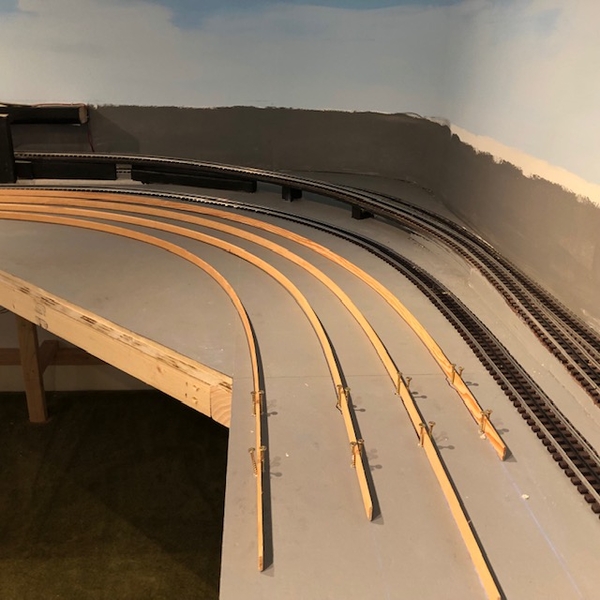

So, with the L-girder bench work built, the next step in my O gauge layout build is to install the plywood roadbed for the track work. This is something I have never done before and I am struggling on how to get started. ![]()

First, is laying out where the track will go. If I was using sectional track, I would assemble the track and lay it out over the joists and mark the outline right on the joists. I could then somehow transfer that to the plywood to create the roadbed sections. However, I will be using flex track, so I can't test fit the track ahead of time. So, how do I determine the layout for the roadbed? I have a cad drawing of the track design, so I suppose I could dimension up the plywood roadbed layout on the drawing and then transfer it on the plywood. Just seems like there must be an easier way.

It also appears to me that with the curved sections a lot of joints in the roadbed will be required to make up the full curved portions. Any tricks here on joint minimizing or the best way to handle this? Any easy way to make the curved sections?

I was leaning towards using 3/4" plywood for the roadbed. There are a few local cabinet makers that sell 3/4" cabinet grade plywood cut-offs in like 8" to 10" widths by 40" long. Maybe these would be useful, but probably not for the curves.

Any help is appreciated. Pictures would be great, as I'm a visual type person. ![]()