My interest and involvement in the "3-rail scale" aspect of O-gauge model railroading has really grown as I've spent more time here on the OGR "3RS" sub-forum. I've been very inspired by the innovative work of others in the "3RS" arena...and have been learning a lot along the way. I always look forward to seeing new threads!

Along those same lines, I recently had a thought: Wouldn't it be nice to have one thread that displays the work of anyone/everyone who wants to contribute? Similar to "What did you do on your layout today?", or "Buy anything cool lately", I'd love to see an ongoing (and hopefully long-running) thread of "everything 3RS"!

By no means would I want this to take away from, or replace, individual detailed "How I did it" topic threads posted by OGR Forum members...let's keep those coming, please! I just thought it would be cool to have ONE thread that captures examples of a wide array of great 3RS work in ONE place...sort of a "one-stop shop", catch-all thread.

Please contribute to this thread with some photos and descriptions of your 3RS work...or with any 3RS questions!!

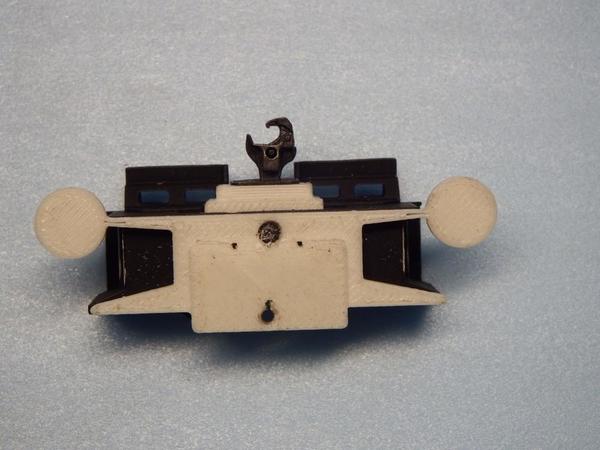

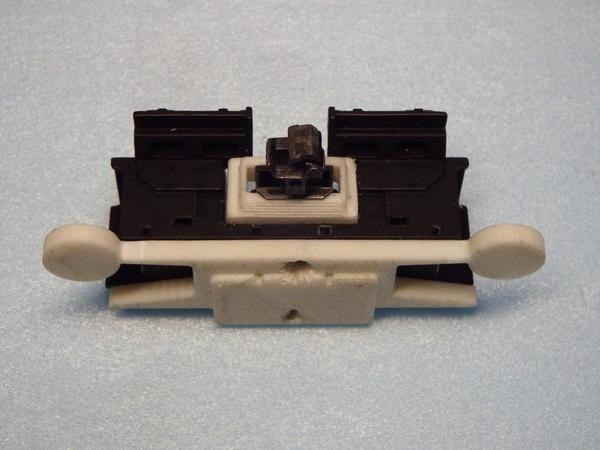

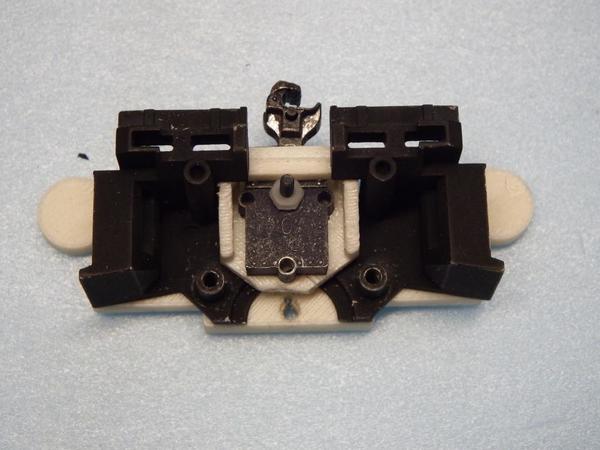

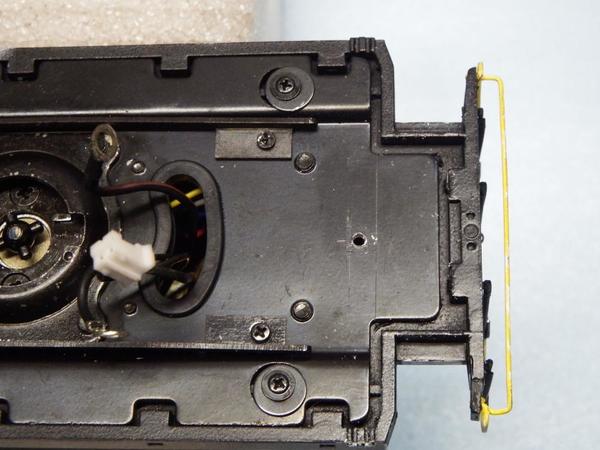

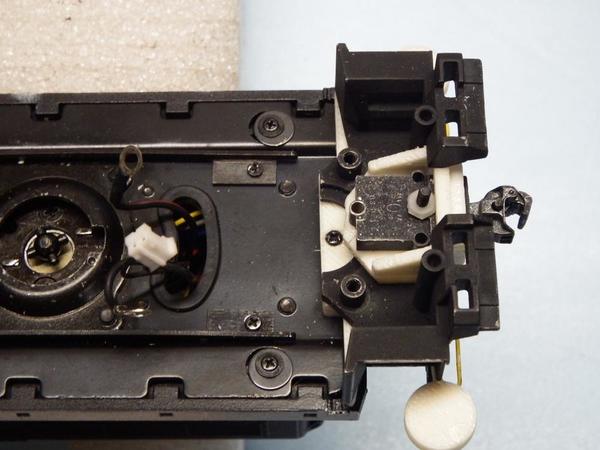

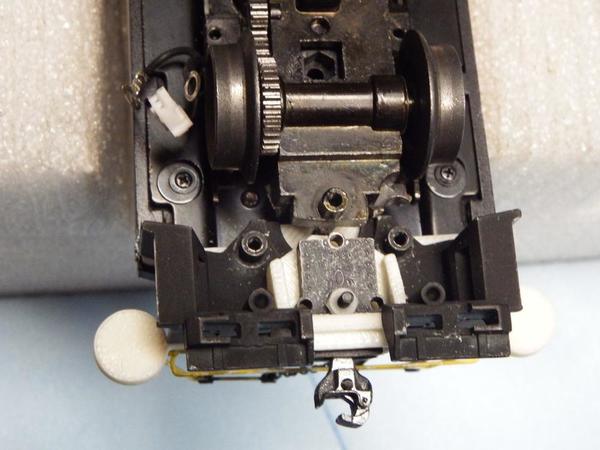

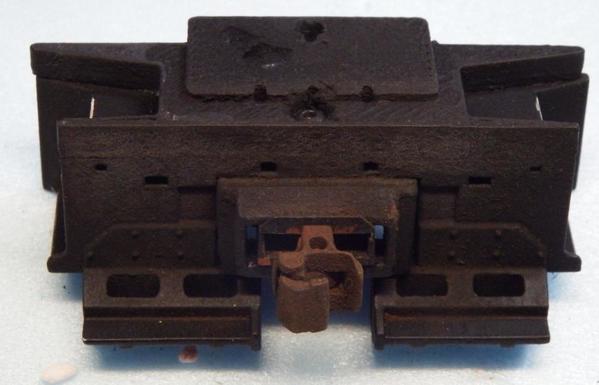

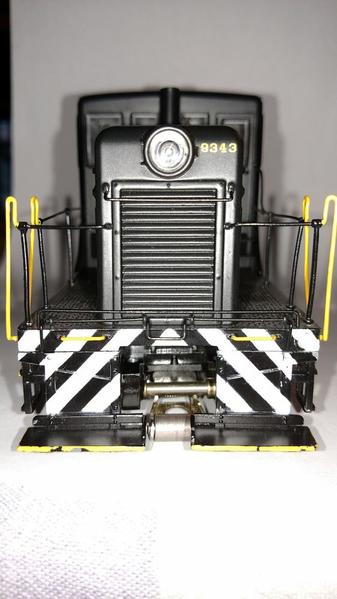

So, to get things started, here are some before and after photos of a Jersey Central "plywood-sheathed" caboose (scratch-built for me last year by fellow Forum member "Brother Love") that I recently 3-rail scaled by replacing the standard 3-rail "claw" couplers with Kadee scale couplers and adding brake line hoses & glad hands. Of course I had to weather it, too!

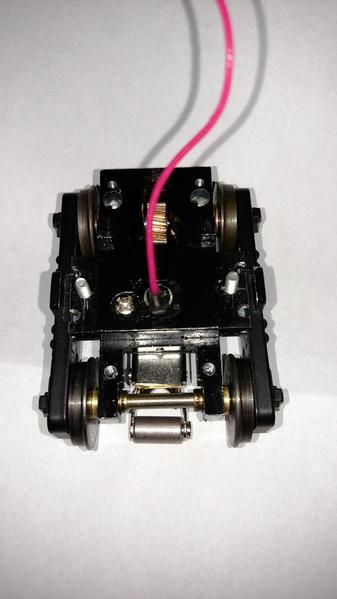

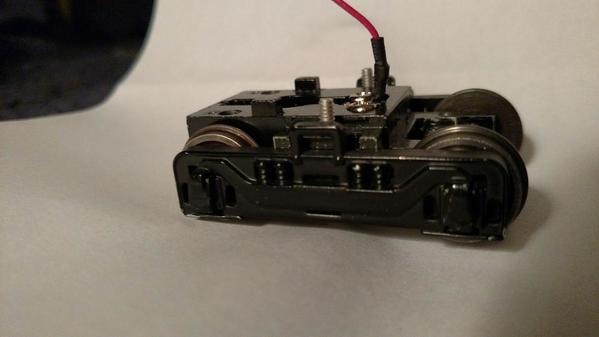

Malcolm was kind enough to supply Kadee-compatible mounting pads to the underframe, so installing the coupler boxes was very easy. All I needed was a few Kadee shims (from Micro-Mark) to get the correct coupler height.

I made use of the air hose/glad hands from the 3-rail Atlas caboose trucks that Malcolm included on the car. I made "mounting pads" for each end of the car from scrap styrene, and then trimmed and glued the brake lines/air hoses/glad hands in place. A little bit of detail painting of the hoses and mounting pads, and they were ready for weathering!

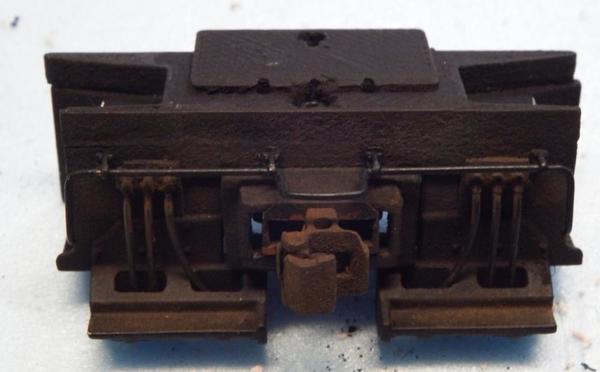

Before:

After: