater does not say hello to the metal reservior.

Rick, you may be lucky. The RCMC is tough. I am a very big fan of the RCMC.

That’s a fine compilation of excellent advice; have printed it for future reference. And wow, I am pleased to be mentioned among some truly distinguished company.😲

Incidentally, I have now got a Hakko soldering iron and the difference between it and the hobby models I have been using is pretty much astonishing.

Hancock52 posted:That’s a fine compilation of excellent advice; have printed it for future reference. And wow, I am pleased to be mentioned among some truly distinguished company.😲

Incidentally, I have now got a Hakko soldering iron and the difference between it and the hobby models I have been using is pretty much astonishing.

Hancock52, yes the Hakko is a good soldering station BUT I also bought the Hakko FG100 tip temperature unit and found that when I set the soldering station to 585F, the tip was only at 450F; you then have to recalibrate the station.