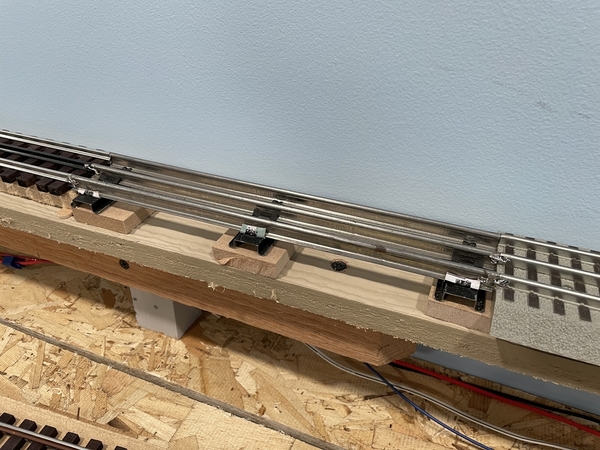

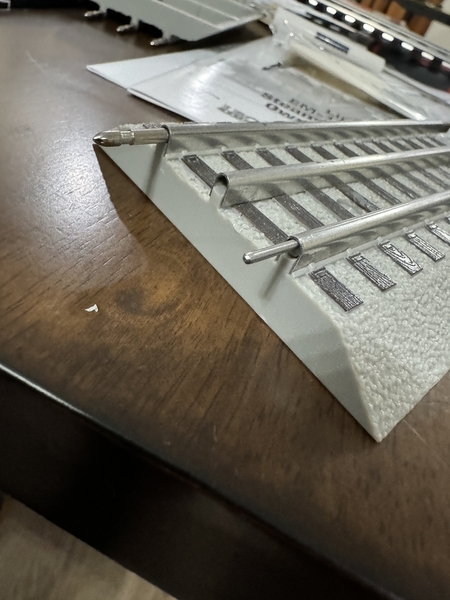

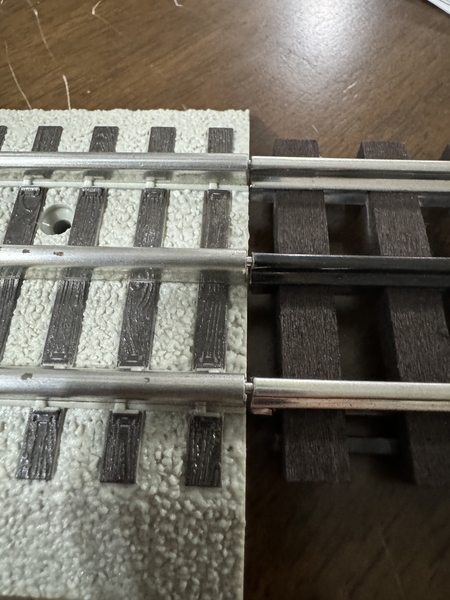

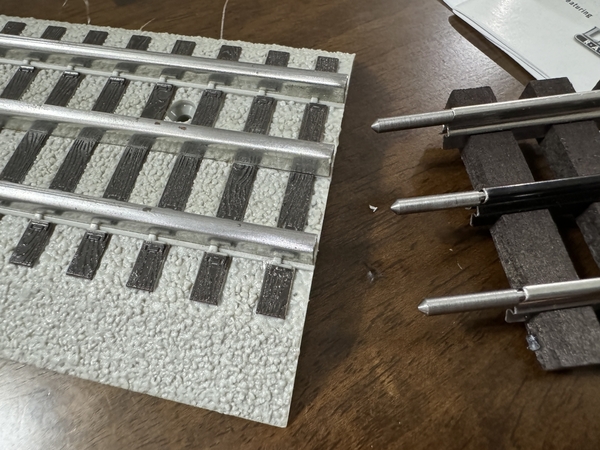

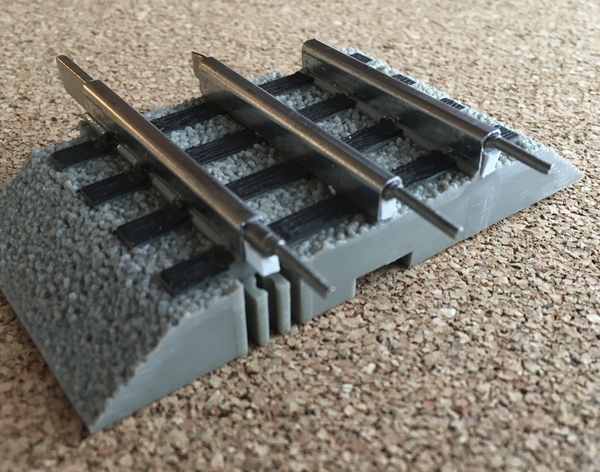

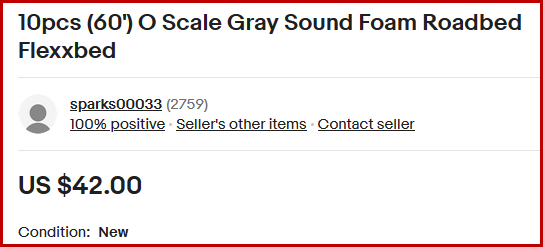

I’m about to begin transitioning to Gargraves track from Fastrack. I have the Lionel Fastrack 6-12040 adapters to do that as well as the Gargraves #801 pins.

It seems like it should be simple to remove the tubular track pins on the one end of the adapter piece and install the Gargraves pins but I don’t want to damage anything and I especially want to ensure the GG pins stay in place.

So - any advice to doing this task to avoid making a mistake will be greatly appreciated!

Thanks.