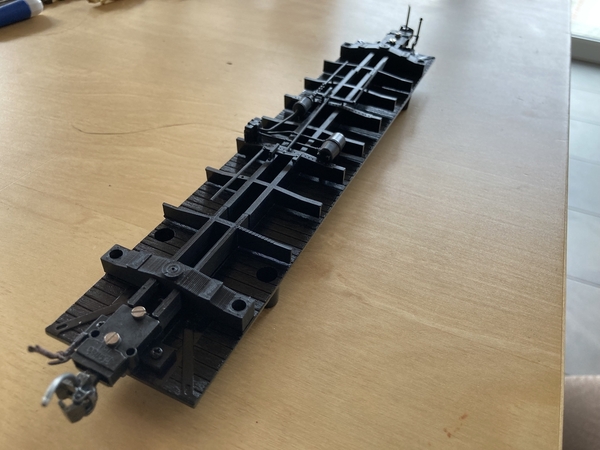

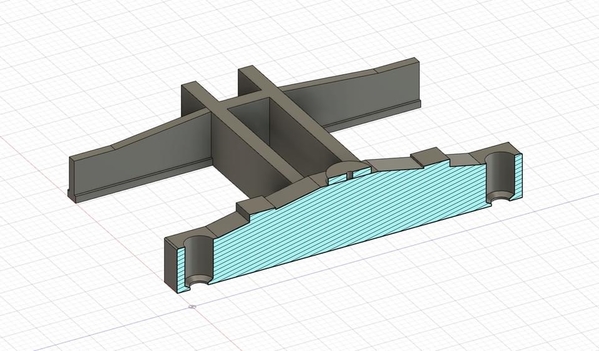

Dear Friends, I have started with 3D printing and already found a very handy project where the designing and printing really did a great job to solve the problem with Atlas underbody bolsters always being a mess. That's clearly the down side of multi-gauge manufacturing that you always need enough clearance for the 3-rail fraction.

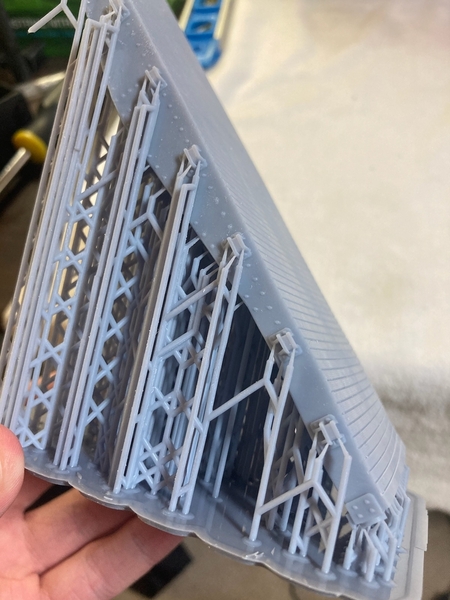

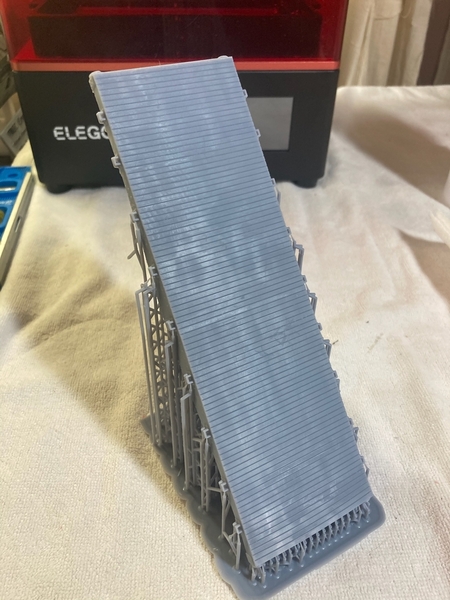

My Prusa i3Mk3 was surely quite an investment and to build it up from parts a challenge. It runs surprisingly well and the filament forms super strong parts.

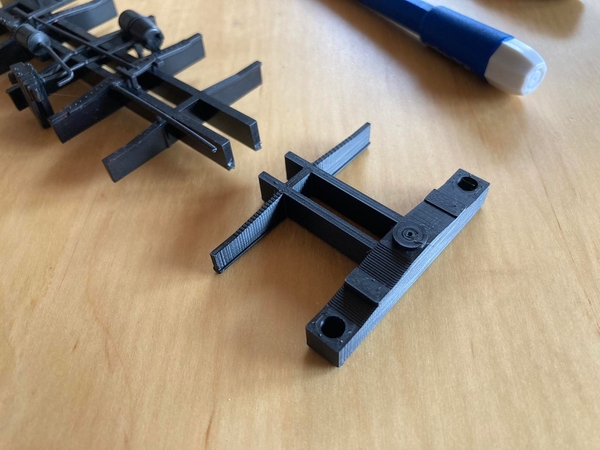

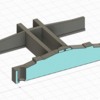

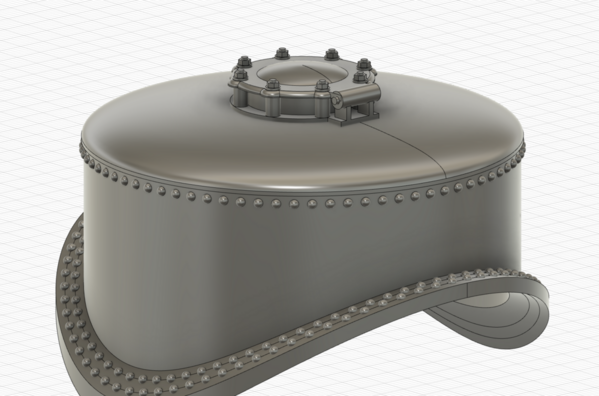

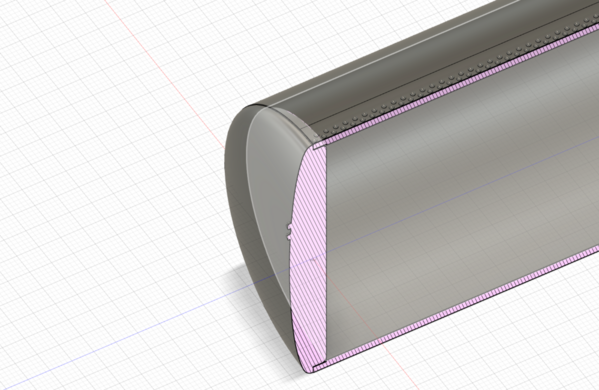

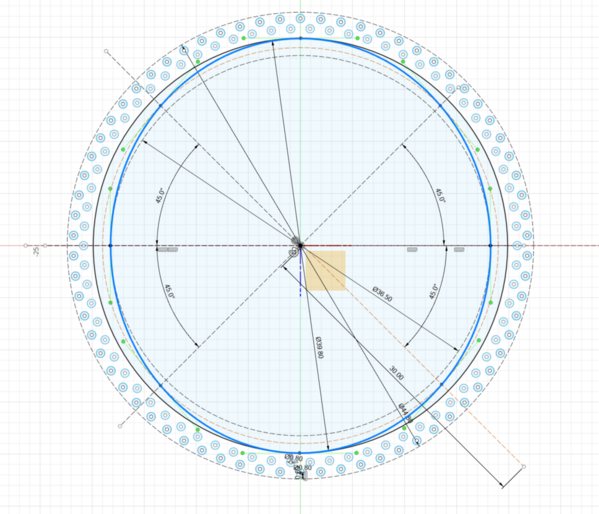

I've designed the part in Autodesk Fusion 360 after watching some tutorials on YouTube. The software is free for private use.

The amazing thing is how exact the measurements are (0.1mm).

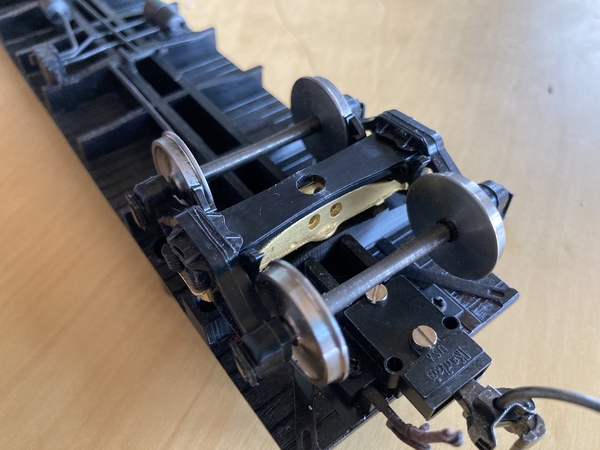

Here's the finished frame with shims between bolster and draft gear box. I incorporated these into a next version of the part.

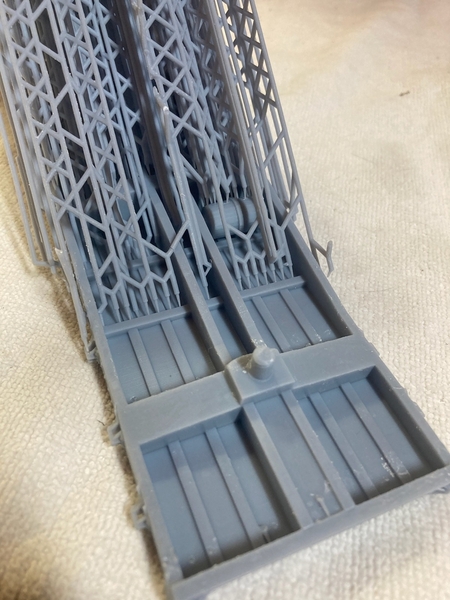

I am a big time fan of Jay Criswell's cast proto:48 conversion bolsters to re-use your old IM truck parts. The wheels are NWSL.

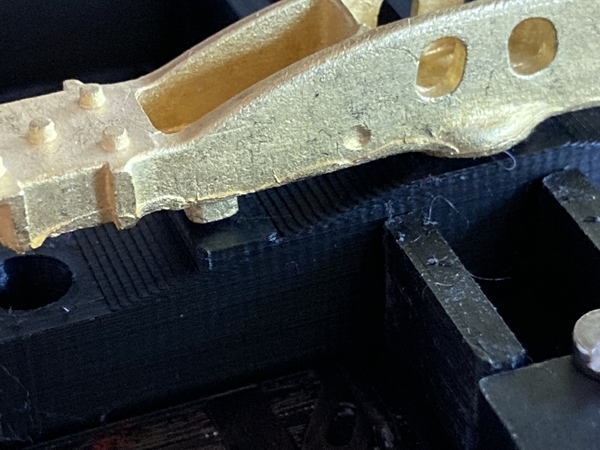

The print is so exact that you can easily achieve a perfect fit of that trucks, they glide on these little pads and ensure an upright car body.

You might have seen some stepping in the filament print. That's clearly there but could be sanded easily. I did not because you can't see what's going on under that truck from no angle.

This boxcar conversion was a real learning challenge but now I have the file to print these as needed. More cars are waiting in the basement.

Greetings from Austria

Sarah