I've had my 671 since the 50s. I bought a 681 at a Stout auction 6 or so months ago. I checked it out and thought it ran pretty well.

I'm the the final throes of putting my train stuff away in anticipation of starting the process to build my layout. On a lark I took out the 671 and 681 and sent them on some final laps around my test oval. I was surprised how much faster the 681 was. I had my ZW up all the way, and the 671 wouldn't derail on the curves (on carpet) after making quite a few complete loops. I could not put the control more than halfway for the 681 before it derailed.

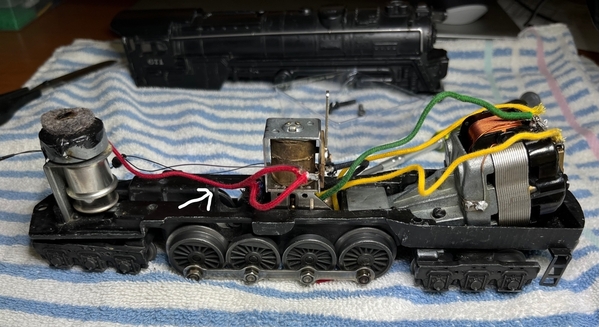

Prior to this I took apart the 671 and rewired everything. All contacts were cleaned, new brushes installed, the armature was cleaned, all wheels were lightly oiled, grease applied, and so on and so on. In other words, I can't think of anything to do to it to make it run faster. I did not put forth the same level of effort on the 681.

I pulled up some old threads about these engines, and one did say that the 681 had awesome performance. It didn't say the 671 was bad, it simply implied it was just not as good.

Is this to be expected between the 2? Did I miss something in my 671 refurbish?