DoubleDAZ posted:Roger, I'm not trying to be argumentative either, but it sounded like you were/are upset by the comments. My caution was about resale value when you cut a costly switch. It destroys the resale value and alters the geometry forcing you to cut more tracks to make things fit. And if you don't do it right, you can end up with problematic joints, especially with already tight O31 curves and passenger cars that are generally longer than other rolling stock. I wasn't saying it won't work.

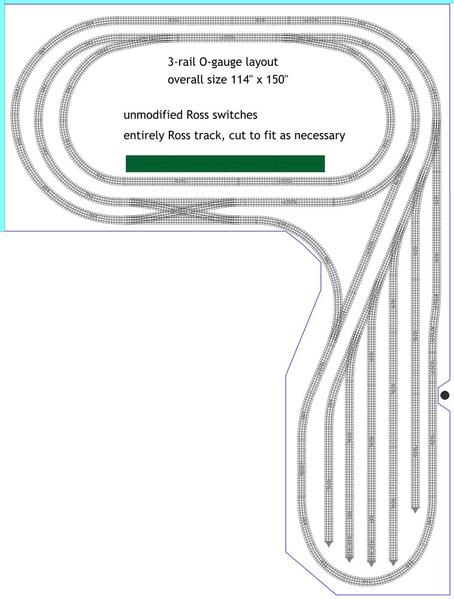

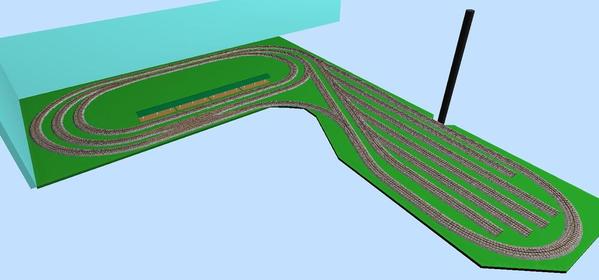

In your design, you appear to be joining 2 cut O31 switches and adding a small piece of cut flex track to complete the O31 curve into the siding. In all I counted 10 switches and a bunch of small pieces of flex that you plan to chop up. I don't know how much experience you have with flex track, but it might not be as easy as you think to bend those small pieces. And that's not even considering the small "S" curves you have in your yard. Even NJSCOTT said he wouldn't do it again and he was cutting #4s which don't have the tight turnouts of the O31's.

And when you asked in the other forum, did you tell them you were cutting 10 O31 switches and a bunch of other track or show them how you were going to make all this stuff fit? No one here said you can't cut a switch, but you're chopping up a bunch of switches and track and I can't imagine many members here suggesting you do that.

Also, when I commented, alternate designs had been offered and not having to cut switches was a reason to consider one of those designs. However, I also said that if you want to stick to your original plan, then the only option is to cut them. I was just offering the cons of cutting before you made your decision to try to build the original design.

And I don't know what the limitations are for your bench work space and why you can't expand it so you don't have to cut so much track. I get that you want what you want, but you asked for comments, so we gave them. I think you're asking for trouble with all the cutting, especially all the small tight curved pieces, to make things fit, but it's your choice and I hope it all works out. I recently bought some ScaleTrax flex track and bending a full section, much less just a small piece, to O31 is not an easy task.

I apologize if I gave any impression of being upset about any of the comments made here. I have the highest regard for everyone in this forum, and that is why I have asked for comments and opinions. In fact I am at present trying to rework my layout to incorporate some of these suggestions, as well as some of the aspects of Ace’s alternate layouts.

I asked about the cutting down of the switches, not because I am upset that several have spoken against it, but honestly because I want to hear the cons regarding doing that, before I get too committed to it.

Now that said, I really have tried to be clear, and have stated several times, that I plan to use Ross Switches and Track exclusively, and that the Atlas flex track, and other bits that are not Ross, are only shown in my plan, so that I could get actual finish out lengths of straight track in the SCARM software plan. I have used the longest Ross sections available, and then filled in with Atlas flex track, making sure not to use any sections that are longer than the longest Ross sections (29.3”). I have also used Atles flex track to create special length curves that would be cut from standard curve sections. Further, the pieces making up my straight sections are still subject to a fair amount of redesign so that there will be as few short little pieces as possible.

Again, I sincerely appreciate all of the comments, suggestions, and recommendations given here. I will use some, but probably not all of them.

Roger