As has been mentioned the tray can fill quickly. These two trays were replaced with larger tray when I installed Atlas 6924 relay boards.

The top tray has been changed it wasn't large enough.

Holes (1" done with a ship auger) plastic staples and wire ties do a decent job of securing most underlayout wiring. The small grey wire nuts are termination of a set of MTH crossing gates.

This area eventually required a second set of holes and the tray was replace with a larger one.

The 6924 relay retrofit project required extensive additional wiring.

Wiring for the remote layout section seperate from the main layout.

Coal tipple end of wiring. Black and white THHN 14 ga solid copper is track power. The brown thermostat cables with up to 8 #18 ga solid is for accessory and switch control. Each of these wires/cables are 45 ft.

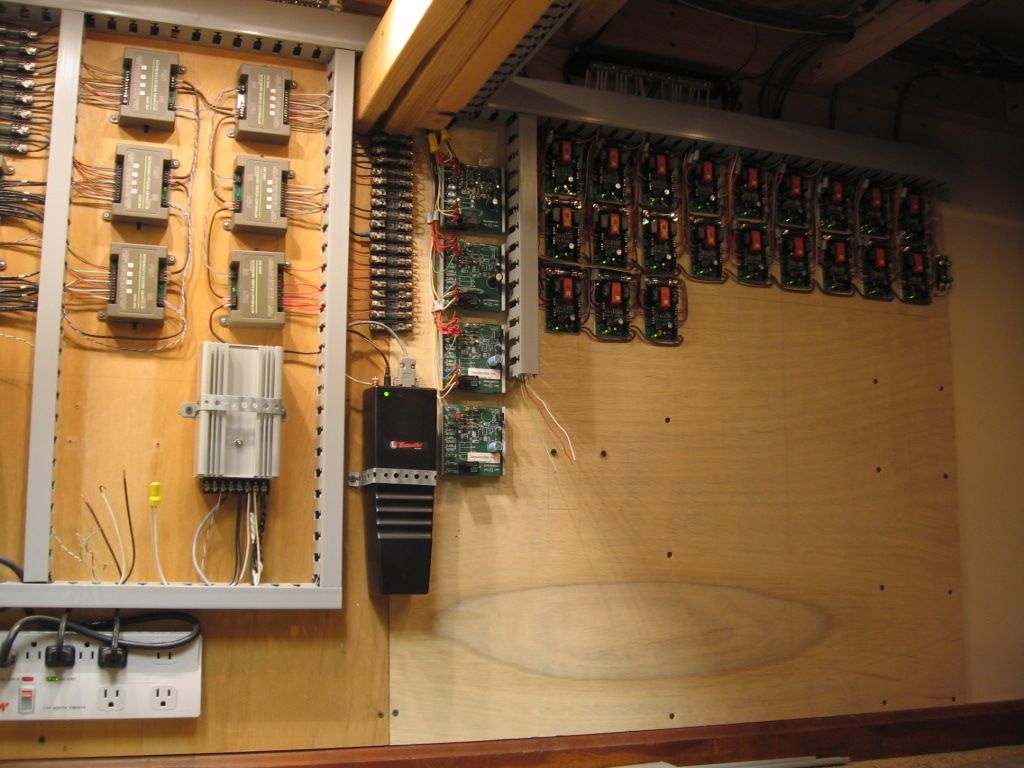

Control center power wiring, two track power districts. Wiring was routed up the wall over the ceiling and back down another wall to the power/control center. I installed spare accessory and switch wiring even if it isn't used.

Control center accessory and switch wiring. Note that the tray to the left has been replaced, again it wasn't large enough.

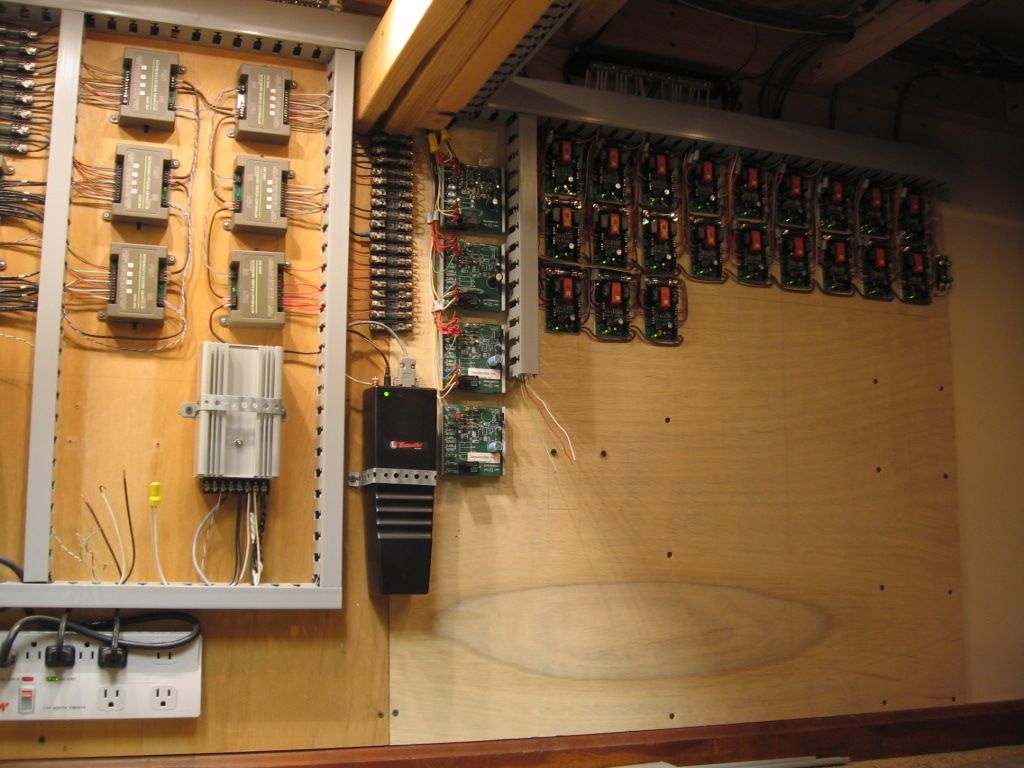

Eventually the 6924 board area looked like this.

I have dwarf lights install, but no signal system and very limited accessory wiring done. Both would require additional wiring, and more wire management.

It starts to get intense as each level steps up the wiring requirements.

The small PC boards are for the Atlas 6931 dwarf lights.

Have fun with your wiring.

Mike