I recently picked up this nice looking Weaver 2-8-0 engine. It runs smoothly, but has a very annoying high pitched whine as well as a grinding sound that I tried to capture in the video. Is this a normal sound for these engines ? I took the shell off and found several loose screws (not including mine LOL ) and tightened them. Nothing looked like it was rubbing. It has the normal looking DC motor connected to the gear with a plastic piece connecting the 2 parts. The whine is the most annoying. You can hear it above the sound of 12 scale freight cars running on the tracks. The grinding I'm not too fond of, but I bought a new MTH UP Golden Spike 4-4-0 a while back and it runs great, but has a similar grinding sound. Both engines have a louder sound going forward and slightly quieter sound going in reverse. Anyway, I bought the Weaver based on a couple of great reviews from people on here. Just want to know if something is wrong or this is how they sound. Thanks. - Scott

Replies sorted oldest to newest

Here is mine running…does seem a bit quieter.

Attachments

You’ll have to pop off the boiler shell to investigate, sounds motor/ gear train related. Look to see if something is scrubbing the flywheel, see if the motor mount screws are loose, and motor TO mount screws are loose,….check the condition of the grease, or lack there of in the gear box. ……is this a new to you noise?…or has it been that way from the get-go?.

Pat

@taycotrains posted:Here is mine running…does seem a bit quieter.

Yes, it does sound ALOT quieter. LOL.

@harmonyards posted:You’ll have to pop off the boiler shell to investigate, sounds motor/ gear train related. Look to see if something is scrubbing the flywheel, see if the motor mount screws are loose, and motor TO mount screws are loose,….check the condition of the grease, or lack there of in the gear box. ……is this a new to you noise?…or has it been that way from the get-go?.

Pat

I'll go take it apart again. I did find the 2 motor mount screws were loose and tightened them. The gear box seemed to be full of bearing grease (as prescribed in Weaver's paperwork). The noise came with the engine which I just received last week, so not sure if that's why it was sold or not. Bought it on Trainz.com. Thanks for the help.

Scott

If the 2-8-0 has brake shoes. They could have been tweaked and rubbing against the drivers rim.

I have one and its quieter than that in forward and makes some noise in reverse.

Has it been run much ? it may need breaking in . It sounds like gear train and motor noise.

They did use a cheap motor in them and they make a fair amount of noise.

Be sure gearbox isnt touching against frame.

The brass boiler shell doesn't absorb sound like diecast locos .

I have put blue painters tape on inside of boiler shell to deaden sounds of gear train.

It is a nice loco and worth a little tinkering to quiet it down.

The growling sounds like gear noise. That high pitch wine going forward though.... sounds like an automotive timing chain after it wears through the guides and starts sawing the cover😉

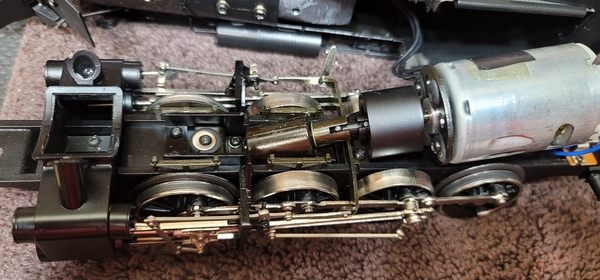

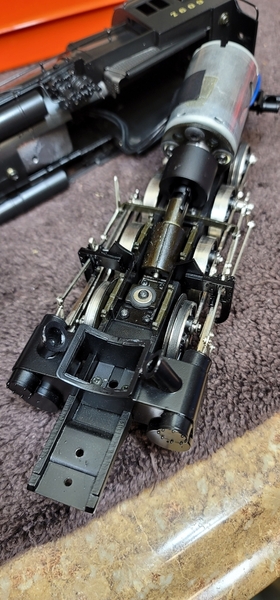

Here are a few pics of it after the shell is removed. I'll have to do more investigating tomorrow. The instructions said it requires "bearing grease" on the gear. Is that standard automotive bearing grease ? Everything else I've ever owned I've used Labelle 106 lithium grease. Thanks for all the suggestions.

Attachments

Does it have Engineer On Board? Some of them make the motor whine.

Is the flywheel out of balance? That will cause a thrumming noise when running.

Also, Fastrack makes everything noisier.

I use Red-N-Tacky, but any grease is way better than no grease! Note of caution, most brass locomotive gearboxes are pretty sensitive to a lack of grease, I've seen a number of them eat themselves! By all means, generously grease that gearbox with some grease!

Also missing one traction tire, and the other one is coming off. Pretty sure it has no bearing on the noise, but…

This brake shoe looks tweaked. Almost looks to be in the traction tire groove and maybe rubbing the rim.

Attachments

Try greasing the gear box, and oiling the ends of the motor shaft. If that doesn’t make any difference, the noise is more than likely coming from that giant Mabuchi motor. Most Weaver & Williams brass locomotives are geared to the moon, and thus the motors scream just to crawl,……some of those engines just simply sound like they’re gonna blow themselves to bits, ……

Pat

Well, I have 4 new traction tires to install tomorrow and if the snow isn't too bad, I'll head out for some grease to pack that gear box and oil the ends of the motor shaft. Then see how she runs. I'll report back. Thanks again to all.

I have several of these Weaver H10s 2-8-0's and they are all silent runners. I never have heard one scream like yours does. They have a 16:1 gearbox so are not "geared to the moon." The high gear ratio Pennsy brass models are the Williams K4's, which have 40:1 gearboxes and the Weaver T1 4-4-4-4 with a whopping 72:1 gearbox. That one does have some motor whine, as would be expected.

This model does not have Engineer on Board, as the photos show no sensor or stripes on the flywheel. I suspect the motor itself could be making that racket. You could loosen the motor mount screws, loosen the small Allen screw that secures the flywheel, slide the flywheel off the shaft (this takes pressure from 2 screwdrivers to pry it forward) and test the motor by itself.

@Bob posted:I have several of these Weaver H10s 2-8-0's and they are all silent runners. I never have heard one scream like yours does. They have a 16:1 gearbox so are not "geared to the moon." The high gear ratio Pennsy brass models are the Williams K4's, which have 40:1 gearboxes and the Weaver T1 4-4-4-4 with a whopping 72:1 gearbox. That one does have some motor whine, as would be expected.

This model does not have Engineer on Board, as the photos show no sensor or stripes on the flywheel. I suspect the motor itself could be making that racket. You could loosen the motor mount screws, loosen the small Allen screw that secures the flywheel, slide the flywheel off the shaft (this takes pressure from 2 screwdrivers to pry it forward) and test the motor by itself.

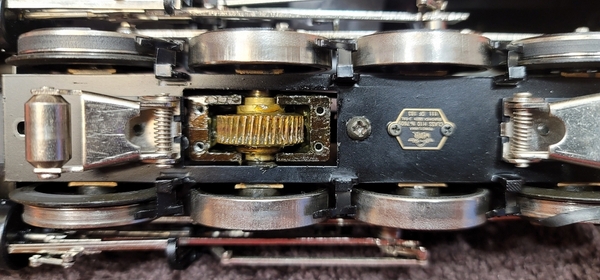

The worm wheel in the pics of that locomotive has very fine teeth. If it were 16:1 those teeth would be far fewer, and further apart,….I’m not seeing 16:1 with that worm wheel…….

Pat

I measured several of the Weaver and Williams brass that came through here, and some did have up to 44:1 gear ratios. With the motor screaming at 8,000 RPM, they were doing around 38 scale MPH. I never saw one with 72:1 gear ratio, that wouldn't have much of a top end I suspect!

@harmonyards posted:The worm wheel in the pics of that locomotive has very fine teeth. If it were 16:1 those teeth would be far fewer, and further apart,….I’m not seeing 16:1 with that worm wheel…….

Right you are, that looks like the ones I'm talking about. ![]()

@gunrunnerjohn posted:I measured several of the Weaver and Williams brass that came through here, and some did have up to 44:1 gear ratios. With the motor screaming at 8,000 RPM, they were doing around 38 scale MPH. I never saw one with 72:1 gear ratio, that wouldn't have much of a top end I suspect!

Right you are, that looks like the ones I'm talking about.

Yes, the caveat being the die cast 2-8-0 that Weaver built with the integral gear box as part of the frame. That locomotive has a better gear ratio not quite as steep as we see in the brass engines……I wanna say the die cast 2-8-0’s are in the 20:1 ratio,…..but clearly the OP’s model is a brass engine, with a fully divorced gear box,…

Pat

You guys are right. I just took one of the Weaver brass H10s models apart and measured the gear ratio. It was not 16:1, but rather 19:1. That concludes this part of the discussion.

If Scott greases and lubes everything, and she still screams, he can swap out the 550 motor for a 555, it won’t cure it, but it may make it a lot more tolerable,…..auction sites sell them for small money, and that’s a direct bolt on swap….

Pat

I was about to go out to home Depot and get some red and tacky grease, but it's snowing quite heavily at the moment and looks like there are quite a few accidents already on the roads. It's supposed to change over to rain later today so maybe this evening or tomorrow.

@harmonyards posted:If Scott greases and lubes everything, and she still screams, he can swap out the 550 motor for a 555, it won’t cure it, but it may make it a lot more tolerable,…..auction sites sell them for small money, and that’s a direct bolt on swap….

I keep a couple of the Mabuchi 550 motors on hand, they're cheap and I see a surprising number of Weaver and Williams steam with defective motors. If free-running they draw more than around 2x what the free-running 550 draws, I swap them out. I've found motors that draw several amps free-running, I expect more like 200-300 milliamps.

@gunrunnerjohn posted:I keep a couple of the Mabuchi 550 motors on hand, they're cheap and I see a surprising number of Weaver and Williams steam with defective motors. If free-running they draw more than around 2x what the free-running 550 draws, I swap them out. I've found motors that draw several amps free-running, I expect more like 200-300 milliamps.

Correct, ….the 550’s I’ve come across are all amp hogs,…..more than likely so they can spin to oblivion because as we noted earlier in this conversation, all those Weaver/Willaims brass engines are geared to the moon,…..you give up a touch of top end speed swapping to the 555, but the trade off is it doesn’t sound like it gonna explode at any given second……those 550’s sound more like a Cessna trying to clear a runway than a model train,…..😉

Pat

The extreme case was a Williams with the 44:1 gearbox, I did a couple for a customer, top speed was right around 40 scale MPH, and they were screaming with the 555 motors.

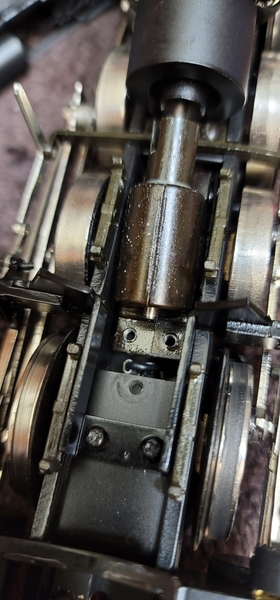

So, packing the gear box with Red and Tacky didn't change anything unfortunately. So, I used the old auto mechanic trick of using a screwdriver to touch parts of the engine and put my ear to the handle to see what made the most noise. The motor was very quiet. The top of the gear box was slightly more noisy, but the screw holding the bracket for the top of the gear box was the loudest. I discovered that if I removed the screw and raised the bracket, the noise lessened. I ended up putting 3 flat washers under the screw and that has significantly reduced the screaming noise. The grinding noise is still there, but over all a lot of the noise is gone. There is still a faint screaming noise. Raising the bracket raises the top gear off the lower gear, so not sure if that is the best solution, but the engine seems to run ok. See the videos for shell off and shell on performance. I'm just concerned that raising the top gear will cause damage. Any thoughts ?

Scott

Attachments

@DFG56 posted:Raising the bracket raises the top gear off the lower gear, so not sure if that is the best solution, but the engine seems to run ok. See the videos for shell off and shell on performance. I'm just concerned that raising the top gear will cause damage. Any thoughts ?

AAMOF, that may be a big problem! ![]() The mesh of those gears is critical, and weaver gearboxes aren't known for their robustness in the best of times! I'd find out what's really going on, but loosening the mesh of the gears sounds like a really bad idea.

The mesh of those gears is critical, and weaver gearboxes aren't known for their robustness in the best of times! I'd find out what's really going on, but loosening the mesh of the gears sounds like a really bad idea. ![]()

That's what I thought you'd say. ![]() Well, then, I'm at a loss as to how to proceed. I don't see anything else that is adjustable or that I can take apart.

Well, then, I'm at a loss as to how to proceed. I don't see anything else that is adjustable or that I can take apart.

The bracket you loosened just secures the gearbox to frame to keep it from tipping forward.

If you have bottom cover on tight and side screws in gearbox tight the gears will stay in correct mesh.

You were going in right direction with your quieting efforts.

@DFG56 posted:That's what I thought you'd say.

Well, then, I'm at a loss as to how to proceed. I don't see anything else that is adjustable or that I can take apart.

What you said about the bracket raising & lowering the worm off the worm wheel makes no sense, all of the years I’ve been doing this, I’ve never seen a gear box with an adjustment screw……I believe the bracket you’re referencing raises & lowers the pitch of the gear box angle. That bracket should “float” either on rubber pads, or on a spring. If you piled washers on it, and in affect, locked it down to the chassis, you’ve effectively put that gear box in a bind. That gear box needs freedom to roam ever so slightly, the drivers are on a suspension system. Thus, the gear box needs to be allowed to follow the suspension travel. The noise you’re hearing now coming from the gearbox is the gearbox in a bind. The screaming noise is coming from that crappy 550 3 pole motor. Perhaps you missed my reply regarding a 555 motor swap. That would be an ok upgrade and will certainly take a lot of the harshness out of that engine. You’re gonna have to reevaluate how you modified that gear box mount, and ditch the noisy 550 motor, otherwise, you’re just banging your head against the wall,…..

Pat

Why does it look like the left rear driver is off the track in your video? I had a Lionel Berkshire new from factory that had a bent frame. They replaced the engine. Trainz might take it back.

Gunny

I was assuming he was tinkering with something that affected the gear mesh, that would be bad. As Pat says, if the gearbox isn't floating, that's a whole different issue.

@gunny posted:Why does it look like the left rear driver is off the track in your video? I had a Lionel Berkshire new from factory that had a bent frame. They replaced the engine. Trainz might take it back.

Gunny

It's because it's missing the traction tire. The one's I have are too big and keep coming off. I'll have to find the right size.

Scott

Well, I took the entire engine chassis apart tonight and managed to put it back together without losing any parts. WHEW !!

The whine is still there, but is better. I'll try playing with the number of washers to get the alignment better. Hopefully that will do it. Time for bed. Back at it tomorrow. Thanks for all your help and suggestions.

Scott

What Pat (harmonyards) said about the gearbox alignment is spot-on. By raising the front of the gearbox, you're actually forcing things into poor alignment. Your loco ran quieter that way, because the "balls" of the dogbone shaft coupling between the motor and the gearbox were constrained and no longer free to rattle around.

One thing to add: I think your existing motor is actually a Mabuchi RS-545. This is a small loco; I don't believe that Weaver used the RS-550 because it didn't fit, so unfortunately the 555 won't fit either. A small Pittman like a 9432 would be a nice upgrade over the stock motor, it would also reduce the top speed a little. But I don't think the motor is where most of the noise is coming from. There are other things you could do to mask the noise. But try to solve the root cause of the problem first!

@Ted S posted:What Pat (harmonyards) said about the gearbox alignment is spot-on. By raising the front of the gearbox, you're actually forcing things into poor alignment. Your loco ran quieter that way, because the "balls" of the dogbone shaft coupling between the motor and the gearbox were constrained and no longer free to rattle around.

One thing to add: I think your existing motor is actually a Mabuchi RS-545. This is a small loco; I don't believe that Weaver used the RS-550 because it didn't fit, so unfortunately the 555 won't fit either. A small Pittman like a 9432 would be a nice upgrade over the stock motor, it would also reduce the top speed a little. But I don't think the motor is where most of the noise is coming from. There are other things you could do to mask the noise. But try to solve the root cause of the problem first!

Ted, the motor in the OP’s engine has the hallmarks of the 550, …..it could be a 545 as you mentioned….the white plastic end cap was the tell-tale for me,….yes, a Pittman would be a superb upgrade, but would require more involved modifications, like boring the flywheel, etc,……

Pat

@Ted S posted:One thing to add: I think your existing motor is actually a Mabuchi RS-545. This is a small loco; I don't believe that Weaver used the RS-550 because it didn't fit, so unfortunately the 555 won't fit either.

I've replaced several RS-545 motors in Weaver locomotives with the RS-555. It's slightly longer, but it managed to fit.

@DFG56 posted:So, packing the gear box with Red and Tacky didn't change anything unfortunately. So, I used the old auto mechanic trick of using a screwdriver to touch parts of the engine and put my ear to the handle to see what made the most noise. The motor was very quiet.

Is there not a bushing on each end of the shaft that the worm is mounted on ? On all the Samhongsa gearboxes which I have worked on the shaft the worm is on has bearings on each side of the worm and they are captive within the clamshells of the gearbox thus the gear mesh is not user adjustable. That screw with spring should adjust the angle the gearbox shafts meets the motor shaft. I cannot be certain but the shaft coming from the flywheel looks to be meeting the worm shaft at quite an acute angle. That would put a side thrust pulling up on the rear bearing of the gearbox. That in turn would be holding the worm against the worm wheel even though the front bearing is not in place. The rear bearing is acting as a fulcrum. Looking at the grease oozing out of the front of the gearbox makes me think the front bearing is not in place on the worm shaft. I posted photos back around 2018 - 19 showing a version of that gearbox where the worm wheel also acts as an idle gear if you want to look at my earlier posts. The worm shaft however has the bearings I speak of showing in those photos. I have to leave now but will return Sunday night and will re-post those pix when I return. The pix in that discussion are of a Williams / Samhongsa loco with a 42:1 gearbox and I have a series of pix showing what I did to eleminate the whine from the mabuchi 550 three pole motor they are quite prone to whine. Five pole motors push less air around and don't whine as much. All said, I suspect you may be missing the front bearing on that gearbox. j

@JohnActon posted:Is there not a bushing on each end of the shaft that the worm is mounted on ? On all the Samhongsa gearboxes which I have worked on the shaft the worm is on has bearings on each side of the worm and they are captive within the clamshells of the gearbox thus the gear mesh is not user adjustable. That screw with spring should adjust the angle the gearbox shafts meets the motor shaft. I cannot be certain but the shaft coming from the flywheel looks to be meeting the worm shaft at quite an acute angle. That would put a side thrust pulling up on the rear bearing of the gearbox. That in turn would be holding the worm against the worm wheel even though the front bearing is not in place. The rear bearing is acting as a fulcrum. Looking at the grease oozing out of the front of the gearbox makes me think the front bearing is not in place on the worm shaft. I posted photos back around 2018 - 19 showing a version of that gearbox where the worm wheel also acts as an idle gear if you want to look at my earlier posts. The worm shaft however has the bearings I speak of showing in those photos. I have to leave now but will return Sunday night and will re-post those pix when I return. The pix in that discussion are of a Williams / Samhongsa loco with a 42:1 gearbox and I have a series of pix showing what I did to eleminate the whine from the mabuchi 550 three pole motor they are quite prone to whine. Five pole motors push less air around and don't whine as much. All said, I suspect you may be missing the front bearing on that gearbox. j

Thanks John. I did not find your previous posts, so if you have any pix showing how to work on this gearbox, I would appreciate them.

Scott

Scott, I'm not at home yet however the gearbox is easily removed. Remove the bottom cap and the gearbox lifts off . Then the two halves of the clamshell are held together with a couple screws. There are likely some screws which connect the gearbox to that arm with the screw and spring which come loose also. j

I have Weaver A-5.

It makes gear noise going forward, but not backward.

Took it apart, thoroughly added grease by removing the plate that covers the bottom of the gear box (4 tiny screws.) Lubricated everything that I could access from inside.

No improvement noise wise. Grease pushing out front of gear box. Suspect front bearing missing.

It appears that further disassembly of gear box requires dropping the geared axle and gearbox out of the frame to open gear box.

That is beyond my pay grade.

I will have to live with the noise!

@ctr posted:I have Weaver A-5.

It makes gear noise going forward, but not backward.

Took it apart, thoroughly added grease by removing the plate that covers the bottom of the gear box (4 tiny screws.) Lubricated everything that I could access from inside.

No improvement noise wise. Grease pushing out front of gear box. Suspect front bearing missing.

It appears that further disassembly of gear box requires dropping the geared axle and gearbox out of the frame to open gear box.

That is beyond my pay grade.

I will have to live with the noise!

If there is a removable cover on the bottom of the gearbox once it is removed then the top of the gearbox lifts off from the top side of the frame. However the boiler must be removed to do so. j

I mentioned yesterday that I would post some photos of the inside of another Samhongsa gearbox. Though the box I show is different than the one in Scott's loco it shows the bearings which appear to be missing on the front of his loco's gearbox. I don't think I have seen grease ooze out in the volume showing on his loco on any loco I have owned. Let me add some context to the gearbox photos I am posting. A couple of years ago we were having a discussion about the Williams, Weaver / Samhongsa gearboxes and I was trying to show how little difference there was between the 42:1 and the 21:1 version of the similar gearboxes. The primary difference was that the 42:1 version has a single helix worm and the 21:1 version has a double helix worm. A single helix moves the worm wheel 1 tooth per worm revolution and a double helix moves the wheel two teeth per rev. The second difference is that the teeth on the worm wheel have a different skew angle. For our trains, a typical skew angle on a worm wheel's teeth for a single helix worm is about 5degrees and 10degrees for a double helix. You can see the difference in the photo where I placed a straight wire between the worm wheel teeth on the two gearboxes. Since I cannot see what is inside Scotts gearbox I cannot be assured that the worm is as contained as the one shown in my gearboxes you could remove the bearings from my gearboxes and the worm would still mesh with the teeth of the worm wheel till the teeth were chewed up. Thus the grinding sound that several people have spoke of. I made some notes on a couple of my pix which I emailed to a supplier in Korea to see if they could supply said parts. They could not. Though Samhongsa made some very nice locomotives their quality control was not always what it should be. I would not be surprised if some gearboxes left the factory missing a bushing or having the worm wheels mismatched with their worm. I ran into that problem on the two gearboxes shown here the 42:1 and had a single helix worm and a worm wheel with the skew angle which matched the double helix and the 21:1 box had double helix worm and a worm wheel for a 42:1 box. If you look at my pix you will see that the parts are marked with red and green markers. I did not want to mix any parts up so I removed and cleaned one gearbox and marked it's parts with red before I removed and cleaned the second gearbox parts and marked them with green. These locos were bought new in the box from different dealers years apart and this was the first time the gearboxes were removed. So there was little to no chance anyone swapped them after they left the Samhongsa factory. The two locos seemed to run fine with the wrong worm wheels but no doubt they would have wore out sooner as the contact patch where the teeth mesh was smaller on the mismatched gears.. I did swap them before I reassembled the respective gearboxes. Surprise,, the current draw and start voltage both dropped in the locos which I swapped the worm wheels. j

Attachments

Wow, John. What a great description and pictures.

Let me ask this. Over the weekend I was able to adjust things with a flat washer on top and bottom of the worn out rubber bushing on the screw that holds the top part of the gear box to the frame. This corrected the angle of the dog bone connecting the motor to the gear box. So, now, there is almost no noise. Absolutely nothing like the screaming and grinding I started out with. The bearing grease is still coming out of the bearing hole though. You make the comment that without the bearings, the teeth will eventually grind themselves to pieces. If I (again) disassemble the engine and open the gear box and find the bearings are missing, where would I find new bearings ? Also, Trainz responded to my email offering to fix, give a refund, or exchange if I so desired. I really like the engine, but don't want to chance the gears grinding themselves to dust, or going to the trouble of opening everything up and not being able to replace the bearings. I'm contemplating sending the engine back and seeing if they can take it apart and replace the bearings, or just get a refund and look for one that doesn't have this issue.

Scott

Scott, I seriously doubt your engine is missing the bearings. That thing would be carrying on ferociously if even just one was missing. The reason you’re seeing grease ooze out the nose of that gear box is because it’s not a 100% sealed unit. The worm shaft in the gear box becomes a very effective pump impeller. So the grease is pushed towards the front of the enclosure. Beings there’s no seals, any tiny gap, and the grease leeches out,….it’s only going to spit out what it can’t hold, and eventually, the oozing will stop,….

Pat

Really glad that you were able to tame the noise. I wanted to share two more ideas in this thread for your consideration, and for future reference. First: From the photos, it's evident that the horned balls of your dogbone shaft rotate in a parallel plane. Some folks swear that the horns should be at right angles to each other, to discourage the shaft from "ping-ponging" back and forth between the U-joint cups. It's not difficult to make a new shaft, or even to cut your existing one, sleeve it, and reassemble with epoxy at 90 degrees. Heck, some people use Toyota or BMW #0 vacuum hose to connect the motor and gearbox shafts, doing away with U-joints altogether. If the hose has a snug fit, I would bet that this is very quiet, and the elasticity of the rubber might allow the motor to get a "head start" against the load when the slack is stretched. Food for thought...

Second idea: This Weaver loco, and many of the Williams that hit the Forum with noise complaints are made of BRASS. There's a reason they don't make tubas out of die-cast metal! Brass resonates, and it will amplify any mechanical noise or vibration. Auto sound and car customizer stores sell a material called DynaXorb which is a soft rubber matting used for sound attenuation. You can buy it in one foot squares with adhesive backing. A small rectangle of adhered to the inside of the boiler does a lot to mask the noise. But as I said, you should address the root mechanical causes of the noise first, instead of just trying to cover it up.

Also, did we ever figure out what kind of motor your loco has? Good post!

Scott the outer side of the bearings are likely flush with the side of the gearbox and should be visible if you wipe the grease away. Take a toothpick or small screwdriver and see how far you can push it into the opening that grease is coming from. The amount of grease oozing out is such that the bearing if there is wore out or perhaps the grease is coming from around the outside of the bearing. The bearing and it's seat can wear just like the hole the the shaft passes through. The rear bearing and it's seat in one of the Williams 42:1 gearboxes I own was wore to the point the bearing was spinning in it's seat. However grease never flowed out the way it is on your loco. Perhaps you overstuffed the gearbox when you greased it. I took some shim brass and cut a 3/16" X 3/4" wide ribbon and formed it around the outside of the bearing and clamped it between the two clamshell halves it stopped the bearing from spinning yet there is still some float so the bearing can align with the shaft without binding. As far as new bearings go I was asking myself the same thing as I was patching my gearbox. The shaft the worm is on is metric guessing around 3mm (not going to pull a body off tonight to measure) and ball bearings are available starting around 1mm ID so I'm fairly sure with some searching you can find an ID which matches the worm shaft diameter. They even come with flanges which would be a big help. I think that is the direction I am going. However a thought I had a time or two is to try modifying a pair of the bushings from an American Flyer Alco diesel motor. The hole in them is near ,122" which is about .002 larger than 3mm they might work. Think I like the idea of ball bearings better. Also; I think Ted is on to something about using vacuum hose between the flywheel and the worm shaft. I was having a time quieting down my Williams PRR 2-8-2 with a 42:1 gearbox and I removed the dogbone shaft then substituted some 1/4" OD silicone tubing it made a big difference. I had to insert a snug fitting piece of brass tubing down the middle to keep it from stretching and bowing out at high speeds but I cut the brass tube so it did not touch the flywheel or the worm shaft and I floated the motor in 1/8" thick foam tape like the heating / air-conditioning people use. Loco is quiet enough now that the wheels rolling on the track drown out the gearbox and motor. Another thing I did was to line the boiler with that foam tape like Ted suggested. The 42:1 gearbox and having to spin the motor at 10,000rpm to drive 45smph can make quite a noise but I no longer hear the motor and gearbox I only hear the wheels roll. One forgiving factor I was able to get away with a 385 motor because the 42:1 box creates 2.5 x the torque as a typical MTH 16:1 box. Isolating the motor from any metal to metal contact with the boiler and chassis was of prime concern you can see the foam surrounding the motor. Same foam I used to line the boiler. j

Attachments

Thanks to everyone for all the great information. I thought I knew something about repairing Lionel and American Flyer engines, but you guys are the true gurus of train repair. I opted to return the engine to Trainz as they were gracious enough to take it back. I have to say that I am impressed with their customer service. I have purchased a number of items from them over the years, and this fortunately was the only item that had an issue. So, kudos to Trainz.com and thanks again to all of you. I learned a lot.

Scott