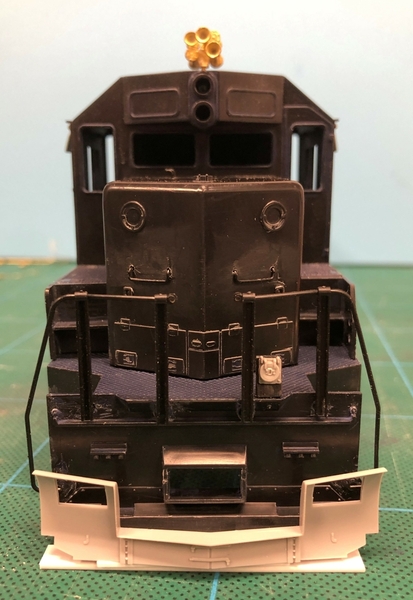

Hello 2-railers! I picked up a Weaver Missouri Pacific GP38-2 a few days ago. After repairing a broken u-joint, it now runs well.

I've read that it's not an accurate model of a GP38-2, but the price was right. There are a few things I plan on changing: Mopac GP38s & GP38-2s did not have dynamic brakes, so I'll make this one non-DB. I plan to shave off the molded grabs and add wire grabs, and maybe add lift rings. I'll add cab window glazing, sunshades and replace the fans. The blue paint Weaver used is too dark, and the road number font and spacing is incorrect, so I'll repaint it in Modelflex 16-86 Mopac Blue and add some custom decals. I'm planning on renumbering it to MP #2137:

http://www.rr-fallenflags.org/mp/mp2137amr.jpg

It won't be perfect, but will be a little closer to what Mopac had.

Question: The previous owner had glued the delrin stanchions to the sill, which were broken in a few spots. I plan to upgrade the side handrails to brass wire with either Precision Scale brass or plastic stanchions. Has anyone used Precision's plastic stanchions and how they hold up versus brass? Any feedback is welcomed.

Thanks!

Tim