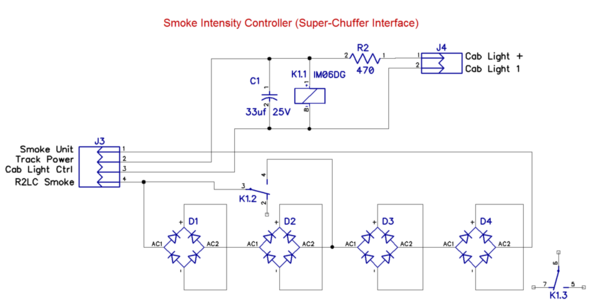

One of the things that is nice to do with an upgrade is to have a dual-level smoke feature so that at idle there is less smoke. I've done a few of them wiring the components by hand, but it's pretty time consuming. With the advent of a cheap place to get circuit boards in small quantities, I decided to streamline the option with a PCB. This is used with the Super-Chuffer, connected to the cab light output. When the cab light comes on, I not only light the cab light, I also pick the relay. This switches in a pair of bridge rectifiers wires as diode pairs to drop the voltage on the smoke unit by about 3 volts. The other two bridge rectifiers are there to always drop the voltage to the smoke unit. I used the larger thru-hole bridges to have a little better power dissipation than the surface mount versions. This circuit is designed to run from the R2LC TMCC smoke output and power a single 16 ohm resistor. Since I use the MTH smoke unit in many conversions, it's convenient to simply leave the stock resistors and isolate one to make it easier to install the smoke unit.

I also have a diesel version that I have to build up next, that one has the motion sensing circuit that I use in my locomotive motion sensor and the relay to switch the smoke intensity.