This is project I had been thinking about for a number of years now. Suggestions that 3rd Rail do one have been unanswered. I thought a 2 rail engine could be converted though I had never done one before. I acquired a basket case Sunset K5 a few years ago and was hoping I could find a 3 rail chassis to put under it. Even picked up an MTH PS1 NYC USRA Pacific for this project. While the axles lined up, the narrow smokeboxes with its narrow steamchest of the USRAs and similar Southern PS4s Pacifics didn’t fit the much larger K5 smokebox. Later found NYC Hudson steamchests would fit but but were more forward than the K5 and would have required a lot of cutting and splicing.

Start point.

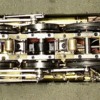

Hence the attempt to modify the K5 chassis with big flange wheels and pickups.

Drivers used were from a K-Line Scale Hudson. Pilot and tender wheels from various MTH passenger car trucks that had been a victim of zinc rot. Wheels were bored to accept the Sunset axles save the engine trailing truck which is from a Lionel L2a Mohawk. Couldn’t find wheels close in size the ones in the Sunset trailing truck.

After pressing the drivers on their new axles I found they were 0.040” out of gauge on the stepped axle. Cutting back the steps and the wheelsets no longer fit in the frame so .025” had to be milled from each side of the frame.

Wheels now mounted in the narrowed frame and K5 brake shoes with their new top mounts. The original side mounts were hitting the big flanges requiring new mounting locations.

Next hurdle was getting the new wheels and valve gear to clear the Sunset main rod, crosshead, and crosshead guides. The K-line shoulder screw heads were milled about .025” and rod ends also thinned using a counter bore and custom pilot.

Photo shows the clearance now between the rod bolts and crosshead guide.

Driver flanges cleared only because the center driver is blind. Three flanged drivers would not have fit. Engine truck wheels did have to have their flanges reduced to avoid hitting the frame and front driver. May require more modification after running on various curve diameters.

Being three rail I had to add pickup rollers. These were mounted on .062” copper clad epoxy circuit board which I have lot of from making my own circuits back in the day.

Also a 4 lobe cam and micro switches added for sound and puffing smoke.

It took about 8 tries trying to get the drivers quartered using my new to me NWSL quarterer. I finally realized the spring loaded axle centers were not holding the wheels centered so I made my own centers to fit the wheels. These worked first try.

All for now. Next up tender mods.

Pete