Luckily I snapped a bunch of pics just in case:

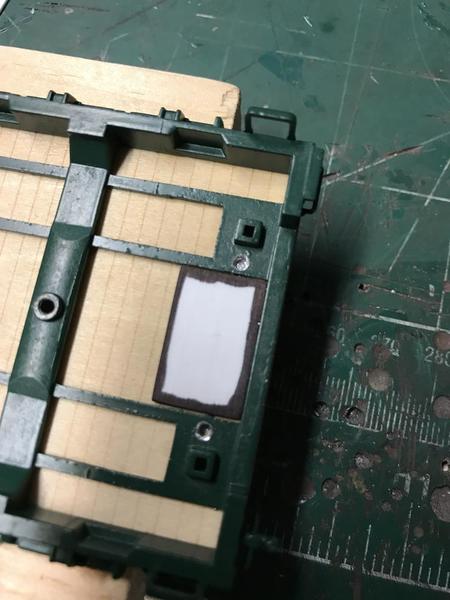

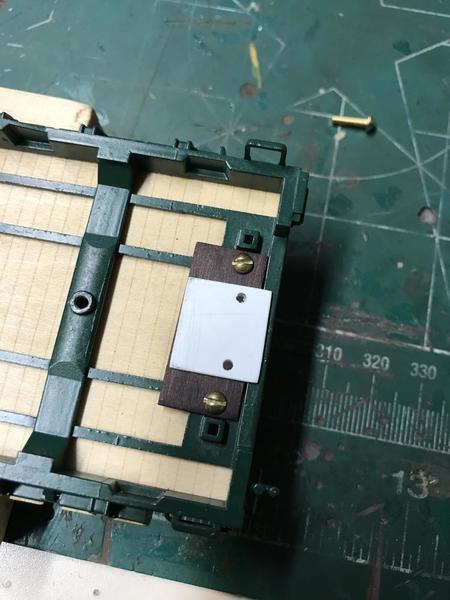

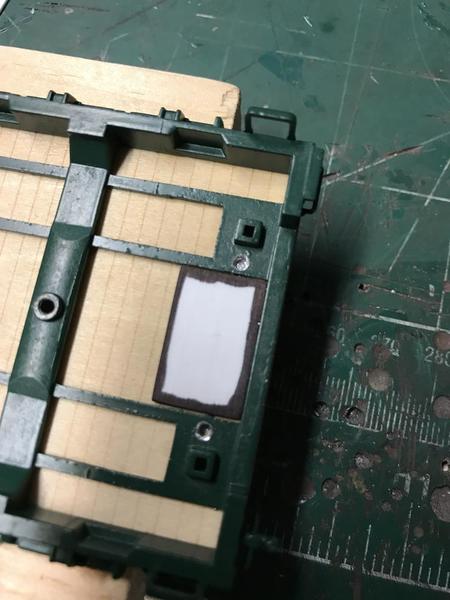

start by adding a plate onto the wood, this needs to be brought to the same height as the die cast framing. This is styrene attached with gel super glue.

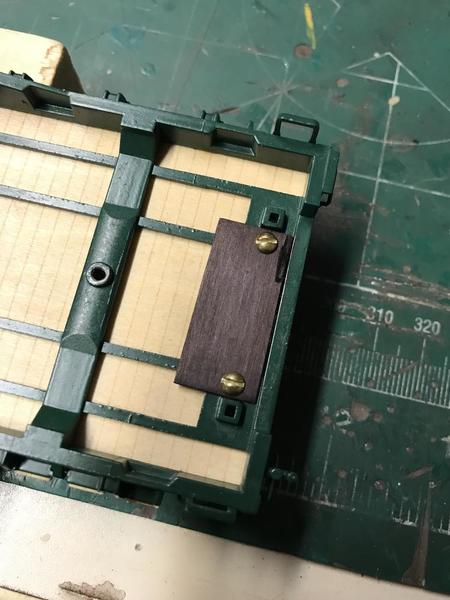

Next make another styrene plate to raise the height to be even with the end sill.

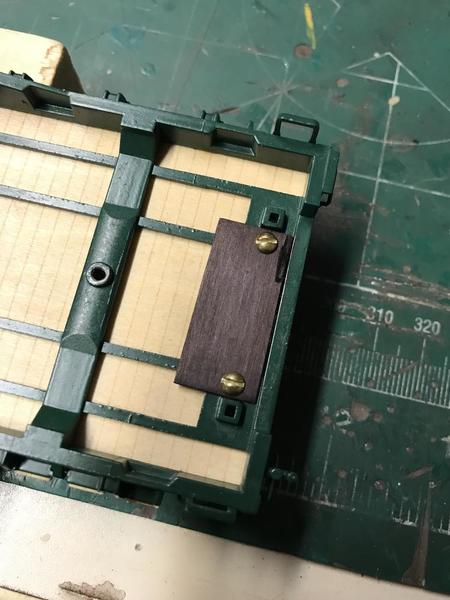

Next drill 2 holes in the small area by the stake pockets and tap them to your desired screw preference. I use 2-56. Be careful when drilling and tapping to not go thru the basswood deck.

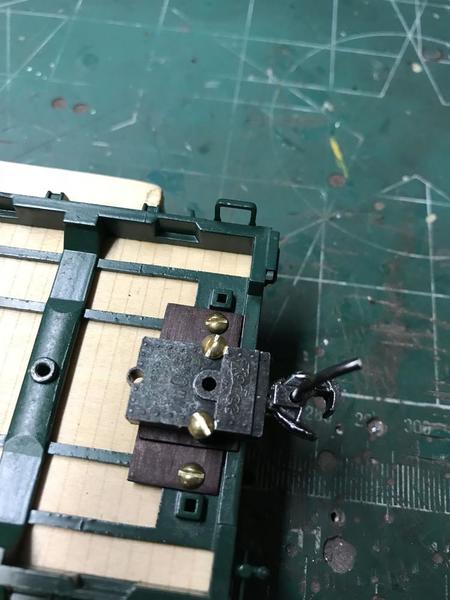

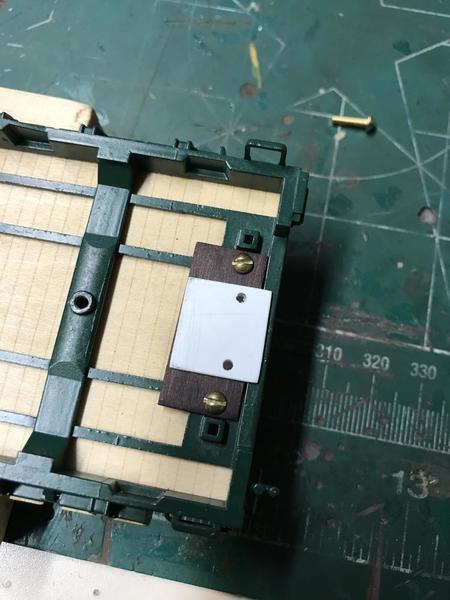

Now you’ll need to cut down some screws to attach the plate. I also put some plastic solvent glue between the plates.

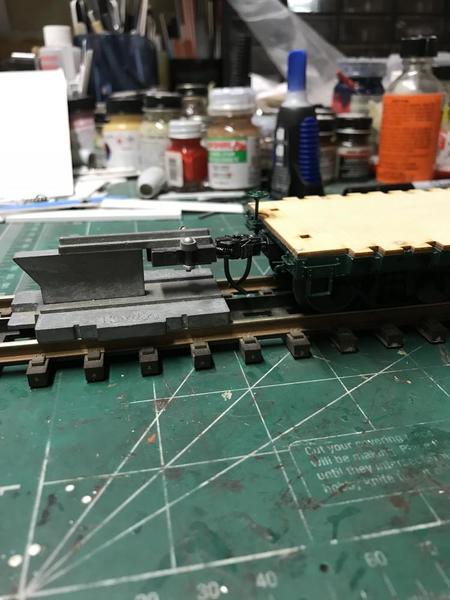

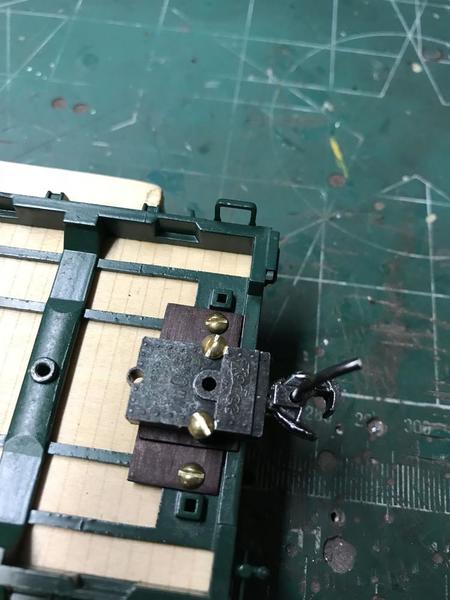

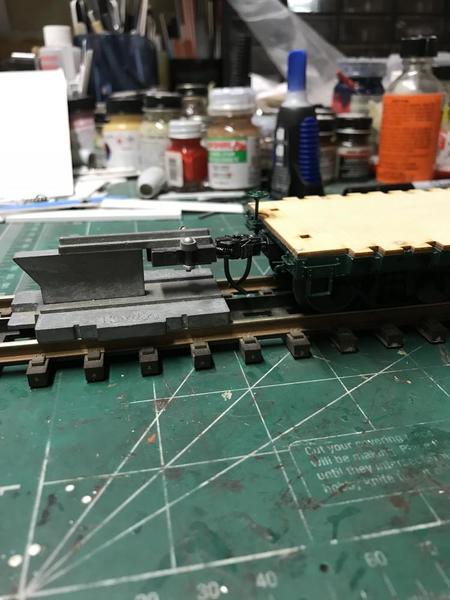

now reattach trucks, check against the height gauge, and make a shim for correct mounting. Again carefully drill thru shim and the 2 installed plates, then I just threaded the screws in the hole, no tapping, as it’s only plastic. Cut down some more screws and mount your couplers. I also superglued the shim to the underlying plates.

Doublecheck your work and call it done. I pulled on these pretty hard by hand and they are strong, so I’m positive you could put quite the train behind one of these without incident.

just exercise patience when drilling and tapping so as to not go thru the deck. I kept removing the drill and checking to see if I’d hit wood. I also use a Kadee tap that I cut the end off so it threads all the way to the bottom of the hole. Not a hard job

Good luck!