I have this old motor out of a Lionel 2020 Turbine and i'm trying to get it to working condition. When i apply power to the motor it just hums and acts like it's trying to turn but failing. Any ideas?

I have this old motor out of a Lionel 2020 Turbine and i'm trying to get it to working condition. When i apply power to the motor it just hums and acts like it's trying to turn but failing. Any ideas?

Replies sorted oldest to newest

Is the motor still in the engine? If so there is a little cover where the worm from the motor shaft meshes with the gear of the rear axle. It is possible there is some grease that has hardened up over the years in there that needs to be cleaned out and replaced.

If the motor is still attached to the frame, and the grease doesn't seem to be the problem, perhaps there is something else in a bind. Try removing the motor from the frame, but keeping it electrically hooked up. put the frame on a track, power it up, and touch the motor "shell" to the frame (I believe the motor has to be "grounded" to the frame for it to run). If it runs like that, you have a problem with something in the frame.

If the motor won't run when there is no load connected to it, then it's probably time to start cleaning up the brushes and commutator face.

Hope this helps,

J White

Where are you connecting the wires?

What else is connected to the motor terminals?

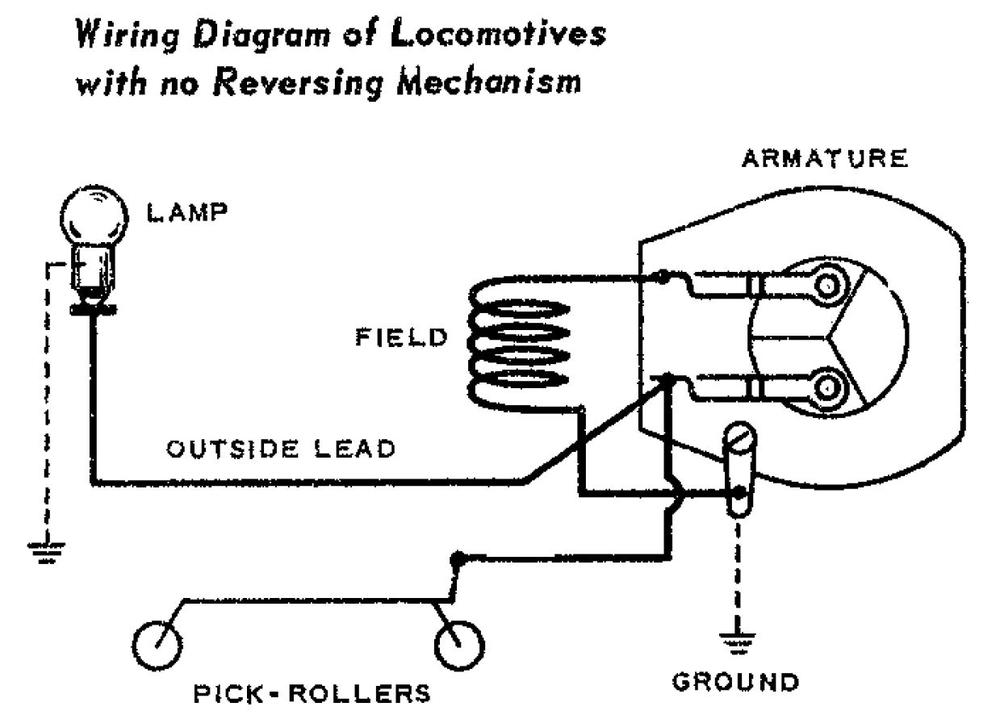

It sounds like you may be only applying power to either the field or the armature.

The two must be wired in series.

Those motors were made for many years and they are almost bulletproof. They rarely burn out and you can easily rebuild them . Check the leads/wiring as suggested by CJ, clean the commutator and make sure that the e unit is sending power to it. Lionel used a three pole AC motor in its design and they are not the best at slow speed operation. The DC can motors are better at this but had Lionel chose a 5 pole AC motor they would have probably worked as well as the can motors.

Wire it this way(disregard the lamp connection):

There are a lot of reasons - too many to diagnose. You can find books and downloads on how to care for these old units and I'd suggest starting there.

quote:There are a lot of reasons - too many to diagnose.

Certainly there are many reason a Lionel turbine motor might not run.

There are a fair number of folks participating on this site who are very willing to walk the orignal poster through diagnosing, and repairing his motor.

I don't mean to slight any of the responses, including my own. At this point I think it would be good to know:

Is the motor still mounted to the chassis?

What wires are connected to it?

Where did the original poster attach the leads to try it?

Clear pictures would be helpful. This site makes it very easy to put pictures in a post.

Sounds like you need an electrical tune up on the motor, clean and service the brushes and armature area first then see what might be wrong after that. The older motors need to be serviced every so often or will stop working.

Too many people on here want to make it more complicated then what it is!

Lee Fritz

If the motor has been removed from the loco, first turn the gear end of the motor by hand to insure that it will run when power is applied. Then hook up the motor to your transformer following the wiring diagram posted by ACDX Rob in a previous post. The motor should run. If it runs, you should disassemble and overhaul the motor and clean all parts with naptha, available at your local hardware store. Pay special attention to cleaning the copper commutator surface of the armature, the carbon brushes, springs and the entire brushplate. Replace the brushes and springs if necessary. Reassemble, making sure to oil the sleeve bearings with oil, and the ball bearings with grease. A drop of oil on the front of the armature shaft will complete the overhaul. Wire up, and the motor should run like new.

If the motor is still installed in the loco and does not run, then you will need to isolate the motor from the e-unit to properly diagnose the problem. Remove all wires to the motor, and wire it up as previously stated. If the motor now runs, the e-unit is in need of service. If is still does not run, a complete overhaul is needed.

Larry

There are a fair number of folks participating on this site who are very willing to walk the original poster through diagnosing, and repairing his motor..

Landon,

CW is right on the money. So far there have been many trouble shooting areas covered. Just covering those will take quite a while. At this point, patience is of the utmost importance. Good Luck!