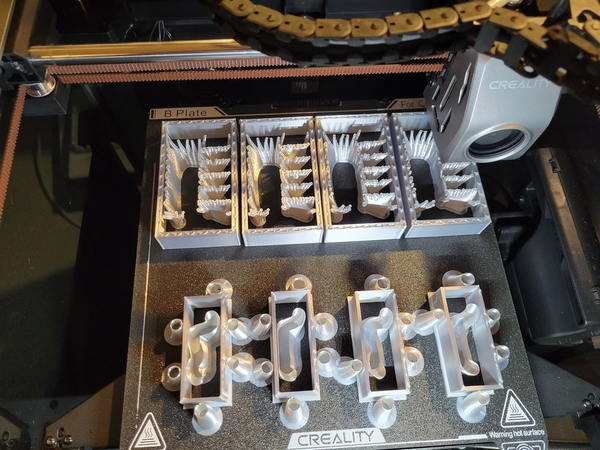

I thought this was an interesting look inside all the supports required to print these two piece trackside cabinets for the ultrasonic sensor boards. About 25% of the material I used for the printing is used for supports!

|

|

I thought this was an interesting look inside all the supports required to print these two piece trackside cabinets for the ultrasonic sensor boards. About 25% of the material I used for the printing is used for supports!

Replies sorted oldest to newest

John, it looks like you are well ahead of the learning curve. Seems I was just reading about your purchase of the printer. Those come out nice.

I purchased a scale sink for a building interior which isn”t that big. Seems there was as much throw away as product.

Well, this is Rod Stewart's design, I just did a few tweaks on it. I have the ultrasonic boards so I though I'd make some cabinets. I'm printing them with silver silk, it really looks like metal.

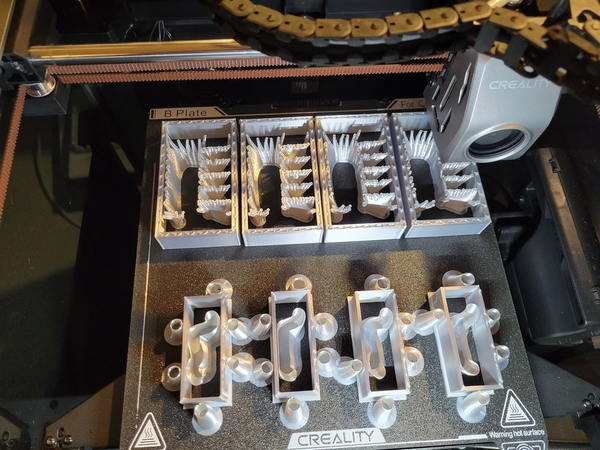

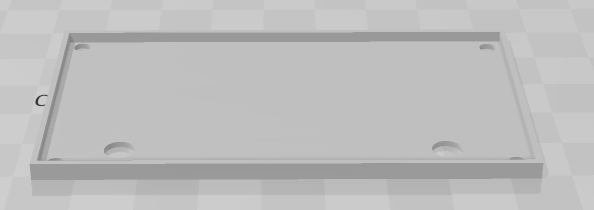

I'm creating a base to locate them now. You screw this down, set the PCB on it, and feed the wires through the two holes. That way the cabinet isn't going to wander around and you can lift it off to get to the innards.

Nice work John; they are looking good! ![]()

@Rod Stewart posted:Nice work John; they are looking good!

Thanks,

I decided that it would be handy to have a base under these so they have a place to be positioned. I attached the 3D file to this post. It has 3mm holes for mounting to the platform and larger holes for the wires at each end of the board.

That base looks good John. Just curious about the inside dimensions? If you are using your final R1.4 pcb design they should fit fine of course, being only 38 x 51 mm (1.5 x 2"). The boards I have used exclusively so far are my own layout; 76 x 43 mm. Just wondering if they will fit inside the raised perimeter of that base?

Rod

Very nice John.

@Rod Stewart posted:That base looks good John. Just curious about the inside dimensions? If you are using your final R1.4 pcb design they should fit fine of course, being only 38 x 51 mm (1.5 x 2"). The boards I have used exclusively so far are my own layout; 76 x 43 mm. Just wondering if they will fit inside the raised perimeter of that base?

The older boards may not fit, but I only have the later R1.4 boards here, so they'll work fine. I ordered a big batch of the R1.4 boards from JLCPCB, so I built for that form-factor.

The internal size inside the rim is 42mm x 77mm, so your boards wouldn't quite fit inside the rim.

It looks like if you flipped the bottom part over when you print the supports would not be needed.

@gunrunnerjohn will you share your tweaked base where the top set down in the little indention.

@Darrell posted:It looks like if you flipped the bottom part over when you print the supports would not be needed.

Nope, the depression in the top gets screwed up when I print it upside down.

@Shawn_Chronister posted:@gunrunnerjohn will you share your tweaked base where the top set down in the little indention.

Sure, here it is.

It was suggested that the base cabinet should really be concrete, so I printed a couple in gray, I think they may be a better match. Here's a contrast...

Not totally happy with the lines, but it was cheap filament that I don't think likes the speed I'm printing at, even though I slowed it down to half speed.

@gunrunnerjohn posted:It was suggested that the base cabinet should really be concrete, so I printed a couple in gray, I think they may be a better match. Here's a contrast...

Not totally happy with the lines, but it was cheap filament that I don't think likes the speed I'm printing at, even though I slowed it down to half speed.

I like the concrete look; mind you I may be kind of partial! And the lines look fine when you realize that concrete in the real world is rarely perfectly smooth, just saying.......

I think I figured out where the lines are coming from. The cheap gray filament I bought doesn't stick as well as the Creality Hyper-PLA, and it appears it was wandering around.

My first clue was this print... ![]()

![]()

OHMIGOD; something doesn't look right! ![]()

I couldn't quite figure how it happened until I saw it again as it was printing and it had come loose from the build plate. Then the penny dropped and I could see how it got looking like that. It was funny that it picked up printing almost normally after creating the bird's next, I'm amazed it did that!

You can try adjusting the plate temperature, or print with a brim to help adhesion.

For the Base... Rays Block Veneer - Project: 1029, could dress it up a little... throw a 4" concrete slab on the top.

@Darrell posted:You can try adjusting the plate temperature, or print with a brim to help adhesion.

I can't imagine a brim would help, the supports cover a broad base. If that ain't gonna' stick, I doubt a few more lines of filament would havechanged it. I never had this problem printing with the Creality Hyper-PLA, it's this cheap filament that is different. Live and learn, don't buy cheap filament. ![]()

That print definitely had enough surface area touching the build plate and should not have moved.

Until very recently FDM printers were printing anywhere from 50-150mm/s. John's printer can do 600mm/s (it can probably do 800mm/s). At half speed... 300mm/s it's 2-6 times faster than most FDM printers. Not all filament producers have formulated their filaments to handle these new printing speeds. If you get one of these new 'speedy' printers be aware that not all of the filaments on the market can meet these new printing standards.

Yep, it's back to the premium filaments for me! ![]()

Access to this requires an OGR Forum Supporting Membership