New thread for a new project - I'll be modifying a Weaver Baldwin Consolidation into a model of the New Haven's F-5 class.

Prototype background: In 1912, New Haven subsidiary Central New England Railway purchased 15 Consolidations from Alco. They were intended for drag freight service across the Maybrook Line (New Haven CT to Maybrook NY via Danbury CT and Poughkeepsie), which was just being assembled by the New Haven through consolidations and upgrades of existing disjointed routes. The Central New England owned outright the segment from Hopewell Jct, NY, through Poughkeepsie to Maybrook, and on October 1, 1912, the mountainous segment from Danbury to Hopewell Jct was also leased to them. Trains and locomotives operated though the whole route, and crews were split 50-50 between the New Haven proper and CNE.

By 1920, much larger L-1 class 2-10-2 engines had taken over most service on the Maybrook, and the CNE Consolidations were dispersed around the system. The freight roster was dominated by 2-6-0 Moguls, so the displaced Consolidations were useful as heavier local freight engines. They retained their Central New England lettering until the CNE was fully absorbed in 1927, and retained their numbers (150-164) through the end of steam service in 1950. Several spent their last years in local freight service out of Waterbury, where many great color photos were taken of them, a rarity for New Haven steam locomotives.

Not entirely set yet, but my model will most likely represent #153. This is one of the engines that had color photos taken in Waterbury, and it has the correct valve gear for the model. Many good black and white photos can be seen here: NYNH&H STEAM - CLASS F-5 2-8-0 (google.com)

The Weaver Baldwin Consolidation is already a close match - changes needed on the engine include new marker lights and head light, modifying the firebox to the correct shape, adding arched cab windows, adding Alco builders' plates, and adding separate pilot support posts.

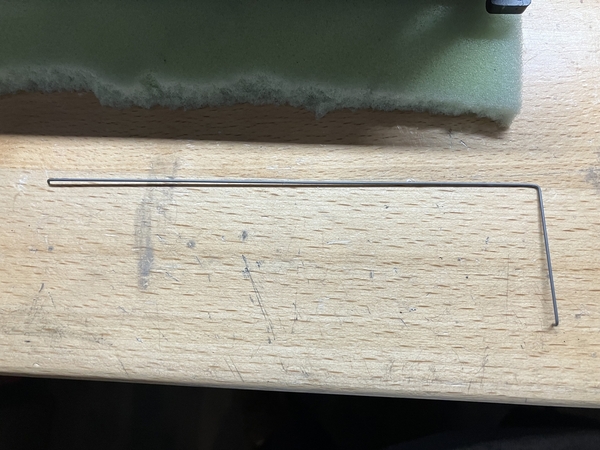

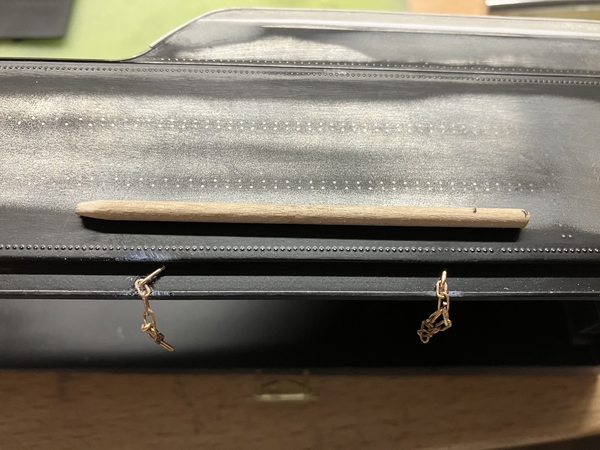

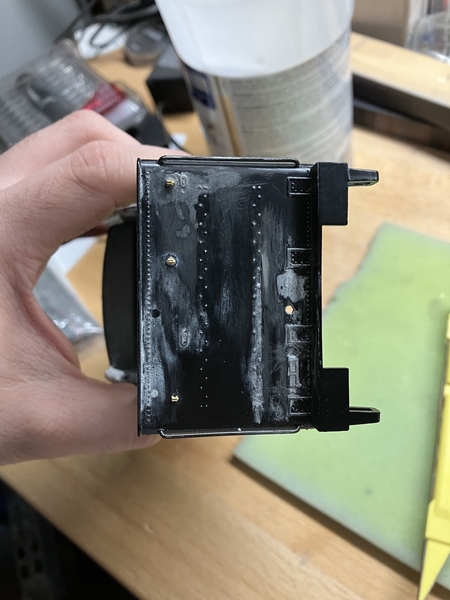

On the tender, changes include extended coal bunker sides that slope inward, electrical conduit run to the back headlight, and the addition of a polling pole and re-railers hung off the tender frame. Here is an example of some of those modifications I did to an 0-8-0 tender:

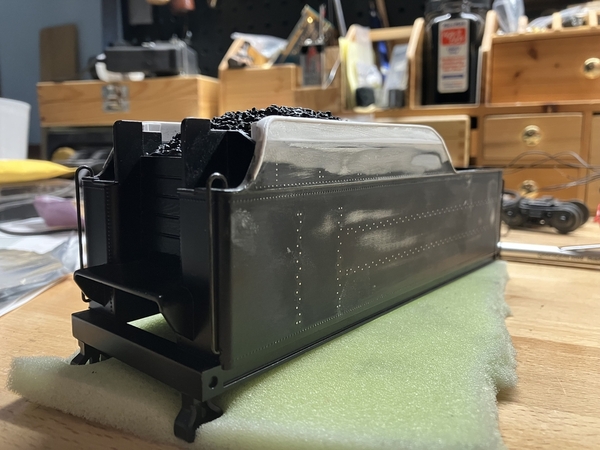

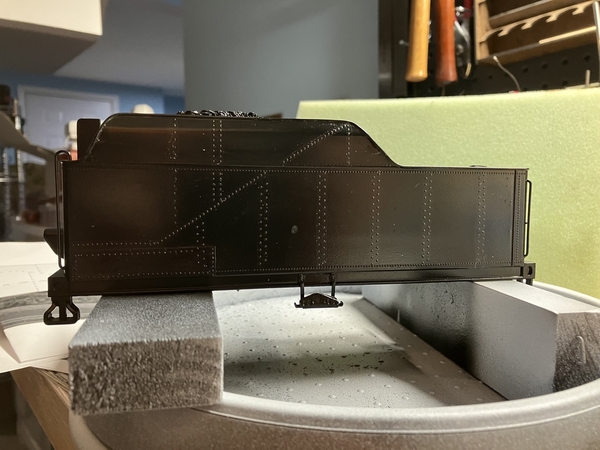

Here's my starting point:

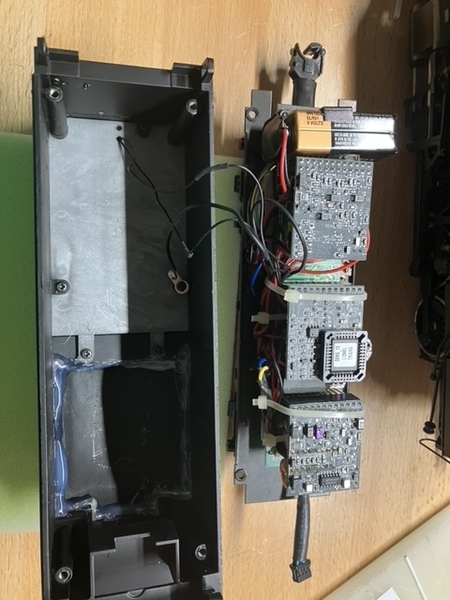

First thing to do is to open everything up and see how it ticks.

~Chris