Hi Chris, thanks for the picture of your jig! You wouldn't happen to have a picture of your table saw setup would you?![]()

Fine tuning track work before adding scenery was in order this week. The double track, which will be visible when scenicked, required attention, whereas the single track will be hidden. Making a scale GG1 successfully negotiate superelevated S curves on a grade took some doing.

After the initial GG1 test, other bad actors on the layout were tried over the same section, just to confirm the sound construction. I now sleep better at night.

Bruce

Mike, I will take some photos of the table saw set up later today and post.... Been meaning to do this but haven't gotten around to it.....

The super elevation looks good Bruce. Always wise to check clearances many times before and during scenery construction.

Bob

RSJB18 posted:The super elevation looks good Bruce. Always wise to check clearances many times before and during scenery construction.

Bob

I hear you there, Bob. I manually test clearances with 2 K-Line 21" cars. Many adjustments have been made since beginning train operation but I seem to be nearing the end of major realignment. Adding scenery and catenary comes next.

Thanks!

Bruce

brwebster posted:Fine tuning track work before adding scenery was in order this week. The double track, which will be visible when scenicked, required attention, whereas the single track will be hidden. Making a scale GG1 successfully negotiate superelevated S curves on a grade took some doing.

After the initial GG1 test, other bad actors on the layout were tried over the same section, just to confirm the sound construction. I now sleep better at night.

Bruce

Great work, bruce! Love especially the Flying Yankee beautifully restored.

Pete

Great scenes Everyone, Mike G, I just went back in this topic to review your New Train Room, it’s looking great, and I wish you good luck while working in this new train room. Elliott, Big Boy 4005, I am so sorry to hear about your toe incident. Hopefully, Lord Willing, your doctors and their staff will fix you up. Your layout is Magnificent. Keep us posted....Paul 2, all I can say is Wow, the scenic building flats are looking good....Chris A, Your scenic detailing and buildings are very realistic. I love the retaining wall very much, as well as the scenic background. Wow. There are sonany beautiful pictures on this really long thread...Trumptrain and Briansilvermustang, Your Layouts are so Feature rich. And Moonson, Your Layout looks so real, I firmly agree with the fellow that related your work to the great HO layout, Franklin and South Manchester, (possibly mis-spelled this). I have the video on that layout, it’s a masterpiece...Happy Railroading fellows...

Attachments

Attachments

Thanks for your concern and well wishes. I think I have a plan where I can get down the basement and move around just enough while staying off the foot after the surgery. I'll take the stair lift up and down, and use a rolling office chair while I'm down there, to get around.

Bob - That's just it, the size of the layout was behind the accident. I had been working in that area, but knew the track was clean there. I had seen the stuff sitting there, but forgot. When I was running the train, I was coming around from the opposite direction, and thud.

Mike - I have enough engines, but many of them have difficulty making it around the layout smoothly. The one I fried was one that did go all the way around. I think the one I grabbed to replace it should work. I've got to get down there tonight, and finish the run to make sure things work for tomorrow and next Saturday.

Ray - If nothing else, I can park it up by the roundhouse. It looks fine. The last two weeks have been crazy between dialysis and all my doctor visits. Last week I had something every day except Sunday, and that was my nephew's graduation party. Then I've had something every day this week too. It will be a little quieter next week, maybe.

Pat - Thanks, but the toe is mine. Brian is too smart to step on a nail.![]()

John - Train running isn't really in the cards. This layout isn't one that you can set and forget. It takes constant monitoring, and there are switches that need to be thrown. That means moving around. I may finish building my signals, put away a bunch of papers, and perhaps work on a little scenery. I could also unpack some trains.

Doug - Thanks, me too. There's a lot I want to get done before the before the convention. Some of those plans are out the window now, but others can still get done.

Larry - Thanks, I do all of my medical stuff at the University of Minnesota. They are fantastic! A number of my doctors are heads of their departments. Doesn't get much better than that. They do a lot of pioneering work there. I'm in good hands.

Great work, bruce! Love especially the Flying Yankee beautifully restored.

Pete

Thanks Pete. Just in case you are interested, the Yankee Flyer is a modern MTH Premier rendition.

Bruce

brwebster posted:Great work, bruce! Love especially the Flying Yankee beautifully restored.

Pete

Thanks Pete. Just in case you are interested, the Yankee Flyer is a modern MTH Premier rendition.

Bruce

I picked up an old Yankee Flyer motor in a box of junk motors. It looks repairable, but I would need to find old parts. How does the motor on the YF remake compare to the 1938 motor?

Bruce the track looks great. You should be able to have some great action in the attic!!

HCSader73 posted:brwebster posted:Great work, bruce! Love especially the Flying Yankee beautifully restored.

Pete

Thanks Pete. Just in case you are interested, the Yankee Flyer is a modern MTH Premier rendition.

Bruce

I picked up an old Yankee Flyer motor in a box of junk motors. It looks repairable, but I would need to find old parts. How does the motor on the YF remake compare to the 1938 motor?

This I do know, they are 2 completely different animals Pete. I couldn't say for certain what available parts might interchange with originals from 1938.

Bruce

Mark Boyce posted:Bruce the track looks great. You should be able to have some great action in the attic!!

Thanks so very much, Mark. Coming from you it means a lot.

When initially designed, this area was envisioned as having most of the track hidden by mountainous terrain. After dragging a 30 car freight through the twisties a few times,I realized the view needs to be left unimpeded.

Bruce

There is nothing similiar between the old and new flying yankees. The MTH has two motors,

one in the loco, and one in the obs car. They each have their own electronic reversing unit.

Somehow the ones in mine got out of sync and there was no way to resync them. The

train was unusable because one motor was always doing something the other wasn't.

Called MTH, too bad, so sad. Last MTH I ever bought.

So here are some photos of the zero clearance plate I made for my table saw, the thin Kerf 7 1/4" saw blade I am using to cut small parts and also plastic walls, roofs and parts during kit bashing.... This really stops any small parts that I cut from falling through the gap or worse getting in the gap and binding up.

I also included some other photos of some set ups you might find useful, if you open the photo attachments there are some labels on the bottom of the photos to help describe what it's used for.

There are some photos of a cross cutting sled which I used to cut the 100 + oak planks for the loading dock on the mine run building... Not a good application for the chop saw..... the sled works really well as it moves with the miter gauge that runs in the tracks in the table top. by adding a stop to it I could cut about 4 or 5 at a time, move the sled in cut off 5 and then pull them back toward me. If it's not obvious, you have to use one hand to hold the parts your cutting firmly, so you can cut them on the way "in", and remove them safely on the way "out, back".... It helps alot to have the stop moving with the sled so the parts remain at 90 degrees and don't shift.

Take it from someone who has been using table saws since going to the high school woodshop all summer long in the 1970's for Summer School.. Always wear Safety Glasses... I got lazy, and LUCKY, about 4 years ago ! An employee of mine dropped a carbide tooth saw blade by accident on the plywood floor in the mobile shop, I put it in the saw and started cutting with it. One of the carbide teeth came off and hit me in the forehead about an inch and a half above my eyes... Huge WAKE UP CALL for someone who was starting to get lazy about always wearing glasses...

Anyway, these set ups (pictured below), work well, on my cast iron Craftsman Table saw. I found that 5/16" thick Baltic Birch plywood was a perfect match (thickness) for a plate, Baltic Birch is 5 ply plywood really stable, never warps. Traced the original steel plate, cut it with a sabre/jig saw, sanded it smooth by turning my belt sander on it's side and using it like a bench sander.... Could be done with a sanding block and bench vise. Once it fits the oval opening, install it, put the rip fence over it, turn on the saw and raise the blade through the plate. Depending on what make saw you have, you might find a replacement plate already properly sized at Rockler Woodworking, I know I have seen them sell "blanks".

I also found the need to make a second rip fence liner so I could bring it down to the table top with NO GAP, I had some thin wood and plastic parts get under the gap on the factory fence. Tried taking the fence apart and moving the rail to the lowest positions, but I still had a gap of around 0.040 inches....

Attachments

beardog posted:There is nothing similiar between the old and new flying yankees. The MTH has two motors,

one in the loco, and one in the obs car. They each have their own electronic reversing unit.

Somehow the ones in mine got out of sync and there was no way to resync them. The

train was unusable because one motor was always doing something the other wasn't.

Called MTH, too bad, so sad. Last MTH I ever bought.

No sync cables between the cars? I know my Electroliner and Liberty Liner have 'em...

-MMM-

maybe this was earlier?

They acknowledged the problem, just would not do anything

Attachments

M. Mitchell Marmel posted:beardog posted:There is nothing similiar between the old and new flying yankees. The MTH has two motors,

one in the loco, and one in the obs car. They each have their own electronic reversing unit.

Somehow the ones in mine got out of sync and there was no way to resync them. The

train was unusable because one motor was always doing something the other wasn't.

Called MTH, too bad, so sad. Last MTH I ever bought.

No sync cables between the cars? I know my Electroliner and Liberty Liner have 'em...

-MMM-

Mitch, Ron P. here. Just Got back from 2 wks out west. In a store in Law Vegas there was a 7 ft tall giraffe made out of spark plugs. I will post pictures soon. Pretty neat!!!!!!! I love your posts.

Got three more flats done tonight. Only have five more to do. Making up some different sized pieces to get into the smaller areas helped save some time. I might just be able to finish the five tomorrow. Thanks Chris for all the help with this answering my questions on this project. Pic..................Paul

Attachments

BRWEBSTER, Looks good! Its always a good idea to check clearance along the way! I know form my last build! But that's another story! LOL![]()

LEAPINLARRY, Don't cut yourself short! You have one of the nicest layout I have seen on here, really something to be proud of!![]()

CHRIS A., This is such great information you are sharing with the rest of us! I know table saws are full of danger after running the tip of my thumb threw one last fall! If time permits I will try and build a new plate today and work on a cross cut sled! I do have a question, can you explain how the system is working in picture #5? Thanks again for all the great information you share here on the forum!![]()

GANDYDANCER, just as always wonderful looking pictures of your layout!![]()

PAUL2, The flats are looking great, at this rate you will have one huge city scape! I have to agree with you about ChrisA. He is great with sharing information, which in turns helps the rest of us have an easier time building!![]()

As for me I got the last piece's of sheetrock in place and the first coat of mud on! But before I closed everything up I put a few things in the train room time chest. I put an S scale crane car, and envelope with the story of the build to date, Pictures of my wife and Tank, and one of me with Tank. Sealed it up and put a picture of Tank on the outside guarding everything! Here are a few pictures.![]()

Attachments

Mike- great stuff for the time capsule!

Paul- the flats are coming along nicely, can't wait to see them on the layout.

Chris- I'm with you on table saw safety (all tool safety for that matter). I've also been using them since high school and they still get my total respect. I love the jigs. I recently finished a big project in my house (aka- "The CEO's PROJECT") and I made several jigs along the way that will go into storage if I need them again one day.

Bob

Attachments

Mike: Photos 5, 6 & 7 are trying to show a safe way to cut small stock - around 1/16" thick clearance between the blade and the ripping fence. The notched piece of pine is keeping the stock pushed up against the fence and also down on the table top.... It should be placed over stock, and kept right where the cutting starts, so for longer pieces, the pine block is being held in the same position, the stock you are cutting is sliding under it.....The Oak pusher behind it is used to get it through the cutting blade, so it can be pulled out from the exit side.

So as pictured, with the fence to the right of the blade, it's right hand on the oak block, left hand on the notched pine block. The pine block should never go past the blade until you are almost done cutting and the oak block is pushing both the stock you are cutting and the pine "holding" block. In the piece shown, I took some 3/4 inch stock and first ripped off 1/4 inch x 3/4 inch stock, then laid the 1/4 inch stock flat on the table top and ripped it again in 1/16" x 1/4 " pieces, approx 3" x 12" in O scale.... I find it better to use oak for the pusher blocks, if you use 3/4 or 1" white pine the small 1/16" thick piece won't last very long which is what is going between the blade and the fence to push your work through.... So you can use pine, but you will want to have a few pieces available as once it breaks off, you need a new pusher block. You can also keep rotating it and use all 4 corners before you have to cut off all the rough broken edges.

Attachments

Mike, that is way cool. You are the first one I know of that when building put a time capsule in during construction. You have to feel good knowing the drywall is done...........Paul

Thanks Chris, I didn't know the oak block was being used for pushing, so the notch pine is like a feather board? Thank you again I have learned some much for you!![]()

paul 2 posted:Mike, that is way cool. You are the first one I know of that when building put a time capsule in during construction. You have to feel good knowing the drywall is done...........Paul

Thanks Paul, but I still have another coat of mud to put on the wet sand before primer and paint! I hope to have the mud done this weekend, then all work stops for 2 weeks cause we have a lot of people coming for the 4th and longer. My Daughter and her family are going to be using my train room as a hotel cause of the amount of people staying here! I hope its still in one piece when the 4 grandkids are done in there! LOL![]()

Mike, exactly... you got it. Feather board is exactly right term !!!

One other quick hint.... not necessarily for this set up.. but I learned the hard way that "pusher sticks" should NOT HAVE ANY 90 degree corners on the side you are "pushing with", you don't have to sand it into a work of art, but at least chamfer off sharp 90 corners.... Had one kick back out of a saw 12 years ago when I was building a doll house for my daughter, end up cutting up my forearm pretty good even with a heavy weight sweat shirt on....

Point taken Chris! Right now I just use the one that cam with my table saw, I thought about building one out of wood with a handle on it. I am always building something around here! LOL![]()

mike g. posted:As for me I got the last piece's of sheetrock in place and the first coat of mud on! But before I closed everything up I put a few things in the train room time chest. I put an S scale crane car, and envelope with the story of the build to date, Pictures of my wife and Tank, and one of me with Tank. Sealed it up and put a picture of Tank on the outside guarding everything! Here are a few pictures.

Mike,

I've been waiting for this post on the "Time Capsule" to see what your plan and choices were going to be. Tank guarding the family & train room is a great idea. Thanks for sharing and continued good luck.

On 6/26/2018, I wrote:

"Working on the smoke unit of my Lionel 18009 NYC Mohawk, to improve smoke output. Now I have to make some time to visit an auto parts store and get some liquid gasket, to replace the gasket on the smoke unit that always breaks when you take it apart."

Yesterday, I finally got the chance to finish the job. For those who are looking to make their 18009 Mohawks smoke better, I recommend checking out the thread at:

https://ogrforum.ogaugerr.com/...ly=71819767851650702

In my case, following the comments in that thread, I:

1: Opened up the output hole at the base of the "stack" output tube. As it came from the factory, the hole was very much smaller than the tube itself. My guess is that this was to provide more "smoke" to the cylinder smoke manifold.

2: Since I never cared much for cylinder smoke anyway, I removed the manifold and plugged the hole in the smoke unit that feeds smoke to it with a bit of cork.

3: I decided that using liquid gasket compound to reseal the smoke unit when I was done would be too permanent and hard to remove, should I need to open it up again in the future. So I used black silicone seal instead. It seals just fine, and wouldn't be difficult to remove if the need arises. I let it cure for about an hour.

After reassembling the Mohawk, I powered it up and set it out with a Lionel REA express reefer and five Atlas 60' NYC passenger cars behind. It sure smokes now! Mission accomplished.

Next step: to install the Evan Designs LED I just ordered in the headlight, replacing the stock GOW light bulb.

Pretty much nil activity around here. Even with A/C, the house is kinda muggy for doing work in the workshop. Got Beardog's package, chock full of interesting goodies...I think some of the items may find their way onto the For Sale forum at some point.

Did a little work on my Hogwarts Express down at the A&M Museum this week; the drivers were slipping, so I reversed the traction tires, which helped somewhat.

Shop Supervisor Norma Bates Kitteh decided to do an extended sabbatical from last Sunday to last Thursday, which prompted the usual calls to the animal shelter, neighbors et cetera. She's back and confined to the house for the time being.

Other matters are still ongoing; have a look at my profile if you care to. ![]()

Mitch

M. Mitchell Marmel posted:Shop Supervisor Norma Bates Kitteh decided to do an extended sabbatical from last Sunday to last Thursday, which prompted the usual calls to the animal shelter, neighbors et cetera. She's back and confined to the house for the time being.

Glad to hear you got your fuzzy friend back, Mitch. All of ours are indoor-only, but a few years ago, one did manage to get out. He was gone for three days, but finally showed up again on a Sunday night at around midnight, dirty and hungry. He hasn't repeated that performance.

--John

Managed to get two more done. That leaves three more to go then I brush them down with a foam applicator and then seal the flats. Once that ries I'll apply a dilute wash of water and black indigo ink. Pic.............Paul

Attachments

Mike, Great choices for the time capsule!!!! Good spot for them!

This Carolina Craftsman Kit for the mill includes their separate sale 20 foot mill wheel kit. I didn't know this wheel kit existed, when l bashed and scratched several other mills with wheels of different sizes including very large, as seen on some mills l have visited. This kit wheel is much more detailed, down to bolts for the spokes, than mine. I am happy with my method, though, for before developing it, l was stymied as to how to build a decent looking round wheel. This one takes more time to build, but will stand a much closer inspection. I have the paddles all in place today, the most difficult part. The other parts of the mill building is roofed and windowed, but need chimneys and other small details. This did get a minor bash in how the building sections go together.

Mark, Thanks on your thoughts of the time capsule, It was arrived from different ideas of a lot of folks here. I put it at the top of the wall cause if it ever comes down I don't want it crushed at the bottom!![]()

Paul, The flats are getting there! You better slow down or you might run out of things to do! LOL![]()

Oh wait your building a Train Layout, You will never run out of things to do! LOL![]()

Colorado Hirailer, sounds like a nice kit, Please post some pictures when you can!![]()

Attachments

A feel good day today. I got the last three buildings flats mortared. Now I can start brushing off some of them to apply a sealer. I am glad this tedious job is over with. My eyes were starting to cross LOL. Pic.............Paul

Attachments

Paul, Congratulations on the final flats!! It will be good to move on to the next step for sure!

Looks like a great day for train running, Beardog!!

I think it was BEARDOG that told me to use rite die and make the pieces of wood more to scale. Got a pail and made up the die and soaked the wood. Now I have it drying in the kitchen by the sink. Have this great CEO that doesn't panic when I do stuff like this in the kitchen. Plus I put Masonite down with newspapers on top of that. Now I can go back to working on the flats. Pic................Paul

Attachments

Looks like creosote now, Paul! Looking good!! ![]()

With the wood dyed and drying I gather all the flats and went outside and gave them two quick coats of sealer. Once they dried I brought them back in the house and tomorrow morning I'll give them a wash of dilute indigo ink and then they should be ready for windows and gluing sections together. Pics.............Paul

Attachments

Painted telephone poles, worked on farm scene, and of course ran trains. Because I don't have storage shelves or display cases, I have decided to switch out my motive power on a weekly basis to keep a current going through them. There are units that haven't been on the rails in 5 or 6 years (not good)!

Dave

Attachments

Great looking poles!! I really like the farm scene! It will be good to get some of those engines running again!!

Mark Boyce posted:Great looking poles!! I really like the farm scene! It will be good to get some of those engines running again!!

Thanks Mark!

Paul, the flats are going to look wonderful, it is nice to see this stage of your mission coming to an end! The timbers should look great once you have them cut and your stock pile bins built, Nice WORK!![]()

Lovindemtrains, the polls look great, but I have to say I really like the farm scene with the back drops, THey fit right in! Just wonderful!![]()

Great work is being done by all! Its nice to check in and see all this great work! As for me I just got the second coat of mud on the train room sheet rock. I am going to try and get in there before the kids come to wet sand it so it will be ready for primer and paint after the 4th!![]()

Attachments

luvindemtrains posted:Painted telephone poles, worked on farm scene, and of course ran trains. Because I don't have storage shelves or display cases, I have decided to switch out my motive power on a weekly basis to keep a current going through them. There are units that haven't been on the rails in 5 or 6 years (not good)!

Dave

@luvindemtrains Dave, where did you get that backdrop? On my phone i really had to look close to see where your model ended and the background began. Very nice work!

John D. posted:luvindemtrains posted:Painted telephone poles, worked on farm scene, and of course ran trains. Because I don't have storage shelves or display cases, I have decided to switch out my motive power on a weekly basis to keep a current going through them. There are units that haven't been on the rails in 5 or 6 years (not good)!

Dave

@luvindemtrains Dave, where did you get that backdrop? On my phone i really had to look close to see where your model ended and the background began. Very nice work!

Good Morning John. I appreciate the compliment. The backdrop came from backdrop warehouse.

Dave

NYC Lakeshore Limited circa 1956.......

Attachments

Yesterday, I dropped my entire layout from 44" to 36". I also put casters on the new legs to enable me to move the layout for access purposes. I added 2 locking casters to the front corners. This was a project I've been wanting to get done for a few weeks now but finally was able to get done yesterday.

Man i'm glad that's over!!!

Luvindemtrains, that is a great scence. Once you add some more foliage you won't be able to tell where the backdrop does start. What is the size of that backdrop, height and length?? Mike good to hear you are now in the final stages of mudding. Elliot impressive work on the ballast. You have set some pretty lofty goals for us. Also Elliot I need your address so I can put it in my GPS. You can send it to my email.....pstackow@yahoo.com. Looking forward to seeing your layout and meeting you in person. Today I was all ready to start the wash on the flats when I realized that I forgot to add concrete paint to the tops of the flats. So right now I have them drying. So later today I'll appply the wash. Also have to start gathering things for the trip to the Menards train show in Eau Claire. Was going to go on Friday but now going on Thursday and take two days to get there.....................Paul

Thanks Paul. The height is 36" and that scene is a just over 4.5 feet so I believe I purchased it at 6 feet long which is shortest length you can purchase from BW.

Dave

John D. posted:luvindemtrains posted:Painted telephone poles, worked on farm scene, and of course ran trains. Because I don't have storage shelves or display cases, I have decided to switch out my motive power on a weekly basis to keep a current going through them. There are units that haven't been on the rails in 5 or 6 years (not good)!

Dave

@luvindemtrains Dave, where did you get that backdrop? On my phone i really had to look close to see where your model ended and the background began. Very nice work!

Yea, totally agree. Thats a great backdrop for the scene. You'd have to look a couple of times to determine if the house on the left was on the backdrop or not. Really nice!

MJCAT thank you much...mission accomplished, lol!

Dave

I suppose those of you in the East are fighting the heat just like me. Was forced to crank up the AC in the attic train room this morning to help maintain comfortable temps in the rooms below. Now there's no excuse to postpone further layout construction. First on the list is to ballast that track I did final adjustments to. It looks as if more home made ballast will need to be produced to complete the job. The hot, sunny weather should help speed up the process.

There ya go, man. Keep as cool as you can.

Bruce

brwebster posted:I suppose those of you in the East are fighting the heat just like me. Was forced to crank up the AC in the attic train room this morning to help maintain comfortable temps in the rooms below. Now there's no excuse to postpone further layout construction. First on the list is to ballast that track I did final adjustments to. It looks as if more home made ballast will need to be produced to complete the job. The hot, sunny weather should help speed up the process.

There ya go, man. Keep as cool as you can.

Bruce

Stay hydrated, Bruce! Drink lots of water and eat fruit. Friend of mine, who is a kidney doctor, says we guys tend to damage our kidneys because we get dehydrated easily. Soda pop is carbonic acid, not water. Alcohol dehydrates, so beer isn't the answer (darn!). Caffeine dehydrates, so coffee isn't the answer. So lemonade if you don't have sugar issues, and water for all.

Thanks for that important information, Pete F.

FrankM

Brian, Great engine shoot! A man that has everything in trains does show class! LOL![]()

GANDYDANCE1950, You never stop to AMAZE!![]()

Jim, sure sounds like a lot of work! Question did you shrink or did you get shorter visitors? LOL![]()

Paul, its a good thing you found it before you sealed them! Have a fun time at the Menards show and please make sure you tell Dad HI!![]()

Peter, that is great information, but I don't think its going to help me cut back on my beer! LOL![]()

Mike, glad you got the second coat done. Hope to be ready to prime after the 4th. ![]()

Howard, another great scene as always!

Paul, I often get caught with gotchas, I'm glad you caught the concrete tops now!

Yes the heat is a problem, though it is cool compared to what our friends in the southwest experience. Yesterday it hit 90 degrees, about 70 percent humidity. There are some summers we never see 90 here. My wife was watching the Pittsburgh news, and they forecast several days 90 to 92, but it is always hotter there than here. Thunderstorm just came up; I just brought the flag in.

After some busy days going through stuff at may parents' house in preparation for the salvage folks coming and hauling the unwanted away, I was ready for trains. I did a bit yesterday running various engines and posted a few on the For Sale forum. I wrapped up a couple deals after mowing this morning. A wonderful non-powered unit and caboose are still available.

Attachments

JIM HORNADAY 062618 posted:Yesterday, I dropped my entire layout from 44" to 36". I also put casters on the new legs to enable me to move the layout for access purposes. I added 2 locking casters to the front corners. This was a project I've been wanting to get done for a few weeks now but finally was able to get done yesterday.

Man i'm glad that's over!!!

Drat Jim, I forgot yours too! ![]() Great job! I raised a layout once, but never lowered one. I put casters on a movable section, and it worked pretty good.

Great job! I raised a layout once, but never lowered one. I put casters on a movable section, and it worked pretty good.

I'm glad for you it is done!! Please post some photographs of your layout sometime!!

Art, the towns are looking great. I have always been partial to the older looking buildings. Not just because they remind me of when I was growing up but they just have so much more character to them. Late this afternoon I apllied the wash to all the larger flats. Letting them dry outside and will probably take a bit because it is on the humid side. Once they are dry I can do the smaller flats and then they are ready for their windows. Pic.......Paul

Attachments

mike g. posted:Brian, Great engine shoot! A man that has everything in trains does show class! LOL

GANDYDANCE1950, You never stop to AMAZE!

Jim, sure sounds like a lot of work! Question did you shrink or did you get shorter visitors? LOL

Paul, its a good thing you found it before you sealed them! Have a fun time at the Menards show and please make sure you tell Dad HI!

Peter, that is great information, but I don't think its going to help me cut back on my beer! LOL

Hey Mike,

I think a bit of both actually!! LOL

Mark Boyce posted:JIM HORNADAY 062618 posted:Yesterday, I dropped my entire layout from 44" to 36". I also put casters on the new legs to enable me to move the layout for access purposes. I added 2 locking casters to the front corners. This was a project I've been wanting to get done for a few weeks now but finally was able to get done yesterday.

Man i'm glad that's over!!!

Drat Jim, I forgot yours too!

Great job! I raised a layout once, but never lowered one. I put casters on a movable section, and it worked pretty good.

I'm glad for you it is done!! Please post some photographs of your layout sometime!!

Thanks for the kind words Mark! The casters will make it much easier to work on. I tend to jump the gun a bit on projects so I then have to go back and make corrections! Yes I will post pics soon!

down by the station...

Attachments

JIM HORNADAY 062618 posted:Mark Boyce posted:JIM HORNADAY 062618 posted:Yesterday, I dropped my entire layout from 44" to 36". I also put casters on the new legs to enable me to move the layout for access purposes. I added 2 locking casters to the front corners. This was a project I've been wanting to get done for a few weeks now but finally was able to get done yesterday.

Man i'm glad that's over!!!

Drat Jim, I forgot yours too!

Great job! I raised a layout once, but never lowered one. I put casters on a movable section, and it worked pretty good.

I'm glad for you it is done!! Please post some photographs of your layout sometime!!

Thanks for the kind words Mark! The casters will make it much easier to work on. I tend to jump the gun a bit on projects so I then have to go back and make corrections! Yes I will post pics soon!

briansilvermustang posted:

Jim, I do exactly the same thing. Putting the cart before the horse!

Brian, yes one of those would look great with your ore cars. I could fix you up with one.

Mark Boyce posted:

Mike, glad you got the second coat done. Hope to be ready to prime after the 4th.

Howard, another great scene as always!

Paul, I often get caught with gotchas, I'm glad you caught the concrete tops now!

Yes the heat is a problem, though it is cool compared to what our friends in the southwest experience. Yesterday it hit 90 degrees, about 70 percent humidity. There are some summers we never see 90 here. My wife was watching the Pittsburgh news, and they forecast several days 90 to 92, but it is always hotter there than here. Thunderstorm just came up; I just brought the flag in.

After some busy days going through stuff at may parents' house in preparation for the salvage folks coming and hauling the unwanted away, I was ready for trains. I did a bit yesterday running various engines and posted a few on the For Sale forum. I wrapped up a couple deals after mowing this morning. A wonderful non-powered unit and caboose are still available.

Thanks Mark!

Attachments

I had to get some yard work done this morning before the heat set in. While I was out there I put the wash on the remaining building flats. Once they dry I'll bring them in. If by chance I have some time I'll start getting some windows in. Have to finish up things around here first to get ready to leave for Wisconson and the Menards train show and a stop at Elliots to seee his layout and won't be back till sometime next week...........Pic...........Paul

Attachments

building flats are looking great Paul !!

have a great time at Elliot's and train show !

I second all that Brian said, Paul!!

Great work everyone! I hope you all have a fun and safe 4th!![]()

Attachments

M.O.W. (maintenance of Way) or as I like to call it - "Model Train Yoga". ![]() I'm standing, I'm kneeling, I'm crawling around under the layout, on my back, on my stomach, on my side, working from odd positions. When it's all done believe me, I feel like I just had a workout.

I'm standing, I'm kneeling, I'm crawling around under the layout, on my back, on my stomach, on my side, working from odd positions. When it's all done believe me, I feel like I just had a workout. ![]()

Redoing some track work and investigating 4 switches that went south. 3 of the turnouts needed new switch motors and the last was a wiring issue. Track work - just when you think your're done...I noticed that certain locos would derail in certain spots "every once in a while". Aggravating when the train will go around successfully a bizillion times and the bizillion +1 time there's a problem and only certain finicky locos and only a certain spot.

Anyway, all's well now. No photos to share with you. Most of the work I did was underneath and no one can tell I did anything except that now the trains run smoothly and the switches work.

Happy 4th everyone!

Nice pictures Brian!![]()

Ralph, sorry you had some issues with the layout, but sure am glad you have everything running smooth now!![]()

thanks Mike !!

Attachments

Brian, More great photographs! Excellent!

Ralph, That sounds miserable to me! I used to do all those things without a second thought, but not any more. I now know what people mean when they say the hurt in places they never knew they had!! I'm glad you got the fixing done!!

thanks Mark !!

![]() have a GREAT 4th everyone !!

have a GREAT 4th everyone !! ![]()

Attachments

Tried running some trains on the 12" to the foot layout again today.

The Lake Tahoe lumber and fluming Co. GLENBROOK narrow gauge

2-6-0, fully restored. It can only haul lumber, etc because it was

restored to original specs and therefore the brakes do not meet

current standards to haul passengers. Another short vid of the

V&T No. 25 2-6-0. A very short vid of the Mckeen car, this is where

my camera died. And a few stills of the GLENBROOK and V&T

Attachments

Managed to find few minutes and was able to glue the windows into four flats. That's all till we get back....Pic......Paul

Attachments

Ooh!!! Looking great, Paul!

the tunnel cleaning crew was out last night...

and the tunnels were busy this morning...

Attachments

Attachments

Not much done on the layout, but a bit of 12" to the foot action on the A&M today!

https://ogrforum.ogaugerr.com/...-on-the-aandm-7-6-18

Mitch

Last night, I was standing on a stool on one side of the layout room to see something and then I realized I could see the entire layout. I managed to get this with my cell, the only photo ever showing pretty much the entire layout. Only the far wall to the left is missing, and that's just a backdrop and some trees. But for the most part, it's all here:

pretty neat Lee ! looks GREAT !!

I haven't touched the layout this week. I know it's working because I had it running last Sunday for NYC Z-man (Jim).

My nephews came over on Tuesday, and helped me move the chop saw and some other stuff out to the shop. The rest of the week has been spent on doctor visits and picking up for tomorrow's open house / picnic. Paul, Dave and Ray Marion are coming over. If Menards keeps doing the show, the open house will become an annual event.

I'll get back to work Sunday. I'll probably have another week before the surgery, and then I'll be pretty limited in what I can do.

briansilvermustang posted:pretty neat Lee ! looks GREAT !!

Thanks!

With a small layout, though, such a photo can be disconcerting. You see it all in one shot and think, "Man, that's all there is to it?" I usually take measure of my layout one small section at a time. To see it all like that, I don't know...

p51 posted:briansilvermustang posted:pretty neat Lee ! looks GREAT !!

Thanks!

With a small layout, though, such a photo can be disconcerting. You see it all in one shot and think, "Man, that's all there is to it?" I usually take measure of my layout one small section at a time. To see it all like that, I don't know...

Really kinda depends on your perspective, right Lee?

Attachments

Great job Paul! The flats are nice and will b e waiting for you when you get back!![]()

Love the pictures Brian!![]()

Lee, Wonderful layout, shows how you get great pictures!![]()

That was the Google Earth view of Lee's layout!!! Very nice!

Big_Boy_4005 posted:I haven't touched the layout this week. I know it's working because I had it running last Sunday for NYC Z-man (Jim).

My nephews came over on Tuesday, and helped me move the chop saw and some other stuff out to the shop. The rest of the week has been spent on doctor visits and picking up for tomorrow's open house / picnic. Paul, Dave and Ray Marion are coming over. If Menards keeps doing the show, the open house will become an annual event.

I'll get back to work Sunday. I'll probably have another week before the surgery, and then I'll be pretty limited in what I can do.

Better get a move on! I'm catching up to you on ballasting, Elliot. Finished a full 6' of it this week. 😉

Here's hoping all goes well with the surgery. Best of luck.

Bruce

Big_Boy_4005 posted:I haven't touched the layout this week. I know it's working because I had it running last Sunday for NYC Z-man (Jim).

My nephews came over on Tuesday, and helped me move the chop saw and some other stuff out to the shop. The rest of the week has been spent on doctor visits and picking up for tomorrow's open house / picnic. Paul, Dave and Ray Marion are coming over. If Menards keeps doing the show, the open house will become an annual event.

I'll get back to work Sunday. I'll probably have another week before the surgery, and then I'll be pretty limited in what I can do.

Prayers for a successful surgery, Eliot.

Pete

Not much going on here lately. I did checkout my Premier FA-2 ABBA set that I am meeting a fellow Forum member next weekend to complete a trade. I just have to box it up so it doesn't get broken before I can deliver it. ![]()

p51 posted:Last night, I was standing on a stool on one side of the layout room to see something and then I realized I could see the entire layout. I managed to get this with my cell, the only photo ever showing pretty much the entire layout. Only the far wall to the left is missing, and that's just a backdrop and some trees. But for the most part, it's all here:

Lee, your layout is very inspirational indeed!

Attachments

While prepping a couple of gi-raffe shells for shipping, I did a bit of research on Joe D.'s Plexiglas gi-raffe ramps.

While they do a fine job with the gi-raffes:

They do tend to foul siderods a bit:

So, they'll have to be used with narrower locomotives. ![]()

Mitch

Attachments

I've been down, but not out. I didn't hit the lotto like I fantasized, so I built one. Two of these led gimmick games games with sales literature in the mail. (That used to be a railline swingbridge)

.A 2"x2" fan blows styrofoam balls around in a cut down $1store led solar lawn lamp's lens, inverted

A "gaming" train is in the works I guess. I wanted a short gondola, and wanted an ore car. I found one long mpc=2 if one is nearly squared ![]()

Actual colors are yet t9 be determined. The Gon is slightly shorter than a 6112 now. Better on the 0-21" micro track.

The next split might allow a this ore that prize car ![]()

Speaking of fantasy, I wanted a figure for my Island of Misfits Toys but had no luck. The loco & passenger car that has square wheels; was a must. So I made one from wood; elve style ![]() . It's about 1.5" long

. It's about 1.5" long

I've railnpowered and at least partially lit 4 VW busses now.  No two are driven identically. 1 Worm&gear, the rest are pulley & rubber band, but no two motors or pulley ratios are the same. . Low volt champ needs just 2v.- 9v max., Two can take 14v, other two at 24v and excepting the one, they start and run at 7v.

No two are driven identically. 1 Worm&gear, the rest are pulley & rubber band, but no two motors or pulley ratios are the same. . Low volt champ needs just 2v.- 9v max., Two can take 14v, other two at 24v and excepting the one, they start and run at 7v.

One sprung contact shoe for now; not turnout friendly.

The police van is done.

I have ambulance decals. It needs flahers.

I need fire dept. decals. It's bubble lights, but I need to work out a pulsing mech. (Pulse vs a flasher

And I need "taxi" or MOW/road name logo for black and yellow.

I have old decal making image lifting "paint" called "decal it" . So, if I can find two identical images, anything goes.

You paint a coat or a few coats, dry, wash away the paper in warm soap&water and you are left with a rubbery decal. Kind of thick, but strong.

Not super high quality, but I was impressed with my three coat test on a PRR keystone in a magazine. The problem was a slight opacity. The background must be similar to the paper stock or the opacity becomes easy to see. I think one coat decals can be done with care. ( Stick them with more compund. A gloss.)

So that's some of my spring projects; time for me to catch up on yours ![]()

Attachments

You have been very imaginative and resourceful once again!!

M. Mitchell Marmel posted:

And I am sure the Gi-raffs will greatly appreciate the absence of steamers heading up their consists... would you want to be sucking in smoke and cinders??? I am very surprised your shop steward allowed this unhealthy practice ![]()

![]()

![]()

Paul is absolutely correct! We rode the Western Maryland Scenic RR with standing room only tickets. Open vestibule. That’s okay for people, but cruelty to animals!!!!!!!!!! LOL

Now I know what my Mum and Dad meant when they said they would have cinders and ash on them when riding to and from Pittsburgh on the B&O.

p51 posted:Last night, I was standing on a stool on one side of the layout room to see something and then I realized I could see the entire layout. I managed to get this with my cell, the only photo ever showing pretty much the entire layout. Only the far wall to the left is missing, and that's just a backdrop and some trees. But for the most part, it's all here:

Very nice!!! I like it. It’s point to point?

WP posted:p51 posted:Last night, I was standing on a stool on one side of the layout room to see something and then I realized I could see the entire layout. I managed to get this with my cell, the only photo ever showing pretty much the entire layout. Only the far wall to the left is missing, and that's just a backdrop and some trees. But for the most part, it's all here:

Very nice!!! I like it. It’s point to point?

Thanks!

Yep, it's point to point. Early on, I thought of a continuous run but the more op sessions I went to on other layouts, the less appealing that seemed to me. I'm very happy with it as it is for the most part, in terms of the operating scheme. I built it primarily for that, and to develop my skills.

Tonight, I decided to try switch lists instead of car cards for op sessions, and I'm going to put out the 'bat signal' soon for an op session to test it. I have a set of 5 moves for the same cars on the layout, which means the final puts them all back where they were at the start. That way, if I ever run a series of op sessions in one day (which happens in the Fall, for 'Oly Ops'), I don't need to swap cars around.

Anyway, it took me most of the evening to ID the cars, where they'd go in each move and where they'd wind up so each siding has the right number of cars. But at this point, even if I wanted to swap a few cars around, it wouldn't take much to change all the switch lists...

Attachments

Layout pictures; enjoy!

Attachments

Ran a couple trains... 😏🚂

Attachments

The night scene is terrific. Great.

Attachments

Not for everyone, but I made a portrait(picture) light for a shelf display I put up some months ago. Works just as I intended.

Attachments

Very nice Ted.

Received my new K-Line MP-15 Demonstrator. Looks great but unfortunately it has to go into the engine shop for repairs. something is not right with the flux capacitors.......

Bob

Attachments

WOW, that is a sharp engine Bob, looks great !

Looks GREAT Ted !!

Looks super Ted. Where did you get that 1966 SS 396 ?

The light turned out looking great Ted, Nice work!![]()

Wonderful looking engine Bob! Sorry it already has to go to the shop, hope its nothing really bad!![]()

Attachments

briansilvermustang posted:

Great pictures as always, Brian! Every time I see your photos, I think to myself, "Brian has the hardest working railroad going. The railroad never sleeps!"

HCSader73 posted:

Trust me, I’m there... ![]()

Attachments

Thanks JD... PS, the trains also run around my bedroom,

so I can even run trains while I am sleeping..." The railroad never sleeps!" LOL

Attachments

katy409 posted:Looks super Ted. Where did you get that 1966 SS 396 ?

Ya got the year right, hard to tell in the dark. Here’s a better pic. From Diecast Direct.

Attachments

Attachments

GREAT looking train Ted ! layout is looking good too ![]()

Looked sadly at it while walking past on the way to work on the current demanding project; prep the show car for the Concours. And we thought working on layouts was hard!! HA!

While tackling the laundry from our trip to Wisconsin I got windows glued in 7 flats. I only have two more to go. While up at the Menards show I picked up a double track bridge and a single track bridge for my next module. But first I have to concentrate on the brewery. Pics....................Paul

Attachments

Thaddeus- Very nice NKP. Looks really sharp in the sunlight!

Paul- the next module?????? I thought you were almost at the end....... I swear you keep extending your basement to run more trains. ![]() The flats look great!

The flats look great!

Kerrigan- A Concours car? Really? Photos please ![]()

Brian- The never ending collection...what more can I say.

Bob, I still have to build 8 more tables or modules of varying sizes................Paul

In an effort to maximize the space on my layout, I modified the O-72 switches that form crossovers on my layout. I cut the diverging rails on each switch, with the end result being center-rail distance of 4.2" down from 5.25"

I should've done this while I was initially laying the track, but it's done now and I'm happy with the results. The "S" curve is still there, but all my trains roll right through, and I think it looks better with the mainlines closer together. Here are before and after shots.

Thanks to Marty Fitzhenry for the tips on how to make the cuts and for encouraging me to give it a shot.

John

Attachments

brianbluemustang... mmm... naa...![]()

![]()

Attachments

Disassembled some failed experimental ideas in the interest of simplicity. A proposed station complex was just too much clutter to add to an already claustrophobic attic.

Firmed up the design of a triangular section of layout where many tracks converge. Engine fueling facilities and a small station serviced by a road will likely exist in this area. Spent some time this afternoon placing structures and leveling some real estate to suit. Mandatory clearance checks meant the rest of the session was spent running trains. There is something magical about being totally immersed in my little fantasy world. Makes the real one almost tolerable.

Bruce

brwebster posted:Disassembled some failed experimental ideas in the interest of simplicity. A proposed station complex was just too much clutter to add to an already claustrophobic attic.

Firmed up the design of a triangular section of layout where many tracks converge. Engine fueling facilities and a small station serviced by a road will likely exist in this area. Spent some time this afternoon placing structures and leveling some real estate to suit. Mandatory clearance checks meant the rest of the session was spent running trains. There is something magical about being totally immersed in my little fantasy world. Makes the real one almost tolerable.

Bruce

Well said!

I have always said that my trains are my therapy.

Brian, sure looks like you have things going nicely at your place! All the trains look wonderful! Never seen a Conrail Mustang, but then again there is a first for almost anything! LOL![]()

Paul I am glad your almost done with the flats, they are looking just outstanding!![]()

Thaddeus, Wonderful looking train! Congrats!![]()

Bluecomet400, Nice looking track work there! Plus you gain extra space for more stuff! LOL![]()

NS6770FAN, The ballast turned out looking nice! Great job!![]()

Bruce, running trains lets you forget about a lot while your in your own little world! That is a good thing for most of us!![]()

For me I haven't done much to the train room as we have had family from out of state and they are using the empty room as there hotel. But I did get a TV mounted in the corner so I am all ready to get back at it once they leave next week some time. I still have to finish putting on the second coat of mud, sand, primer and Paint. Then I can get started on bench work! The son-in-law brought me some more carpet to finish the floor which was very nice of him! I hope you all have been doing well, I try to check daily but it doesn't always happen!![]()

Attachments

Forgetting things has never been an issue with me, Mike. Remembering stuff is where I run into troubles. ![]()

Jim, I hope to some day transition into formal operating sessions, even if they be somewhat limited by the layout size. If ever that happens, I might require some kind of professional therapy. ![]()

RSJB18. Thank you very much

Bruce

photos added...

After roughing in the ballast the girder bridge supports began to take shape.

testing for fit.

Train runnin' time....

A new member of the family.

MU'd GG1's haulin' a**, er, reefers and boxcars.

Back to work today, experimenting with structures and mock up placement on the triangular section. In the process I roughed in the landscaping around the varying grades. The rear portion is next.

Bruce

Bruce, That overpass and concrete walls look great!! Yes it takes time and care to fit everything for clearance with interesting angles!!

Bruce, Mark is correct the retaining walls along with your girder bridge are looking great! It's always best to check clearance along the way, Don't ask me how I know just take my word for it! LOL![]()

Attachments

Today (yesterday) added a swimming hole. The layout is too small for buildings so it will be seasons and people. Like origonal poster said it was done a little at a time. buy woodland scenics water, order people, cut and mold pond, paint, get sand, make water fill pond ETC, ETC....

Attachments

Attachments

Cool Brian! That 3rd picture down is GREAT looking!![]()

now I just need to get a scene like that on the layout... ![]()

Im sure you will, you have plenty of room in your new train room outside!![]()

Bruce and Pete, a belated thanks for the well wishes regarding the toe. Bruce, I'm pretty sure that you'll finish ballasting before I do.

A toe update: It now looks like the toe will cause us to cancel our eastern trip for now. We'll try to recreate it in the spring. The toe is actually looking better, but that is no indication of the bone's condition. With the trip off the table, the plan is for a more wait and see attitude. Now I just want to get through the convention, then we can reevaluate.

Not much to report on the layout. My wife and I unpacked a bunch cars the other day, and placed on the layout. We also have been working on cleaning the room just outside the train room, to make it look decent for the convention. My goal is to get back to work this week.

practicing for Friday...

Attachments

Ran another train. WARNING Fantasy train, may offend your prototypical sensibilities..., he said, mostly tongue in cheek. 😏

Attachments

Nice video and great looking train Ted! I love your night shots and videos!![]()

mike g. posted:Nice video and great looking train Ted! I love your night shots and videos!

Night shots outa necessity, Mike. I need to hide all the background stuff on the floor in the basement. Some day we’ll rise above it all. ![]() Too much fun running trains to put it all away and build for months or years. You know what that’s like.

Too much fun running trains to put it all away and build for months or years. You know what that’s like.

Either way Ted, I still love them! I hope to post some from my future layout down the road! That's why I am putting in LED Track Lighting! LOL![]()

Elliot, very sorry to hear you have to cancel your fall trip. Better to listen to the Doctors and get that foot and toe taken care of and all healed up. You now have the time to put in more time on your layout to get it ready ready for the tour. With you planning your trip in the spring it gives me more of a chance to get more done on my layout too. I didn't accomplish as mich as I would of like to today. But I finally got started on piecing the brewery together, especially the angular building. I knew I was going to have to cut a flat or two to piece together . On the back side of the angular building is where I had to piece in. I got a couple done tonight. I'll let the glue dry overnight and tomorrow I can fill in whatever gaps there are with plaster and then paint the plaster areas with concrete paint. A couple of pics.......Paul

Attachments

Looks good Paul! Sorry you had to cut some down, but I am sure you have it all covered! I sure hope you had a nice time with Dad! Keep up the GREAT WORK!![]()

Elliot, I'm sorry you have to cancel the trip East for the wedding and all, but it sounds like the best thing given the information you have passed on. Keep working at your health, and we hope you can get back to the layout soon!

Paul, The angular building is looking very good! All the walls are turning out very nice indeed!

Brian, Mike is right; you should have room for a scene like that in the new building. I have seen a couple of CN engines on the B&LE here in Butler. When CN bought it, they said they were going to operate as before; but I am surprised it has taken so many years to see their engines.

Ted, that is a really nice train and video.

Here, I was trying to figure out why an MTH Premier engine I acquired in a trade Saturday wouldn't smoke. It makes smoke, but the fan won't run. I'll have to investigate further. NS SD70ACe. Yes, I know, decades too modern for me with the steam, F3s, BL2s, RSD5...I was glad to pass on the other set to a Forum friend who has wanted one for a long time.

Attachments

Nice looking Engine Mark, You still might have got the better end of the trade!![]()

Thank you Mike! He got an FA-2 set. Nice too.

WOW Bryan, that is just amazing! makes you want to sit down grab a dog and beer and watch the game! Very well done!![]()

Thanks Mike, can't wait to hook lights up and see what a night game will look like.

Bryan, I agree with Mike! Play ball!!!!

Attachments

Marc, they look great! I plan on adding ties to my tubular track when the time comes. I would also like to see more photos of your layout. I planned on doing a upper level similar to what you've done. Something that borders the edges of the bench work, with return loops at the ends.

Rusty

Thanks Rusty

I forgot how time consuming it was to make ties since I cant find the proper thickness of wood and have to mill it out of a larger piece.

I just started the layout in March, its "3 levels", subway, main level and mountain type area which will be Halloween Town. The layout is still very much under construction and fairly fluid.

I'll try and setup a photo album soon and its a small layout but I am not nearly as talented as most on this forum with respect to layout, scenery etc etc.

Mark Boyce posted:

Here, I was trying to figure out why an MTH Premier engine I acquired in a trade Saturday wouldn't smoke. It makes smoke, but the fan won't run. I'll have to investigate further. NS SD70ACe. Yes, I know, decades too modern for me with the steam, F3s, BL2s, RSD5...I was glad to pass on the other set to a Forum friend who has wanted one for a long time.

Mark,

It appears to be a form of desperation anxiety peculiar to us transition era freaks. This disease is brought on by a lack of ear piercing turbo whine. Fortunately, there's a vibrant black market out there with a cure

Bruce

Attachments

Bryan, nice job on the baseball field. I remember when you were just working on the lights. Nice you were able to find some time for train layout in your hectic schedule. On a side note I sold your shirts. Needed to buy more trains for myself LOL. Post some pics when you get a chance to show your progress......................Paul

Laundry day.....layout day. I glued two walls for the angular building together. I also glued another flat to make up the buildings behind the tracks. Doing that I found out I had to open the area between the sidings and wall so the flats will sit at the same height. Hope later this afternoon to glue the third wall in place. Pics...........Paul

Attachments

looking GREAT Paul !!

Thanks Paul and Mark, and all of those who have had me in their thoughts and prayers over the last two months.

I went to the foot doctor today, it's been 8 weeks that I've been going. I have great news! The toe is healing well enough that I get to keep it. So I'll have the vascular procedure in the near future, to increase blood flow, and I'll be in business. At the current rate of healing, I'm hoping to have it closed up by the end of October. Then we can re-plan our trip for the spring.

Time to get back to work on the layout!

GREAT NEWS Elliot ![]() glad things are looking up for you !

glad things are looking up for you !

" a quick flash back " ![]()

Attachments

Elliot, that's great news. Keep it healing. Don't push yourself. Slow and easy does it every time. By the way I forgot to mention, Shirley and I on the way home stopped in Rochelle for lunch at the Sunrise Restaurant and after lunch we got over to the train park. In the time we were there we caught 6 trains.............................Paul

paul 2 posted:Bryan, nice job on the baseball field. I remember when you were just working on the lights. Nice you were able to find some time for train layout in your hectic schedule. On a side note I sold your shirts. Needed to buy more trains for myself LOL. Post some pics when you get a chance to show your progress......................Paul

Thanks Paul, going to try to get some more time today but dealing with some rental property issues (water damage) so don't know if I'll get time or not. This first coat of mud is taking awhile to dry.

As for my shirts I should have not had you pick them up since I saw Al at the fireworks last week. I guess I'll get them when I'm first in line for the new Menards opening. Lol

Elliot, that's fantastic!

Hey Elliot- that's great news. The power of positive thinking (and healing), does work. Sorry you had to postpone your trip but not loosing a body part is well worth it. Now you can concentrate on the layout and convention tour.

Bryan- great baseball field. Can't wait for the first night game. Of course you could call it Wrigley Field and never have night games (OK- I'm dating myself a bit here) ![]()

Paul- the flats are going to be nice when they are all done.

Mark- that diesel is a bit too modern for your layout. Call it Back to the Future.

Bob

Big_Boy_4005 posted:Thanks Paul and Mark, and all of those who have had me in their thoughts and prayers over the last two months.

I went to the foot doctor today, it's been 8 weeks that I've been going. I have great news! The toe is healing well enough that I get to keep it. So I'll have the vascular procedure in the near future, to increase blood flow, and I'll be in business. At the current rate of healing, I'm hoping to have it closed up by the end of October. Then we can re-plan our trip for the spring.

Time to get back to work on the layout!

Great news, Elliot! God is good, always!

You are right. Al should of kept the shirts for you. I am not to be trusted LOL. By the way you will be second in line at Menards. I will be the first in line LOL. I heard a rumour it may open July 24........Paul

Fantastic,Elliot!

Too bad we'll never get to see the Stark Industries electro-servo positronic iron toe you had on order. ![]() ,

,

Sure glad to hear the news.

Bruce

paul 2 posted:Elliot, that's great news. Keep it healing. Don't push yourself. Slow and easy does it every time. By the way I forgot to mention, Shirley and I on the way home stopped in Rochelle for lunch at the Sunrise Restaurant and after lunch we got over to the train park. In the time we were there we caught 6 trains.............................Paul

Paul I'm glad that you were able to stop in Rochelle. It's one of our favorite local train watching locations.

Art

Big_Boy_4005 posted:Thanks Paul and Mark, and all of those who have had me in their thoughts and prayers over the last two months.

I went to the foot doctor today, it's been 8 weeks that I've been going. I have great news! The toe is healing well enough that I get to keep it. So I'll have the vascular procedure in the near future, to increase blood flow, and I'll be in business. At the current rate of healing, I'm hoping to have it closed up by the end of October. Then we can re-plan our trip for the spring.

Time to get back to work on the layout!

Elliot, that is great news! I'm very happy for you.

Art

Wonderful news Elliot! God is watching over you! The power of prayer really works!

YES ![]()

Big_Boy_4005 posted:Thanks Paul and Mark, and all of those who have had me in their thoughts and prayers over the last two months.

I went to the foot doctor today, it's been 8 weeks that I've been going. I have great news! The toe is healing well enough that I get to keep it. So I'll have the vascular procedure in the near future, to increase blood flow, and I'll be in business. At the current rate of healing, I'm hoping to have it closed up by the end of October. Then we can re-plan our trip for the spring.

Time to get back to work on the layout!

GREAT news!!!

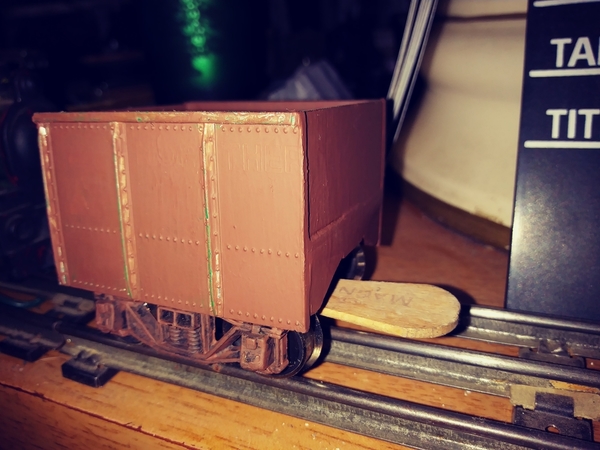

Going down to check to see if the flats are dry so I can glue some more together. In the meantime this afternoon I got this in the mail today from forum member and friend Mark Boyce. Tomorrow it will join the growing line of Weaver TOFC's...........Pic.............Paul

Attachments

Elliot, That is great news indeed!

Bruce, Ah so that is the diagnosis!!

Bob, Yes, back to the future. While it will operate on 042 curves, it looks a bit silly doing it to me.

paul 2 posted:

Wow, Paul! I could hardly have driven it over to you that quickly! Yes, I would like to see the "fleet" in a photograph!