Originally Posted by MichRR714:

Originally Posted by clem k:

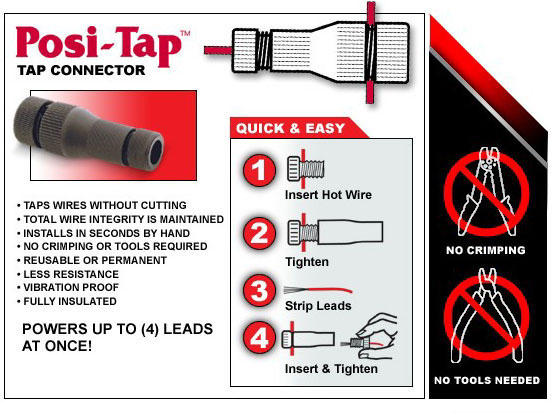

do you have to cut the buss wire, to put the Posi-Taps on ?

Clem according to the directions you would not cut the bus.

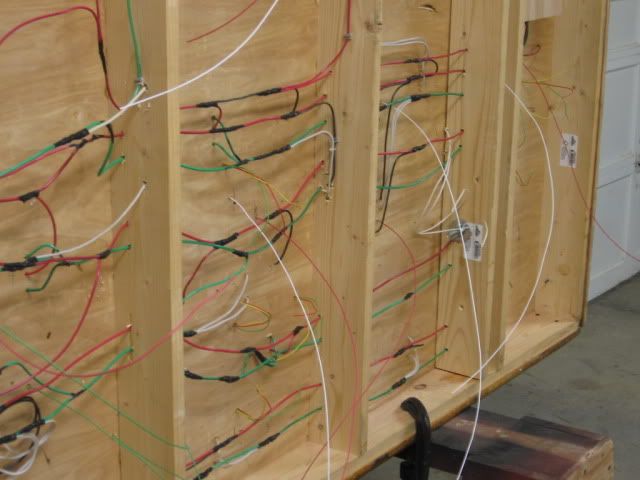

You out just unscrew the bottom cap from the body, slip the wire into the cap's channel, then screw the body back onto the cap. A metal pin inside the body pierces the wire to make the connection to the bus. Then unscrew the top cap to add the feeders from the track. Strip a little insulation off the ends of the feeders and insert into the body. As you screw the top cap on it twists the stripped wire around the internal pin and locks the wires in place. They are very tight connections and are great for command control wiring.

They are very quick connections and easy to use!

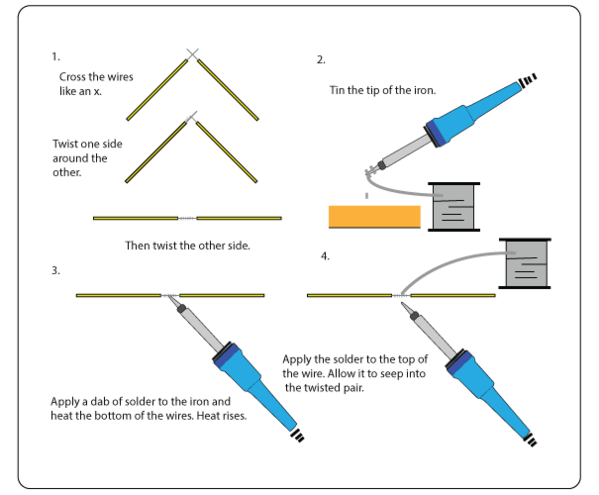

I also like the Posi-Lock connectors for splicing inline.

Originally Posted by lehighline:

Brian,

I have never seen Posi-taps before, but they look like an excellent device! Where do you find them?

Chris

LVHR

Chris, I have seen them at Walmart and some auto stores, but in small packages. I order right from the website in bulk and have them delivered to my door.