What a nice build, your 2-8-0 is so nice.

@86TA355SR posted:Which brand rivet decals are you using?

Thanks.

Archer. I also used ones from Micro Mark a few years ago, and only remember that I thought they were far harder to use than Archer's.

~Chris

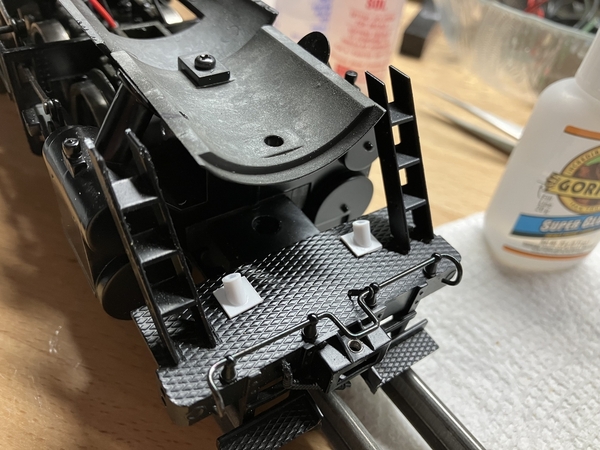

I made my own pilot support poles out of styrene and am now happy with them. Main bracket is made from sheet stock, a small tube, and a dowel. The pole itself is a dowel that fits snugly inside the tube.

Using the same mounting holes I drilled for the original poles:

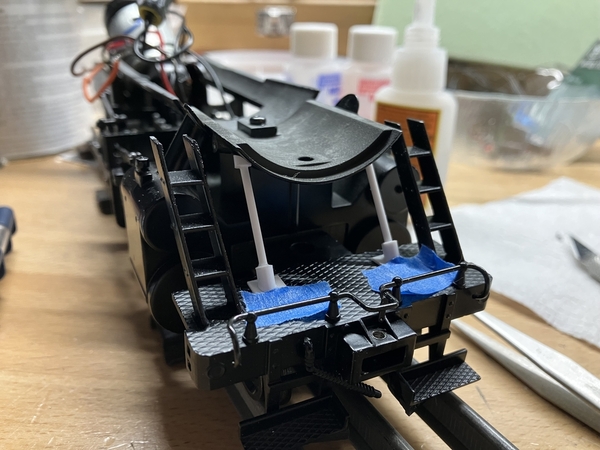

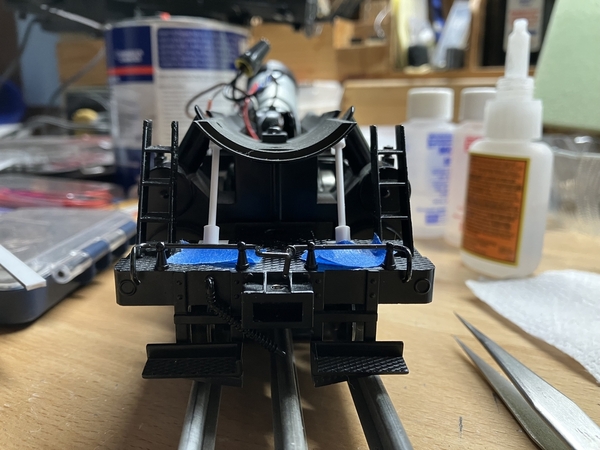

Fitting the pole:

I used another piece of tube at the top of the pole to provide a visual transition onto the underside of the boiler. They are not attached to the boiler at all, but press up against the underside when the bracket is held flush to the top of the pilot (using blue painters' tape for the test fit). I'll paint these separately from the rest of the engine and add them after assembly to ensure they fit correctly.

~Chris

Attachments

A bit of progress over the last week:

1. I received a new version of the steam dome, shorter and flatter up top. Looks much better to my eye.

2. Front headlight bracket was removed, a piece of the boiler casting that extended into the headlight cut off, and the marker lights cut off and the holes filled.

3. There was no room for a Kadee coupler box on the pilot, so I modified the coupler to mount to the existing cast-in box.

4. A new whistle and safety valves were mounted to this piece between the steam dome and cab.

~Chris

Attachments

Chris, nice solution to the front coupler by adding a piece to catch the screw where the spring would reside. The regular length Kadee’s don’t have a lot of meat on the shank after you drill the hole. I never thought of modifying the shorter version. I’ve gone to using the Atlas, Kadee lookalike. They are sold in a 4 pack without boxes. They offer a wider shank than the Kadee and a mold line that helps you find the center. You still need to file notches in them behind the coupler to get them to pivot properly in the cast pilot box if your doubleheading.

When you started this project. I went on the New Haven Google site to check out the photos. While not the particular engine your modeling. They were used in the Walpole, Norwood area of MA. . just a few miles from where I grew up. I’m guessing they served Bird & Son in East Walpole which had constant rail traffic.

The details your adding are making this on par with a full brass engine with road specific details. I’ve enjoyed following along.

Nice job on the Kadee.

Thank you Dave and Harley!

Dave - the idea of filling in the short Kadee came accidently. I purchased the short coupler to see if I could shoehorn in the shorter coupler box, and after I realized I couldn't I just made use of what I already had. Working well so far.

The regular assignments of the 15 F-5's in the 1940s were the local freights out of Waterbury and Boston, and that most likely included the Walpole local that served Bird & Son. There was a great article in the Shoreliner on this industry a few years ago, in Volume 35 Issue 3: "Bird Mills -- East Walpole on the Wrentham Branch". I'll dig out a copy when I have a chance and see if there is an F-5 in there.

~Chris