ScottV - you got me! you guys are a rough crowd. I've been working out how I was going to build my ancient twin pine - present well before the founding of the town.

When I reconfigured my layout to include a curved yard I wanted to deck it over to allow space for more buildings. That meant I needed the deck to be a few inches higher than the "lower" part of the town. The stairs are just a sandwich of 1/4 nominal plywood sandwiched together at 2 inch intervals to get the step effect and the strength to span an access "hatch".

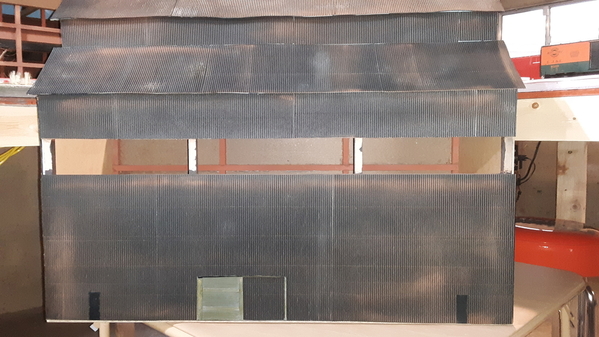

All the structure in this area is removable, this then exposes the access hatch where I can stand up in this space to work on the track and switch at the right side of this photo. All the buildings, street lights and signs have electrical quick connects for service work as needed. This is one reason I will limit the use of a plywood deck to build my next layout. Fine tuning the grade change using 2x4 blocks was tedious and it transmits sound to the plywood base.