Non-Contact Turnout Points Detector

Brief Description:

The detectors consist of a small magnet (Ø0.125” or 0.125” square) mounted on the throw bar, and a pair of hall-effect sensors mounted on the turnout ties, in close proximity to the magnet. The detectors (hall-effect sensors) do not come in contact with the magnet, throw bar, points, or any of the moving parts of the turnout, so they do not add any load. The detectors do not rely and are in no way connected to the circuitry that operates the turnout machine. Instead, they sense the true and actual position of the throw bar, and hence, of the points.

I was going to wait a couple more months before posting this, but several questions have come up that are related to my subject.

As some of you know, I followed my provisional patent application of 2013 with a non-provisional application early this year, and I am waiting for it to be granted. A letter I received a few months ago indicated that the patent may be granted as soon as November 2014.

I have installed about 20 of the detectors already, both on single turnouts as well as on crossover turnout pairs, they work as intended, and are simply great. I have some of the annunciators (LED’s) mounted adjacent to the turnouts, and others (single, bicolor LED’s) mounted on the control panel.

At the prices I believe model railroaders would be willing to pay for the detectors, there wouldn’t be enough profit to justify the resources and effort required for me to advertise, sell, and provide adequate customer service. Therefore, I will offer what I have to anyone interested, and I will just cover my costs. I will be glad to consider providing any additional work, such as adding wire leads to the detectors, making the magnet holders, and providing LED’s and LED holders, at minimal cost.

Earlier this year I ordered pilot production runs of three models, and will be ordering more in a month or so. I will also order pilot production runs of the two ‘under’ models, and the RCS crossover model, as I described later.

My Non-Contact Turnout TRUE Position Detectors are available for the Atlas and RCS turnouts, and these are the various models.

Currently Available (in a few months):

• V5B Standard Atlas. Detector to be mounted on top of an Atlas turnout. Drives one turnout direction annunciator consisting of two LED’s (one green and one red) or a single, common anode bicolor (red-green) LED

• XVR Crossover Atlas. Detector to be mounted on top of one of the two Atlas turnouts in crossover arrangement, to be used together with a V5B on the other turnout. The V5B-XVR pair allows a single annunciator (two LED’s or single bicolor LED) to be used to indicate the direction of both turnouts in a crossover arrangement. If the points of either turnout are not fully thrown in the proper direction, the annunciator will be off.

• R5B Standard RCS. Same as the V5B but for RCS turnouts.

Coming Soon:

• V5B-U Under Atlas. Same as the V5B, but to be mounted underneath an Atlas turnout.

• XVR-U Crossover Under Atlas. Same as the XVR, but to be mounted underneath an Atlas turnout.

• RXVR Crossover RCS. Same as the XVR but for RCS turnouts.

Note on the soon-to-be-available Under Mounted detectors, V5B-U and XVR-U.

Although these are the easiest to install and will be totally hidden when installed, since the detector and magnet are under the turnout, access to the magnet and detector may be more difficult later on.

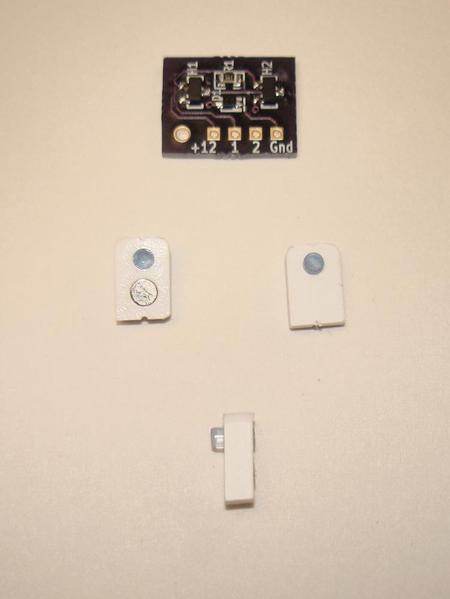

The Detectors:

Magnet holder for Atlas V5B

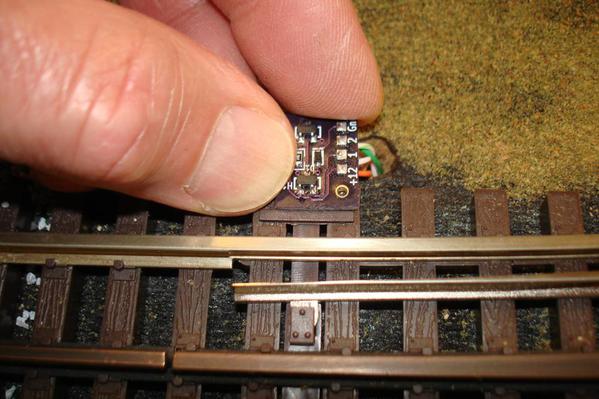

Atlas V5B (or XVR) Installation

1. Drill hole for wires

Mount magnet holder (easy snap on, add little adhesive)

Hold detector in place to spot screw hole location

Drill Ø3/64" hole for #0 x 1/4" screw

Secure detector with screw - Done!

May add simple cover to hide detector

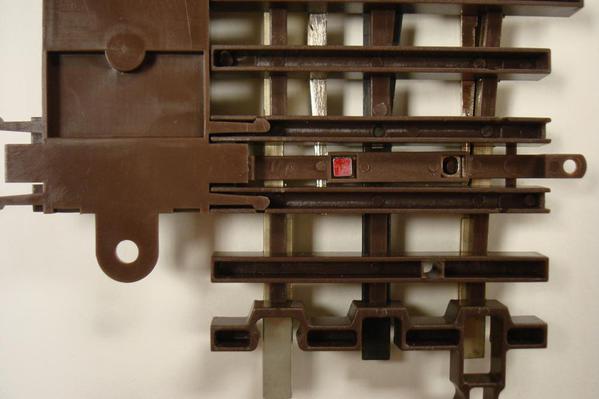

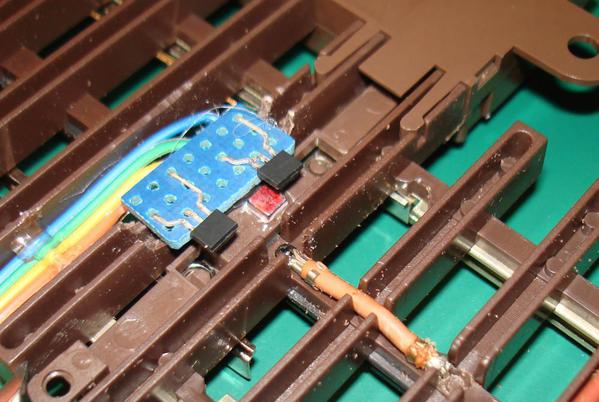

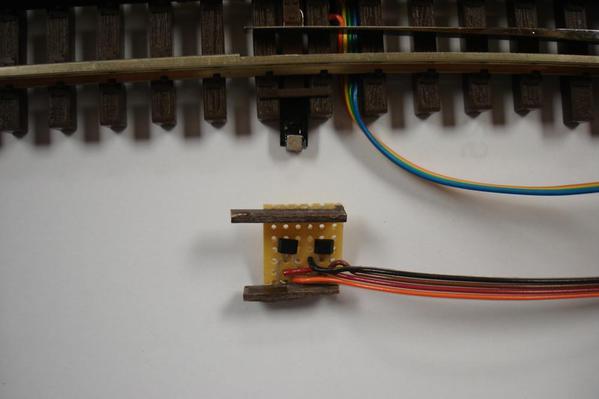

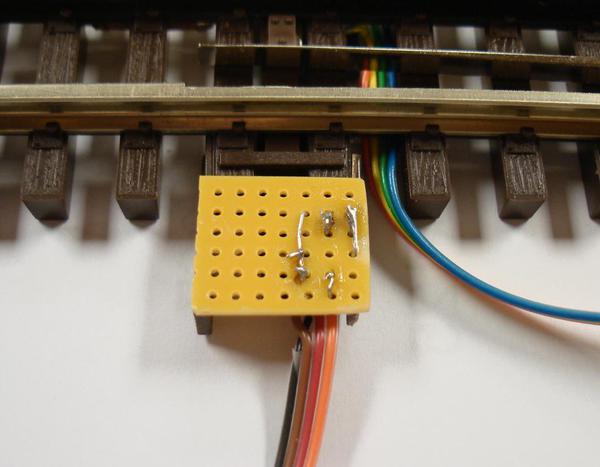

RCS R5B Installation

Glue wood spacers on ties and magnet (on small wood carrier) on throw bar

Secure detector in place with two screws - Done!

Atlas V5B-U (or XVR-U) Installation

Magnet and spacer

Glue magnet with wood spacer in throw bar recess (a perfect fit!)

Hold and mark detector location (to match magnet location)

Press detector in place and add a little adhesive - Done!

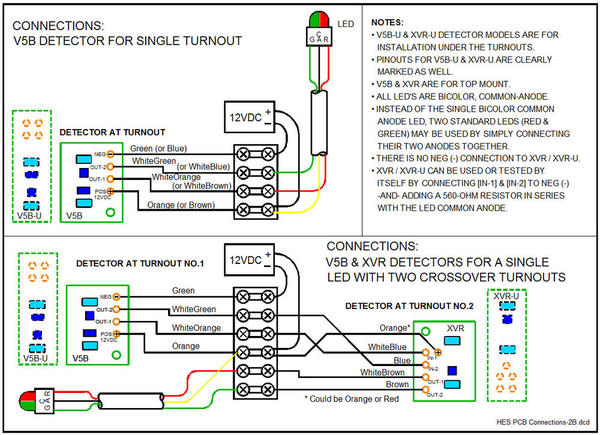

Now the detector(s) have to be wired. Here is how:

Wiring Diagram

Thank you for reading this far!

If you have any questions, please don't hesitate to post them or to email me.

Alex