richs09 posted:Jerry - again, your work is really well done. I'm curious about how you cut the shells - obviously the cuts need to be square and with minimal ragged edge. I also see in your earlier post to this thread that you've added a thin piece of styrene to made sure all of the spaces between the windows are uniform. What glue did you use? Are the chassis done the same way -- cutting the original Gilbert chassis?

Rich,

I"ll try to be brief. The shells were cut with a Zona type saw using a machinist square as a guide:

The other side was cut the same way using the square to make the cut. Then a piece of tape to guide the saw on the roof:

The piece of styrene to take the place of the saw width was cemented with MEK. A thin piece of styrene sheet was also cemented on the inside for added strength. When assembling the pieces, the car was trued up on a flat piece of glass to make sure it was straight in all directions. A bit of filing may be necessary to keep it perfectly straight. Then when dry, the gap and the filler piece was undercut slightly with a triangular jeweler's file and the resulting "gouge" filled with a mixture of styrene dissolved in MEK. I used scrap pieces of the cars cut into small pieces then put in an airtight bottle with a little MEK. After a few days, I stirred it with a metal spatula, either adding more plastic or MEK until the paste was the consistency of toothpaste. It was liberally troweled into the gouge and allowed to dry for a week or more. It will shrink, but after a week or more, it's completely dry and solid. It then can be treated like the rest of the car since it was basically "welded" together. A caution, however. MEK is highly flammable and dangerous, so I did the mixing, etc. outside in the nice weather. Lacquer thinner would work too.

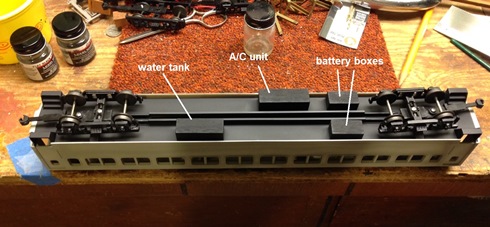

As to the frames, since the originals are either sheet metal or die cast, it was easier to make new frames from .060" styrene sheets with styrene channels for the frame rails and bars for the bolsters. I added wooden blocks to simulate the battery boxes, water tanks and A/C unit. After all, I was just trying to simulate a "what if", not a contest model. As I said before, sometimes close enough is good enough:

And thanks for the link to the circuitry. It will come in handy. I have dozens of LEDs taken from an on-sale, after Christmas light string. Hey, I'm cheap! I usually use a Gilbert transformer and the LEDs are 3V max.

Sorry for being long winded again. Maybe others can use some of my suggestions. Isn't this what this forum is about?