All,

Beta 3.0 engines are now available!

Thank you,

Mark the Menards Train Guy

|

|

Replies sorted oldest to newest

Thanks Menards. I look forward to sending you my feedback!!

Oh my gosh - here we go again!

I'm betting sell out will occur in 2.75 hours

Wow- that was fast. Such a short turn around they must have been planning v 3.0 while 2.0 was in production.

I finally managed to snag one this time!

@RSJB18 posted:Wow- that was fast. Such a short turn around they must have been planning v 3.0 while 2.0 was in production.

It was Air Freighted for faster delivery. Apparently they want this beta test phase expedited.

Finally got one ... and ships to Canada as well ![]()

Hopefully with full production in 2022.......![]()

So what's your guess that they changed in 3.0?

Finally, I was online at the right time!

well i got one this round.......

Ordered. Looking forward to testing it out and seeing what else you guys have up your sleeves!

I really, really hope they put metal gears on the worm wheel. If they did that, this loco will last for years.

However, I am not overly optimistic. The changes in 2.0 seem to be mostly in software, which is cheap and easy to modify.

@RoyBoy posted:I really, really hope they put metal gears on the worm wheel. If they did that, this loco will last for years.

However, I am not overly optimistic. The changes in 2.0 seem to be mostly in software, which is cheap and easy to modify.

Plastic gears would definitely be a deal-breaker for me. That would be good info to have before pulling the trigger.

I did not get the 2.0 so I could not do a direct comparison with the 1.0, but from what I've read, the major performance and cosmetic issues were resolved. I just happen to check my phone and was able to get a 3.0. It will be interesting to compare side by side. At this price point, I'm not really expecting metal gears, however my 1.0 has about 40 hours on it pulling 5 aluminum cars.

Steve

@AtoZ Lewis posted:Finally, I was online at the right time!

I had just stepped out of the shower when my phone pinged. Great timing.

Steve

I see they must have tired of the nitpicking as to what type of F unit it is. Now just called Santa Fe Diesel.

Looking forward to more road names in the coming year.

Steve

@Steve "Papa" Eastman posted:Now just called Santa Fe Diesel.

Steve

Problem solved. Too many things begin with the letter 'F' anyway - right? ![]()

John

This time I'm in. I can't just sit back and let everyone else have the fun testing these.

Still available at 2:08.

@Steve "Papa" Eastman posted:At this price point, I'm not really expecting metal gears, however my 1.0 has about 40 hours on it pulling 5 aluminum cars.

Steve

My feeling is that the life of the plastic gears is not determined by operating hours or operating load, but by the number of temperature cycles the locomotive goes through in use, or in storage. Since the expansion rates of nylon and steel and different, the gears will eventually crack and slip.

NOTE: I am not talking about the idler gears on the side of the trucks. Since these are slip fit, they will last for many years. The gears of concern are the worm gear on the motor (which I think has been changed) and the worm wheel gear on the driven axle.

Plastic gears that are press fit onto steel axles/armatures are the ones that will fail.

Look at all of the wonderful David O. King models from the 80's that are no longer operational because their plastic gears have split.

We are officially sold out. Sorry for everyone who missed out!

-Mark the Menards

Snagged one! Woo Hoo! At this price point I am planning to repaint it to Amtrak. I had a nylon geared B&M from Lionel as a kid that just kept stripping out at the axle. I eventually gave up on it. Hopefully that won't happen to this one - but with dual motors, remote control, I'm willing to try it!

I don't claim to be an expert on plastic versus metal gears but all my HO engines have plastic gears on the axles.

True, there is a lot more force on an O gauge engine versus an HO engine but I've been running some of my HO engines for 45 years without any problems. I'm assuming my plastic gears are hi grade nylon.

It seems like metal gears would wear faster if not properly oiled versus plastic gears. I just use a light '3 and 1' oil on them.

The worm gear on all my engines are brass. Also, the combination of the two may work well to prevent 'wearing'.

I think a lot of people view plastic as cheap.

I've 'googled' nylon versus metal gears and find a lot of positives for nylon.

Nylon is also more quieter than metal gears.

It seems like nylon would, also, last longer if not properly lubricated as, I'm guessing, a lot of railroaders don't lubricate their engines as often as they should.

All my engines have this type of gear where the center is brass to prevent any cracking on the axle.

These comments should 'stir up' some debate!

Fast sell out.

Man these go quick. Still no mention of fully featured conventional operation though...

@MG Brown posted:Fast sell out.

Menards marketing is great. Waiting for Beta 4, 5, 6, ……

Ron- I would agree with you about Menards marketing.

I will wait to make the "buy" decision until the production version and hope that they offer other liveries.

@CAPPilot posted:Menards marketing is great. Waiting for Beta 4, 5, 6, ……

Really? I tend to think they are honestly trying to get feedback from us so they can put the best product possible into production, which benefits everyone. Call me naive, I guess.

Nylon gears will fail. Bachmann was using nylon for a long time and gear failure is a problem with their older locos. Many of the better brands, Kato, Atlas, BLI, etc. use engineering plastic that doesn't suffer from the splitting cracking issues like nylon does. I have N scale locos that are over 30 years old with plastic gears that don't have issues. I have a Weaver O gauge loco with a metal gear that did split rendering the truck it is in non-functional, so gears splitting isn't just a concern for plastic gears, though far less likely to happen with metal.

I am going to hold off on the Menard's locos offerings for now. The remote thing is one major thing that makes it a non-starter. The other is the chrome. Makes it look cheap. Maybe when they get through all of the Beta units and get the bugs works out, then I'll look at getting one.

Would be nice to have Menards report the differences 1 to 2 and 2 to 3...

@Jeff T posted:Would be nice to have Menards report the differences 1 to 2 and 2 to 3...

That would be nice.

Steve

@Landsteiner posted:So what's your guess that they changed in 3.0?

A key question. Without previous release owners getting a chance to purchase one for comparison who knows if it is for the better?

@Jeff T posted:Would be nice to have Menards report the differences 1 to 2 and 2 to 3...

Cannot provide good feedback without that.

I would only be able to report the difference between 1.0 and 3.0, but it will be interesting. Kind of a fun process to be involved in. Being on the west coast I expect there will be a number of reviews before I even see mine.

Steve

I have a Beta 1 release, and will report the differences when I receive the Beta 3 model.

Lionel acted upon feedback and the latest two generations of LionChief are able to run with a full conventional feature set.

@bmoran4 posted:Lionel acted upon feedback and the latest two generations of LionChief are able to run with a full conventional feature set.

Current Lionchief R-T-R sets do not have conventional operation built in to them. They can only be run with a remote or Bluetooth app. LC+ & LC2 engines on average cost considerably more than this Menards engine because they have considerably more features.

@Jeff T posted:Would be nice to have Menards report the differences 1 to 2 and 2 to 3...

Menards asked for user feedback to be sent directly to them. Everyone here will nit pick at this thing until Menards includes every feature found in a Vision Line locomotive and still want it to cost $170.

supposedly now has twin motors- fixed quick start up issue & the horn button sound problems...& packaging...

@Sal V posted:supposedly now has twin motors- fixed quick start up issue & the horn button sound problems...& packaging...

It always had twin motors, all of the other things mention were done in 2.0

Please correct me if I'm wrong, but I find it interesting it was months from Beta 1 to Beta 2. Now Beta 3 is out weeks after Beta 2. Seems like a quick turnaround to take customer feedback from Beta 2, make the changes, get it mfg'd in China, get in a container to menards and sold.

I too am extremely interested in the real changes between the models from the mouth of Menards.

I need a santa fe warbonnet engine like I need a hole in the head, but I'm interested to see what road names go into production.

@samparfitt posted:I don't claim to be an expert on plastic versus metal gears but all my HO engines have plastic gears on the axles.

True, there is a lot more force on an O gauge engine versus an HO engine but I've been running some of my HO engines for 45 years without any problems. I'm assuming my plastic gears are hi grade nylon.

It seems like metal gears would wear faster if not properly oiled versus plastic gears. I just use a light '3 and 1' oil on them.

The worm gear on all my engines are brass. Also, the combination of the two may work well to prevent 'wearing'.

I think a lot of people view plastic as cheap.

I've 'googled' nylon versus metal gears and find a lot of positives for nylon.

Nylon is also more quieter than metal gears.

It seems like nylon would, also, last longer if not properly lubricated as, I'm guessing, a lot of railroaders don't lubricate their engines as often as they should.

All my engines have this type of gear where the center is brass to prevent any cracking on the axle.

These comments should 'stir up' some debate!

Tell that to all who owned mpc diesels with the nylon gears. Once brass replacement gears came out as a fix, guess where the owners of those locomotives went.

@PRRick posted:Please correct me if I'm wrong, but I find it interesting it was months from Beta 1 to Beta 2. Now Beta 3 is out weeks after Beta 2. Seems like a quick turnaround to take customer feedback from Beta 2, make the changes, get it mfg'd in China, get in a container to menards and sold.

I too am extremely interested in the real changes between the models from the mouth of Menards.

I need a santa fe warbonnet engine like I need a hole in the head, but I'm interested to see what road names go into production.

Menards air frieghted these which is obviously much faster than a boat and the current supply chain hot mess.

Perhaps these 3.0 units have some of the mechanical changes requested from 1.0 and the software enhancements from 2.0. Just a guess...

Even after the final product goes to production, people here will still critique it and criticize them for not addressing their one or two concerns which may or may not be trivial. Menards pays little attention to the comments made here because it's hard to determine which comments are from actual owners. It's probably a bit interesting to Menards to see when & which changes are made that go unnoticed.

Mark the Menards Man, Thanks for the engine project. The next test piece if there is one needs to be with a clear body shell. Then a black bonett, followed with a yellow bonett, and on and on. Keep up the great work, Dave

@H1000 posted:Menards asked for user feedback to be sent directly to them. Everyone here will nit pick at this thing until Menards includes every feature found in a Vision Line locomotive and still want it to cost $170.

Menards has a pretty good locomotive, especially at that price point, even if the final revision costs more. Astonished version 3 is out a few weeks after version 2 if it includes user suggested updates.

Between 2.0 and 3.0 it appears Menards turned on a dime and left 9 cents change.

Having worked in manufacturing, I don't see how they could analyze customer feedback, make changes, test and release in that short a time.

Given that nothing has really changed in the decoration department, I suspect Menards is simply using up the remains of a large inventory of body shells and frames. Or clearing the decks before Chinese New Year.

Rusty

Dave Nichols I would hope Menards bring their product to market before we all add our wish list, remember these are big trains for small hands

Dave Khoeler WHATTTTTTTT

Playing devil's advocate, it is possible that when Menard's received its run of the 200 Beta 2.0 locos, they already knew at that time that it was full of flaws, and had already identified several of them to fix going forward, and then just sold the 2.0s with great fanfare asking for consumer tests and reports. They didn't want to eat that loss.

So, they may have beenb already making the manufacturing changes to the very first 2.0 proto-type, before they even advertised the run of 200 Beta 2.0s for sale. They may have known that many of the reviewers would point out some of the defects they had already perceived and that thesewere already in the works being fixed for the 3.0

Mannyrock

Menards hasn't even (other than the Beta testing) had a chance to market their F units, to the public in their stores! As far as the Big Trains for Small Hands) reference, Its from an old Lionel add, they Knew, who these trains were designed for, children !

Just let Menards do what it does best!

Mannyrock, so they could hear every one here complain about it? I dont think so!

Lets give credit where credit is due, the company is soliciting and apparently listening to company feedback, they are producing small batches which indi ates to me a working partnership with the manufacturer, and they have invested in a workaround for shipping by using air transport. Using air instead of sea shows a level of commitment. I have no need to quibble over road names at this time, good job Menards, keep it up.

They’re practicing Agile development.

Design -> Build -> Release -> Feedback -> Prioritize Next Features.

Then start the cycle over. Continue repeating this cycle until you have a viable product to sell at scale.

@ChiTown Steve posted:They’re practicing Agile development.

Design -> Build -> Release -> Feedback -> Prioritize Next Features.

Then start the cycle over. Continue repeating this cycle until you have a viable product to sell at scale.

Sorry, but given the quick trunaround, I'm beginning to think 2.0 may have been more of an "Ooops," and was released before everything was implemented.

Seriously, how can anyone effectively analyze customer input, institute changes, order and receive replacement components (if any) and set up production and test before release within 20 days? Especially given current supply chain issues. Unless all that was done was twiddling with the firmware, which doesn't appear to be very sophisticated for this product.

Of course, we won't know exactly what other changes occurred until folks get their 3.0's and start their own testing.

I have no issue with Menards offering their own locomotive, it just seems like it's being rushed through right now.

Rusty

Geez, you blink and miss them!!!! Lol

@Rusty Traque posted:Sorry, but given the quick trunaround, I'm beginning to think 2.0 may have been more of an "Ooops," and was released before everything was implemented.

Rusty

Rusty,

Not every iteration is of the same time period. People in IT always do 2 week iterations which is wrong. The iterations should be 2-6 weeks in length and produce a logical unit of work. In other words, primarily, a set of features that work together.

Also every new feature, or feature improvement, doesn’t have to come from customers. They may already have had improvements they had queued up and were working on before 2.0 even shipped.

Steve

I believe Mannyrock, Steve and Rusty all bring up valid points. I too was surprised by the rapid release of 3.0 after 2.0--a 20 day interval to be exact. Version 2.0 came approximately 150 days after 1.0. If you subtract out from the 20 days the air shipping time and the several days to receive user feedback...well, there is hardly enough time to change much of anything based only on December user feedback even under Agile software development and Just-in-Time manufacturing. Maybe a Menards rep will chime in on this.

I don't think the menards rep needs to respond here other than to solicit feedback. Regardless how you feel about development cycles it appears those actually tasked with carrying out the project are doing so to the best of their ability. I see no need for armchair quarterbacking.

Gosh Necrails,

The whole reason we are on these boards is to do arm-chair quarterbacking! :-)

I mean, really, . . . what else have we got to do?

Mannyrock

necrails shut your front door i feel cold air. Dave

@Bruce Brown posted:I believe Mannyrock, Steve and Rusty all bring up valid points. I too was surprised by the rapid release of 3.0 after 2.0--a 20 day interval to be exact. Version 2.0 came approximately 150 days after 1.0. If you subtract out from the 20 days the air shipping time and the several days to receive user feedback...well, there is hardly enough time to change much of anything based only on December user feedback even under Agile software development and Just-in-Time manufacturing. Maybe a Menards rep will chime in on this.

What you assume is that every change made to 3.0 came from 2.0 and not 1.0. Did you consider that Menards has incorporated some of the feed back from 1.0 that will now show up in 3.0? Maybe those improvements include mechanical updates that take far longer than software.

Also keep in mind that the 3.0 units were air shipped which usually arrive at your distribution center in matter of days, not months like shipping on the water. Is it possible that 2.0 could have been here in 20 days had it been shipped via plane instead of boat?

@prrhorseshoecurve posted:Tell that to all who owned mpc diesels with the nylon gears. Once brass replacement gears came out as a fix, guess where the owners of those locomotives went.

I have run many MPC engines and never had a gear failure plastic or otherwise. I have to say I have heard these stories for years and worked in a repair station years ago, I had one engine come in with a gear failure and it was because of damage to the truck not a failure of the gear.

@Jeff T posted:Cost of customers doing your testing... Regardless, would be nice to know what was changed.

You have it right, this is not a 2 grand engine yet it seems to have what it takes, yes a few issues but again lets look at price. If they get this right and I believe they will, this could be the next K-Line scale Hudson. Fair price quality.

I have been attracted to the Warbonnet F3's for as long as I can remember. I am very interested in Forumites opinions about the Menards units as an AA and the Lionel scale units produced about 14 years ago. As I understand it, the Lionel units have TMCC, one powered A and (in the photo) an unpowered B and another unpowered A. I have seen the three unit set on auction sites LN/Ex for about $475-$550. Two Menards A units would be about $340. How would you assess value here? On top is a Lionel scale F3 A, the middle a new Menards F3(7), and on the bottom the scale Lionel F3 ABA. I totally understand that the Lionel units are more expensive, but then again, that is for an ABA, no?

@Al Nevada posted:I have been attracted to the Warbonnet F3's for as long as I can remember. I am very interested in Forumites opinions about the Menards units as an AA and the Lionel scale units produced about 14 years ago. As I understand it, the Lionel units have TMCC, one powered A and (in the photo) an unpowered B and another unpowered A. I have seen the three unit set on auction sites LN/Ex for about $475-$550. Two Menards A units would be about $340. How would you assess value here? On top is a Lionel scale F3 A, the middle a new Menards F3(7), and on the bottom the scale Lionel F3 ABA. I totally understand that the Lionel units are more expensive, but then again, that is for an ABA, no?

How much do you think menards could build an unpowered A & B for? I'll bet it's less than Lionel considering the cost of their curret rolling stock.

@H1000 posted:How much do you think menards could build an unpowered A & B for? I'll bet it's less than Lionel considering the cost of their curret rolling stock.

Remember the orange and blue box will always for the foreseeable be at the premium. The Mernards is a a great engine to install TMCC to get a feel on how to do it. The engine is scale in size has nice graphics and is sold at a great price.

@H1000 posted:How much do you think menards could build an unpowered A & B for? I'll bet it's less than Lionel considering the cost of their curret rolling stock.

An un-powered "A" unit would be easy for them to build. They have all the parts and paint masks already in production.

Making a "B" unit would be much more expensive. It would require a completely new body mold and frame stamping.

I am still curious as to where the mold for the A unit body came from. Was it an old project of some manufacturer that never came to fruition?

@RoyBoy posted:I am still curious as to where the mold for the A unit body came from. Was it an old project of some manufacturer that never came to fruition?

Menards has previously stated that this project is all new tooling.

Hmm, . . . let's see.

200 x $160 x 3 Beta runs = $96,000.

Not a bad haul, from the folks volunteering to test them.

All in all, a brilliant marketing campaign.

Mannyrock

@Mannyrock posted:Hmm, . . . let's see.

200 x $160 x 3 Beta runs = $96,000.

Not a bad haul, from the folks volunteering to test them.

All in all, a brilliant marketing campaign.

Mannyrock

Well are they just supposed to give them away? You get to keep it when you're done with your evaluation. It's not that much different from buying a regular production engine from any other manufacture.

@Mannyrock posted:Hmm, . . . let's see.

200 x $160 x 3 Beta runs = $96,000.

Mannyrock

A drop in the bucket for Menards $10.7 Billion in revenue (2020.)

Rusty

I use a Williams B unit with my 2 version 1.0 A units.

Steve

For the ones that have two beta 1's or a beta 1 and 2 ... does the same remote work to run them both ?

@yamawho posted:For the ones that have two beta 1's or a beta 1 and 2 ... does the same remote work to run them both ?

I have 2 Beta 1’s. You need 2 remotes to run 2 loco’s, but either remote will run either engine, just not at the same time.

Steve

@Steve "Papa" Eastman posted:I have 2 Beta 1’s. You been 2 remotes to run 2 loco’s, but either remote will run either engine, just not at the same time.

Steve

So can you run both together on different remotes ?

@Steve "Papa" Eastman posted:I use a Williams B unit with my 2 version 1.0 A units.

Steve

Williams... F7? F3? FA?

They all have different heights.

@RoyBoy posted:Williams... F7? F3? FA?

They all have different heights.

It was used, no box so I really don’t know, but it matches perfectly

Steve

@BobbyD posted:If it is the one in his videos it appears to be the Williams F7. Old Kusan tooling correct?

This was my video.

Steve

@Steve "Papa" Eastman posted:

Yep, that video. Old Kusan tooling Williams F7 B unit. Looks nice with the Menards A unit.

F7B units would be correct, EMD never made an elongated aFP7, or 9 B unit, they were run with regular B units

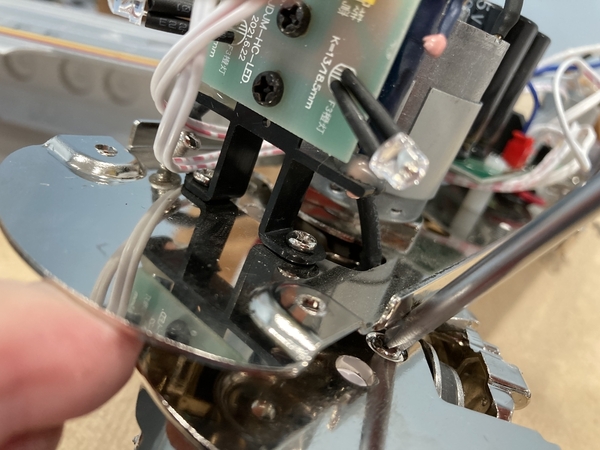

Beta 3.0

2-minutes of run time evaluation:

Cow catcher shorting out on center rail

Rubber tires rolling. May need to buy Lionel tires to replace these with- the rubber seems too pliable perhaps.

Shorting on center rail - while on low profile tubular track (Marx and Lionel)

This is a design/manufacturing defect I will need to work around.

Note the metal under the coupler sags. If it didn’t sag, it wouldn’t touch the center rail.

I like the engine sound and momentum. The horn sounds toy-like.

Couple of paint smudges behind the rear doors, but otherwise looks very good.

Rubber tires rolling after 2 minutes of running at lowest speed with no load on tubular track.

I agree with earlier comments that the couplers are almost non-functional when using manually. I’ll try them on an uncoupling track today, once I tape up the front to prevent shorting.

I paid $210 for Lionel’s lowest end GP38 in 2020 (MSRP $220 as of Jan 5, 2022), and $188 for this Menards engine with the same features 18 months later. With Lionel I get dealer support, increased resale value, blue tooth, iPhone app, future compatibility, and spare tires. Overall I think I will be much better off paying 6% more for Lionel quality and support. Saturday I’ll post in the Saturday Switcher thread this engine’s run through my track. Last Saturday I ran the Lionel GP38 and posted on the Saturday Switcher thread.

Fun to test a brand new product! If I can figure out the tire situation, and after I fix the center rail shorting problem, this F unit should work fine for pulling my Amtrak cars, with no switching duties requiring a functional coupler.

Maiden Voyage: rough ride over the K-Line O42 manual switch; otherwise seemed to traverse the Gargraves flex at about 34” diameter, K-Line O42 auto switch, two Marx O34 auto switches, and Marx 34” dia curves and Lionel straights as well as the Lionel GP38.

I think your point is well taken about the least expensive separate sale LionChief locomotives being competitive in features and price. The current LionChief locos offered for separate sale also can be operated by the universal remote, the app/Bluetooth and, presumably, in the future, employing the new command base in the coming catalogue, which allows control of LionChief locos via the Legacy handheld.

May not be an issue for new hobbyists or those with only one or two locos, but for those who already have Legacy, LionChief might be a plus compared with Menards offerings. We don't know for sure what the final pricing structure will be for Menards locos, but it sounds as if it's likely comparable pricing to existing LionChief locos. Be interesting to see how this plays out. More choices aren't a bad thing, however it goes ![]() . I wish Menards success in this new venture, given that we've been losing manufacturing over the last decade or more, with Weaver and K-Line leaving the industry, and Williams and MTH becoming less and less of a factor.

. I wish Menards success in this new venture, given that we've been losing manufacturing over the last decade or more, with Weaver and K-Line leaving the industry, and Williams and MTH becoming less and less of a factor.

Menards pilot shorting on center rail.

Fixed the cow catcher. Added a piece of cardboard to lift the catcher (cardboard from the free blue Ford box!)

Before:

If you remove a motor power wire, you can just barely get to the screws attaching the cow catcher.

After:

How-To video and successful verification run after adding the shim:

The coupler height was a problem this time. Couplers match between Menards pieces, but not when connecting to Williams or Lionel.

Menards is WAY below the NMRA standard on their flatcar and the F Unit. Almost 25% of the distance. 1/16” or maybe 1/8” discrepancy could be accommodated with a 3/8” knuckle, but not almost 3/16” below standard.

(Coupler knuckles are 0.36” on Menards and Lionel. Add 1/2 of knuckle (0.18”) to the center-of-knuckle NMRA standard height (11/16” or 0.6875) and you get the top of rail to top of knuckle target height of 0.8675”.

I’m thinking when Menards launched their product line they misread or misunderstood the Standard, and set the Top of the knuckles to 11/16” instead of the Center of the knuckles, and haven’t corrected it. Half a knuckle height across the line of products is a really big miss that has persisted for years now - makes me wonder how committed Menards truly is to making improvements.

Post war Lionel Sunoco tanker:

Williams boxcar:

Measurement technique- caliper from top of center rail to top of coupler:

Menards F Unit:

OOPS video:

Also, none of the Menards couplers released over the uncoupling track. Williams boxcar has no issues.

Doesn’t open even when idling over the electromagnet.

@Hannibal-St Joseph RR posted:Fixed the cow catcher. Added a piece of cardboard to lift the catcher (cardboard from the free blue Ford box!)

FYI: It's called a pilot.

Rusty

@Landsteiner posted:I think your point is well taken about the least expensive separate sale LionChief locomotives being competitive in features and price. The current LionChief locos offered for separate sale also can be operated by the universal remote, the app/Bluetooth and, presumably, in the future, employing the new command base in the coming catalogue, which allows control of LionChief locos via the Legacy handheld.

May not be an issue for new hobbyists or those with only one or two locos, but for those who already have Legacy, LionChief might be a plus compared with Menards offerings. We don't know for sure what the final pricing structure will be for Menards locos, but it sounds as if it's likely comparable pricing to existing LionChief locos. Be interesting to see how this plays out. More choices aren't a bad thing, however it goes

. I wish Menards success in this new venture, given that we've been losing manufacturing over the last decade or more, with Weaver and K-Line leaving the industry, and Williams and MTH becoming less and less of a factor.

well said

Rusty - yes it should be called a pilot. You are right, but this nitpick contributes nothing to the conversation about Beta 3.0.

You'll never find cowcatcher in ANY diesel documentation, particularly as many diesels are equipped with snowplows nowadays.

***a Rusty Traque/Blue Streak photo crop***

I pity the cow...

Rusty

@BobbyD posted:After getting control of the dies Williams could always have tooled up a B unit.

Williams did make an F7 B unit for their ex Kusan F7s. They sold them separately from the AA sets. What are you talking about?

@Rusty Traque posted:You'll never find cowcatcher in ANY diesel documentation, particularly as many diesels are equipped with snowplows nowadays.

***a Rusty Traque/Blue Streak photo crop***

I pity the cow...

Rusty

Agreed. Cow catcher has never been used for diesels. The term was a 19th century phrase that referred to heavy-sloped pilots that indeed had livestock and wildlife in mind. Diesel pilots without the plows? Nope. In fact, this is the first time I have heard any hobbyist on this forum refer to a typical diesel pilot as a cow catcher.

@Hannibal-St Joseph RR posted:You are right, but this nitpick contributes nothing to the conversation about Beta 3.0

100%

I appreciate your time for the thorough review. This is the first time I've seen anyone try to fire the couplers with the electromagnetic track. Williams boxcar couplers are notorious for being higher than lionel. There isn't much overlap between Menards and Williams.

Seems like Menards should be talking to you if they're really interested in improving!

@Jim R. posted:Agreed. Cow catcher has never been used for diesels. The term was a 19th century phrase that referred to heavy-sloped pilots that indeed had livestock and wildlife in mind. Diesel pilots without the plows? Nope. In fact, this is the first time I have heard any hobbyist on this forum refer to a typical diesel pilot as a cow catcher.

So the steam engine came first and it was called a "cow catcher". The evolution of steam engines created the diesels. When that happened the "cow catcher" became a "pilot". That begs the question, is it fair to call a cow catcher a plow during the 1800's? Because of its shape, it probably helped move snow off the tracks and, therefore, couldn't it be called a plow, too?

Should we call them toy trains or model trains? We scale them down to correct size and weather them, but, as my wife points out, they remain little trains powered by an electric motor that allows us older boys to play, too.

And then, where does a model or toy engine that sells for under $200 fall in our classification? When does a toy become a model?

And do Menards' buildings fall in line with toys or models? Afterall, there are a lot of photos of them on the forum and they are included in some pretty nice layouts.

I'm looking forward to testing the Beta 3.0. model, err, toy. ![]() I'll see how that little silver and red puppy performs when I have a drink in one and hand and a remote in the other.

I'll see how that little silver and red puppy performs when I have a drink in one and hand and a remote in the other.

beta 1.0 with a Lionel B unit. I have not had any issues with dropping cars. I've run post war passenger coaches or the B unit behind the loco so far.

@RoyBoy posted:Yes. That is a Williams F7. It matches the old AMT tooling, although AMT never made a B unit as far as I can tell.

Correct - AMT (American Model Toys)/Auburn KMT/KUSAN never made up tooling for a B unit to go with the F unit first offered by AMT in the early 50s. Williams (who purchased the original AMT-made tooling for the F unit) eventually had the B unit tooled up to match the A unit originally offered by Jack Ferris' AMT line made in Auburn, Indiana.

@Hannibal-St Joseph RR posted:Beta 3.0

2-minutes of run time evaluation:

Cow catcher shorting out on center rail

Rubber tires rolling. May need to buy Lionel tires to replace these with- the rubber seems too pliable perhaps.

Shorting on center rail - while on low profile tubular track (Marx and Lionel)

This is a design/manufacturing defect I will need to work around.

Note the metal under the coupler sags. If it didn’t sag, it wouldn’t touch the center rail.

I like the engine sound and momentum. The horn sounds toy-like.

Couple of paint smudges behind the rear doors, but otherwise looks very good.

Rubber tires rolling after 2 minutes of running at lowest speed with no load on tubular track.

I agree with earlier comments that the couplers are almost non-functional when using manually. I’ll try them on an uncoupling track today, once I tape up the front to prevent shorting.

I paid $210 for Lionel’s lowest end GP38 in 2020, and $188 for this Menards engine with the same features 18 months later. With Lionel I get dealer support, increased resale value, blue tooth, iPhone app, future compatibility, and spare tires. Overall I think I will be much better off paying 6% more for Lionel quality and support. Saturday I’ll post in the Saturday Switcher thread this engine’s run through my track. Last Saturday I ran the Lionel GP38 and posted on the Saturday Switcher thread.

Fun to test a brand new product! If I can figure out the tire situation, and after I fix the center rail shorting problem, this F unit should work fine for pulling my Amtrak cars, with no switching duties requiring a functional coupler.

Maiden Voyage: rough ride over the K-Line O42 manual switch; otherwise seemed to traverse the Gargraves flex at about 34” diameter, K-Line O42 auto switch, two Marx O34 auto switches, and Marx 34” dia curves and Lionel straights as well as the Lionel GP38.

One point, not to quibble, but comparing a Lionel engine you got in 2020 to what Menards is or isn't these days may not be relevant. The price of Lionel's products have shot up and are likely to go up even more. You are correct IMO about price vs quality, to me saving a couple of bucks and getting something that to me is inferior doesn't make sense. And yeah, it could be a better bargain to buy a lionchief engine used than this new, kind of like back in the day buying a Yugo new or a used Toyota or the like, no comparison.

Current price of a GP38 (BN 2085) on Lionel web site is $220. So it has not changed price in 2 years. I got mine for $210 as a pre-order.

Menards is asking for feedback, so I compared to a brand-new Lionel engine in the same price range with nearly identical features. This Menards engine should work fine for pulling my Amtrak cars - it seems very sturdy - but this isn't about my use of the engine. The objective of Beta 3.0 release was to get people to test it on a variety of track, with a variety of manufacturer's cars, forward, backward, uphill, down, around corners - the kinds of testing that will flush out problems. If the competition (in this case Lionel) has the same problems, then you are competitive. However, in my opinion Menards still has some work to do if they want to release an engine that will please people. If you say you have operating couplers, then they should operate - but if you hang them 3/16" below the published S-2 Coupler Standard (0.688" +/-0.031", or 11/16" +/-1/32" top of rail to CENTER of knuckle), then your plunger won't have enough travel to open the knuckle, and you will disengage from some cars, like the Williams that are 1/16" higher than the NMRA Standard. Menards is asking for feedback - and it is a fun way for me to engage, and a fun way for people to see that I am human.

It is a sign of this forum's camaraderie that people still accept (or ignore) me even though I called the pilot a cow catcher! Repeatedly! Thank you, Menards for a fun experiment and a solid engine for a good price.

Looks like Menards has aways to go on this one. I still don't like the chrome finish on the frame. Smart move asking the forum to test. Lionel should take note. I wish them luck. We will all benefit from increased choices from competition.

Art

" And yeah, it could be a better bargain to buy a lionchief engine used than this new, kind of like back in the day buying a Yugo new or a used Toyota or the like, no comparison."

I believe the point is that new LionChief locos for separate sale are no more expensive than this Menards loco. Charles Ro has some for about $10 more than the Menards diesel if I recall correctly. So the comparison is valid in that sense. No need to go used if you don't want to for similar price and features. But there are only a few types of locos and road names, so there's probably room in the marketplace for both Lionel LionChief and Menards.

Here are my V3 unboxing pictures.

@AtoZ Lewis posted:Here are my V3 unboxing pictures.

- For those who don't have a local Menards the "brown" shipping box is what comes to your door if you order (or have it shipped to a local Menards). Then the clear insert packaging is what is placed on the shelf in the store. As usual very good packaging. No directions at all (what does the switch on the bottom of the loco do?).

- I did not get a V1 or V2 to compare, but this V3 has an impressive slow speed / momentum start up. Way better than my Lionel LionChiefs and I would say better than my MTH Proto V3's. I don't have Legacy so I can't compare to those. I'll post a video shortly comparing engines.

- I grabbed some other Menards cars so I didn't notice anything on coupler height as mentioned above. Nor did I have any issues with the engine rubbing on the tracks as posted above by @Hannibal-St Joseph RR . I am running it right now on my Christmas MTH RealTrax setup that was under my tree. So all O-31 curves and switches. No issues at all.

- The sound is good, as mentioned above the horn sound is not the most realistic.

- The LED's are very bright, again not realistic but very clearly bright.

- I can't get over how smooth the startup is and the momentum transition up and down is very pleasing. You won't make an emergency stop with this engine.

Because I am attaching so many pictures, it won't include them inline with the post. You will have to click on them.

Can't view the pix.

@AtoZ Lewis posted:Here are my V3 unboxing pictures.

Pictures are unavailable

@Hannibal-St Joseph RR posted:Beta 3.0

2-minutes of run time evaluation:

Cow catcher shorting out on center rail

Rubber tires rolling. May need to buy Lionel tires to replace these with- the rubber seems too pliable perhaps.

Shorting on center rail - while on low profile tubular track (Marx and Lionel)

This is a design/manufacturing defect I will need to work around.

**************************

Hi Dan.I think what you are seeing is more of a mistake in assembly rather than a design defect. Mine has run flawlessly and couples up perfectly to MTH Premier passenger cars and Atlas O reefers.

See pics.

@Hannibal-St Joseph RR posted:Current price of a GP38 (BN 2085) on Lionel web site is $220. So it has not changed price in 2 years. I got mine for $210 as a pre-order.

Menards is asking for feedback, so I compared to a brand-new Lionel engine in the same price range with nearly identical features. This Menards engine should work fine for pulling my Amtrak cars - it seems very sturdy - but this isn't about my use of the engine. The objective of Beta 3.0 release was to get people to test it on a variety of track, with a variety of manufacturer's cars, forward, backward, uphill, down, around corners - the kinds of testing that will flush out problems. If the competition (in this case Lionel) has the same problems, then you are competitive. However, in my opinion Menards still has some work to do if they want to release an engine that will please people. If you say you have operating couplers, then they should operate - but if you hang them 3/16" below the published S-2 Coupler Standard (0.688" +/-0.031", or 11/16" +/-1/32" top of rail to CENTER of knuckle), then your plunger won't have enough travel to open the knuckle, and you will disengage from some cars, like the Williams that are 1/16" higher than the NMRA Standard. Menards is asking for feedback - and it is a fun way for me to engage, and a fun way for people to see that I am human.

It is a sign of this forum's camaraderie that people still accept (or ignore) me even though I called the pilot a cow catcher! Repeatedly! Thank you, Menards for a fun experiment and a solid engine for a good price.

Sadly the nitpicking has caused some of my friends to leave the forum. When we finished reviewing our Menards engine we gave it to some youngsters with a layout and no command engine. Not sure if Lionel makes a scale size and detailed engine like this in LionChief. Closest I think is their FT A-A pair which is about $500 for a power and a dummy. Is that correct?

@Art Lites posted:Looks like Menards has aways to go on this one. I still don't like the chrome finish on the frame. Smart move asking the forum to test. Lionel should take note. I wish them luck. We will all benefit from increased choices from competition.

Art

I was thinking they made a minimum production run of frames and trucks and are still using them. Also an easy way to tell "test" units from regular production runs.

@prrhorseshoecurve posted:Williams did make an F7 B unit for their ex Kusan F7s. They sold them separately from the AA sets. What are you talking about?

I never said Williams didn't make F7 B units as I'm the guy who answered his question on what the B unit in the video was. Not sure what you are talking about.

I have no idea if AMT or Kusan or anyone else that originally controlled the tooling ever produced a B unit nor do I even care.

@BobbyD - Lionel shows a Santa Fe FT as a part of the $429 Santa Fe Super Chief LionChief set. 6-84719 in 2019, 2020 and 2021 Vol 1 catalogs. O Gauge - so it’s not exactly scale size.

@BobbyD posted:Sadly the nitpicking has caused some of my friends to leave the forum. When we finished reviewing our Menards engine we gave it to some youngsters with a layout and no command engine. Not sure if Lionel makes a scale size and detailed engine like this in LionChief. Closest I think is their FT A-A pair which is about $500 for a power and a dummy. Is that correct?

Bobby,

I can clearly understand how some could get frustrated with the types of discussion that takes place here from time to time. But in reality isn't that the case no matter what train site you go to?

Not to be funny in any way, out of curiosity, where did your friends that left the forum go to for model train discussion?

Menards needs to either plate the body or paint the side frames, pilot skirt and the fuel tank/frame. Plated trucks/pilot/fuel tank with a painted silver body just does not look right. I vote for plate the silver areas of the shell. That would really make it SPARKLE when running under a lighted Christmas tree. AD

Lionel notched the pilot on later F3's to resolve the shorting issue when entering a grade.

@artfull dodger posted:Menards needs to either plate the body or paint the side frames, pilot skirt and the fuel tank/frame. Plated trucks/pilot/fuel tank with a painted silver body just does not look right. I vote for plate the silver areas of the shell. That would really make it SPARKLE when running under a lighted Christmas tree. AD

I have a 1.0 and I sprayed the frames with dullkote. I may do the rest of the shiny chrome one day.

I didn't get mine yet, but it sounds like there is little or no difference between version 2 and version 3.

I'll see when I get it.

I paired version 1 with an MTH B unit.

John

That helps it blend in better. I would just respray the side frames, front skirt and the fuel tank with Testors silver in a rattle can. Just like refinishing a set off a 2343 F3. It will be interesting to see what the final full production version will be, if they ever go to full production past these teaser runs. My guess we will see full production, maybe even a boxed starter set, for Christmas 2022 selling season. Time will tell. AD

I picked up mine yesterday at the local Menards store…along with the free lighted panel truck…and along with a Menardsville Depot! Well they were having a 15% off sale on anything you could get in a brown shopping bag…what’s a guy supposed to do? 🤪🙀

Anyway…did a cursory inspection after unboxing and other than a very minor smudge…everything appeared to be OK. Placed it in the track, powered it up and it ran fine both forward and back. Checked the sounds…they all worked…although the horn sounds are a bit poor. I did find one issue…when the engine was moving away from me, I noticed the left rear wheel was wobbly and upon further inspection, it appeared as though that axle was bent. Actually, probably wouldn’t have noticed it if there had been cars behind the engine. Tried to make a correction, think it helped a little…but decided not to put a lot of pressure on it and keep from snapping something off. Checked the couplers manually and they operated fine. Today I did paint the side frames and couplers with a silver spray paint…IMHO, I think it improves the look instead having them with a chrome appearance?

FedEx was supposed to deliver mine yesterday, January 4th.

But... As of January 6th, it is stuck somewhere in Minnesota with NO estimated arrival date. ![]()

As of January 7th, it's somewhere in Nebraska with still no estimated arrival date. ![]()

Received my Beta 3 engine from Menards today. Out of the packaging overall appearance is good, no paint blems. In testing the engine runs in reverse, forward on the control, engine travels backwards, reverse on the control, engine travels forward. Headlight and tail light also reversed.

Horn control from the handheld, has been corrected. Horn operates as long as the button is depressed. A Beta 1 engine when operated with the Beta 3 handheld blows the horn as long as the horn button is held down. The horn operation change was made in the handheld control. No wobble in operation, all wheels run true.

The testing continues.

@choochoopaul posted:Received my Beta 3 engine from Menards today. Out of the packaging overall appearance is good, no paint blems. In testing the engine runs in reverse, forward on the control, engine travels backwards, reverse on the control, engine travels forward. Headlight and tail light also reversed.

Horn control from the handheld, has been corrected. Horn operates as long as the button is depressed. A Beta 1 engine when operated with the Beta 3 handheld blows the horn as long as the horn button is held down. The horn operation change was made in the handheld control. No wobble in operation, all wheels run true.

The testing continues.

Thanks Paul, what about coupler height?

Steve

Steve,

Yes the couplers sag both in front and rear. About .100 each.

@PRRick posted:Seems like Menards should be talking to you if they're really interested in improving!

Hi Rick,

The instructions in the ad to purchase Beta 3.0 are to send all feedback to

guest@menard-inc.com

I sent them mine both good and bad.

@choochoopaul posted:"Horn control from the handheld, has been corrected. Horn operates as long as the button is depressed." "The horn operation change was made in the handheld control."

How does the "3" horn sound?

@choochoopaul posted:Received my Beta 3 engine from Menards today. Out of the packaging overall appearance is good, no paint blems. In testing the engine runs in reverse, forward on the control, engine travels backwards, reverse on the control, engine travels forward. Headlight and tail light also reversed.

Horn control from the handheld, has been corrected. Horn operates as long as the button is depressed. A Beta 1 engine when operated with the Beta 3 handheld blows the horn as long as the horn button is held down. The horn operation change was made in the handheld control. No wobble in operation, all wheels run true.

The testing continues.

That's interesting. I wonder if v1.0 handheld can be modified?

@Sam Jumper posted:

Hi Sam…thanks for the compliment…very much appreciated. I do have one other photo of the Menards Santa Fe version 3.0 in a different location on my layout and co-mingling with a couple of steamers…also shows some of the downtown area in the background.

I got mine today. I have all three.

I actually hadn't tested version 2 yet. So I tested both.

Version 2: Horn sounds anemic, but at least it blows steadily unlike version 1

Version 3: Horn is identical to version 2

Version 2: Jack rabbit starts and stops on version 1 were eliminated. Nice and smooth now.

Version 3: Momentum is same as version 2

Versions 1 & 2: Couplers work fairly well

Version 3: Couplers are an abomination and need to be forced open and forced closed to the point where they will probably break trying to do so.

Quality Control on versions 1 & 2 on mine were good.

Quality Control on version 3 on mine were not so good. Loco doesn't always synch with remote. Something is rattling and falling about inside the chassis (Haven't opened it to see what it is yet)

Does anyone have any idea why they even bothered with a version 3 ?? There is no difference between it and version 2 except they ruined the couplers. I think I am done with beta testing these.

John

@Craftech posted:Does anyone have any idea why they even bothered with a version 3 ?? There is no difference between it and version 2 except they ruined the couplers. I think I am done with beta testing these.

John

Probably for the builder to clear the benches before Chinese New Year.

Rusty

@Craftech posted:Does anyone have any idea why they even bothered with a version 3 ?? There is no difference between it and version 2 except they ruined the couplers. I think I am done with beta testing these.

John

My version 3 is fine. It seems like the quality control is suspect. Time to ride the quality control of the finished product. It’s not Beta manufacturing if people are buying them. It’s full on production.

@ChiTown Steve posted:My version 3 is fine. It seems like the quality control is suspect. Time to ride the quality control of the finished product. It’s not Beta manufacturing if people are buying them. It’s full on production.

Do you have version 2? I can't see any difference (except version 3 has really bad couplers)

That's a downgrade.

John

@Jim R. posted:Agreed. Cow catcher has never been used for diesels. The term was a 19th century phrase that referred to heavy-sloped pilots that indeed had livestock and wildlife in mind. Diesel pilots without the plows? Nope. In fact, this is the first time I have heard any hobbyist on this forum refer to a typical diesel pilot as a cow catcher.

You never know. You might wake up one morning and find a cow on your pilot.

Alan

@Craftech posted:Do you have version 2? I can't see any difference (except version 3 has really bad couplers)

That's a downgrade.

John

I didn’t buy version 2, only 3. My couplers are fine. My engine period is fine as far as build quality.

Someone else had the same issue with the couplers:

https://www.youtube.com/watch?v=kQoVll2pevA

Around 8:40

John

@ajzend posted:You never know. You might wake up one morning and find a cow on your pilot.

Alan

More likely hamburger...

Rusty

@Craftech posted:Someone else had the same issue with the couplers:

https://www.youtube.com/watch?v=kQoVll2pevA

Around 8:40

John

Can confirm, he's a pretty cool guy ![]() and also the couplers are a bit better free some more operations, but still to stiff to do any switching on the layout.

and also the couplers are a bit better free some more operations, but still to stiff to do any switching on the layout.

Some examples of v.1 and v.2 had battery boxes that didn't make good contact with the batteries in the remote. Any experience whether they've improved the reliability of that aspect of the product?

@Landsteiner posted:Some examples of v.1 and v.2 had battery boxes that didn't make good contact with the batteries in the remote. Any experience whether they've improved the reliability of that aspect of the product?

Those work fine on versions 2 & 3.

John

@RSJB18 posted:That's interesting. I wonder if v1.0 handheld can be modified?

Bob,

I took the remote from version 3 apart and compared it to version 1. I don't see a difference, but there is an IC with no markings on it on both of them. Maybe I can take a closer look at the two printed circuits.

I did try the version 3 remote on the version 1 loco. The horn blew steadily so something is different in the remote.

Maybe the push button micro switch is different?

John

They will definitely have to improve on the horn sound before I would pull the trigger on a full production model based on the videos I’ve seen.

@Craftech posted:Bob,

I took the remote from version 3 apart and compared it to version 1. I don't see a difference, but there is an IC with no markings on it on both of them. Maybe I can take a closer look at the two printed circuits.

I did try the version 3 remote on the version 1 loco. The horn blew steadily so something is different in the remote.

Maybe the push button micro switch is different?

John

Most likely they changed the firmware in the remote. That IC is most likely a PIC containing the firmware.

That is also the least expensive thing to change, so it makes the most sense from an engineering/manufacturing standpoint.

I have not been able to get any of the 3 versions since they sold out so fast. I admire Menard's for doing this type of research before locking in on a full production run. I don't remember any other model railroad manufacturer doing this. I would like to see the front side screens painted red filling in that noticeable gap. Are these engines similar to Lionel Lionchief engines with the chassis mounted switch allowing the user to opt for conventional operation or using the remote? I would venture a guess that we might see a production run for Christmas 2022.

@Allegheny48 posted:. I admire Menard's for doing this type of research before locking in on a full production run. I don't remember any other model railroad manufacturer doing this.

Actually, Lionel did this with the RS11/C420 chassis (Maddox send Cab 1’s and TMCC gear with), and Weaver did it with at least the U25B. In these two cases that I know of for sure, it was all given for free in exchange for the user feedback. It’s rather uncommon for a manufacturer to actually sell preproduction units AND expect the buyers to deliver feedback.

@Sam Jumper posted:In these two cases that I know of for sure, it was all given for free in exchange for the user feedback. It’s rather uncommon for a manufacturer to actually sell preproduction units AND expect the buyers to deliver feedback.

How many units were distributed and how did they select the the people who received the free units. I get free demos of equipment all the time but I never get to keep them for free, sometimes I get the option to purchase the demo equipment instead of it being returned.

@Allegheny48 posted:I have not been able to get any of the 3 versions since they sold out so fast. I admire Menard's for doing this type of research before locking in on a full production run. I don't remember any other model railroad manufacturer doing this. I would like to see the front side screens painted red filling in that noticeable gap. Are these engines similar to Lionel Lionchief engines with the chassis mounted switch allowing the user to opt for conventional operation or using the remote? I would venture a guess that we might see a production run for Christmas 2022.

No conventional operation unfortunately. Many have commented that they would buy one if it did.

@Craftech @RoyBoy- I would agree that the firmware may be where they made the change.

"How many units were distributed and how did they select the the people who received the free units. "

It was only a handful of units, I suspect, and they were distributed to folks on the AOL Forum and other personal contacts who seemed interested and knowledgeable. This went on for a few years and many of those involved met with Lionel staff during the centennial celebration in Detroit in 2000 (LCCA/LOTS).

@Landsteiner posted:"How many units were distributed and how did they select the the people who received the free units. "

It was only a handful of units, I suspect, and they were distributed to folks on the AOL Forum and other personal contacts who seemed interested and knowledgeable. This went on for a few years and many of those involved met with Lionel staff during the centennial celebration in Detroit in 2000 (LCCA/LOTS).

They were all sold through Menards website. First come first serve......no freebies from what I have read.

@Sam Jumper posted:Actually, Lionel did this with the RS11/C420 chassis (Maddox send Cab 1’s and TMCC gear with), and Weaver did it with at least the U25B. In these two cases that I know of for sure, it was all given for free in exchange for the user feedback. It’s rather uncommon for a manufacturer to actually sell preproduction units AND expect the buyers to deliver feedback.

I'm a beta tester for a major electronics manufacturer. They send me everything for free in exchange for my time. Granted, the electronics testing does tend to become very tedious and time-consuming as various firmware updates are released and software bugs resolved. Then again, I'm retired. All dressed up with nowhere to go as it were.

I was happy to participate and pay for it until this last one (version 3).

$200 later I have no idea what was changed (improved) from version 2. No one else who has both seems to know either. That the couplers are worse on some models is not something they intended so what did they improve and why is it up to us to guess?

John

@Sam Jumper posted:Actually, Lionel did this with the RS11/C420 chassis (Maddox send Cab 1’s and TMCC gear with), and Weaver did it with at least the U25B. In these two cases that I know of for sure, it was all given for free in exchange for the user feedback. It’s rather uncommon for a manufacturer to actually sell preproduction units AND expect the buyers to deliver feedback.

Sam,

It’s rather uncommon for a manufacturer to actually sell preproduction units period.

Mike

@Craftech posted:I was happy to participate and pay for it until this last one (version 3).

$200 later I have no idea what was changed (improved) from version 2. No one else who has both seems to know either. That the couplers are worse on some models is not something they intended so what did they improve and why is it up to us to guess?

John

I hear your frustration, but there's a method to the madness.

It's clear from your comments, and those of many others, that Version 3 is quite successful.

There are two objectives, both of them are intended to make the product more profitable, hence better:

I suggest that No. 2 above was a complete success with Version 3. I'm sure that changes of this type were made because Menards wouldn't go through the process of running a third beta unless there were indeed changes made.

Since you (and apparently the rest of well) didn't find them Menard's should be quite happy with the outcome.

Now, as for them telling you what they were, it's not gonna happen. If they let you know beforehand what to look for you'd be inclined to complain about them. In reality you first need to find them, then complain about them. If you didn't find anything there's nothing to complain about, and nothing for them to change. Success.

Finally, read the fine print on the transaction. They don't owe you these details of what they changed.

I suggest you send your Version 3 back for a refund, while you can, and don't buy a Version 4 beta if one comes out.

Mike

@Mellow Hudson Mike posted:Now, as for them telling you what they were, it's not gonna happen. If they let you know beforehand what to look for you'd be inclined to complain about them. In reality you first need to find them, then complain about them. If you didn't find anything there's nothing to complain about, and nothing for them to change. Success.

Mike

I didn't say "beforehand".

But 200 were sold out in two hours. So the orders were done. If we are beta testing why is knowing what was improved a bad thing? Not everyone has all three to compare like I do. If there is no difference between version 2 and version 3 then wouldn't Menards be more forthcoming saying "We are selling a second run of version 2 for a larger feedback"? New version means some changes were made. I don't see any so this is version 2 reissued. What am I missing ?

I also like these things. Even bought an MTH B unit to go with one of them. But as I stated above I won't be buying another Beta unless I know I will be testing something new.

John

There might have been no changes as they were probably hoping for others to get them besides the initial testers in order to broaden the feedback base. I'm sure you could get your money back; sell it while the market is hot.

Brendan

I’m having an issue with Beta 3.0.

@Mellow Hudson Mike posted:Sam,

It’s rather uncommon for a manufacturer to actually sell preproduction units period.

Mike

That depends, do they want them back? It's a losing proposition when you have to incur the cost to return a product and then paying for the disposal of it. I receive lots of tech equipment sent to me that is beta & demo equipment that the manufacture never wants back because they can't resell it and it's only value is to them is e-waste. About 25% of the time do we have to actually send it back and in those cases the manufacture has to pay for the return cost.

Spare parts I received with my different versions:

1. Extra horn loose in box

2. Extra nylon PCB mounting screw loose inside chassis

If anyone is short either of these or either is broken, let me know and I will send it to you.

John

@Craftech posted:I didn't say "beforehand".

But 200 were sold out in two hours. So the orders were done. If we are beta testing why is knowing what was improved a bad thing? Not everyone has all three to compare like I do. If there is no difference between version 2 and version 3 then wouldn't Menards be more forthcoming saying "We are selling a second run of version 2 for a larger feedback"? New version means some changes were made. I don't see any so this is version 2 reissued. What am I missing ?

I also like these things. Even bought an MTH B unit to go with one of them. But as I stated above I won't be buying another Beta unless I know I will be testing something new.

John

Sometimes the purpose of the beta test is to see if changes can be made without the end user knowing what or why. I did notice some extremely minor changes made to 3.0 that were not present in 2.0. They were ever so slightly noticeable and didn't bother me so I didn't report them to Menards either. They are there and you need to look hard.

In my line work, I receive equipment from manufactures for demo and beta testing purposes. I once received a pre-production network switch from Cisco, and studied it thoroughly to compare it from the previous release to see what had changed. Couldn't find a dang thing! My sales rep later revealed to me the one and only change made... the shipping box size was reduced by two inches in length. They did this to see if the equipment would still survive shipping without damage. Apparently the logistics department figured out they would save a bunch of money on shipping if this worked out.

Menards beta test program appears to be a blind study (they won't tell us whats different to see if anyone will even notice) and it's designed to sample folks 100% at random by offering it online only, in limited quantities and to whoever who shows up first. They didn't select "elite" members of some group or a closed circle of train buddies but rather the masses they intend to sell it to.

@H1000 posted:Sometimes the purpose of the beta test is to see if changes can be made without the end user know what or why. I did notice some extremely minor changes made to 3.0 that were not present in 2.0. They were ever so slightly noticeable and didn't bother me so I didn't report them to Menards either. They are there and you need to look hard.

Oh. That's encouraging. What were they?

Thanks,

John

@Craftech posted:Oh. That's encouraging. What were they?

Thanks,

John

I sent my feedback to Menards as per their request. I assume what little things I noticed had more to deal with stream lining the production and implementing some cost savings.

I am just hoping Menards , makes parts available On their web site. And l little training in their stores wouldnt hurt

I just opened and ran my Beta 3.0. I am very impressed with this entry by Menards. Because it falls within the starter set price point, it's hard for me to judge it because my collection is Railking and Premier diesels and steam. I do like its "command" remote, and it seems to be very responsive at 13 volts. I like the talk and bell a lot. Having the random control tower sounds is super cool especially at this price point. However, the horn, needs improvement. I really like the forward and reverse led lights -- every bit as good as the best. The lights for the number panels should be steady white lights as has been noted in this forum. I also like that they put some engineers inside the cab -- you can tell Menards' folks actually play with trains, too.

I thought I had a defective product. I had no sound or bell/horn. But it turned out that my batteries were weak. Once I put new batteries in it worked great.

When I compare it to my MTH Santa Fe F3 I would say this engine compares well, aesthetically, except for the shiny chrome trucks. The red should be a gloss, candy apple red the way MTH does it -- they nailed it. Menards trucks look as good as MTH

and I also like the yellow paint around the headlight. Nice job, Menards. I think you have a noble contender in the O Gauge category -- definitely at the entry level. I was planning to test it and then sell it. But now it may be a keeper because it is, well, fun to play with like a good toy train should be.

I paired it for fun with my MTH B unit and it looks good as you can see. Menards ought to offer a B unit or a non-powered A. I have not run it with cars yet because my layout is under heavy construction.

And, BTW, that Spaten Oktoberfest in the photo was really good beer. ![]()

@Brendan posted:There might have been no changes as they were probably hoping for others to get them besides the initial testers in order to broaden the feedback base. I'm sure you could get your money back; sell it while the market is hot.

Brendan

I was told some hobby shop was selling three of them as new on "you know where" for over $350 each.

@BobbyD posted:I was told some hobby shop was selling three of them as new on "you know where" for over $350 each.

Not just " some hobby shop" but a sponsor here that regularly posts "big sales" .(under every forum topic) That are actually just reductions from original price markups.

I Wouldn't buy from (N)ew (H)aven if they were the last shop on earth.

Stick with honest ,reputable dealers that don't play games. Like Ro, Trainworld, and Mr. Muffins

Ricko that's pretty good with the new haven thing👌

Here is the analysis that I just sent.

Menards beta 3 Santa Fe loco

About me:

I come from a family of men who repair machines. Great grandfather owned a machine shop and repaired automobiles in the 30’s and 40’s. Father repaired electromechanical desk calculators manufactured by the Friden Corporation. My older brother was an auto mechanic and also had antique cars. I was a field service engineer for medical machines and machines used in the semiconductor industry. I have an antique car collection which I taught myself to repair and maintain. Additionally, I have been playing with trains and repairing them since around 1955. I keep my hand in the repair business.

Here is my rather wordy analysis of the Beta 3 loco.

The good:

The square holes behind the number boards work well for even lighting.

The ornamental horns set closer to the roof should make them less susceptible to breakage.

The plastic bag on the loco seems to have eliminated all the scuffing on the paint job.

Reworking the firmware for smoother starts and stops worked very well. I especially like the fact that you can run in forward at a good clip, throw the loco into reverse, and watch it slow down smoothly before starting up again smoothly in reverse. The start is still slightly too abrupt for my taste. Maybe a little more tweaking on the lowest speed steps would help. The lowest speed step is a hair too fast for my liking.

I like the fact that everything is mounted on the chassis, so there are no plugs to unplug when removing the body.

The shipping packaging is working very well. My loco took some detours on its way to being delivered a week later than originally announced. The box took a beating, but the loco came through unscathed.

I like the general design of the power trucks. It’s especially nice that the side frames can be removed from the bottom, so traction tires can be changed without a complete disassembly of the loco. The power pickups can be removed from the bottom also without complete disassembly of the truck.

The bad:

One of my rollers would not swivel and was too tight to extend. If it is pushed up into the truck, the spring cannot push it down. I reworked it a bit, but it is still not right. Is there any way to get a replacement?

The screws holding the body to the chassis were way too tight. If someone uses a cheap screwdriver, they are likely to strip the screw heads. The assemblers need to dial back the torque setting on their power drivers.

While there appeared to be excessive grease on the external idler gears, the worm on the motor and the driven worm wheel on the drive axle had very little grease. I coated them with “red –N- tacky” which is popular with the train crowd.

It would be nice if the remote battery cover snapped closed, rather than using a screw. When this is put away, it’s always good to remove the batteries. Having to unscrew the cover makes it less likely that the batteries will be removed every time the unit is stored.

My loco shudders, shakes, and shimmies going around O-72 tubular curves. I can’t imagine how it would handle O-36 curves. More on this later.

The rear coupler sits just a bit too low to match up with other rolling stock. The coupler had a loose screw at the top, which made the coupler floppy. Tightening that screw almost all the way secured the vertical motion. Tightening it all the way stopped the coupler from swiveling. I used nail polish on the threads so that the screw would stay where I set it. Maybe some sort of shoulder screw would be a better solution. The rear coupler is also too long for my taste, but that may be subjective. Since it does not have a standard mount, I will have to do some work to mount a shorter coupler.

Are the traction tires a hair too wide to fit the slot in the wheels, or is it just that the wheels are poorly installed on the axles?

The ugly:

Much as I admired the engineering of the truck block, the assembly workmanship was TERRIBLE. It appears to be assembled in a hurry or by inexperienced assemblers, or maybe there were no standards or fixtures available. Out of four axles, there were three different gauges. Measuring from where the wheel tread meets the flange, I got 1.295”, 1.270”, 1.270” and 1.225”. That’s a .070” difference from the widest to the narrowest. My layout has O-72 curves and no switches and the loco still wobbles, shakes, and shimmies around the curves. This loco would never go through switches with the wheels set so far out.

In addition to that, two wheels wobble, either from being pressed on the axle poorly, or maybe the axles are bent. It is reminiscent of an MPC loco with wheels that were not concentric. I have not checked the concentricity of my loco’s wheels yet, but will do so soon.

The truck block still has two plastic gears that must be changed to metal if the loco is to have a long and happy life. These are the driven worm wheel gears and the drive gear for the external idler gears. Due to the different expansion rates of the steel axle and the plastic gears, the gears that are press fit onto steel shafts will eventually split and will rotate/slip on the shaft.

Recommendations:

It’s probably best to determine the audience for this loco. If it’s just for kids, and if it’s designed to be disposable, then you might have nailed it.

IMO you must change the plastic gears that are press fit on their axles. As it is, the loco will run for a year or three, but eventually those press fit gears will crack and slip on the steel shaft. It’s not an easy job to replace them, either.

Trains have always been sold as a lifetime investment in happiness. There are many adults, as well as kids, who have limited resources and will buy these locos. The locos must be reliable for them and it won’t be with plastic gears press fit onto metal shafts.

If the extra cost of metal gears is too much, you can save some money by eliminating the chrome plating. Paint is cheaper than the plating, and the plating has been getting mixed (mostly negative) reviews.

***The assemblers must up their game. The terrible way the truck blocks were assembled on my sample will not work in full scale production and the product will perform poorly, as mine does. I will attempt to re-gauge the wheels on my loco, but that is not the kind of thing the buyers should be expected to do.

It is desirable to be able to operate the loco conventionally, as well as with the remote. I have no idea what the cost is for that, but Lionel found that out with the first Lion Chief locos. The added Lion Chief + was the ability to operate conventionally as well as remotely.

Thank you for reading my review. If you have any questions, please contact me.

Roy Yost from the West Coast

@RoyBoy posted:My loco shudders, shakes, and shimmies going around O-72 tubular curves. I can’t imagine how it would handle O-36 curves. More on this later.. ..........................................................................My layout has O-72 curves and no switches and the loco still wobbles, shakes, and shimmies around the curves. This loco would never go through switches with the wheels set so far out.In addition to that, two wheels wobble, either from being pressed on the axle poorly, or maybe the axles are bent. It is reminiscent of an MPC loco with wheels that were not concentric. I have not checked the concentricity of my loco’s wheels yet, but will do so soon.

There is up and down movement that may be contributing to this. In both versions 2 and 3 if you hold the trucks and pull up and down on the body there is significant up and down movement especially in the rear.

John

So from everything I'm reading here and I've read this entire post, is the problem seems to be quality control. That is a problem with every manufacturer now days and it doesn't seem like an easy fix. Maybe Manards could do something about this with their manufacturers. Because nothing turns a customer off faster than poor quality control.

I got 2 of the Beta 1’s and now have 2 of the Beta 3’s. Never got a 2. I got my extra of each from other people. My Beta 1’s had operational issues as discussed in multiple threads, but no real Quality issues. The Beta 3’s seem to resolve the major operational issues to some degree, but based on mine and the comments of others, Quality too a break.