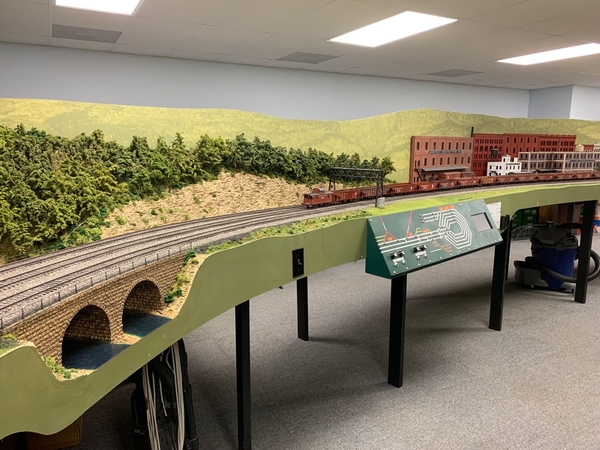

This past week I installed a new control panel for the H&BT branch line interchange with my PRR main line. For this panel I decided to use touch sensing toggles mounted behind a picture frame. I found a suitably sized 29" x 8" picture frame at Michaels. It comes with two .045" thick clear plastic protective sheets designed to sandwich photos in the frame. In this case the "photo" was a straight line track diagram created in Adobe Illustrator (thanks Greg), and printed on 54# paper at the local Office Depot. Berrett Hill LED touch toggles were taped in place directly on the back of the print and positioned so that the LED's shine through small holes punched through the print at the turnout locations.

The control panel sandwich is:

- The picture frame

- Clear plastic face

- Printed track diagram

- Touch Toggles (taped to the back of the print)

- Clear Plastic backer

- Rectangular peripheral retaining ring

As shown in the second photo the touch toggles use modular connectors that plug into control bases, which in turn power the switch machines (like Tortoises). To throw a turnout simply touch the face of the panel at the location of the turnout. As the turnout throws the LED changes color between green and red. Green for the straight path through the turnout and red for the diverting path. Touch it again and it changes state.

As this was my first touch panel there was some trial and error. On-line videos show touch toggle installations without the need for holes in the print – the light just shines through the paper. But with my opaque orange track lines, and thick paper I needed holes in the print to clearly see the LED’s. Also in a first pass I taped the touch toggles to the rear of the plastic/print/plastic sandwich – not directly to the back of the paper. I soon found that two layers of plastic between the face of the frame and the touch toggle prevented sensing by the toggle. Putting the toggles between the layers of plastic did the trick, while serving to press the print against the outer plastic. Holes were drilled in the rear plastic sheet to creat a path for the modular plug wires. I understand a glass picture frame also works well with the touch toggles – but with some added weight. Work remaining to be done on the panel includes painting the rack that holds the picture frame to the fascia.

Bottom line: I especially like the clean crisp look of the panel, and how easy it was to setup and wire.

Sometimes old dogs can learn new tricks. ![]()