Greetings, I actually joined this forum to reply to this thread and share some insight into restoring these.

In the interest of full disclosure I do have a train shop that remains from our antique businesses so there are a couple thousand pieces in my life, and of course I ran into my share of ZWs.

This is not my real job, nor even my real hobby - I restore audio equipment as a hobby and as such generally know which wires not to lick.

that being said, I have 6 zws and found this page when googling info on the copper disc diodes and what people use to replace. I know its a 3 year old thread, but when I fix a stereo, if there is an old thread I append to it for a simple reason: I found it thru a google search for info so some day, somewhere, someone else might as well. new or more info is always good. The 'net can have good uses too. ;-)

So, onto the tech data:

The expen$ive replacement$ using the 16A stud diode is fine and good if you want to throw those bones, but not needed.

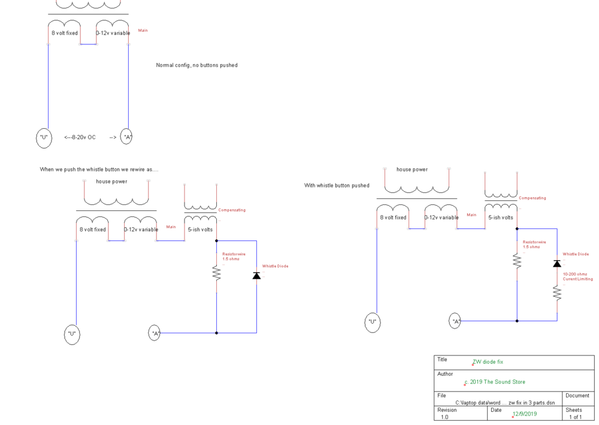

MOx diodes (metal oxides, like the target copper or the seleniums I see far more of) have very limited voltages and even far more limited currents. its hard to find any tech data on our copper discs, but using similar seleniums, we can glean: the single disc is able to withstand the wide open 19.xx OC voltage of the zW. however, consider the 1 inch 6 plate selenium. while it can handle the 120+voltages, a 1 inch selenium is good for roughly 150ma of current. lets say our discs have 2sq inches of usable MOx, I would estimate they pass 300ma of current but suspect more like 200.

the posts by martin above using the NTE 8515 (fwiw I rarely use NTE parts - too generic and questionable sourcing) is very interesting and I essentially copied him. squeezing the anode in a crimp spade or lug and tying to the metal plate was a REAL GOOD idea. you can then just ditch the wire from the old disc retention 'nut' and simplify things.

I use on smaller transformers (like the 1033) the 1N5405 (500v, 3a) and I just ordered a passel of OA60 6 amp diodes from parts express at about .46 cents each.

This should appease anyone that buys my refurb ZWs but in reality, I have a ton of 1N4007s that should do just fine.

Why? the DC offset triggers a specially wired solenoid in the tenders which then powers the whistle or whatever from track current. ya, the ZW can source a lot, but the reality is, the whistle will run all day on a few hundred mA. To draw AMPS would require an air raid siren in the tender. and the newer digital stuff draw almost nothing to detect the whistle signal.

we have breakers in the ZW which are a thermal type, they require a lot of current for a lot of time to activate and we all know, in the meantime wires can and do catch fire. IIRC the wisdom years ago was to use a 3-5 amp breaker inline with the track wiring and loco, lit cars, caboose, whistle, never tripped it.

The last zw I just did used 2 5405's in parallel I an have no doubt it would live long and prosper. What about a derailment short while blowing the whistle? the 5405 has a 200 amp surge rating EACH. so I should survive at 400A.

Also consider, MOx diodes have a crap ton of resistance. I use as a rule of thumb when doing for example a tube radio with a 6 plate Se rectifier, replacing the (usual) 22ohm inrush resistor AND the Se with a 120-150ohm 5-10w cement, then this teeny tiny 1N400x diode. That being said the resistance of the Se is 100ohms plus, or about 16+ ohms per place. Our copper should be similar. when the whistle is running the wires from the throttle has for all intents and purposes 0 ohms and the whistle control 16ish. meaning all the running current will come from the throttle.

I have 4 more Zws on the shelf to do and I will do the next one with 1N4007 and blow the whistle all day just to test it...

thats all for now.

ps: does anyone know how to start MTH PS1 equipment that will make idle sounds but when you try to leave neutral on the electronic E unit, they make a single 'tink' noise and repeated trys will go tink-tink up to 8 of them, then cycle back to 1. what sort of state is it in ? I have 4 never run locos doing that....