Started building the wye and reversing loop extension to my layout this weekend that Jan and Dave helped design over the past couple of weeks.

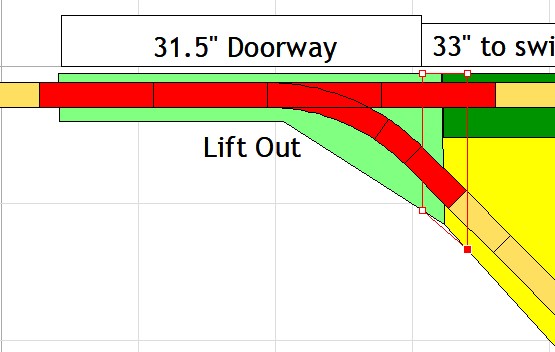

The major issues with the build will be laying out and fitting up the new "wedge" and wye; constructing the liftout across the doorway; cutting out the rear of two closets for passageway for the long extension; and designing and building the reversing loop at the other end.

The basic plan (not to scale) is attached. Most everything to the right (except the top area) is the existing layout. Everything to the right is the new extension.

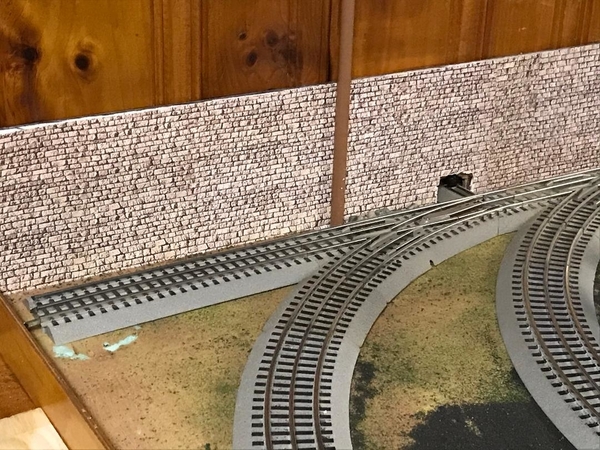

The attached pics show the left (west) side of the existing layout and where the extension will cross the doorway; pass through the closets; extend across the workbench and up the side wall and then come back via the reversing loop and onto the existing layout via the switch on the new liftout.

You can see that the existing shelving across the doorway is not level, so adjustments will have to be made for that. You can also see the main plumbing stack in one of the closets that limits placement of the long straightaway that will extend from one side of the closets through the other. In order to minimize any possible deflection, I am using a 10' oak 1 x 4 board that will extend through both closets and onto the existing shelving. It's pretty stiff but I'll install a couple of braces to minimize any potential deflection of the oak board.

I'll keep posting my progress as it goes along.