I do wish Lionel would improve on having parts that are in high demand and no longer available. I am sure there are many examples of parts that are out of stock because of various design flaws or parts that are often broke during normal use. These design flaws include gears (fail under normal use, i.e. the Niagara), incorrect lens color, defected parts from their vendor including poor quality metal castings (i.e. scale GG1s). The list goes on. The normal parts that get damaged are front pilots, rear platforms, front railing platforms (scale Allegheny), the front bell for the new big boy engines. I would at least like to have a "somewhat reasonable" solution rather than no option (purchasing an entire shell for a $10 part may not be reasonable).

On a positive note, one thing I really like seeing are options that are as "good as" or "better" than original. And there are examples of those as well (i.e. the front support bracket made of steel rather than cast under the boiler (above the chassis) of a Legacy AC-9, improved gears for the Niagara, aftermarket GG1 truck frames, etc.

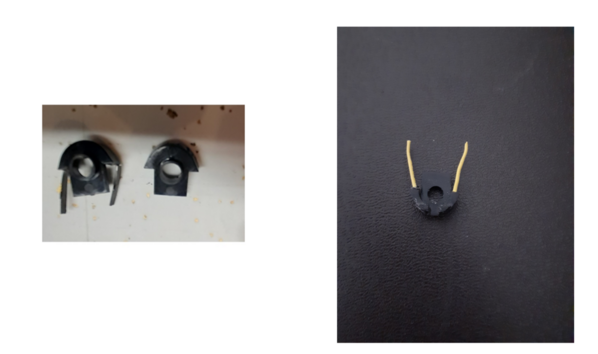

There are times I have to resort to making my own parts, or trying to find a donor, or a re-designed part. And donors can also be a "that's too bad it had to be scraped for parts" type of thing. I do know Lionel will take items and use them to fill the parts needs. I get that. I have my own "scrap" yard of original and sometimes high value items.