This seems like a real opportunity to boost some lagging sales and appeal to STEM interested parents. The whole Maker movement seems to be a good pairing with model railroads. I have seen some amazing s scale models of 1920's Sears houses printed with full interiors. As a shallow end of the pool entry into this 3D printing thing an in store machine that could print parts as the customers browse the store. If they were satisfied those customers might purchase thier own machines or plastic spools. Any hobby shop that printed a scale figure free for thier customers would get some attention and sales from me.

I would have added this elseware but conversation has been stifled for some reason on a topic that the community here was obviously (and remain) interested in.

Replies sorted oldest to newest

I used to be very surprised there was not a HUGE over lap of train guys and Makers. I've since realized that train guys seem to be very set in their ways, for the most part, and also are unwilling to take instruction, or even advice from the younger sort of folk that pack into Maker Spaces. Makers take things apart, question the status quo, suggest ideas, try other approaches and welcome diversity in all things. Makers do things the hard way, just to learn how to do it better the next time.

Train guys tend to keep things together, and are even warned by the folks with the knowledge NOT to see whats inside. Train guys don't like new thoughts, they don't like new ideas, and they close ranks whenever someone suggests trying something different.

Now to be fair, this is not everyone, but it is enough. Enough that the creative minds that might want to share ideas and question the status quo, instead determine that the hobby is not worth the effort, or the money. Their resources are better used elsewhere. You're left with a stubborn few that just like trains too much to quit.

end rant.

All that said, someone with a 3d printer and the know-how to design scratch parts and models could make a killing in a hobby shop... if they could figure out how to market it. Most folks looking for 3d printers would never think of it, instead going to a local MakerSpace.

"We choose to go to the Moon! ... We choose to go to the Moon in this decade and do the other things, not because they are easy, but because they are hard; because that goal will serve to organize and measure the best of our energies and skills, because that challenge is one that we are willing to accept, one we are unwilling to postpone, and one we intend to win .." - John F. Kennedy, September 12, 1962.

I work in 2D with my laser cutting.

When 3D printing started to look viable I tried learning the software needed to create things. I am 100% self taught in CorelDraw, which is used to create the art for 2D cutting and the decal art I do, but I never got a handle on 3D. It was taking too much time to learn compared to results I was getting.

Plus if there is resistance to O scale kits....why would anyone think many folks would want to make kits AND put them together??

Software is the issue with 99% of the folks that MIGHT use it.

Diecast Direct in Frankfort, KY had some simple pre-made 3-D printed parts in 1:50 scale when I visited their store last week. 3000toys.com in MO & DHS Diecast in OH also have simple pre-made 3-D printed models in 1:50 scale. By simple models, I am referring to trash dumpster, traffic cones, porta potty, etc.,, stationary diorama / layout accessories without many working features.

These are just my opinion,

Thanks,

Naveen Rajan

I designed and printed 25 uprights to hold the roofs over my station platforms. The printer I used was at work and I just had to provide the filament.

I would think the best business model for this would be for hobby shops to have printers for rent and sale. The next important part of this equation is to sell pre-made software 3d people, homes, etc. The software purchaser could then print either a limited number of people or items or unlimited depending on the price paid by the user. Not having the 3d files to print seems to be the limiting factor right now.

The term 'Maker' is new to me, but I am all for any modeling method old or new that can be used for making models. I find 3D printing fascinating, but probably won't have time to pursue it until I retire. In the meantime, I want to follow anything you folks are doing with it.

The term 'Maker' is new to me, but I am all for any modeling method old or new that can be used for making models. I find 3D printing fascinating, but probably won't have time to pursue it until I retire. In the meantime, I want to follow anything you folks are doing with it.

I'm borrowing this from wiki, as it is probably worded better than I can do:

The maker culture is a contemporary culture or subculture representing a technology-based extension of DIY culture[citation needed]. Typical interests enjoyed by the maker culture include engineering-oriented pursuits such as electronics, robotics, 3-D printing, and the use of CNC tools, as well as more traditional activities such as metalworking,woodworking, and traditional arts and crafts. The subculture stresses a cut-and-paste approach to standardized hobbyist technologies, and encourages cookbook re-use of designs published on websites and maker-oriented publications.[1] There is a strong focus on using and learning practical skills and applying them to reference designs[citation needed].

Maker space one of various names used for the many places one can go to learn all about these things and get hands on with them. these may go by the name HackerSpace, HackLab, techLab, or any number of similar things. The "hacking" coming from the use, of salvaged electronics 'hacked' apart and repurposed for various projects in conjunction with the term in it's common computer usage. We have sever maker spaces in the detroit area, and they exist all over the country. Many charge a monthly fee of about $50, and with that you get access to all the tools, and a place to work. In addition people are willing to share and teach as needed and classes are often held. one of our local tech labs has a full wood shop, metal shop, pretty well stocked electronics and computers areas, and several other well supplied 'divisions'. Not a bad deal if you want to go MAKE something. If you want to learn more, here is a good place to start: http://makerfaire.com/

Edit: thought I'd add that these folks tend to salvage parts or purchase from online suppliers as the "hobby shops" are typically perceived as having totally failed to support the market that these folks provide. Some electronic part stores have started supplying things, and RadioShack actually had a good line of products directed directly to Makers, but that was too little, far too late for RS.

The 3D printer is a delightful gadget. The houses shown are rather involved and would require a lot of time to print and a thorough understanding of the software used to create the original design and also to print the final result. Much more time than you would like to spend browsing in a store.

Being retired I can spend a lot of time getting to know the software and to understand the capabilities and limitations of the current selection of printers. There are thousands of ready made designs available free at the Thingiverse web site, and that is a great way to get to know your printer. Just print stuff. Anything. Be prepared to spend a lot of time browsing the web and ask Google whatever you really want to know. there are answers to all the technical questions, many conflicting, and most very informative.

I purchased a printer from Amazon, tried it out and found the first one lacking, so I send it back. So much for saving money. The second printer (a keeper) was also from Amazon and cost slightly less than a new Lionel Big Boy, which is still a lot of money.

The software that the 3D printer uses runs on Mac, Windows, and Linux, so almost all operating systems are covered. Any computer will work and some 3D printers can send the file to be printed to the printer on a thumb drive or memory stick. Others require the computer to be running but even a slow computer is much faster than a 3D printer.

C&O Allie didn't say how long it took to print each of the station uprights but anywhere from half an hour to an hour each would be reasonable. So the smaller house would take a day or two probably. Maybe you guys could let us know the real print times.

3D printing will unlock your creative side, and the investment in time learning how it works is what can be fun.

No, it's not for everyone, but if learning new technologies is your thing, then 3D printing will be right up your alley!

p.s. I'm 76 and the printer is just a couple months old but I'm gaining on it!��

3d printers are obviously cool and could likely revolutionize production of many things in the future.

But Maker Culture?![]() How arrogant. I think that's for the next generation or two to decide

How arrogant. I think that's for the next generation or two to decide![]() .

.

That's so funny how the world today loves its own "special sounding" labels like they have come up with a new thought that will obviously be admired for ages, and needs a unique title right away![]() . Life has become one big Ronco ad.

. Life has become one big Ronco ad.

Seems others have been "wasting" for centuries and could have been "making" and "repurposing" instead of "do it yourself", reusing, tinkering, experimenting, or even inventing.

What a novel new concept! Doing it on a computer changes everything too...

..or is it just another monkey's new ax when O'razor's edge is applied?![]()

Diecast Direct in Frankfort, KY had some simple pre-made 3-D printed parts in 1:50 scale when I visited their store last week. 3000toys.com in MO & DHS Diecast in OH also have simple pre-made 3-D printed models in 1:50 scale. By simple models, I am referring to trash dumpster, traffic cones, porta potty, etc.,, stationary diorama / layout accessories without many working features.

These are just my opinion,

Thanks,

Naveen Rajan

Yes, diecast direct has more 3-D printed products in every catalog now. They are up to nearly a page of stuff and I won't be surprised if in a few years it is a whole section in the catalog. They are the only retailer I know playing here, but I expect others.

Someone - it won't be me - is missing a wonderful opportunity to build a site where folks could go and "design" their own building: pic the size, shape, outside surface (bricks, clapboard, type of roofing), select and position windows, then when satisfied, select print, see a price, and decide you want it and pay for it.

If that was true, we'd still be pulling our trains across the carpet by a string.

Rusty

Hold on, it's about to get way more interesting...

Home 3D scanners are in their infancy, but the pace of development has gone from yard limits to tangent cab-signaled mainline. Sometime this year, at least one company will release a dongle for phones that will allow 3D photo capture. The next generation of upper-end phones will have the device on board. See it, snap it, print it, software involvement minimal. Naturally, getting all sides of an object will require multiple views, but for that, the software is already set to stitch them together.

Laser 3D may or may not make it to the home market--at one time, we thought laser printers would be the home standard, but inkjets held up very well. If they do take over, they're a whole lot faster than melted filament. On the other hand, XYZWARE now has the DaVinci Jr. listed at $395 for starters. By this fall, four-color blending will be lower in price and faster, so there'll be less need to print separate pieces in kit form or paint as much. Metal printing for home use may be a while, but commercial service shops already have the ability.

As for the software, I have no idea why it's still so clunky. Granted that young geeks can operate it, even they don't enjoy it. Years ago, when you had to set 8-bit with or without parity and a raft of other parameters just to get online, I said computers had to pass the toaster test. You don't have to decide how long to toast bread at what depth, or whether you're putting it in right side up. You drop bread in, hit a lever and move the knob to light or dark, and when it's done it pops up. Even if you understand how to build a toaster from scratch, most of us would prefer not to do it every morning. When the software catches up, the technology will erupt.

But Maker Culture?![]()

On top of that it sounds like a group of 5th graders came up with the name. I guess that makes farmer members of the Growers Culture or chefs are in the Cookers Culture. Only thing worse than giving yourself a long complicated stupid sounding title is a short stupid sounding title.

Jerry

The idea is evolutionary rather than revolutionary. Punch! Home Design software allowed users to design and print one-dimensional renderings that could be cut and assembled more than a decade ago. I made a few unimpressive buildings, then gave the software to the kid next door who had a budding interest in architecture and construction. The pics of the 3D printer products suggests the latest technology may have the potential to reduce train sales as propagation of structures diminishes space available on layouts for yards, spurs and even mainlines.

What, me worry?

The term 'Maker' is new to me, but I am all for any modeling method old or new that can be used for making models. I find 3D printing fascinating, but probably won't have time to pursue it until I retire. In the meantime, I want to follow anything you folks are doing with it.

I'm borrowing this from wiki, as it is probably worded better than I can do:

The maker culture is a contemporary culture or subculture representing a technology-based extension of DIY culture[citation needed]. Typical interests enjoyed by the maker culture include engineering-oriented pursuits such as electronics, robotics, 3-D printing, and the use of CNC tools, as well as more traditional activities such as metalworking,woodworking, and traditional arts and crafts. The subculture stresses a cut-and-paste approach to standardized hobbyist technologies, and encourages cookbook re-use of designs published on websites and maker-oriented publications.[1] There is a strong focus on using and learning practical skills and applying them to reference designs[citation needed].

Maker space one of various names used for the many places one can go to learn all about these things and get hands on with them. these may go by the name HackerSpace, HackLab, techLab, or any number of similar things. The "hacking" coming from the use, of salvaged electronics 'hacked' apart and repurposed for various projects in conjunction with the term in it's common computer usage. We have sever maker spaces in the detroit area, and they exist all over the country. Many charge a monthly fee of about $50, and with that you get access to all the tools, and a place to work. In addition people are willing to share and teach as needed and classes are often held. one of our local tech labs has a full wood shop, metal shop, pretty well stocked electronics and computers areas, and several other well supplied 'divisions'. Not a bad deal if you want to go MAKE something. If you want to learn more, here is a good place to start: http://makerfaire.com/

Edit: thought I'd add that these folks tend to salvage parts or purchase from online suppliers as the "hobby shops" are typically perceived as having totally failed to support the market that these folks provide. Some electronic part stores have started supplying things, and RadioShack actually had a good line of products directed directly to Makers, but that was too little, far too late for RS.

George,

Thank you for the very detailed explanation! You have given a useful web site to get up to speed!

Rusty

3d printers are obviously cool and could likely revolutionize production of many things in the future.

But Maker Culture?![]() How arrogant. I think that's for the next generation or two to decide

How arrogant. I think that's for the next generation or two to decide![]() .

.

That's so funny how the world today loves its own "special sounding" labels like they have come up with a new thought that will obviously be admired for ages, and needs a unique title right away![]() . Life has become one big Ronco ad.

. Life has become one big Ronco ad.

Seems others have been "wasting" for centuries and could have been "making" and "repurposing" instead of "do it yourself", reusing, tinkering, experimenting, or even inventing.

What a novel new concept! Doing it on a computer changes everything too...

..or is it just another monkey's new ax when O'razor's edge is applied?![]()

Yes, people have been building things forever. Yes folks alway will. No we should not discount a fairly large sub-group of Do-It-Yourself, hands on, people that actually have an interest in how the world actually works simply because the mass-marketed name used to describe them is silly.

As eluded to earlier, the folks themselves chose the term 'Hacker" to describe what they were doing early on. As the group dynamic changed, making, rather than hacking became more of the focus, and anyone that has ever has to sell anything has used a nice, simple product name to appeal to the target audience. Is "Make:" silly? sure. Do you know exactly what the folks intend to do? Yes.

I'll add that I probably should have found a better definition somewhere, But I figured that one would do to explain the concept for one who has never heard of "Maker." I can see the point was missed.

At it's core, 'Making" is about learning new things and getting hands on with these things, and I fully support ANY AND ALL groups that want to teach practical skills to absolutely anyone that want to learn them, no matter what name they choose to use... of in the case of 'makers' was coined by a magazine company and applied to them.

Off for a 10 hour drive and weekend of work...Be happy to respond more when I have the time.

C&O Allie didn't say how long it took to print each of the station uprights but anywhere from half an hour to an hour each would be reasonable. So the smaller house would take a day or two probably. Maybe you guys could let us know the real print times.

The term Maker works for me! I'm glad I opened this topic and learned something new.

Thanks for the reply Allen. The guess of about an hour each seems pretty close.

Thanks for sharing.

I appreciate learning, and likely did learn something along the way.

I do thank you for, and really appreciate your posts George.

You spend the time to supply much extra info on the topics you comment on too![]()

"Maker Culture" isn't new to me. The bubble I keep my sarcastic laughter in just happened to burst on this point. If you dig deep I'm laughing at us!![]()

A paraphrase by Charlie Chaplin, "We laugh hardest when it hurts too much to cry"![]()

Will 3d printing be in every home? No. Not until its near Star Trek duplicator level. But for now its a useful tool, though pricy.

Eventually you will see a couple on every block just like welders, band saws, and lathes.

Vinyl cutters, laser cutters, water cutters, and embroidery machines went trough a stage like this where the public and small business alike tested the waters. I see a similar trend, but without the same hype momentum(is "maker culture" the beginning of that hype? Could be. But we'll have to wait & see![]() )

)

So far, the obvious strengths of the idea is carrying it more than use in numbers. So the "order shop" or site idea, is a really good one.

Sampling 3d ware hasn't been experienced by many really. They will want to see and hold something long before they buy a printer. On piece work, it is a wide open market

I appreciate learning, and likely did learn something along the way.

I do thank you for, and really appreciate your posts George.

You spend the time to supply much extra info on the topics you comment on too![]()

...

Well, thank you, very much.

There are a lot of folks out there with information to share, and I don't see any reason not to hear new ideas from anyone.

As to the topic of printers and costs and such. There are many nice, high end 3d printers out there... then there are countless 'low cost' ones in the $250-$400 range that do the job just fine. If you really want to dive into it, you can buy kits with all of the electronics and the stepper motors for about $100-150, and just the bare bones electronics for about 40 bucks. For a first printer many of the low end assembled versions are actually a pretty good deal, and once you have one printer, you can use it to make many of the parts to build more. As for learning how to use one, there are plenty of resources online, but if you learn better hands on, check out a local MakerSpace, HackSpace, or TechLab... folks are usually excited to see new faces. Sort of like local O-gauge clubs... only for tech stuff.

As far as the next step that may be added on to 3D printing an industrial designer friend I was talking to was telling me about Hydrographics. This is a process that lays a thin ink print onto the surface of water and then a mechanized arm pushes the item to be printed into the water and the print sticks to the surface wrapping any image onto the final product.

My friend said that some company's are experimenting with surface tension and wrapping the image around oddly shaped objects in a process almost like the old fashioned optical games that have a distorted image in a drawing that when a mirrored cylinder is added to the center a perfect picture is reflected in the cylinder.

There would be some real potential to make intricate paint schemes like photorealistic weathering or graffiti In a single pass that could take into account odd shapes like ribs and rivets.

Here is a link that describes some of the applications of the Hydrographics process.

http://hgarts.com/what-is-water-transfer-printing/

My feeling on the "Maker" movement is great, more power to them. my feeling is that expanding knowledge and skills throughout ones life is wonderful and should be encouraged. I don't think it is a new idea nor do I think they think of it as one. Popular Mechanics used to be filled with articles like those now done in Make magazine. I do think this is a reaction to several years of parents not teaching thier children to use tools and any hands on creative work. People on this forum are always bemoaning how kids don't have the basic skills to make a layout to play with toy trains but are on iphone games all the time this seems to be a movement filled with the type of people who would learn those skills if they wanted. I would be interested in some Maker made control system that was published on line I could make with an Ardueno micro computer to control my trains. I'm sure someone will do it some of the guys who made the first video games were mebers of the MIT Model Railroad club who were making the automated signaling.

Here are some hydrographic printed real tree skateboard decks and cell phone cases. You can see the wrap around quality of the prints.

Attachments

SilverLake, A buddy of mine had this hydro-dipping process done on the intake manifold of his car... (Yea, I'm a car guy too...) and took a video of the process... I'll see if I can get a copy and post it... it is really neat stuff. As for arduino controlled trains...things are coming along. There are several folks on the forum here that are playing with this, myself included. The nice thing with Arduino, and other similar things is just how easy they are to use with only a rudimentary understanding of electronics and computers... One of those things where the average person can pick up a starter kit and pick it up pretty easily.

Then there is this: "People on this forum are always bemoaning how kids don't have the basic skills to make a layout to play with toy trains but are on iphone games all the time..." I couldn't say it better myself, You can look above to see me try...

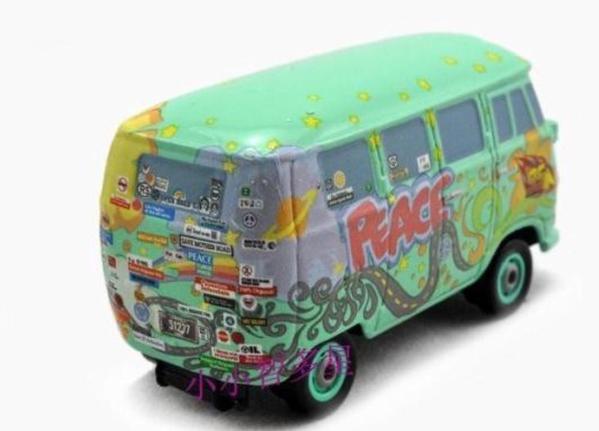

When I first saw the "Cars" movie toys I knew that the detail of the Hydrographics would be amazing for Oscale trains a weathered engine based on the process used to get the detail quality of the bumper stickers in a hotwheels sized car on this one in one pass is amazing.

The idea of printing a fully weathered car or engine based on photographic documentation from the rail fan community so it would look just like a car at a specific time in the career use with rust, fading and so on would be great.

The idea of printing a fully weathered car or engine based on photographic documentation from the rail fan community so it would look just like a car at a specific time in the career use with rust, fading and so on would be great.

Attachments

I was a graphics major. The use of liquid to apply, or control print is old.

Even suspended on the liquids surface.

The process "by hand" took finesse. Better, and automated machines exist now obviously.

Texture, and shapes could be an issue, and that looks like its made big progress.

It didn't interest me much, I only bothered with abstract because of the unpredictability in quality, chance of detail failures, and a bare spot on the wall of my apt.. I don't remember clear portions in the printing though. The ink sat as a scum sheet on the surface.

I wonder if charged pigments are being used now, if clear areas are a clear ink, or does the background ink match the plastic that well?

Here are a few projects that would be interesting to make on a 3D printer two are simpler and could be easily added made like the add on brake blister that Williams uses to modify their GP-7 that just slips onto the long hood. A Paducah Geep yoke would be an interesting print that some would be interested in.

Another interesting modification would be an add on to a RS3 to become one of the variants of the Dewitt Geep RS3m program.

Another interesting modification would be an add on to a RS3 to become one of the variants of the Dewitt Geep RS3m program.

A few more elaborate prints could be cabs that haven't been offered that have some regional appeal. A few I could think of are the BQ23-7 cab.

The Santa Fe modification CF7 could be added to a GP7 body. A lot of these end up with further lives in regional railroad service.

The Santa Fe modification CF7 could be added to a GP7 body. A lot of these end up with further lives in regional railroad service.

Our neighbors to the north have been neglected and a Canadian Cab would be pretty cool to have too.

Our neighbors to the north have been neglected and a Canadian Cab would be pretty cool to have too.

Attachments

Hi Silver Lake,

Interesting post. Can you please share with us where the photos of the Sears/Craftsman houses and references to printing them came from? I have yet to find a *true* O scale model of a bungalow and had been studying various floor plans but I don't have the building chops Let alone time to handcraft. (And not enough LEGO :-) (The few models marked as "bungalows" usually architecturally aren't. Barb's Bungalow is the lone exception but wrong scale.Trust me.) This application would be perfect!

Recently I was speaking with the director of a nonprofit (?) training center in a nearby city. The old computer skills they used to teach job seekers like MS Word and so on aren't useful anymore. So, they are investigating 3-D printing equipment. 'Though I've been following 3D printing news stories and applications for a couple of years, I hadn't heard of the term "maker" before. But reading about it here, it now it makes more sense why this job training facility is switching over their technology training offerings.

Tomlinson Run Railroad

re: The Sears houses.

The ones I saw were being printed at the stand alone Makerbot store in Manhattan. They were making them to show what could be done on thier machines to sell printers but they were willing to sell some of the prints. The model scaled out to 1/64 or S scale so it is not true O scale but it is still huge and would fit in on most layouts.

Here is is a link to download the files. http://www.thingiverse.com/thing:31644

re: The Sears houses.

The ones I saw were being printed at the stand alone Makerbot store in Manhattan. They were making them to show what could be done on thier machines to sell printers but they were willing to sell some of the prints. The model scaled out to 1/64 or S scale so it is not true O scale but it is still huge and would fit in on most layouts.

Here is is a link to download the files. http://www.thingiverse.com/thing:31644

Thanks for the background info and the link. I just happened to see on that website that someone had printed out a section of garden gauge track. It's filed in the same category with the Sears house. Now that's a perfect example of a good use that isn't overly complicated and clearly benefits from replication and the use of plastic.

TRRR