Modelers have added shims to the Fox Valley high rail version so they support highrail and scale. The turnouts that Tom Stoltz made also support highrail and scale, my custom made turnouts do as well. I just noticed the FVM turnouts do not have any wing rails.

@Ukaflyer posted:Are you putting aside using SHS/MTH flexi track because they don’t make compatible turnouts in the style of AM and FVM? Can AM and FVM turnouts be easily connected to SHS/MTH flexi track if you lean towards this track or is it just not worth any extra work to make it fit?

In a nutshell, yes. SHS/MTH only has the R20 turnout.

Easy? Maybe. Depends on how much effort one puts into it. HOer's have been mating code 83 and code 70 to code 100 for decades. Personally, I've never mixed rail codes regardless of what scale I was working in.

Also, are you moving away from AM track because of the need to modify the turnouts? I guess I am coming to the conclusion that the complete FVM track system suits your future needs in its entirety without having the need to modify anything, albeit the rail code is not in keeping for scale use.

My modules were the only time I've used AM track, because it's what the club decided on a standard. We had one turnout at the time and we always ran Flyer or Hirail on that loop.

My home railroad always used code 100 track. If I want to run some HiRail or Flyer, I throw some SHS track down on the floor in the man cave.

As far as "scale use," I'm becoming less fussy about such things as I get older. I try to go for an overall effect, rather than down to the smallest detail. I'm not doing nor never intend to do Proto:64. If my rail's a little high, so what? Besides, FVM track rail height seems pretty close in scale to what the mainlines are using nowadays.

Rusty

As retirement looms in a few weeks time I shall be busy adjusting to a new way of life, especially as our daughter has just had her first baby mid February and I have only seen him twice with lockdown now in place. Also ‘management’ has a list of jobs that need doing before I get permission to start looking at building a permanent layout for running the Flyer. So if FVM seems the preferred route to go then I need to start planning how much I will have to purchase.

@Jim Z posted:I have been busy on my S gauge layout. I built an unloading dock and a coal bin, added a farm scene in a corner of the layout and installed two uncouplers. I also cleaned the dust off my buildings and touched up the ground cover. These are things I’ve wanted to do for a long time but procrastinated.

Oh wow! This is a great looking layout. What is the size of the layout?

@AmFlyer posted:Fox Valley only makes #5's and no one else is going to make numbered S gauge turnouts using .138 rail. Years ago Tom Stotz made them but he quit before I started my layout. So, I took about 5 deep breaths and paid to have the #5, 6 & 8 turnouts made for me. No way I was going to make them. It was really expensive but after three years of operating the layout I have mostly forgotten about the cost and really enjoy the result.

Having been able to see a picture by Rusty showing a number of FVM #5 turnouts, I have to say that compared to ACG R20 turnouts they are definitely in another league. They look pretty good to me.

So looking into this deeper, how safe is it to say that in reality that FVM #5’s are going to fit the bill for most people running either ‘nostalgic’ Flyer stuff like me as well as running things like Lionel’s BB’s and Y3’s at the other end of the scale?

Looking at the pictures of the FVM turnouts I would like to think you could run these large engines through them and not worry too much that they will flow through them easily as compared to an ACG turnout where they squeeze through and you are on tender hooks as to if they make it through.

Is there a demand/requirement for #6 or greater turnouts and what is that need by people? Also, the larger the turnout the greater the footprint and real estate is valuable for a lot of us I would guess.

I doubt there is a large demand for numbered turnouts made with .138 rail. Any supplier of code 100 turnouts could make them, they just need a set of jigs modified to accept the .138 rail. These turnouts are not plug and play. They require rail gaps, wiring and a relay to flip the frog connections. In DCC I believe the pre-made Frog Juicer will do that.

Here is a picture of an interchange using a pair of #6 turnouts. The track is MTH flex. The picture is foreshortened by the camera lens selected. I used #5’s only in the freight yard. The rest are all #6 and #8 turnouts. The #8’s are 18” long. The turnouts were made using rail stripped from the MTH flex. These turnouts were designed and tested to run both scale and high rail. The only downside is they are unforgiving of incorrectly gaged wheel sets. I have spent a lot of time regauging Gilbert and AF by Lionel wheels. The SHS, MTH and AM cars are spot on every time.

Attachments

@AmFlyer posted:I doubt there is a large demand for numbered turnouts made with .138 rail. Any supplier of code 100 turnouts could make them, they just need a set of jigs modified to accept the .138 rail. These turnouts are not plug and play. They require rail gaps, wiring and a relay to flip the frog connections. In DCC I believe the pre-made Frog Juicer will do that.

Here is a picture of an interchange using a pair of #6 turnouts. The track is MTH flex. The picture is foreshortened by the camera lens selected. I used #5’s only in the freight yard. The rest are all #6 and #8 turnouts. The #8’s are 18” long. The turnouts were made using rail stripped from the MTH flex. These turnouts were designed and tested to run both scale and high rail. The only downside is they are unforgiving of incorrectly gaged wheel sets. I have spent a lot of time regauging Gilbert and AF by Lionel wheels. The SHS, MTH and AM cars are spot on every time.

That’s a nice looking layout and a credit to your skills. The multi level operating makes it all the more interesting as well. I like the building facades, can you tell me what they are and where they came from?

You are also lucky in that you have the best of both worlds so that you can flip between hi-rail and scale operations , sounds like the expense of your turnouts paid off.

I was thinking is there a need for turnouts larger than #5 in general for people like myself who are largely Flyer operators, I can’t see one myself, but.........

Tom:

I have used the Fox Valley turnouts since they offered them. I use an altered high rail turnout (see attachment) and run all types of wheelsets code 110, 125, AM, SHS, MTH and L-AF high rail with not problems. I find MTH, SHS and L-AF fasttrack will mate with them with no alterations needed as the rail size is the same in all 3.

Roger

Attachments

@AmFlyer posted:Any supplier of code 100 turnouts could make them, they just need a set of jigs modified to accept the .138 rail. These turnouts are not plug and play. They require rail gaps, wiring and a relay to flip the frog connections. In DCC I believe the pre-made Frog Juicer will do that.

As far as I know right now, there's only one supplier of ready made code 100 turnouts left: Tomalco. Shinohora and Old Pullman have left the building.

What there is, is a potential desire from FVM for #6 and #8 turnouts. If FVM eventually sees a market, I'm sure they would make them.

I had both Old Pullman and Shinohora turnouts on my old railroad and not one single frog juicer. All my frogs were energized through the points. DC and DCC operations were just fine.

Rusty

Rusty, I did not realize only Tomalco was left, that is sad. I agree with you, were there a market someone (FVM) would make them. I wonder why FVM does not set up a build to order program.

Roger, very nice job on those mods/improvements on the turnouts.

UkaFlyer, my skills were limited to envisioning the completed layout, hiring a professional builder and approving changes. The buildings are a mix of the few S scale kits that were available in the correct theme and some customized HO kits. The building fronts in the city are a few S scale kits that looked right, the balance were made from scan files of buildings that were resized to 1/64 and then laser cut out of 5 layers of lexan. These were glued together and detailed/painted by a model maker. The viaduct is the same, it is laser cut clear lexan and styrene plastic parts glued together and painted. Took about a week to do the entire 18' of viaduct, start to finish.

I have some engines with scale wheels that pull passenger trains with high rail wheels, it works perfectly as designed. Over the last two months I have been running trains about 1 1/2 hours a day, plus keeping up with all the minor cleaning and maintenance items.

@DRGWno1 posted:Tom:

I have used the Fox Valley turnouts since they offered them. I use an altered high rail turnout (see attachment) and run all types of wheelsets code 110, 125, AM, SHS, MTH and L-AF high rail with not problems. I find MTH, SHS and L-AF fasttrack will mate with them with no alterations needed as the rail size is the same in all 3.

Roger

I'd love to get more information on exactly what you did to modify them. I am helping a friend with his layout in the near future, and I'd like to do this modification for him.

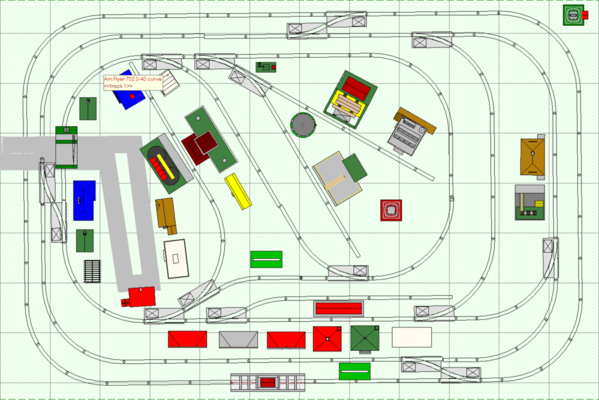

Continuing the discussion of WFH, I had ordered some Mianne Benchwork modules to build an O gauge layout. They could only send 3 4x8 modules at this time so I got to thinking maybe I could do something with my Flyer. I designed the layout below so that I can run three trains at the same time, have possible yards and reverse direction when needed (I may need help with the electronics to do this). The industry and buildings are just place holders at this point and use almost all of the Flyer operating accessories that I have, along with some of my Plasticville. I would appreciate any comments about the design, especially the operating accessories. I've never built or run a Flyer layout so I'm in new territory. Thanks in advance for any help.

LionelFlyer

Attachments

Lionelflyer,

Think you ought to take out the reverse loop. They require special wiring with 2 rail.

Gunny

It looks like several of your operating accessories are too far in the middle of the layout to reach and manage from the edge of the layout.

Chuck:

When using the FV turnouts with mare scale flanged wheelsets there are two areas of concern:

1. The cast frog assembly will not allow these wheelsets to run through the turnout. The wheelsets will drop into the space between the points and the closure rails. To address this issue, I added 0.020 X 0.60" spacers attached with JB Weld. This allowed the scale wheelsets to ride over the space in the cast frog assembly (see Illustration).

2. The guard rails allowed the tread of the scale wheelsets (Code 110 and 125) to be misdirected through the turnout causing them to derail. To address this issue, I decreased the width of the guard rail by attaching a 0.030 X 0.100 spacer to the original guard rail. I roughed up the guard rail with 100 grit sandpaper to increase the bite for the adhesive (I used Eileen's "The Ultimate" ). I painted the spacer with American Accents by Rust-oleum. Color: Espresso, a perfect match for the original FV guard rail. The spacer is difficult to see in the illustration as it has already been painted.

Haven't had any problems in the two years I have had over 20 turnouts on the layout.

Roger

Attachments

Oops! mare = more

Roger

@Rusty Traque posted:As far as I know right now, there's only one supplier of ready made code 100 turnouts left: Tomalco.

Rusty

What about these guys Custom Trax ?

@DRGWno1 posted:Chuck:

When using the FV turnouts with mare scale flanged wheelsets there are two areas of concern:

1. The cast frog assembly will not allow these wheelsets to run through the turnout. The wheelsets will drop into the space between the points and the closure rails. To address this issue, I added 0.020 X 0.60" spacers attached with JB Weld. This allowed the scale wheelsets to ride over the space in the cast frog assembly (see Illustration).

2. The guard rails allowed the tread of the scale wheelsets (Code 110 and 125) to be misdirected through the turnout causing them to derail. To address this issue, I decreased the width of the guard rail by attaching a 0.030 X 0.100 spacer to the original guard rail. I roughed up the guard rail with 100 grit sandpaper to increase the bite for the adhesive (I used Eileen's "The Ultimate" ). I painted the spacer with American Accents by Rust-oleum. Color: Espresso, a perfect match for the original FV guard rail. The spacer is difficult to see in the illustration as it has already been painted.

Haven't had any problems in the two years I have had over 20 turnouts on the layout.

Roger

My understanding from this is that those two shims you JB weld onto the frog allows the flange of scale wheel sets to maintain a reasonable height to allow them to continue through, is this right?

The bit I am confused with now is that if you have shimmed the frog to run scale wheel sets through nicely, won’t hi-rail wheel sets ride up higher onto the shim and you will have a gap between the rail head and the wheel?

Or have I missed something here?

@DRGWno1 posted:…..I decreased the width of the guard rail by attaching a 0.030 X 0.100 spacer to the original guard rail....

Roger,

Thank you! Just to be sure I understand the above statement, I assume you are saying that you decreased the width of the opening between the guard rail and outer rail rather than decreasing the width of the guardrail itself, right?

Also, I recognize this is getting off the topic of this thread, so I am happy to communicate with you directly about this off list at chuck7612@hotmail.com.

Thanks,

Ukaflyer:

Just went down to check on this. Found that the L-AF flanges on their new cylindrical hoppers went through the frog smoothly. There was a slight up tick when riding over the actual frog, but the wheels never left the top of the rail. When running the Code 110 wheelsets, there is a slight drop between the closure rail and the frog at very low speeds. This, however, did not cause a problem for me.

Roger