If you take the side plates off and lower the tank you are well on your way towards later versions

Attachments

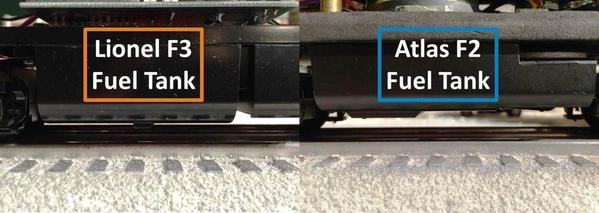

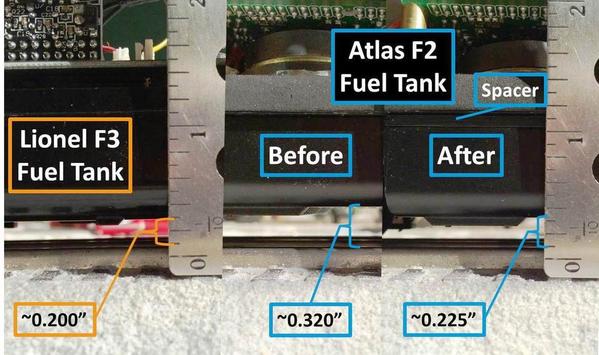

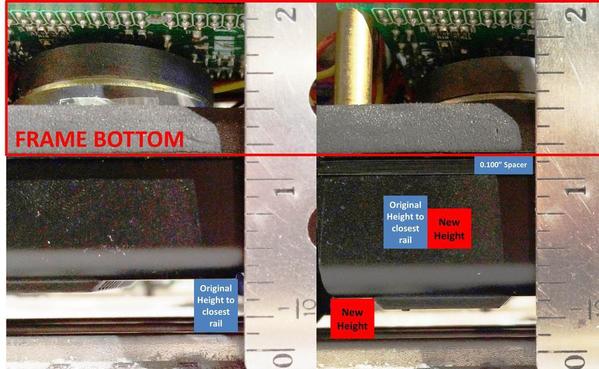

There's been a lot of work done with the Atlas fuel tanks, and its such a simple fix for all of the maker's tanks. I did some work on my own...

Attachments

Fascinating: I will bring all your corrections and improvements to our next design meeting on the E8/E9 project. A lot of the misgivings you mentioned, i.e. grill tabs on the B units, roof overhangs, etc. were left overs from the B unit tooling from the FP7 project. Most projects we do are ALL new tools i.e. SD7/9, E8/9 and PAs. It is true that Ed Rappe prompted me to change the F7A tool so that there were no more tabs on the grills. When you get 4 units back for a refund from a well known customer, you don't ignore the issue. We quickly brought this to the design meeting and they changed the A unit design to do tabless grills. Now we and you are suffering the consequences 10 fold. I usually don't like to change the way things are done if they are working. This is a prime example. I think if we use slightly thicker nickel plated brass, the bending problem will be over.

I don't like to make excuses for mistakes made on these models. But we have had some really hard times with the factory. They changed hands, they held up a container for a 20% ransom on 3 projects in production this year, including the F7s. They fired my star manager and replaced him with newbees. But we are back in business with the core crew from the old factory. They are hot at work on the future Diesel projects, and I will show them these corrections.

Thank you all for your patience with our mistakes. I will focus in the future on making a new 3 rail coupler that is more integral to the diesel truck. Easier conversion to 3RS. More 2 rail features for our 3 Rail models. But do remember, these are really short runs of plastic models, so a lot of engineering is done on the fly, during production. And some of these 3RS features need to be made separately like 2R pilots, steps and Kadee mounts. There is no time for a pilot sample and change this and change that. We gotta catch it all in the final Design. We were robbed of that process by the old factory. They ignored our final corrections, never sent pictures, and when I arrived for inspection, the models were finished as you saw them. Changing them at that point was too risky.

Also, delays are very expensive, $20,000 a month, and cause a ripple effect as once a higher unit price is achieved by the builder, they never go back to a lower unit price no matter what we remove from a list of features.

I had a classic discussion long ago with one of our Korean builders. I presented 2 steam engines too him. First was a small simple loco. He said, "Oh, small engine, very difficult, high cost..." I said, "Oh, ok, how about this big articulated engine?", He said, "Oh big model, more brass, more costs...", so he had an answer for higher costs for any situation I presented. Negotiating with these guys happens on each new project. But as long as you are interested in these models, we will keep making them and fighting for better detail and keeping the prices reasonable.

That is the business of importing. Keep your suggestions coming. The new factory will have the ability to make replacement parts for us even from the old projects, but give us 6 months to get things rolling. The older factory just looks at me and says, "WHY?". They don't get it and never will. Onward.

Regards,

Scott Mann - Sunset Models Inc. / Golden Gate Depot

The atlas fuel tanks may be lowered, but they would still be utterly incorrect for F3's onward.

Thank God they are retooling it for their upcoming F7's!

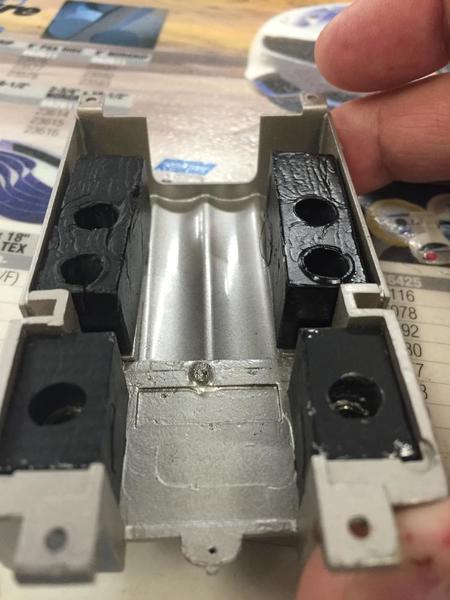

This is my in progress Atlas F3 with Lionel fuel tanks

Attachments

My F's are coming along. Re did the pilot to reflect the Rio Grande chain link coupler bars. Here the fuel tank is lowered. After I do the anti glare paint I will give the whole thing a satin over coat.

Attachments

Beautiful work Santiago! The color match is spot on and the coupler lift bars and tank lowering are really great improvements. I think with the anti-glare paint on the hood it will rival anything out there on looks. Stunning.

Scott, thanks for explaining what happened and what we will see in the future. All good news.

Butch

Once again I have to give kudos to Scott for explaining how things work overseas!!! Why can't the other importers do the same?

Doug

Those engines look very nice, Santiago. What method will you use to mask the windshield and portholes prior to spraying with satin finish?

thanks -- b. smith

Thanks, B! I'll mask with Tamiya's masking tape, I've used it before and it is great.

Thanks, Butch! The pilot brackets are P&D. Even though they are over sized, they are pretty great.

Santiago, Fantastic looking units!!! Your improvements definitely make a huge difference. This is one of the best threads in a long time on OGR. Really appreciate everyone sharing their tips and tricks along with Scott's insights... ![]()

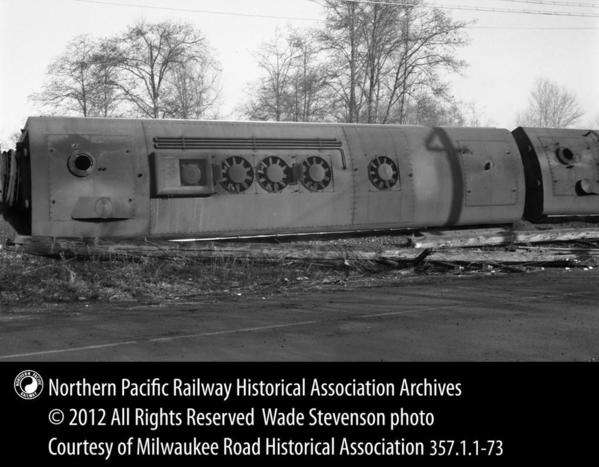

Can anyone send me towards the source for the cooler pipes on the roof of this F7? I can make them for all 3 units but what a soldering adventure that will be. This is the last piece I need for the NP aba set I scored.

Attachments

aterry11 posted:

I don't see the problem. Just make the assembly out of the correct diameter brass wire, and solder it together at the brackets/clamps.

Mr. Hotwater, any idea what the diameter of that cooling pipe is? PSC has the brackets and the end bends and wire just a lot of soldering.

Lionel did those (or very similar) for their E8/9's, however they are not listed on their replacement parts. Might be worth giving them a call or even MTH.

Richard, NOTED. We will address this at our design meeting for E8/9 and beyond. Scott

sdmann posted:Richard, NOTED. We will address this at our design meeting for E8/9 and beyond. Scott

If you need a QA person to double check the NYC E8s, let me know. ![]() As a former QA Engineer, and now a Sr. TSE, with a 6-Sigma Blackbelt, I am supremely qualified to search for production / engineering mismatch. I am also trained in DFM (Design for Manufacturing).

As a former QA Engineer, and now a Sr. TSE, with a 6-Sigma Blackbelt, I am supremely qualified to search for production / engineering mismatch. I am also trained in DFM (Design for Manufacturing).

Scott,

Provided you own the diesel tooling. Why not have the plastic formed here in the US as well as the chassis stampings. I would pay extra for a better product made in the US. If these are small runs and with the state of the economy there should be plenty of shops willing to compete. California labor might be too high, but in places like Houston and some other cities where there are shops going begging, with the oil patch down, the price might be right.

One would have much better control.

Ron H

B Smith posted:Those engines look very nice, Santiago. What method will you use to mask the windshield and portholes prior to spraying with satin finish?

thanks -- b. smith

I matched the anti glare green to the best of my abilities, I'm happy with it. I'm going for the richer "unfaded" green. Here are some pictures of my trying it out. I use Tamiya tape, and as you can see it works wonderfully. May spray the A's tomorrow, I first have to sacrifice an albino rooster to see if the Gods are with me. Nerve-racking to say the least.

Attachments

Santiago - are you going to remove and swap/re-mount the vent windows like a couple of the other guys did earlier on this thread? Your workmanship is top rate - please keep sharing it with us. For 2 railers following this thread yesterday I replaced the Q2 QSI firmware sound set with the latest Q3 EMD 567 - huge improvement. The Quantum Upgrade software ran about an hour and 20 minutes to load the firmware and uploading tuned CV's took another hour running CV Manager. The new sound is awesome and the units run smoother, especially at startup. Something I'll do on my F7's after I finish some higher priority projects.

Ed Rappe

I can't believe I said Sunset and Atlas fuel tanks. It's the Sunset and Lionel fuels tanks. Post edited.

Ron H posted:Scott,

Provided you own the diesel tooling. Why not have the plastic formed here in the US as well as the chassis stampings. I would pay extra for a better product made in the US. If these are small runs and with the state of the economy there should be plenty of shops willing to compete. California labor might be too high, but in places like Houston and some other cities where there are shops going begging, with the oil patch down, the price might be right.

One would have much better control.

Ron H

Because whether he owns the tooling or not it is illegal to remove any tooling from China, for anything. That was part of the Sanda Kan debacle. They all had to find other manufacturers in China to use the tooling from Sanda Kan.

Thanks, Ed. Yes I will fix the window vents, but more towards the end as glazing is almost the final touch.

Santiago your green looks great! For a freshly painted unit it looks to be right on and matches the newness of the existing paint. I don't know if you weather your models or not, but you can always lighten the color with a little weathering to show a unit that has been out in the sun for a few years. I'll bet that green will be the icing on the cake. Nice job!

Butch

Santiago, one more question about masking the windshield and porthole windows: do you use a template to make a single piece of masking tape the right size and shape for the opening, or do you use narrow strips of the Tamiya masking tape to go around the edges, then fill in the center, particularly on the windshields? I'm trying to decide which way will be easiest. Like you, I want to put a flat on some F units. Thanks for any advice you have....

Thanks, Butch!

B Smith, Tamiya doesn't curve all that well, so I make a template then cut the tape with xacto and apply. For curves I use a regular circle cutter with blades. It may take more than one piece to cover but that's no biggie.

My pilots are finished! I tucked the coupler on this one a bit for looks, so it's not operational. The only thing this unit will face will be the breathtaking sights of the Colorado Rockies anyways ![]() . The trailing one looks the same except it is operational.

. The trailing one looks the same except it is operational.

I also added a speed recorder that goes all the way to the frame . Everyone can do this and it makes a considerable difference.

Also, 3rd rail should improve on its lettering. Not only the colors are off on this EMD logo, it is pretty much illegible.

Attachments

Fabulous!!!!!

Did one anti glare today. This is the most difficult thing I've done when upgrading a model. Thankfully it came out well. Masking the windshields was annoying as hell!

Attachments

Attachments

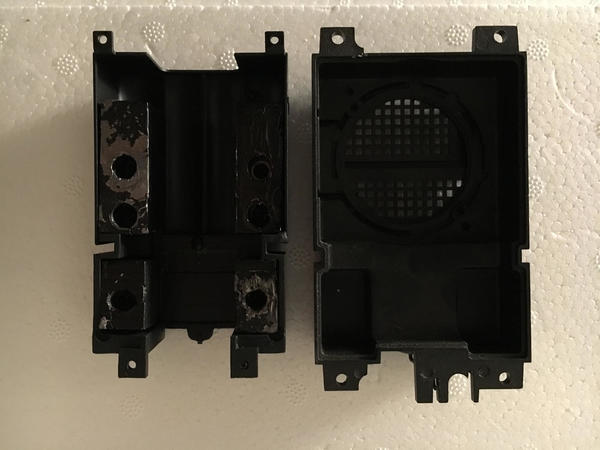

I started on the re-wiring of my F7. I realized the third electrical board in the unit was a board to switch between conventional and TMCC. I'm replacing everything with an ERR cruise commander and a different sound card.

The original mess of wires.

Cleaning up through deletion of superfluous wiring.

Attachments

Ouch Ron! That's a rough way to get started with a new model!

nothing a few cold ones can't solve!

As to windows masking, I have read that Vaseline or similar can work. Place it on the area to be masked along with tape/paper for larger areas, apply the paint, then remove the Vaseline. I havent tried it myself, but it sounds like it could work, although it might be just as much trouble to apply it to windshields/windows as tape.

Amen to the cold ones Aaron.

Santiago the anti glare looks perfect.

Ron H

Nice job Santiago! The green and light orange of the Rio Grande really compliment each other. Very clean separation lines and your tape job was excellent. I really look forward to seeing this model once dull coated.

You've made some really nice changes that most modelers can handle and really dolled up this model. This is the beauty of the SS/3rd models. With excellent factory bones, paint and basic details, the modeler is free to customize them to whatever he wants and have a really outstanding personalized model. I own some KEY E and F units and your F-7 is rivaling them for a whole lot less money. Nice job.

Butch

aterry11 posted:

aterry11,

What I have used in the past for details, such as these, like I needed on my scale Mikado (See air line thread here), I use similar air lines from Lionel.

Check this out, from their new Mikados, its a 4x air line that might come in handy.

On the Lionel support page, just search for "air line".

Thanks,

Mario

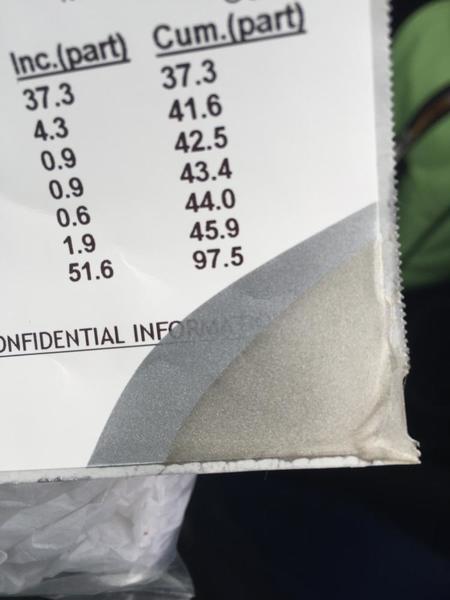

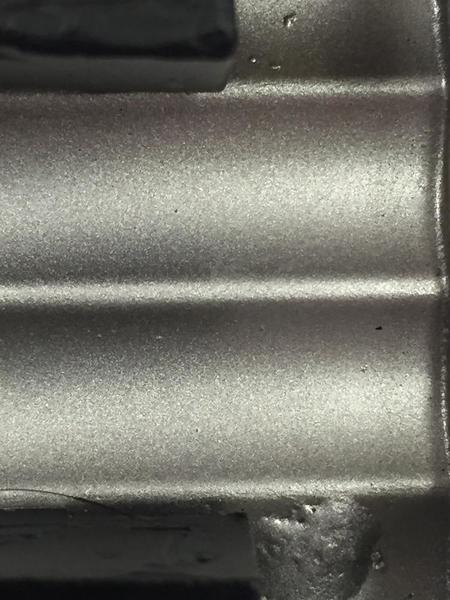

This is the matched paint from Genesee Paint in Utica, NY. Gary paint matched LOS' fuel tank from his F7, first with a handheld optical device, then tweaked it by eye. Only took one tweak to nail it.

Its on the left lower bulge of the tank.

on the top in this picture! I know it's there, I watched him dab it on.

Its now in a spray can, ready for the trip back west.

Attachments

If someone has their Sunset F unit body already off the chassis I'd appreciate you reporting back what the outside diameter of the Canon motor is. I need the info to determine if the Sunset motor will fit in the body of an old USH GP-7 I'm repowering.

thanks

Ed Rappe