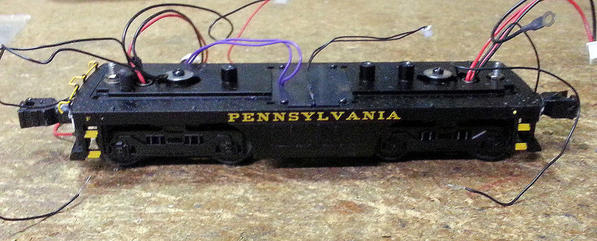

I took my 44-Ton locomotive apart and started seeing if I could come up with electrocouplers for the upcoming command conversion. I ordered an assortment of Lionel's shortest couplers and lined them up on the bench. I selected the 610-1912-050 as the most likely candidate based on it's mounting. It has a big block of metal that I could grind away to make whatever mount I needed.

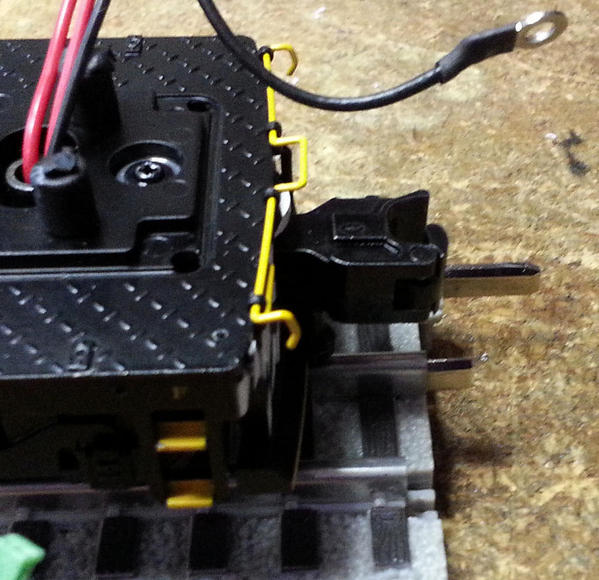

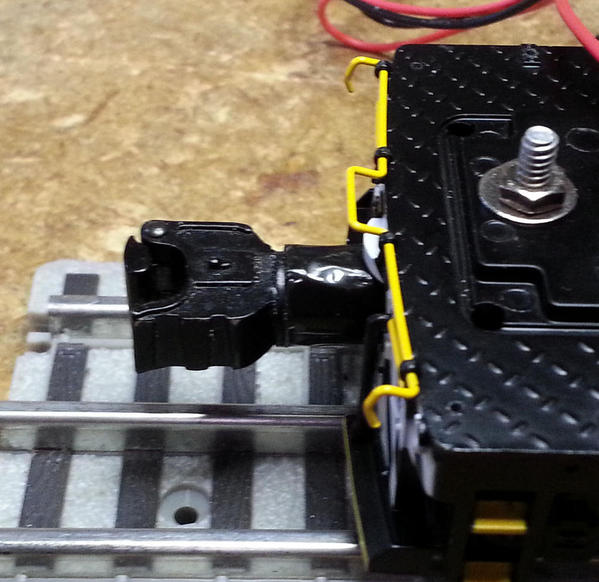

The object of the exercise is to have the coupler at the correct height and to be able to use the existing centering spring, otherwise I doubt I could have the coupler center properly.

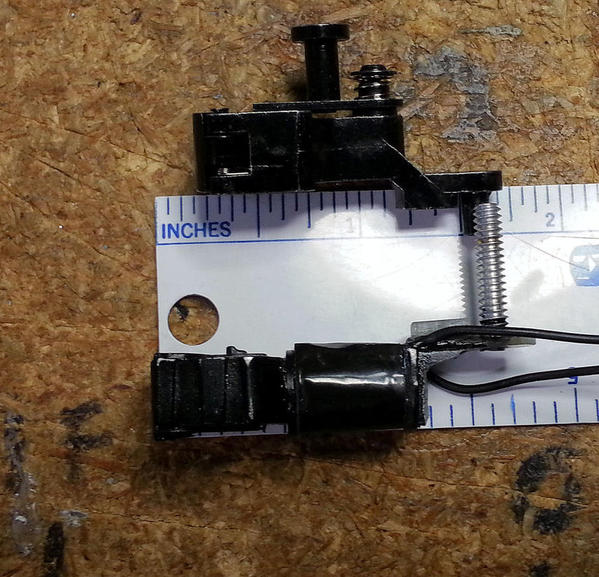

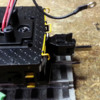

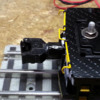

The first issue is the oddball offset nature of the mount, it's clear that no coupler is going to just drop in. I ended up grinding off pretty much all of the mounting end and creating the offset mount using some fiberglass board material I had around. The following pictures are what I came up with on my first cut. I used a #6 screw as the shaft, and I'll Loctite the nut on the top and cut off the excess screw to finish up. The end result did end up about 1/4" longer, I couldn't see any way around that with any of the electrocouplers.

I welcome comments, criticism, or better ideas. ![]()

Edit: Fixed type on part number.