A friend sent me info detailing to an extent how to reduce AF parallel track centers to 2.5".

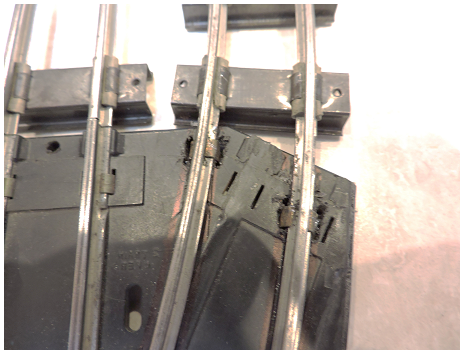

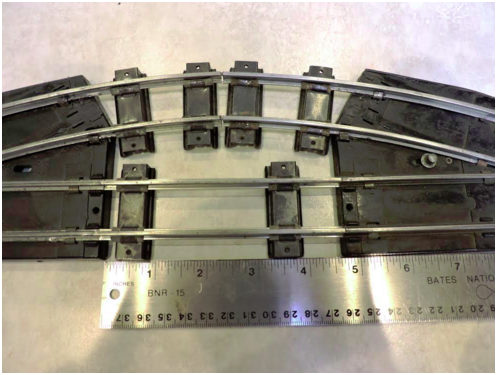

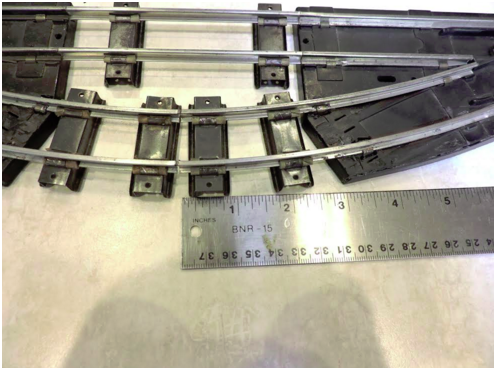

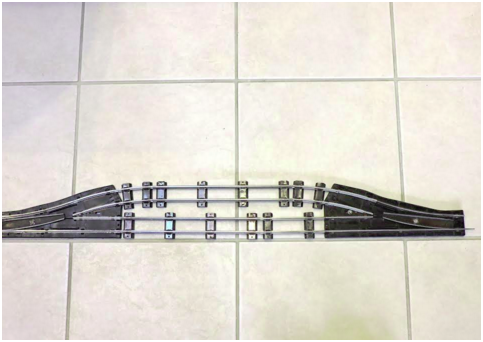

Some surgery on the switch is required for some of the applications. Others require only a little creative "rail re-orientation".

Mark

|

|

A friend sent me info detailing to an extent how to reduce AF parallel track centers to 2.5".

Some surgery on the switch is required for some of the applications. Others require only a little creative "rail re-orientation".

Mark

Replies sorted oldest to newest

Mark, a very nice writeup and pictures, thanks for posting this.

I also modified some turnouts by reversing the rails as shown here to get some yard tracks on 2.5" centers. Between every pair of close tracks I left a larger gap so I could put the remote uncouplers on all the sidings. Just a caution, using a 2'5" center to center spacing on mainline tracks with 20" radius curves will limit what engines and cars can be run without hitting each other on the curves.

Mark, the modified turnout will definitely allow longer cars to operate without hitting the lantern housing. Connecting a curve track will create a double S curve. It should not cause a problem for original Gilbert equipment but the newer AM passenger cars may not like it.

Mark,

I wish that this had been posted a few years back! Looks like another project on my list, this one may have to move towards the front. I could sure use more yard tracks.

Would it be possible for you to mark on these pictures where the rails were cut, that would help this old guy.

Ray

Mark,

Thank you, the picture as you posted it with the arrows is a great help.

Ray

Mark's cut mark on the divergent rail is in the correct place. Rather than fool with mounting short pieces of rail on the turnout I just cut a piece of curve track to the correct length to go from the frog to meet up with the parallel straight track as one piece. I also did his switch 14A configuration with the straight rails. I did not cut the plastic base and glue them together, too much work at the time.

At one of the DuPage shows in the early 90's I came across a guy selling American Flyer compatible Right of Way Industries #4 and #6 turnouts. They were built with wood ties and GarGraves rail and have the closed frog with the movable point like the current FasTrack turnouts. I bought a stack of #4's and used them rather than cut up any more Gilbert turnouts.

Mark, it sounds like a complete success! I would assume the original metal slug with the triangular tip that holds the points in position will have to be removed to use a Tortoise machine. They would not be necessary any longer. Look forward to pictures of the installed turnouts with the freight cars on the mainline and passing siding.

I said I'd supply some photos so here goes.....

Mark! Do you realize how many projects you are adding to my list? Just a little kidding but this one has got to move to the top of the list, it will almost double storage. Thank you for all the info on these mods.

Ray

Mark, great job!

Mark, I have acquired several of the Flyer turnouts and have begun to modify them using the ideas you have planted in my empty head. I have found a way to use the original Gilbert switch motors under the switches. I will explain this procedure and illustrate with pics. I would also like to take some pics before I do the mods on the layout to show the difference these switches make in the track-work. Thank you again for this thread that you have posted.

Flyer for ever!

Ray

The reverse loop circuit boards I used are PSX-AR-AC. The main advantages are they work for any track configuration and they do not rely on turnout position. The disadvantage is they are expensive. The solution Ray posted is a fine alternative and much cheaper. It might be a bit more complex for the wye.

Ray, I look forward to the pictures.

Mark, you are correct! That is what happens when posting quickly from a hotel room and the wife is in a hurry to leave for the dinner reservation! I need to double check prior to clicking the Post Reply tab.

Hi

This is great but I am dumb guy and need to see everything visually. Any chance someone can post a video of this process? Unfortunately my simple mind functions better when I can see how its done. i know a lot of you tube videos have helped me with auto repairs. Thanks

Thank you I will check it out.

Hi guys,

I will try to post some pics and explain my process for using the original motors in the Gilbert turnouts.

The light shutter is removed and the coil is removed and installed on the bottom side of its base.

I marked the position of the of the plunger lock on the plunger plate, before taking it off to bend the plunger plate, so I could reinstall in the original position.

When the turnout is reassembled it operates as the original turnout did, but now the motor is under the turnout and out of sight. Of course you need now to cut a hole in the layout to clear for the motor.

Ray

Very clever and the neat bends and reassembly make it look factory quality.

Mark, I had a Tortoise here and did try it but, having the contact piece on the throw, the Tortoise would not operate the switch points, to much drag. I wanted to leave the contact piece on the plunger bar, I believe I can use that piece to operate the lights along side the track to indicate the routing of the turnout. I also found on some of the turnouts when remounting the motor I will have to use a nut on the mounting screws, some of the original tapped holes were pretty worn but I can camouflage the nuts with body filler and paint.

Ray

Ray, the tortoise has two sets of contacts builtin so you could ditch the turnout contacts.. Sorry if you knew that already.

Brendan

Brendan, thanks for the info, I did not know about the contacts but at the same time I considered that I will be doing 20 or so turnouts and by using the original motors I can save a couple hundred dollars by investing a little time.

Ray

Mark, Thanks for the videos, I would not say that your traversing those turnouts is slow, moderate speed yes. Hey those Marx bridges are cool, I have two on my home layout but only with single tracks.

I did do some trial runs through my first set of modified turnouts using a number of locomotives, from a Flyonel GP to a Flyonel Challenger, and rolling stock from a few freight cars to an AM streamliner coach. All went through without a hitch at a number of different speeds.

Again, Thank you

Ray

Mark, I did make a fixture for bending the actuator arm, I can post a picture if you want with dimensions. I made it out of hard maple because I am also a woodworker.

Ray

Mark,

Sorry that it has been a while before I got back to this. The first thing I did with the Jig was to cut three pieces of the hard maple, two pieecs the same length and the third piece 1/4" shorter. I laminated the two of the longer pieces and when cured I milled the step to the size shown, 1/8" high x 3/16" wide. At this time I drilled the hole in the laminated pieces for clearance of the plunger. I than put a piece of .030" styrene against the step on the laminated piece and fastened the third piece to it with double sided tape. I then drilled thru the clearance hole in the laminates, as a guide, and thru the short piece. I then drilled two holes thru all of the pieces for some 3/8" capscrews, drill these just large enough for the bolts to fit thru them, than on the back side of the laminated piece I opened the two holes just large enough to accept T-nuts. I needed to put wax on the capscrews to make it easier to turn them in, after doing a few of the actuators the screws tuned rather freely but were not at all sloppy.

I should mention that after doing each bend I did follow it up by finishing the bend on my arbor press to make it tight as possible..

Ray

Mark, I thought I might bring this thread back to life for a bit. Now that I have begun to revamp my layout with these improved turnouts I found that my Gilbert uncouplers no longer fit, this being a problem because my desire is to operate as well as run trains. I disassembled several of the remote units and found that by cutting the top layer of the uncoupler and carefully bending the sheet metal parts and that by cutting more holes in the layout these will also work with the closer track centers.

Ray

Mark, I am in total agreement with you on not getting to close with the track centers, especially on the mainline. I have some big steam power and using the Gilbert track with the rubber roadbed 2.5" is as close as is possible in the yards. On the main with the tight radius of the Gilbert track I keep somewhere over 3 1/4 centers, but even that is much tighter than the 5 1/4 required with the stock turnouts. I will get some pictures and hopefully some videos if and when I can at least get ruining again.

Ray

Hi Mark,

I wanted to resurrect this thread to find if I might get permission to post the PDF from David on another web sight. This information is to good to keep to ourselves. I would post it in total along with the information on my modifications to the Gilbert throws. I will not do this without permission from you and or your friend.

Thanks

Ray

Hi Mark,

I have contacted David and will await his reply. Thank you again for posting this procedure, I love the results, one of the best ideas on my layout.

Ray

I agree!! I though I could not get anymore switches on my layout. I tried surgery on one and it turned out great. Now I need more switches......

"I agree!! I though I could not get anymore switches on my layout. I tried surgery on one and it turned out great. Now I need more switches......"

LOGCRUISER,

You mention that you need more switches in your post, I have a number of extra switches. Are you interested in doing the conversion using the original Gilbert motors or would you do the Tortoise conversion? I have quite an abundance of the older style Gilbert switches but I know that using their motors would not work very well.

Ray

Mark,

I have not received a reply from David so I will just post a link to the OGR thread that you had started here.

Ray

I had mentioned earlier on this thread that I would post some photos. This is still a work in progress, 36 Gilbert switches now modified with most of them reinstalled. I still need to do repair of the scenery but finally done with switch mods. All of these switches have the Gilbert motors mounted to them. I now have room on the layout for roadway in front of the backdrop and the closer spacing of track at the turnout makes for better visual effect. I also now have space for the depot and terminal that other club members suggested I needed seeing that I love the stream-liners. All in all I am very happy with the results and want to thank Dave, Mark and Tom for your input on this project.

Ray

That looks fantastic Ray. You sure did a lot of work to modify that many turnouts and re-lay that much track.

Thank you Mark & Tom,

Yes it was a good deal of work to get them modified but it was/is rewarding the way the layouts appearance has improved plus the space it freed up. As I stated most are reinstalled, the switches on the back side of the layout are on the grade and upper level of the layout and a little more difficult to fit and rewire. Once the track work is completed I will repair the scenery and then move on to add to the scenic effect. I want to get the track work completed though so we might be able to have a play trains/operating session with some of the club members.

Ray

Hi, The new layout has started and I plan to modify some switches per this thread. Anyone have any suggestions for cutting the motor housing and excess material off AF switches?

Thanks, Tim

Tim,

I cut the plastic with my band saw but if you have a scroll saw that should also work, if nothing else try a coping saw, it will take longer but use what you have. I need to mention remove the metal parts before cutting.

Good luck

Ray

Ray, that picture of the station and train shed is especially enlightening. The previous track locations are visible behind the station. The extensive turnout mods you did obviously make a major difference in your layout! Also, we now know where all the rubber roadbed went, it is on your layout!

Tom,

I was blessed to have a major American Flyer dealer in the area. When he bought some collections he would sometimes get large quantities of the roadbed and I was able to buy large quantities and hold it till l built the layout. Once the track was down l found there was more than I could use and it was sold.

Ray

HI, Bandsaw works great - hope the blade lasts. Tim

Here is an old thread that shows how Ray, and others, have modified Gilbert turnouts.

Access to this requires an OGR Forum Supporting Membership