Hello everyone, I replaced a like new subject engine e unit because it was shorting. The new one was a brand new e-unit that functioned when I tested it but when I installed it it works but the engine won't go forward or backward? Can someone tell me why the drum works and it clicks but the engine won't start? Also can someone please tell me what causes shorts and E units any help much appreciated as usual, thank you very much, Jerry

Replies sorted oldest to newest

First off, I would review this websites info: https://dfarq.homeip.net/how-d...-lionel-e-unit-work/

My 2 cents worth follows.

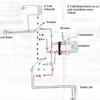

The schematic of the E unit is a bit confusing because most drawings show things mechanically, not as a line schematic. Hopefully you have a volt/ohm meter to do some tests with. Are you sure you made all the connections between E unit and motor correctly? You know you have the E unit solenoid right since it is cycling. You won't blow anything up, the E unit drum mechanism feeding the motor is just a device that is in series with the motor, and wrong connections mean it won't work, not catch fire. With the motor powered up and while you are cycling the E unit, are you seeing AC voltage on the brush and field leads going to the motor? Do you know the motor is actually good? Is the commutator clean or very dirty? Are there brushes in the holders? You should see them if you look closely at the space between the commutator and brush holder. For deeper trouble shooting, if you unsolder the 3 motor leads, one each to the brushes and one to the field, the coil on the actual motor frame or armature you can make some ohm meter readings. You should get a low resistance reading, but not a short, of the field to motor frame with an ohm meter. Reading across the brush leads should also give you a reading, and as you rotate the motor you should get a reading as it goes around a full revolution. With the leads free, you should not read anything from brushes to field winding. The motor is series wound, and the drum basically swaps the brush connections end for end to the field. If you isolate the brush leads and the field, hook one brush to the field, and AC to the other brush, and AC returnt to the metal motor frame, and the motor should run one direction, then switch the connections, the brush lead you fed AC to now put to he field and the AC to the brush that was first hooked to the field, and it should run the other way.

I added a crude schematic of the E unit if it was drawn as a 2 pole 4 position rotary switch, the colored paths showing the electrical path for forward and reverse.

Attachments

Thank you very very much for your reply. I will dive into it again. Best, Jerry

@CALNNC posted:..schematic of the E unit is a bit confusing because most drawings show things mechanically, not as a line schematic...

This one is pretty good...

I just replaced it with another E unit and it works fine but I have a few e units from MPC in the mid-70s and my blue wire goes to the field not green. Much thanks again, Jerry

By the way if one goes bad and shorts like my original one did what is shorting?

@Jerry A posted:By the way if one goes bad and shorts like my original one did what is shorting?

A finger to frame or often the drum plastic bearing points break off cocking the drum and allowing the drum to short to frame and thus fingers touching the drum to frame. Again, typical failure is the drum- and when it fails, it can wipe out the fingers if they take current and heat up- they lose their spring and it's total replacement time of both drum and fingers.

Best thing on a e-unit is just remember how they should work. On four finger board, the two outside wires go to power and the field. It does not matter which one goes where. On both boards the center wire wire goes to a brush. It does not matter which brush except for two motor units. There the motors have to go the right direction so both trucks are going the same way. If they are not going the same way reverse the two brush connections on one motor.

I've learned a lot from you guys and I appreciate it. Jerry