Unfortunately don’t have one to send. Wish I did

Probably just as well Bob, I'd just crash it trying to get the video. ![]()

![]()

Yes flying inside might not be the best idea but it would look great

Watching ...

Looking good, John!

Peter

Thanks Peter. Got the rest of my switches in from Ross, just have to find time to make more progress, this is a busy time and lots of other stuff is popping. I don't know how other folks get anything done after they retire, I'm busier now than I ever was! ![]()

John,

I think this is part of the trap, we work to retire then realize it is a swap from a career to home, hobby, family, friends and Mother Nature :-p

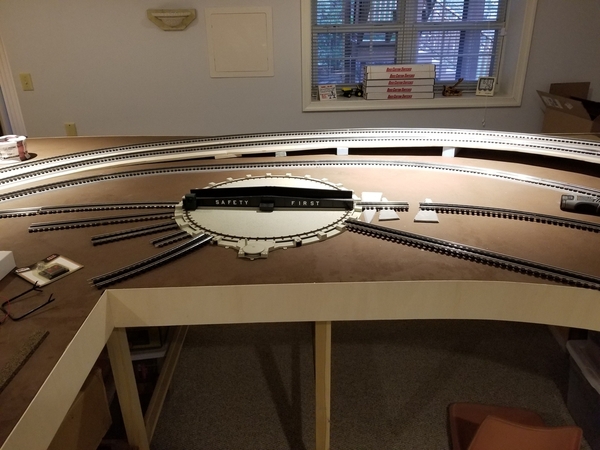

Made some progress on one end of the layout, go a bunch of track and eight switches laid in. I don't know why I thought this would go quick with 22 switches and over 400 feet of track, but it's sure taking longer than I had originally anticipated! I like the fact that I can cut flex track to size, brings me back to the tubular track days. OTOH, it ends up being more time consuming and it's really easy to screw up. I also found out, to nobody's surprise, that the paper plan doesn't always work when you actually get track in hand! I've had to get a bit creative in a couple of places, but over all I'm happy with how it's coming.

This section was all cleaned up and with the arrival of my remaining switches, it's all in place.

A view from the end.

This is the workshop end, the rail at the edge is my maintenance siding, that's where I'll put stuff on from the bench for testing and drive it out onto the layout.

Attachments

Hey John,

I like the "drive-up" service center. Filler up with water, "black diamonds", earl ( as Norton alias Art Carney used to say) and wash the windows! Looks good!

John

Inching along... ![]()

And you haven't finished the landscaping yet??![]()

Great work John, looking good. It seems like everything to do with trains takes longer than anticipated. Maybe it's just because when you're retired, "There's no rush!" ![]()

Rod

Hey John there ya go ! look's great so far. Flex track is great, but it definitely takes a lot longer to lay down then standard track. OTOH you have a lot more flexibility.

Alex

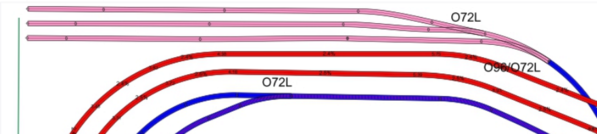

Yes, Alex, I had a lot more flexibility, that was part of the problem! ![]() One issue with flex track it's so much easier to create a paper plan that won't actually work in reality, and it's not that obvious until you are physically placing track! Several places I found that due to the placement of my switches and the models used, my turns were too tight. I'm shooting for a bare minimum of O72 anywhere on the layout, so if they work out to be less, I had to rejigger the plan to make them work.

One issue with flex track it's so much easier to create a paper plan that won't actually work in reality, and it's not that obvious until you are physically placing track! Several places I found that due to the placement of my switches and the models used, my turns were too tight. I'm shooting for a bare minimum of O72 anywhere on the layout, so if they work out to be less, I had to rejigger the plan to make them work.

@modeltrainsparts posted:And you haven't finished the landscaping yet??

All I have to say to this is...

Attachments

Looking good, John.

Thanks Pat, baby steps, but we'll get there.

Lookin' great, John.

@gunrunnerjohn posted:Made some progress on one end of the layout, go a bunch of track and eight switched laid in. I don't know why I thought this would go quick with 22 switches and over 400 feet of track, but it's sure taking longer than I had originally anticipated! I like the fact that I can but flex track to size, brings me back to the tubular track days. OTOH, it ends up being more time consuming and it's really easy to screw up. I also found out, to nobody's surprise, that the paper plan doesn't always work when you actually get track in hand! I've had to get a bit creative in a couple of places, but over all I'm happy with how it's coming.

This section was all cleaned up and with the arrival of my remaining switches, it's all in place.

A view from the end.

This is the workshop end, the rail at the edge is my maintenance siding, that's where I'll put stuff on from the bench for testing and drive it out onto the layout.

Looks good John.

Two questions....

1- What happened to the second level shelf on the left? Did I miss a post?

2- I would have expected the service track to make a right turn and land the trains right at the bench ![]()

Stick a couple of buildings in the middle and call it scenery. We will not pass judgement. ![]()

Bob

Looking forward to seeing a locomotive testing the trackwork. Use the one most likely to derail. Do you have a finnicky steam locomotive to run?

Ron H

@RSJB18 posted:Two questions....

1- What happened to the second level shelf on the left? Did I miss a post?

2- I would have expected the service track to make a right turn and land the trains right at the bench

After considerable thought and consideration, I realized that my plans for that would really not work out very well. Any scenery for a town that was placed that far away would be pretty much lost when you're viewing it from 12-13 feet away. Besides, with the lack of space for sidings, I decided that maybe a three-track siding back there made more sense. ![]() The three tracks in pink replaced the shelf.

The three tracks in pink replaced the shelf.

As far as the track to the bench, I figured the track in front of my side bench and cabinet would probably not have been all that functional. ![]()

![]()

@Ron H posted:Looking forward to seeing a locomotive testing the trackwork. Use the one most likely to derail. Do you have a finnicky steam locomotive to run?

Ron H

Does a bear do his business in the woods? ![]() I'm sure I can rustle up some temperamental locomotive for the test.

I'm sure I can rustle up some temperamental locomotive for the test.

Attachments

@gunrunnerjohn posted:After considerable thought and consideration, I realized that my plans for that would really not work out very well. Any scenery for a town that was placed that far away would be pretty much lost when you're viewing it from 12-13 feet away. Besides, with the lack of space for sidings, I decided that maybe a three-track siding back there made more sense.

The three tracks in pink replaced the shelf.

As far as the track to the bench, I figured the track in front of my side bench and cabinet would probably not have been all that functional.

Does a bear do his business in the woods?

I'm sure I can rustle up some temperamental locomotive for the test.

One can never have enough sidings. Wise move.

It looks great, John!!

John, Your track work is easy on the eye. Nice eye candy.

You're getting there, John. It's going to be fabulous.

Looking good!

I see you used curves switches with a continuing curve on the inside route that I assume is O-72. I had allot of issues with these situations where I matched the O-72 line I scribed on the table, only to find out I needed a little bit more relief for the curve radius when transitioning to the switch and off of it. I tested a few of bigger engines but not all of them, where I found the conflict later on. Definitely encourage you to try your all your big engines in these places for these situations.

@Tom Tee posted:John, Your track work is easy on the eye. Nice eye candy.

It's supposed to be train candy Tom! ![]()

@Phil McCaig posted:You're getting there, John. It's going to be fabulous.

Someday... ![]()

@Hump Yard Mike posted:Looking good!

I see you used curves switches with a continuing curve on the inside route that I assume is O-72. I had allot of issues with these situations where I matched the O-72 line I scribed on the table, only to find out I needed a little bit more relief for the curve radius when transitioning to the switch and off of it. I tested a few of bigger engines but not all of them, where I found the conflict later on. Definitely encourage you to try your all your big engines in these places for these situations.

Actually, coming in and leaving the curved switch the curves are wider, I just tried to keep it flowing. The curve after the exit is right at O81, it exactly matches the O81 Atlas curve. Going into that switch, there is 18" of almost dead straight track. I didn't have a choice about the O72-096, it was the only thing that would do the trick in that space. I looked at the larger curved switch, but it was way out of hand for the space I have there. There is no curve anywhere that's less than O72. I tried to keep things in the 80-90 range. I have some O81 & O90 atlas sectional track that I use to judge what I'm bending.

Not to say I won't have issues somewhere, with this much track and that many switches, I'm bound to screw up in a place or two!

John, I have enjoyed seeing the progress. That's impressive bench and trackwork!

I like your service track arrangment. That's a good place to confine those initial test runs when a repair comes in. I've sometimes made the mistake of letting some rather filthy customer repairs from the store track crud over my whole layout.

With all that track and potentially hard-to-reach locations, how are you planning to handle track cleaning?

@GregR posted:With all that track and potentially hard-to-reach locations, how are you planning to handle track cleaning?

Uh oh, here's a possibility for another 26 pages.![]()

john

you have a lot of columns in your basement.

John,

Alex M. had a nice industrial area on his last layout on the island. Perhaps he could post or share that design with you for the siding space. Did you get any photos at the open house?

Yes GRJ....your scenery seems to be lacking...lol. OTOH...your layout will be quite worth it once you can get the consists running...keep rockin!

I may be mistaken but I think that after we cut a close tolerance round hole in the plywood and the Homasote we determined that the columns were decorative. Oh well...

Nice!!

Yep, I could have chopped those columns down, but When looking at the floor, I'd have had to do something about the rug and the Pergo floor, the column intersects there. That would have been messy, I don't have any of the flooring or rug, so they stayed. Actually, I'm thinking the one that's closest to the left side I may actually cut a road through it for some scenic relief, I think that would look cool. They'll also get some sort of decoration, maybe I'll make them into giant redwoods. ![]()

@GregR posted:With all that track and potentially hard-to-reach locations, how are you planning to handle track cleaning?

Track cleaning? What's that? ![]()

![]()

@Lehigh74 posted:Only 2.

Well, technically, two and two halves.

@redjimmy1955 posted:Yes GRJ....your scenery seems to be lacking...lol. OTOH...your layout will be quite worth it once you can get the consists running...keep rockin!

Yep, I had this silly idea of getting the track all in place first. ![]()

Attachments

JOhn

Track work coming along nicely!!! You are so right about the flex track taking more time but after its laid in place its worth the effort. Hopefully you have someone to help as a second set of eyes and hands surely helps.

Wish I was closer for some help as my dremel has been idle for some time now.

Steve

Yep, I have a friend that was here and is coming back on Sunday, hopefully we'll have more progress to report. It's sooooo much easier with two people, especially when one of you is up on the layout screwing down track.

With the combination of the Dremel and my trusty 6" cutoff saw with the aluminum oxide cutting blade, we can make short work of cutting track to size. I'm am ending up with a lot of 3-4" pieces of track, somehow you can never plan all the cuts to use everything. ![]()

@gunrunnerjohn posted:I may actually cut a road through it for some scenic relief, I think that would look cool. They'll also get some sort of decoration, maybe I'll make them into giant redwoods.

Great Idea!!!

That's the idea Ron, and mine won't be closed to traffic like the one you picture is now. ![]()

I have a little awl and reamer that I open them up. I try to not get carried away so the pins still fit tight.

using a slip switch. . . I know you love wiring. The one I wired required two DZ- relays.

If you come up with a better wiring diagram .. please share!

Nope, I'm planning on two DZ relays for my two double slips, only way I see to power all the pieces. They're going to be the most wiring intensive part I suspect. With switching the powered rails and non-derailing on all the entry points, it'll be a busy section right under those two! ![]()

Attachments

Wait a minute!! Am I understanding correctly that these columns are DECORATIVE????

That drill trick to clean out the burrs inside a cut rail came just in time for me. I just finished laying all my track!! 🤪

I have used an awl and a sharp tapered punch tip but the drill is much quicker. Only go in half the length needed so there is still a good squeeze on the pins. I seem to have a batch of N.O.S. GG track that has tighter I.D. than my last batch.

Double slip wiring. Wired as if it was two switches.

Edit / add: As you work a curve, with flex track, the three rails will be different lengths. Adjust/cut as needed.

@Mark Boyce posted:Wait a minute!! Am I understanding correctLt that these columns are DECORATIVE????

My question as well. Short work for a Sawzall ![]()

@Mark Boyce posted:Wait a minute!! Am I understanding correctLt that these columns are DECORATIVE????

That drill trick to clean out the burrs inside a cut rail came just in time for me. I just finished laying all my track!! 🤪

Mark:

I use a small Phillips screw driver that fits the hole in the rail.

As I explained earlier, even though the columns are decorative, removing them would require work on the wood and carpeted sections of the floor, neither of which I have extra material for. It just didn't seem worth it to rip them out when it's actually kinda' cool to have them to build around.

You could paint them green and call them beanstalks

I'm thinking more along the lines of giant redwoods. I just have to find someone that can paint convincing tree bark on them. I'm considering a road through the one nearest the walkway, that would be a cool touch. ![]()

A trick we used to do when selling homes with small rooms was to use a flat wall paint color called Ivory Linen. It is like slightly aged piano keys. Interior decorators used this for staging small room homes because the eye does not readily focused on that color. The walls became visually recessive. Used the same color in enamel for the wood trim.

However in reality I found the John's columns to be a non issue when working on the layout.

As I mentioned earlier, Johns RR has a lot of what I call eye candy. Any one descending into the train room is first greeted on the landing with a wall filled by scores of beautiful engines. Then after a 180 degree turn this overwhelming RR empire strikes you. There is this very interesting track arrangement mounted on the grey roadbed framed by meandering bench work which could appear as a growing organic entity expanding and embracing the columns in a very nicely finished rec room, it all becomes a stylistic complement. Once the third dimension of the second level is finished there will be an increase in definition. The ascending grade wrapping around the back side adds topography to the valley of the scene.

I guess a good question for John would be what kind of comments do visitors have? Both RR people and non RR people. Outsiders perspective may provide an interesting insight. We all may be making too much of the columns.

IMO, this is a project any one of us would love to have.

Well, I have to say, many of the rave reviews have been for the benchwork, and I can thank Tom for pushing me in that direction. A number of people have come over just to see how that was done and were planning on looking into enhancing their layout with curves like mine.

Hey John,

Put a bunk bed and a hotplate down there, and there will be no need for you to ever go upstairs again. :-)

You been talking to my wife? She keeps saying that! ![]()

So, how does one get A table built by these professionals?

John, I totally agree once you had the room with the columns all the hassle, mess, and attempt to close in the flooring and ceiling to look like the column wasn't there is not worth it even if you wanted to do it. I just never heard of decorative columns in a house. I guess I am just used to columns being in the way no matter what a person wants to use the room for. I'm afraid I am in the 'Crappy Basement Layout' league. I was never sure if the basement was crappy, the layout was crappy, or both. ![]()

@Mark Boyce posted:John, I totally agree once you had the room with the columns all the hassle, mess, and attempt to close in the flooring and ceiling to look like the column wasn't there is not worth it even if you wanted to do it.

My original layout plan stopped just short of the columns, so I figured they might support a backdrop of some kind. However, someone came in and talked me into an extension that went beyond the columns! ![]()

![]()

@Mark Boyce posted:I just never heard of decorative columns in a house. I guess I am just used to columns being in the way no matter what a person wants to use the room for.

I was a bit surprised to find they were decorative, I actually expected them to be functional. However, since this place is truss construction, the spans are not a problem, and the columns are totally hollow. I briefly considered hacking them off, but then decided against it. I'd also have to consider how stupid the half-columns would work without these still standing. Also, I just didn't want to have to project of removing them and cleaning up all the issues they left behind...

Considering the recent spike in lumber prices that seems like a rather small stack of money.![]()

Good point Tom, let me finish counting here...

Humm...sitting in that position...that pile of gold bricks...begs the question...did he just produce that pile?

I'll come out of retirement to build a layout for him!

If he's pxxxing gold bricks, I want to get to know him! ![]()

@Mark Boyce posted:I just never heard of decorative columns in a house. I guess I am just used to columns being in the way no matter what a person wants to use the room for.

Mark, a pair of columns either smooth or fluted are a common design demarcation between two different living ares in today's homes here in this area at least.

Usually we RRers have to contend with concrete filled 4" support columns. I have one in the middle of one set of whisker tracks.

Attachments

Yes Tom, what you have is what I am used to. Half our basement level is garage, with a column like yours between the two car stalls. A lot of houses have columns in finished basements.

A little more progress yesterday. Got all the switches and track back in place on the lift-bridge and finally made the cuts and allowed the bridge to be free! Also laid the inner loop on this part of the table, but still have to add the passing siding, the switches are hanging in space now. Had to order another case of Gargraves track, I'm running out and still have quite a lot of track to lay. ![]() I counted up ordering exactly what I need, but since individual pieces cost more, it only costs about $30 to do the whole case and have some left over.

I counted up ordering exactly what I need, but since individual pieces cost more, it only costs about $30 to do the whole case and have some left over.

A view I haven't seen for a while, the liftbridge can be raised now! ![]()

All the track on the liftbridge has been nailed down (OK, screwed down) and cut to allow bridge operation.

The inside loop is now complete, just have to add the passing siding at the far end inside the 3rd track.

Attachments

well done John!

Nothing is so easy as the job you imagine in your head.... Oh, I can do THAT...

Really taking shape now, John.

Datza nice![]()

![]()

![]()

![]()

Every new section I find that the paper plan is only a reasonable facsimile of what actually gets put on the table. Funny how all the stuff on the paper never fits like you think when you start actually laying track. ![]() This is the first time I actually tried to use a layout program, and I have mixed feelings. On one hand, I did get what looked to be what I wanted on the paper, so that was the good side. However, when I start laying track, I found out that a lot of the stuff that looked good on the paper didn't exactly work out in real life. I've gotten somewhat more cautious about assuming that my paper plan is all going to work out. In the places where I was using O72 sectional track... it didn't really work out at times. When one of the first track loops deviates from the exact shape of the plan, the ripple effect is enormous, and you end up changing a lot of other stuff, if only a bit, to make everything come out as you planned.

This is the first time I actually tried to use a layout program, and I have mixed feelings. On one hand, I did get what looked to be what I wanted on the paper, so that was the good side. However, when I start laying track, I found out that a lot of the stuff that looked good on the paper didn't exactly work out in real life. I've gotten somewhat more cautious about assuming that my paper plan is all going to work out. In the places where I was using O72 sectional track... it didn't really work out at times. When one of the first track loops deviates from the exact shape of the plan, the ripple effect is enormous, and you end up changing a lot of other stuff, if only a bit, to make everything come out as you planned.

So, if I had any advice for someone doing a new layout using a track planning program, I'd say either follow the plan to the letter or plan on alterations all along the way. I think the "flexibility" of flex track is the Achilles Heel of of using a track planning program. The ability for the program to "smooth" the track makes it look better than it is. Also, it's easily possible to end up with sharper curves than you intended that look "fine" on paper until you try to put the track down.

This is the biggest layout I've tackled, so it's been a learning experience all along. The journey continues... ![]()

The track looks smooth, John! I found the same issues using software for a track plan for the first time. Since I only looped twice around, and left plenty of room between track for grades and scenic features, I didn't have much of the ripple effect, but I do know what you mean. My plan only called for flex track at key points where things didn't quite fit with sectional, and it all worked out. Of course my plan has only a fraction of the track yours has.

How do you like the Mianne lift bridge? What is the headroom clearance? I am assuming you only have it raised partially or you layout is higher than I thought.

Awesome work John. Very motivating for me to get my behind in gear!!!!

Joe Gozzo

Mark Boyce - I own a Mainne Lift gate and love it. One word of caution to note. My table is 36" (actual leg length to bottom of table) and my lift gate does NOT go up anywhere near high enough for my 6' tall body to walk under. My wife who is 5'6 has hit her head because she is just a tad too high. I installed Foam Pipe Wrap on the three beams on the gate as HEAD Protectors. The height of your table is going to dictate how high it can go up. The slides are the similar to those on cabinet drawers. Hence if they are 36" long and have to overlap by 8-10" you do not get 6'. If your table height is 48" you just added over a foot to the raised height. Overall I love the gate and would not trade it. My one complaint is the short cord used to go to the control. If your gate is wider than a foot you can't reach it from both sides. Hence why John and others installed switches. I also will be installing switches.

@Mark Boyce posted:How do you like the Mianne lift bridge? What is the headroom clearance? I am assuming you only have it raised partially or you layout is higher than I thought.

The top of the layout table is 41" and the clearance under the liftbridge is 62" from the ground. Yes, I have to duck a little, but I don't have to crawl!

@Trainlover160 posted:Awesome work John. Very motivating for me to get my behind in gear!!!!

Great, it's a race! ![]()

John! That’s great news. Glad you’re getting a place to play.

Marty, I just had to stop spending all my time on repairs and upgrades and take a little time to do work on the layout. Still quite a ways from running trains, there will be a lot of wiring coming next!

Curtis and John, I thought it was low. I agree it is better than a duck under or crawl under. It could be what John Armstrong called a nod under. Yes, switches on both side are a must. Thank you!

John, You have discovered the short coming of track planing programs. Ya done good quite soon! It took me several layouts to walk away from them. They are OK for a basic island multi looper but industrious efforts bring out their limitations. Using spiral easements on all curves of any degree needs hands on touch, templates and trammels for large intricate pikes where there really is no room for error which can Domino the right of ways.

@Tom Tee posted:John, You have discovered the short coming of track planing programs. Ya done good quite soon! It took me several layouts to walk away from them.

Yep, being somewhat of a computer geek and using my computer for many tasks, this looked like a natural. It was actually very beneficial in any case, just not the do-all solution I was expecting. Actually, my Fastrack plans usually worked out right on the money, because every piece was a fixed size and curve. Throw in all the variables of flex track and the plan goes out the window.

I realized after the first track sections were laid that I was going to be doing a lot by the seat of the pants. I'm sure I don't have near the fine track work that you produce, but I can see that it's very difficult to capture all the little nuances of track work exactly in the program without a ton of work. I'd rather put that work into actually getting the track down.

I'm still stunned that from what I started with for my original plan how this mushroomed into what I have now. I probably have twice the track and switches that I ever expected to use.

John.... I but I like your repairs. With MTH demise and my obsession with MTH, I’ll “NEEEED” you. But yup, better to play!

Well, there's just a little extension of the time to turn some repairs/upgrades around. I'm waiting on parts for weeks now for several upgrades, and with the holidays and lots of family stuff, it's been slow slogging the last few weeks. I also am resolved to get trains running soon, that will probably actually help the repair work, I'll have a real test track!

Gotcha, my early sketches had about two dozen switches and as of Thanksgiving I just hit 110. However do not sell yourself short, anyone can lay nice right of ways in 0 flex. GG flex can be a real challenge for many to lay out smooth transitions and fixed curves.

When I said your layout is like eye candy it is primarily because of the flow of your track laying and turnout selection and placement.

Tom, you're simply out of control, I think you're trying to pave the whole basement with track. I suggest you at least leave a path to walk on! ![]()

![]()

John I’ve thoroughly enjoyed following along. Your construction and track work are top notch (I know Tom played a big part, but so did your skill). Getting the track work right is key to enjoying your layout.

Andy

John, Nice to see your progress! This is looking like a super start, now on to the wiring.

I’ve enjoyed watching the progress on your layout. We purchased a new house with a finished basement around the same time you did, so I’ve been keeping close attention on your posts and picked up many tips for mine by watching yours.

I already had most of the track, but it’s Fastrack. Since Fastrack is rigid, I had the opportunity to somewhat reverse the method of construction. I’m a layout building rookie, so I didn’t know if my initial plan would work how planned. So, I picked up a 4 ft role of brown paper and taped it down to the concrete floor. Then built and heavily modified the track layout on top. Followed with wiring and locating the buildings. Even built the modules for the elevated sections.

I am now testing the layout with various trains for the holidays to insure proper clearances and wiring. In January, the temporary layout will be disassembled, but not before tracing out the entire layout, marking each piece and wire location. I will then have a full size template to build the benchwork.

I will be building my own since I have a fairly equipped woodworking shop. Just need to finish the walnut bedside tables that were promised to the wife for Christmas.

@gunrunnerjohn posted:Marty, I just had to stop spending all my time on repairs and upgrades and take a little time to do work on the layout. Still quite a ways from running trains, there will be a lot of wiring coming next!

John, I'm glad to see you doing something for yourself. Now i think it's time for me to follow your lead and get back to my layout. A little less on upgrades and repairs and more enjoyment for myself, only thing is we most likely will soon be empty nesters (one or two years ). Won't need this large home any longer . So as i build it will be bittersweet for me, i won't go crazy because it will only have to be dismantled.

Your track work is looking fabulous !

Alex

Thanks guys, I'm hoping to FINALLY be able to run trains at home on a decent sized layout. ![]()

Alex, that's a bummer that you have to take it apart again. Are you building it in a modular fashion so it's easy to disassemble? I can assure you, mine is NOT modular, large hammers and a couple of Sawzalls will be required to get this layout out of the basement! ![]() I don't plan on moving anytime soon, and I'm pretty sure this is the last layout I'll be building.

I don't plan on moving anytime soon, and I'm pretty sure this is the last layout I'll be building.

@gunrunnerjohn posted:Tom, you're simply out of control, I think you're trying to pave the whole basement with track. I suggest you at least leave a path to walk on!

Guilty as charged.

"I suggest you at least leave a path to walk on!"...That is exactly what I have left. Paths. The basement now is pretty much full of free form finger modules forming puzzle paths. Even my modules have grown modules. However the nice thing is that there are no duck unders for running trains, total stand up walk around, and I do mean walk around. I believe this layout could keep at least six people busy operating.

Due to repeated casts I have been using a knee scooter to get around. Duck unders were out of the question.

I think I may be subconcsiously building endless benchwork to avoid starting scenery. ![]() Have not done serious scenery in half a century.

Have not done serious scenery in half a century.

John, your RR is an example of what could be a wise goal of most all layout builders. A sensible balance of layout size to room ratio, ease of operation, full visibility, and total access.

A posters comment I am looking at seriously. Could a drone be used to film a large layout?? Could a good operator be able to maneuver a video drone around a basement layout with an 8' ceiling?

Gotta run, just got in the rail joiners from Justrains that I needed for my 3 rail Atlas track on my 5th level subway layout. Something for the neighborhood kiddies to run if we ever get to having visitors again.

Tom, my ceiling here is 7 1/2 feet high and the layout top is 41" high. I'm sure someone could fly a drone in that 4' space, but it ain't me! ![]()

@gunrunnerjohn posted:Thanks guys, I'm hoping to FINALLY be able to run trains at home on a decent sized layout.

Alex, that's a bummer that you have to take it apart again. Are you building it in a modular fashion so it's easy to disassemble? I can assure you, mine is NOT modular, large hammers and a couple of Sawzalls will be required to get this layout out of the basement!

I don't plan on moving anytime soon, and I'm pretty sure this is the last layout I'll be building.

It's not really modular , but it will be quite easy to dismantle when the time comes. One thing is for sure, my next home will make certain for it to be the forever home and the layout will be the last one too. Next move will be our fourth, getting tired of lugging everything from home to home lol. I've actually spent some time in my layout room the past two weeks, made some changes and was able to make some progress. Hoping i can enjoy this current layout for two years.

Alex

Alex, where's your layout progress thread? ![]()

@gunrunnerjohn posted:Alex, where's your layout progress thread?

I will post on it right after the holidays, want to get a bit more done. Most likely two weeks

Alex

I'll look forward to it. ![]()

Gunrunner John, your layout is looking so good, it’s a lot more work, thinking, planning than a lot of folks can imagine. Your trackwork is great, I used Gargraves a little bit, mostly Atlas O and ross custom track and turnouts. I did use Ross’s pre curved track because I’m not good at bending gargraves track. My smallest diameter is 072, largest 0120, I just had to watch for clearances, using the inter-modal cars and the VL GG1’s for heights, and kept a 2 percent grade. Yes, soon you are going to love running those larger scale Big Boys and Challengers on your layout, it’s a great time to be in the model railroading hobby. Thank you for making this fun to read thread, your ideas, model work is amazing. Happy Railroading Everyone and Merry Christmas.

I am looking forward to seeing my big iron chewing up the track. ![]() It's been quite a while since I could actually run something large at home, I used to have to pack them up for club runs. Someday soon... I'm starting to get the hang of Gargraves flex track, but I don't hold the ultra precision that some do, I am just shooting for wide enough curves and no big kinks in the track. If it looks good and everything runs good, trackwork is done.

It's been quite a while since I could actually run something large at home, I used to have to pack them up for club runs. Someday soon... I'm starting to get the hang of Gargraves flex track, but I don't hold the ultra precision that some do, I am just shooting for wide enough curves and no big kinks in the track. If it looks good and everything runs good, trackwork is done. ![]()

I will say, this being larger than anything I've attempted before, it is a butt-load of work, and it's not nearly done yet! Wiring is still to come...

Things slowed down for the holidays, but I have started to make a little progress. I have all the main level track in place with drops for power dangling under the table. I also decided to use the CSM2 breakout boards for the DZ-2500 switch machines, so I'm waiting on twenty-odd boards to come in to get those underway. With the switches wired and the power drops in on the main level, I was able to put the second level deck back in place, it's just propped up right now, working on the permanent supports, trying to make them a bit more attractive than plain wood. Some changes in the exact track position have made the supports more "interesting" to do, there'll have to be some creative solutions in a couple of places.

I was mulling over the turntable idea I had, but the 32" one I was considering was a non-starter, no way I could possibly fit it in. However, just for fun, I found the Atlas 24" one, and it will actually fit in. Takes up a big chunk of the one end of the table, but I'll have my TT. Of course, this is changing a bit of the track I had already completed, there's always that issue that crops it's head.

I know it's a low-cost TT, but with the little motor drive fitted, it actually works better than I expected, the alignment is more consistent than I would have imagined coming from either direction. It's also very easy to install since it doesn't have the recessed pit that would have required me to tear up a bunch of the benchwork below and brace it for the hole for the pit. I think it'll be a fun addition to the layout, and it looks like I can park a bunch of my smaller steam and some diesels here, that will be nice. The power for the TT, whisker tracks, and TT control will all be controlled by manual switches and also through some Lionel SC-2's so I can command control it from the remote. Someone complained that the Atlas TT had trouble swinging a heavier locomotive, so I plopped my battery powered camelback on it. While the camelback wouldn't be that heavy, the three pounds of batteries add to it's "heft", so it's actually as heavy as any of my smaller steam and a lot heavier than most of the diesels. The TT had no issue at all swinging that. As many others have said, I took it out of the box and in about ten minutes the motor drive snapped the installed belt, that had been on there since manufacture and had obviously dried out a bunch. I'm going to round up the recommended Danko O-ring as a replacement for the remaining belt I have installed now, I have no idea how long it'll last. (Note the picture is still the hand crank).

Another brainstorm popped into my head in looking at my three hidden yard tracks, there was a possibility of adding about 30" to each of them. Can't have too much yard space, so I made a little lift-out panel and it'll get the track extensions. I needed it to lift out to be able to freely access the sump pump box under it in case (or rather when) I need to deal with any sump pump issues. I just used four dowels glued into the 3/4" panel to align it exactly to the main table surface, it's ready for some track.

Attachments

Some of my brainstorms turn into Cat 5 hurricanes John ![]() Better be careful!

Better be careful!

I like the TT and added yard space is always a plus.

Bob

John is that tt the old one or the new one. Just wondering if the new one has the same problem with the o ring as the old one